BlenderBuddy 2Instructions for Use

BlenderBuddy 2Instructions for Use

![]()

![]()

phone: (800) 748.5355fax: (801) 973.6090email: [email protected]web: www.maxtec.com

![]()

![]()

NOTE: The latest edition of this operating manual can be downloaded from our website at www.maxtec.com

WARRANTY

Under normal operating conditions, Maxtec warrants the BlenderBuddy 2 to be free from defects of workmanship or materials for three (3) years from receipt. Warranty does not cover breakage/abuse. These warranties are from the date of receipt, provided that the product is properly operated and maintained in accordance with Maxtec’s operating instructions. Based on Maxtec product evaluation, Maxtec’s sole obligation under the foregoing warranty is limited to making replacements, repairs, or issuing credit for equipment found to be defective. This warranty extends only to the buyer purchasing the equipment directly from Maxtec or through Maxtec’s designated distributors and agents new equipment. Routine maintenance items, such as O-rings, are excluded from the warranty. Maxtec and any other subsidiaries shall not be liable to the purchaser or other persons for incidental or consequential damages or equipment that has been subject to abuse, misuse, misapplication, alteration, negligence or accident. These warranties are exclusive and in lieu of all other warranties, expressed or implied, including the warranty of merchantability and fitness for a particular purpose. For product warranty returns, please contact Maxtec Customer Service for a Return Material Authorization (RMA).

DESCRIPTION

The BlenderBuddy 2 is an accessory designed for use with air/oxygen blenders. It utilizes a Maxtec Designed for Blenders (DFB) flowmeter which is designed and calibrated specifically for air/oxygen blenders to provide increased accuracy compared to standard flowmeters. By utilizing dual-scale graduations, the flowmeter provides two flowmeters in one for increased accuracy at lower flows. The flowmeter features a high-quality acrylic block body and precision valve. The BlenderBuddy 2 also provides a sensitivity analysisthe port that may be used to measure the gas concentration from the blender. A small continuous sensor bleed is provided which enables gas analysis regardless of which outlet port is used on the blender.

INTENDED USE

The BlenderBuddy 2 is a flowmeter intended for use with an air/oxygen blender and is to be used by physicians, respiratory therapists, and other authorized hospital personnel to administer selected doses of medical gases to a patient The BlenderBuddy 2 also contains a gas analysis port which ay be used with a suitable oxygen analyzer to measure thegas concentration.

- Read this User Manual before installing or operating the BlenderBuddy 2.

- This manual instructs a professional to install and operate the BlenderBuddy 2. This is provided for your safety and to prevent damage. If you do not understand this manual, DO NOT USE the BlenderBuddy 2 and contact your provider.

- Use BlenderBuddy 2 only for its “Intended Use” as described in this manual.

- This product should only be used under the proper supervision of a healthcare professional.

- The BlenderBuddy 2 is for use with air/oxygen blenders only. The accuracy of the flowmeter will be affected if the BlenderBuddy 2 is used in any other way.

- Follow all manufacturer instructions for proper air/oxygen blender and bleed operation.

- ALWAYS activate the blender bleed when necessary according to the blender manufacturer’s instructions. Failure to do so may result in inaccurate concentrations from the blender.

- The flowmeter is capable of delivering flows greater than the indicated value (flush flow). Adjusting the flow beyond the indicated range will result in an undetermined flow.

- The BlenderBuddy 2 is capable of delivering gas mixtures at pressures equal to the blender outlet. Always confirm proper setup before patient use.

- Check for leaks and proper operation before placing the BlenderBuddy 2 into service.

- ALWAYS confirm prescribed flow and oxygen concentration before administering to patient and monitor on a frequent basis.

- The BlenderBuddy 2 may contain magnetic, ferrous material and is NOT for use in MRI environments.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

To Reduce the Risk of Fire or Explosion:◆ ALWAYS follow ANSI and CGA standards for Medical Gas Products and Oxygen Handling.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

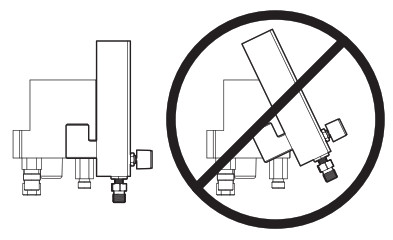

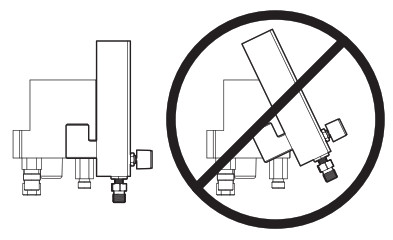

CAUTION◆ The BlenderBuddy 2 must be operated with the Flowmeter in a vertical, upright position.◆ Gas temperatures other than 70° F (21°C) may affect the accuracy of the indicated flow.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

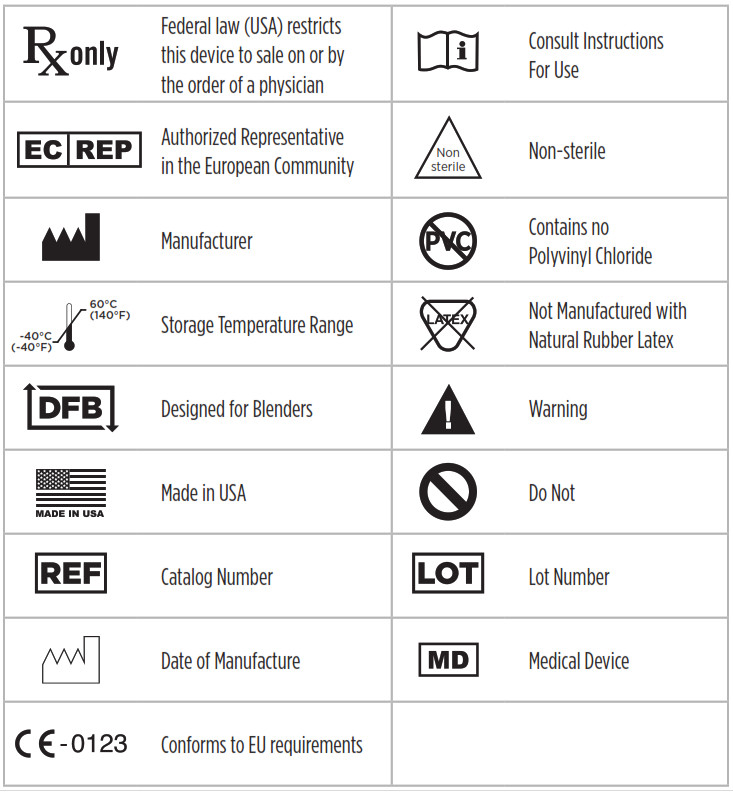

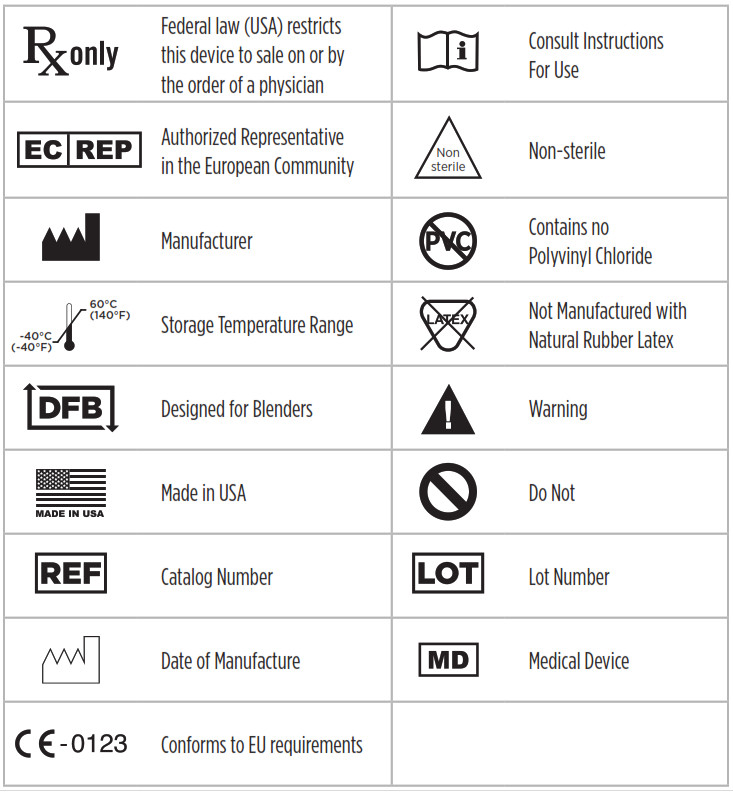

SYMBOL GUIDE

The following symbols and safety labels are found on the BlenderBuddy 2:

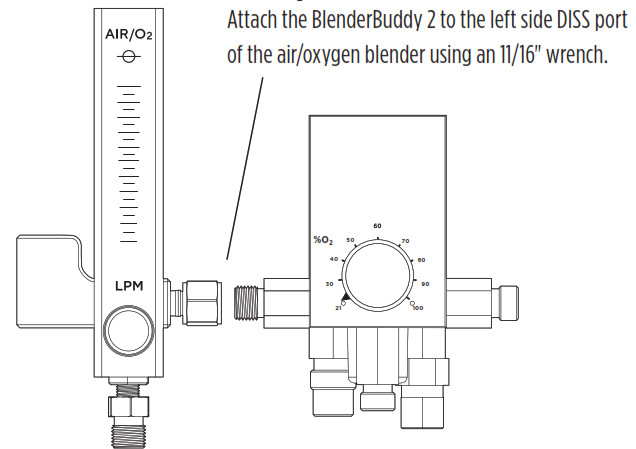

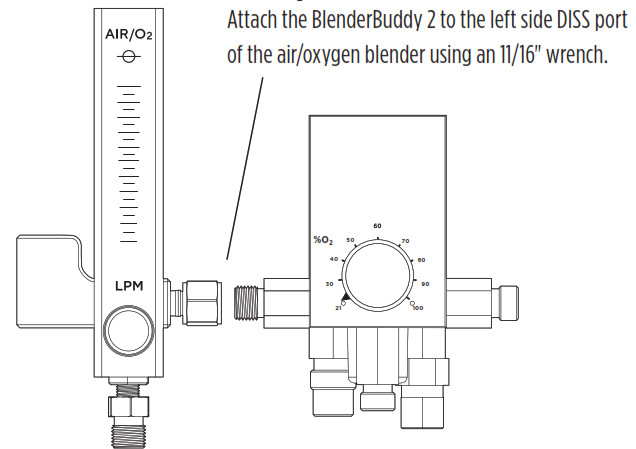

INSTALLATION/OPERATION

NOTE: Low flow BlenderBuddy 2 models (3, 15 and 30 LPM) should only be used with Low Flow blenders. High Flow BlenderBuddy 2 models (70 LPM) should only be used with High Flowblenders. Use outside these applications may result in flowmeter inaccuracies. Align the flowmeter in an upright, vertical position with the blender and firmly ighten the fitting.

NOTE: A small continuous sensor bleed is provided to the analysis port which enables gas analysis regardless of which outlet port is used on the blender.

FLOWMETER OPERATION

Adjust the flowmeter to the desired set-point as read by the center of the float ball

- To increase flow—turn the knob counter-clockwise

- To decrease flow—turn knob clockwise

CLEANING & MAINTENANCE

CleaningExterior surfaces may be cleaned using a cloth and mild detergent, isopropyl alcohol solution, or germicidal wipe.Maintenance The BlenderBuddy 2 does not require any periodic maintenance or contain any user-serviceable components.

SPECIFICATIONS

Flowmeter Accuracy:

| MODEL | FLOWNETER GRADUATIONS | ACCURACY | FLUSH FLOW |

| 3 LPM | 01′ (0.1-1) LPM 0.5 (1-3) LPM | ± 0.5 LPM | 20-30 LPM |

| 15 12M | 0′ 25 (0.5-3) LPM1 (5-15) LPM | 0.5-3: ± 0.5 1.1115-15: ± 10% of indicated value | 20-30 LPM |

| 30 IPM | 025 (0.5-3) LPM 2.5 (5-30) LPM | 0.5-3: ± 0.5 LPN5-30: ± 10% of indicated value | 35-45 LPM |

| 70 LPM | 1(2-15) LPM 5 (15-70) LPN | 2-4: ± 0.5 LPN5-70: ± 10% of indicated value | 70-80 LPM |

Weight ……………………………………………………………………………………………………………. .88 lbs. (.4 kg)Total System Response Time …………………………………………………………………………….≤ 30 secondsStorage Temperature …………………………………………………………………-40°F (-40°C) to 140°F (60°C)The BlenderBuddy 2 is calibrated for air/oxygen gas mixtures at 70° F (21° C) and is compensated for the pressure drop of a typical blender with inlet pressures at 50 psig. Specifications are subject to change without prior notice.

2305 South 1070 WestSalt Lake City, Utah 84119(800) 748-5355www.maxtec.com

References

[xyz-ips snippet=”download-snippet”]