1/4″ 90°Air Mini Die GrinderOwner’s Manual

![]() WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.Item # 48142

WARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.Item # 48142

Thank you very much for choosing an Ironton product!For future reference, please complete the owner’s record below:Serial Number/Lot Date Code: ________________________________Purchase Date: ____________________________________________Save the receipt, warranty, and this manual. It is important that you read the entire manual to become familiar with this product before you begin using it.This 1/4″ 90°Air Mini Die Grinder is designed for certain applications only. The distributor cannot be responsible for issues arising from modification or use of this product in an application for which it was not designed. We strongly recommend that this product not be modified and/or used for any application other than that for which it was designed. If you have questions about a particular modification or application, DO NOT use the product until you have first contacted the distributor to determine if the product can or should be modified or used in such an application.For technical questions, please call 1-800-222-5381.

Intended Use

This Ironton 1/4in. air angle die grinder features a 90° angled head that provides easy access into tight spaces. Features sealed ball bearing construction, 20,000 RPM with variable speed control, a sturdy aluminum housing, rear exhaust, and more. Ideal for polishing and light metal removal.

Technical Specifications

| Item | Description |

| Air Consumption | 3 CFM |

| Speed (RPM) | 20,000 RPM |

| Air Inlet Size | 1/4 in. NPT |

| Minimum Air Hose Size | 3/8 in. |

| Tool Weight | 1.1 lbs. |

| Tool Length | 6.38 in. |

| Collet Size | 1/4 in. |

| Variable Speed | Yes |

| Side Handle | No |

| Working Pressure | 90 PSI |

| Weighted Sound Pressure Level | 81.0 dB (A) |

| Sound Power Level | 92.0 dB (A) |

| Vibration in Handle | 0.9 m/s2 |

WARNING

WARNING

- Read and understand all instructions. Failure to follow all instructions may result in serious injury.

- The warnings cautions, and instructions in this manual cannot cover all possible conditions or situations that could occur. Exercise common sense and caution when using this tool. Always be aware of the environment and ensure that the tool is used in a safe and responsible manner.

- DO NOT allow persons to operate or assemble this product until they have read this manual and have developed a thorough understanding of how the product works.

SAVE THESE INSTRUCTIONS

Important Safety Considerations

- DO NOT modify the tool in any way. Unauthorized modification may impair the function and/or safety of the tool and could affect the life of the tool. There are specific applications for which the tool is designed.

- Use the right tool for the job. DO NOT attempt to force a small piece of equipment to do the work of larger industrial equipment. There are certain applications for which this equipment was designed. It will do the job better and more safely at the capacity for which it was intended. DO NOT use this equipment for a purpose for which it was not intended.

- Industrial or commercial applications must follow OSHA requirements.

WARNING

WARNING

WORK AREA SAFETY

- Inspect the work area before each use. Keep work area clean, dry, free of clutter, and well lit. Cluttered, wet, or dark work areas can result in injury. Using the tool in confined work areas may put you dangerously close to other cutting tools and rotating parts.

- Do not use the tool where there is a risk of causing a fire or an explosion; e.g., in the presence of flammable liquids, gases, or dust. The tool can create sparks, which may ignite dust or fumes.

- Do not allow the tool to come into contact with an electrical source. The tool is not insulated and contact will cause electrical shock.

- Keep children and bystanders away from the work area while operating the tool. Do not allow children to handle the tool.

- Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in your work area. Some of these hazards may be below the work surface hidden from your view and may cause personal harm or property damage if unintentionally contacted.

PERSONAL SAFETY

- Stay alert, watch what you are doing, and use common sense when operating the tool. Do not use the tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the tool may result in serious personal injury.

- Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Air vents on the tool often cover moving parts and should be avoided.

- Use safety apparel and equipment. Use ANSI-approved safety goggles or safety glasses with side shields, or when needed, a face shield. Use a dust mask in dusty work conditions. Also use non-skid safety shoes, hardhat, gloves, dust collection systems, and hearing protection when appropriate. This applies to all persons in the work area.

- Do not overreach. Keep proper footing and balance at all times.

- Remove adjusting keys or wrenches before connecting the tool to the air supply or turning on the tool. A wrench or key that is left attached to a rotating part of the tool may cause personal injury.

- Secure the work with clamps or a vise instead of your hand when practical. This safety precaution allows for proper tool operation using both hands.

![]() CAUTION

CAUTION

TOOL USE AND CARE

- USE COMPRESSED AIR ONLY. Use clean, dry, and regulated compressed air to power the tool. Do not use oxygen, carbon dioxide, or any other bottled gas as a power source for this tool.

- Lubricate the tool before its initial use and before and after each additional use.

- Do not force the tool. Pneumatic tools do a better and safer job when used in the manner forwhich they are designed. Plan your work, and use the correct tool for the job.

- Check for damaged parts before each use. Carefully check that the tool will operate properlyand perform its intended function. Replace damaged or worn parts immediately. Never operate the tool with a damaged part. · Do not use a tool with a malfunctioning switch. Any power tool that cannot be controlled with the power switch is dangerous and must be repaired by an authorized service representative before use.

- Disconnect the air supply from the tool and place the switch in the locked or off position before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally. · Store the tool when it is not in use. Store it in a dry, secure place out of the reach of children. Inspect the tool for good working condition prior to storage and before re-use. · Use only accessories that are recommended by the manufacturer for use with your tool. Accessories that may be suitable for one tool may create a risk of injury when used with another tool. Never use an accessory that has a lower operating speed or operating pressure than the tool itself. · Keep guards in place and in working order. Never operate the tool without the guards in place. · Do not leave the tool running unattended. · Inspect the tool, hose, and accessories for damage or excessive wear before each use. If you find damage do not use the tool.

Safety Signs and Labels

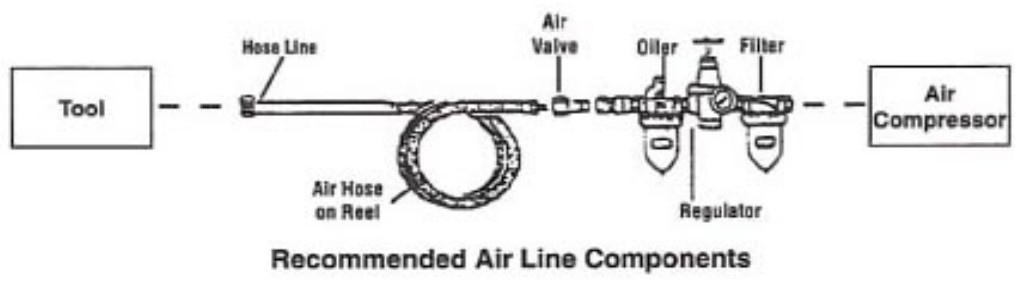

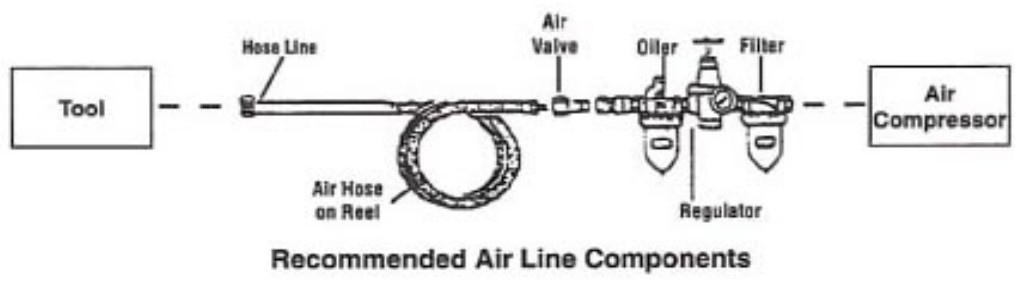

Air Supply

WARNING: Operating the tool at pressures over the rated capacity may causesevere damage and/or personal injury. Do not exceed 90 PSI while operating the tool. Do not use an accessory rated at a lower maximum pressure than the tool itself.

WARNING: Operating the tool at pressures over the rated capacity may causesevere damage and/or personal injury. Do not exceed 90 PSI while operating the tool. Do not use an accessory rated at a lower maximum pressure than the tool itself.

- Make sure that the air valve (or trigger) is in the OFF position before connecting to the air supply.

- Do not exceed an air pressure of 90 PSI.

- Drain the air tank daily. Water in the airline can damage the tool.

- Clean the air inlet filter weekly.

- Keep the hose away from heat, oil, and sharp objects. Check the hose for wear and make certain that all connections are secure before every use.

Assembly

Install a 1/4″ air nipple (not included)

- Wrap the 1/4 in. air nipple with pipe thread seal tape (not included), and then thread it into the air inlet on the air tool.

- Connect the 3/8 in. I.D. air hose (not included) to a quick-connect coupler (not included) and then to the air nipple.

- Turn on the air compressor and set it to 90 PSI. Do not exceed the recommended air pressure of 90 PSI.

- Check the air connection for leaks.

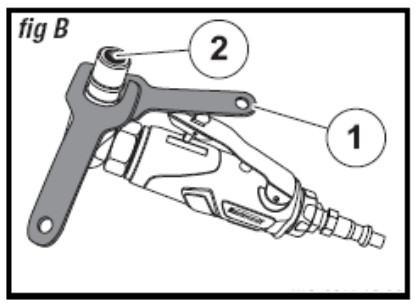

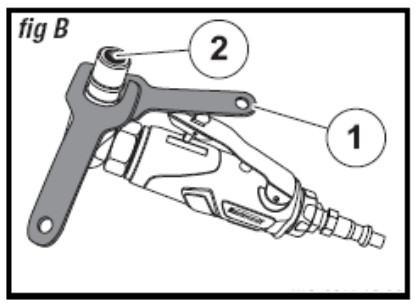

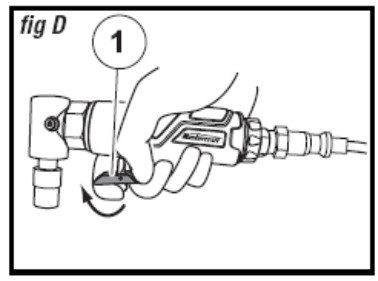

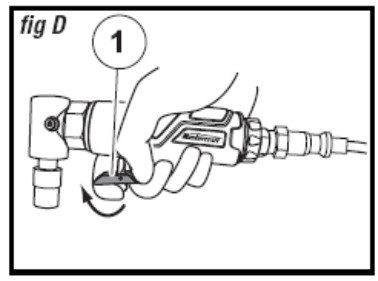

Install the grinding accessory

Use the two wrenches (1) to loosen the chuck (2). Insert a suitable grinding accessory into the chuck, and firmly retighten the chuck to lock the grinding accessory in place using the wrenches (fig B).

Lubrication

Air tools require lubrication throughout their lifetime. The air motor and bearing use compressed air to power the tool. Compressed air contains moisture which may rust the air motor and other internal parts of the tool is not kept lubricated. Failure to lubricate the tool properly will dramatically shorten the life of the tool and will void the warranty. The tool must be manually lubricated before its initial use. If you are not using a lubricated air supply, the tool must be manually lubricated before and after each use, as well as after each hour of continual use. To manually lubricate the tool, add a few drops of pneumatic tool oil to the tool’s airline connection.

Before Each Use

![]()

![]()

- Inspect the tool for damage or excessive wear.

- If you are not using a lubricated air supply, lubricate the tool.

- Drain water from the air compressor tank and condensation from the airlines.

- Connect the air supply to the tool. Do not exceed the maximum air pressure of 90 PSI.

Operating Instructions

To start the tool, press and hold the trigger. To stop the tool, release the trigger.

After Each Use

- Disconnect the air supply from the tool.

- If you are not using a lubricated air supply, lubricate the tool.

- Store the tool.

Maintenance

![]()

![]()

Troubleshooting

If any abnormal vibrations or noise occurs, immediately turn the tool off and have the problem corrected before further use. Have necessary repairs made by qualified service personnel.

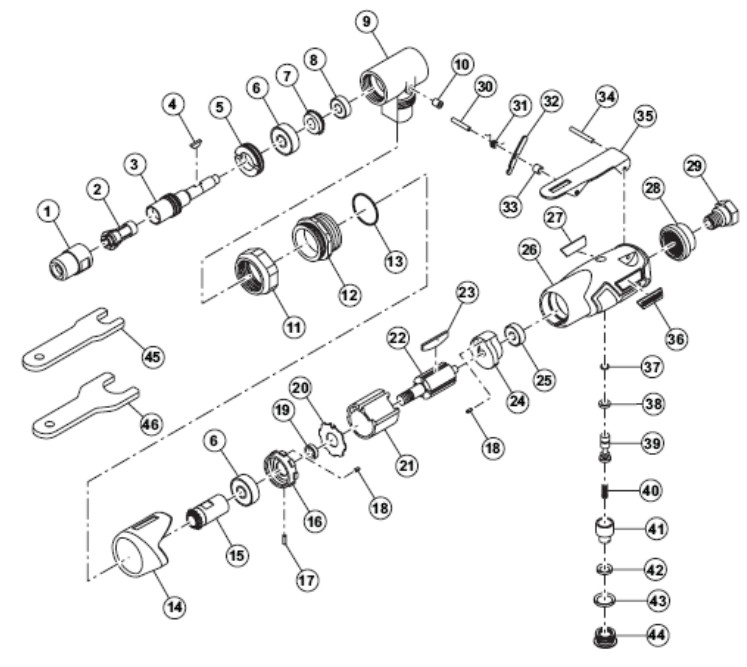

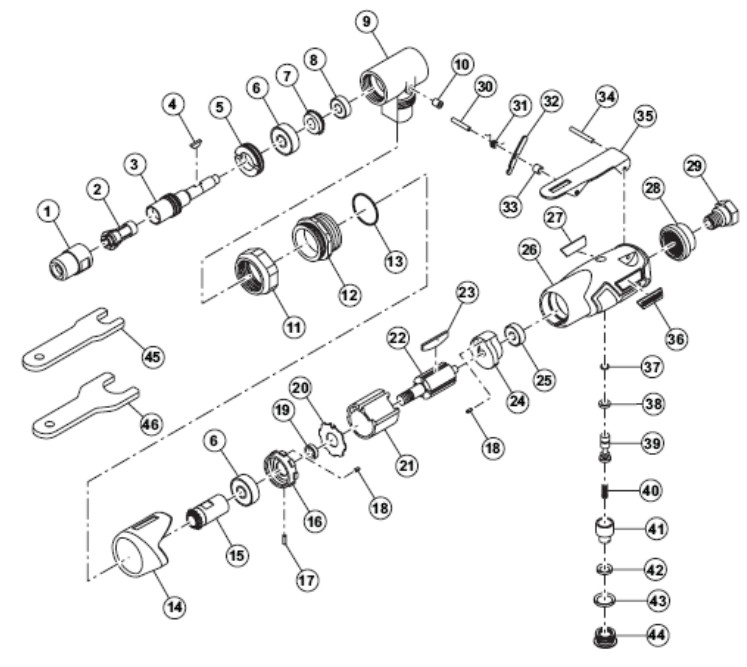

Diagram

Parts List

| Part No. | Description | Quantity |

| 1 | Chuck screw | 1 |

| 2 | Chuck | 1 |

| 3 | Axis of rotation | 1 |

| 4 | Semicircular key | 1 |

| 5 | Screw set | 1 |

| 6 | Bearing | 2 |

| 7 | Gear wheel | 1 |

| 8 | Bearing | 1 |

| 9 | L switch | 1 |

| 10 | Oil valve | 1 |

| 11 | Screwcap | 1 |

| 12 | Locknut | 1 |

| 13 | 0-ring 22.4 X 1.8 | 1 |

| 14 | Front cover | 1 |

| 15 | Gear wheel | 1 |

| 16 | Front plate | |

| 17 | Pin 1.5 X4 | I |

| 18 | Pin 2 X 6 | 2 |

| 19 | Bushing | 1 |

| 20 | Washer | 1 |

| 21 | Cylinder | 1 |

| 22 | Rotor | 1 |

| 23 | Rotor blade | 4 |

| 24 | Back cover | 1 |

| 25 | Bearing | 1 |

| 26 | Housing | 1 |

| 27 | Label 2 | 1 |

| 28 | Muffler cover | 1 |

| 29 | Air inlet | 1 |

| 30 | Pin 3 X 18 | 1 |

| 31 | Spring | 1 |

| 32 | Trigger pin | 1 |

| 33 | Trigger ring | I |

| 34 | Pin 3 X 24 | I |

| 35 | Trigger | 1 |

| 36 | Label 1 | 1 |

| 37 | 0-ring 4.6 X 1.6 | 1 |

| 38 | 0-ring 5.6 X 2 | 1 |

| 39 | Valve stem | 1 |

| 40 | Spine | 1 |

| 41 | Air regulator | 1 |

| 42 | O-ring 7 X 2 | 1 |

| 43 | O-ring 11 X 2 | 1 |

| 44 | Screw cap | 1 |

| 45 | Wrench I | i |

| 46 | Wrench II | 1 |

Replacement Parts

- For replacement parts and technical questions, please call Customer Service at 1-800-222-5381.

- Not all product components are available for replacement. The illustrations provided are a convenient reference to the location and position of parts in the assembly sequence.

- When ordering parts, the following will be required: Model Number, Serial Number/Lot Date Code, and Description.

- The distributor reserves the right to make design changes and or improvements to product lines and manuals without notice.

Limited Warranty

Northern Tool and Equipment Company, Inc. (“We” or ‘”Us”) warrants to the original purchaser only (“You” or “Your”) that the Ironton Air Tool product purchased will be free from material defects in both materials and workmanship, normal wear and tear excepted, for a period of one year from date of purchase. The foregoing warranty is valid only if the installation and use of the product is strictly in accordance with product instructions. There are no other warranties, express or implied, including the warranty of merchantability or fitness for a particular purpose. If the product does not comply with this limited warranty, Your sole and exclusive remedy is that We will, at our sole option and within a commercially reasonable time, either replace the product without charge to You or refund the purchase price (less shipping). This limited warranty is not transferable.

Limitations on the Warranty

This limited warranty does not cover: (a) normal wear and tear; (b) accessories both consumable and durable; (c) damage through abuse, neglect, misuse, or as a result of any accident or in any other manner; (d) damage from misapplication, overloading, or improper installation; (e) improper maintenance and repair; and (f) product alteration in any manner by anyone other than Us, with the sole exception of alterations made pursuant to product instructions and in a workmanlike manner.

Obligations of Purchaser

You must retain Your product purchase receipt to verify date of purchase and that You are the original purchaser. To make a warranty claim, contact Us at 1-800-222-5381, identify the product by make and model number, and follow the claim instructions that will be provided. The product and the purchase receipt must be provided to Us in order to process Your warranty claim. Any returned product that is replaced or refunded by Us becomes our property. You will be responsible for return shipping costs or costs related to Your return visit to a retail store.

Remedy Limits

Product replacement or a refund of the purchase price is Your sole remedy under this limited warranty or any other warranty related to the product. We shall not be liable for: service or labor charges or damage to Your property incurred in removing or replacing the product; any damages, including, without limitation, damages to tangible personal property or personal injury, related to Your improper use, installation, or maintenance of the product; or any indirect, incidental or consequential damages of any kind for any reason.

Assumption of Risk

You acknowledge and agree that any use of the product for any purpose other than the specified use(s) stated in the product instructions is at Your own risk.

Governing Law

This limited warranty gives You specific legal rights, and You also may have other rights which vary from state to state. Some states do not allow limitations or exclusions on implied warranties or incidental or consequential damages, so the above limitations may not apply to You. This limited warranty is governed by the laws of the State of Minnesota, without regard to rules pertaining to conflicts of law. The state courts located in Dakota County, Minnesota shall have exclusive jurisdiction for any disputes relating to this warranty.

![]()

![]()

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

- lead from lead-based paints,

- crystalline silica from bricks and cement and other masonry products, and

- arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as dust masks that are specially designed to filter out microscopic particles.

[xyz-ips snippet=”download-snippet”]