LiftAll Synthetic Web Sling Safety Bulletin Instructions

- Sling users must be trained in operating practices, including sling selection, use, inspection, rigging practices, cautions to personnel, and effects of environment.

- Inspect sling at least daily and remove from service if damaged.

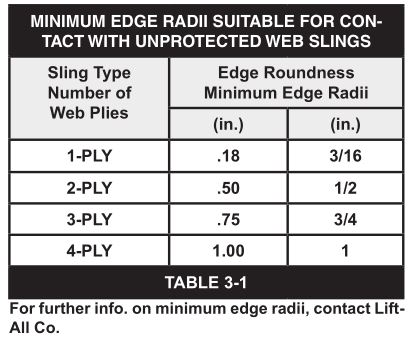

- Protect sling from being cut or damaged by corners, protrusions, or from contact with edges that are not well rounded (Table 3-1), using material of sufficient strength, thickness and construction to prevent damage.

- Use sling properly – Do not exceed a sling’s rated capacities and always consider how the sling angle affects the amount of tension on the sling (See Table 4-1).

- Stand clear of load. Do not stand on, under or near a load, and be alert to dangers from falling and moving loads, and the potential for snagging.

- Maintain and store sling properly. Sling should be protected from mechanical, chemical and environmental damage.

1. SLING USERS MUST BE TRAINED AND KNOWLEDGEABLE

Sling users must be knowledgeable about the safe and proper use of slings and be aware of their responsibilities as outlined in all applicable standards and regulations.

ASME B30.9 states: “Synthetic web sling users shall be trained in the selection, inspection, cautions to personnel, effects of the environment and rigging practices.”

OSHA Sling Regulation 29 CFR 1910.184 states that a qualified person is one: “who, by possession of a recognized degree or certificate of professional standing in an applicable field, or who, by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.”

If you are unsure whether you are properly trained and knowledgeable, or if you are unsure of what the standards and regulations require of you, ask your employer for information and/or training— DO NOT use web slings if you are unsure of what you are doing. Lack of skill, knowledge or care can result in severe INJURY or DEATH to you and others.

2. INSPECT SLING FOR DAMAGE

Damage to a web sling can significantly reduce its capacity to hold or lift loads and increases the chance that the sling will fail during use. If you are not sure if a sling is damaged, DO NOT USE IT.

2a. HOW TO INSPECT SLINGS

Perform a visual inspection of the entire sling and feel along its entire length for any of the types of conditions listed in Tables 2-1 and 2-2.

2b. REMOVAL FROM SERVICE

Remove sling from service immediately if ANY of the listed types of damage are detected, even if the damage is not as extensive as the relatively extreme examples illustrated in Table 2-2.

Never ignore sling damage or attempt to perform temporary repairs of damaged slings (e.g., tie knots in the sling, etc.).

TABLE 2-1. REMOVAL FROM SERVICE CRITERIA:

- Holes, tears, cuts, snags or embedded materials.

- Excessive abrasive wear.

- Exposed red core warning yarn if provided.

- Broken or worn stitches in the load bearing splices.

- Identification tag is missing or not readable.

- Sling has been tied into one or more knots.

- Signs of ultraviolet (UV) light degradation

- Any heat or chemical damage, i.e. acid or alkali burns, melting or weld spatter.

- Fittings with any cracks, excessive wear, or other damage, such as deformation, corrosion, or pitting.

- Hooks with throat opened more than 15% or twisted more than 10 degrees out of plane.

- Any conditions which cause doubt as to the strength of the sling.

2c. ENVIRONMENTAL CONSIDERATIONS AND OUTDOOR USE

Exposure to sunlight, and other environmental factors such as dirt or gritty matter and cyclical changes in temperature and humidity, can result in an accelerated deterioration of web slings. The rate of this deterioration varies with the level of exposure and with the thickness of the sling material.

Visible indication of such environmental deterioration can include the following:

- Fading of webbing color

- Uneven or disoriented surface yarn of the webbing

- Shortening of the sling length

- Reduction in elasticity of the sling due to an exposure to sunlight, often evident by an accelerated abrasive damage to the surface yarn of the sling

- Breakage or damage to yarn fibers, often evident by a fuzzy appearance of the web

- Stiffening of the web, evident when web slings are exposed to outdoor conditions

SUNLIGHT / UV EXPOSURE SERVICE LIFE

Nylon and polyester web slings possess a limited useful outdoor service life due to the degradation caused by exposure to sunlight, or other measurable sources of UV radiation.

Lift-All web slings that are regularly exposed to outdoor conditions should be identified with the date they are placed into service, and should be proof tested to twice its rated capacity every six months.

Lift-All nylon and polyester web slings shall be permanently removed from service when the cumulative outdoor exposure has reached the limits shown in Table 2-2.

TABLE 2-2. OUTDOOR EXPOSURE LIMITS

• 2 years for 1 ply and 2 ply web slings• 3 years for 3 ply and 4 ply web slings

2d. INSPECTION FREQUENCY

Initial Inspection – Each new sling must be inspected by a designated person to help ensure that the correct sling has been received, is undamaged, and meets applicable requirements for its intended use.

Frequent Inspection – The sling must be inspected by a designated person before each day or shift in Normal service conditions, or before each use in applications where a rapid rate of sling wear or other degradation may exist (Severe service conditions).

Periodic Inspection – Every sling must be inspected “periodically”. The designated person should be someone other than the person performing the frequent inspection.

The frequency of periodic inspections should be based on the sling’s actual or expected use, severity of service, and experience gained during the inspection of other slings used in similar circumstances, but must not exceed a one year interval. General guidelines for the frequency of periodic inspections are:

• Normal service—yearly• Severe service—monthly to quarterly• Special service—as recommended

A written record of the most recent periodic inspection must be maintained. (See WSTDA WS-1 for definitions of service conditions.)

3. PROTECT SLING FROM DAMAGE

ALWAYS protect web slings from being cut or damaged by corners, edges and protrusions using protection sufficient for each application.

Do not ignore warning signs of misuse. Cut marks detected during any sling inspection serve as a clear signal that sling protection must be added or improved.

EXPOSURE OF SLINGS TO EDGES

Edges do not need to be “sharp” to cause failure of the sling. Table 3-1 shows the minimum allowable edge radii suitable for contact with unprotected webbing slings. Chamfering or cutting off edges is not an acceptable substitute for fully rounding the edges to the minimum radius. Slings can also be damaged from contact with edges or burrs at the sling connections.

3b. SLING PROTECTION

A qualified person must select materials and methods that adequately protect slings from edges or surfaces. Lift-All offers a variety of patented cut protection products, including Edge Defender ® cut protection pads and Sling Shield ® aluminum corner protectors.

However, as no protective device is ‘cut proof’, several ‘test’ lifts (done in a non-consequence setting), should be performed as necessary to determine the suitability of protection devices for each application. After each ‘test’ lift, inspect all slings and protection devices for damage.

4. SLING SELECTION AND USE

In order to safely lift a load and not exceed the sling’s rated capacity, a qualified person must select slings having suitable characteristics and consider the following:

- Load information including size, shape, weight, composition and center of gravity

- Lifting conditions including overhead clearance, temperature and chemicals

- Hoisting equipment and attachment options including the number and method of connections to the load

4a. RIGGING CONFIGURATION AND LOAD STABILITY

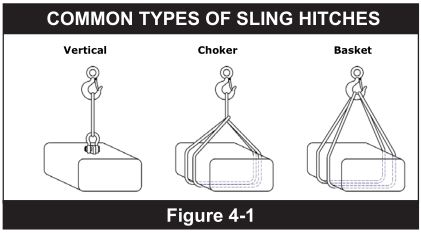

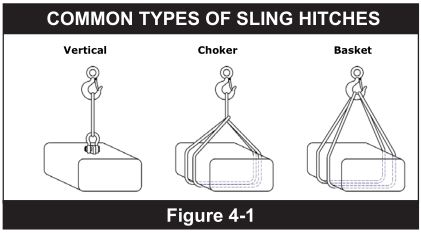

A qualified person must review each lift, create a rigging plan, and select the sling hitches (see Figure 4-1). This process should consider:

Load Control and Stability: A qualified person must choose the quantity of slings, location of attachments, and the hitch types needed to effectively maintain load control. Resistance to tipping must be maintained if the slings are attached below the center of gravity.

Sling Securement: Each sling must be hitched to prevent slippage, yet not restrict the sling from maintaining uniform tensioning.

4b. SLING CAPACITY AND THE EFFECT OF ANGLES

Do not exceed the sling’s rated capacity or the capacity of any of the components of the rigging system.

Sling Capacity: Determine the load weight, the tension applied to each sling, and verify that the amount of tension applied to the sling does not exceed its capacity for the chosen hitch.

Effect of Sling Angle: The sling angle affects the amount of tension applied to the sling (see Figure 4-2). As the sling angle decreases, the tension on each leg increases. This principle applies when one sling is used to lift at an angle or when a basket hitch or multi-legged bridle sling is used. Table 4-1 provides information on increased tension as a function of sling-to-load angle. The use of slings at angles of less than 30 degrees should be avoided.

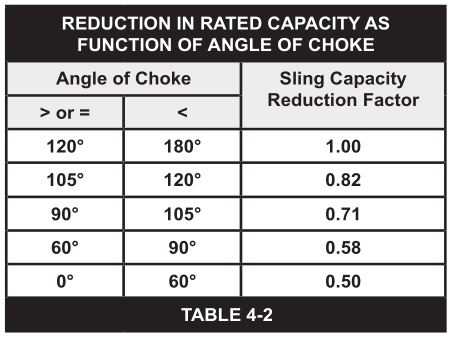

Angle of Choke When a choke hitch is used, and the angle of choke is less than 120 degrees, the sling choker hitch capacity decreases. To determine the actual sling capacity at a given angle of choke, multiply the sling capacity rating (for a choker hitch) by the appropriate reduction factor determined from Table 4-2.

4c. SLING HARDWARE AND CONNECTIONS

Connection surfaces must be smooth to avoid abrading or cutting web slings.

4d. AVOID ACTIONS THAT CAUSE DAMAGE TO SLINGS, SUCH AS

- Using hooks, shackles or other hardware that have edges or rough surfaces

- Twisting, kinking or knotting the sling

- Using slings to pull on stuck or constrained objects

- Pulling slings from under loads when the load is resting on the sling—place blocks under load where feasible.

- Dropping or dragging slings on the ground, floor or over abrasive surfaces

- Choking on the hardware

- Shortening or connecting slings by knotting, twisting, or other methods not approved by the sling manufacturer or qualified person

- Exposing slings to temperatures above 200°F (90°C), or below -40°F (-40°C)

- “Tip loading” a sling hook instead of centering it in the base or “bowl” of the hook

- Driving over slings with a vehicle or other equipment

- Accelerating or decelerating the load too quickly (i.e., “shock loading”)

- Exposing slings to damaging acids or alkalis

5. ALL PERSONNEL MUST REMAIN CLEAR OF LOADS AND ALERT TO RISKS

To prevent possible injury when using slings, all personnel must:

- Stand clear of lifted loads and never be under, on or near suspended loads

- Avoid placing any parts of the body between the sling and load, or between the sling and lifting hook or connections

- Be alert to the potential for the sling to become snagged during a lift

6. MAINTAIN AND STORE SLING PROPERLY

Attempt to keep slings clean and free of dirt, grime and foreign materials. If slings are cleaned, use only mild soap and water, and:

- Do not use bleaching agents

- Do not machine wash or tumble dry slings, as this can significantly reduce their strength

When not in use, slings should be stored in an area free from environmental or mechanical sources of damage, such as: weld spatter, splinters from grinding or machining, or sources of UV, heat, or chemical exposure, etc.

ADDITIONAL FACTORS TO CONSIDER WHEN HANDLING LOADS

- Integrity of the attachment points

- Structural stability of the load

- Loose parts that could fall from load

- Power lines in the area

- Secure a clear load path and avoid any contact with objects that would impede load movement

- Tag lines can often be attached to the load and be used to aid in controlling load positioning

FOR ADDITIONAL INFORMATION

This bulletin does not contain all of the information that may be necessary to ensure the safe use of web slings. Some additional sources of training information include:

- WSTDA WS-1 Recommended Standard for Synthetic Web slings

- ASME B30.9 Sling Standard

- OSHA 29 CFR 1910.184 Regulations

- Lift-All Catalog and website at www.lift-all.com

- Rigging handbooks

Call for information on Sling Inspections and Safety Seminars.

800-909-1964

© Lift-All Co., Inc. 2018

References

[xyz-ips snippet=”download-snippet”]