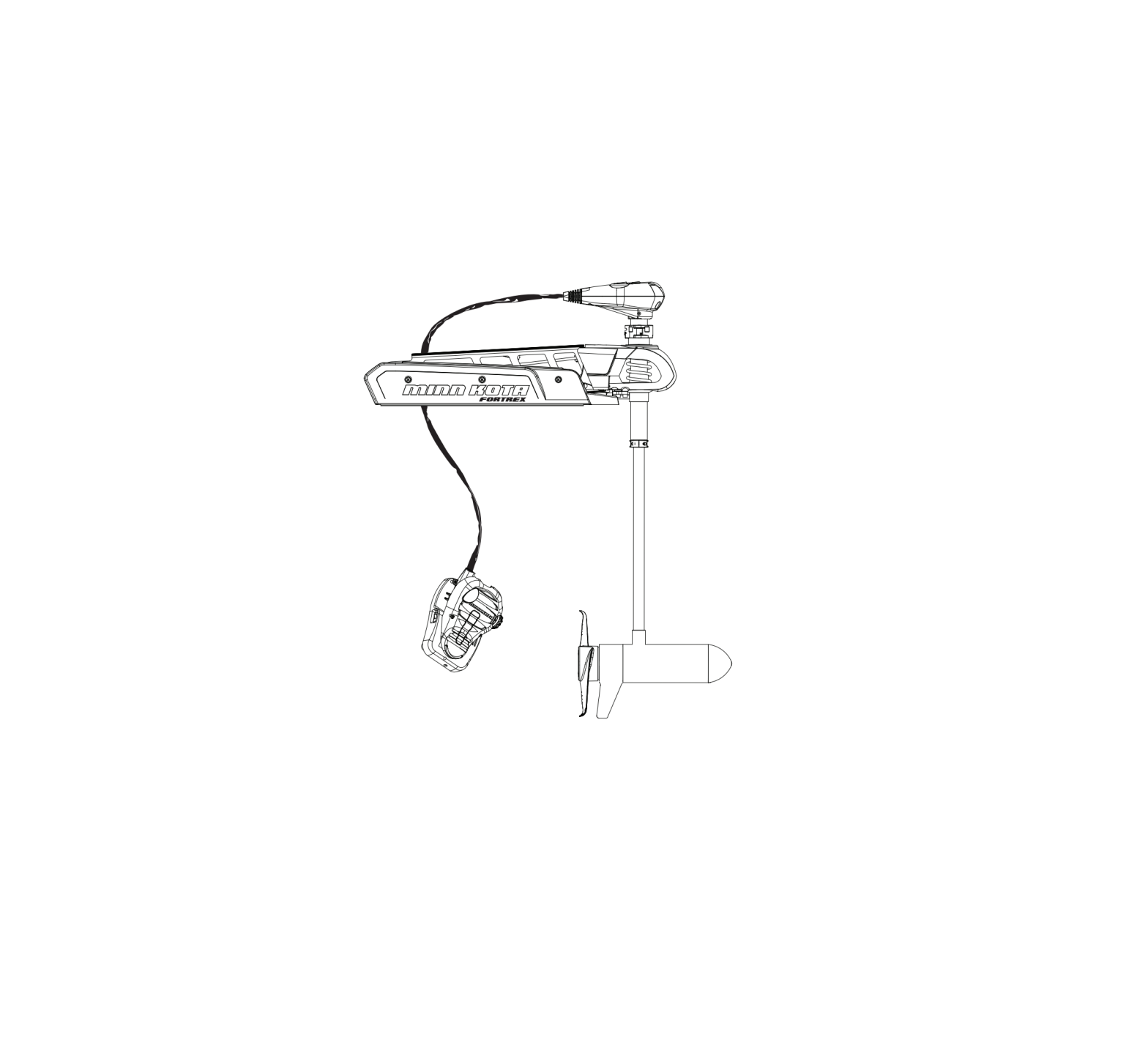

MINN KOTA 1368670 Fortrex 80/US2 Bow-Mount Trolling Motor

THANK YOU

Thank you for choosing Minn Kota. We believe that you should spend more time fishing and less time positioning your boat. That’s why we build the smartest, toughest, most intuitive trolling motors on the water. Every aspect of a Minn Kota trolling motor is thought out and rethought until it’s good enough to bear our name. Countless hours of research and testing provide you the Minn Kota advantage that can truly take you “Anywhere. Anytime.” We don’t believe in shortcuts. We are Minn Kota. And we are never done helping you catch more fish.REMEMBER TO KEEP YOUR RECEIPT AND IMMEDIATELY REGISTER YOUR TROLLING MOTOR.

| NOTE: Do not return your Minn Kota motor to your retailer. Your retailer is not authorized to repair or replace this unit. You may obtain service by: calling Minn Kota; returning your motor to the Minn Kota Factory Service Center; sending or taking your motor to any Minn Kota authorized service center. A list of authorized service centers is available on our website. Please include proof of purchase, serial number and purchase date for warranty service with any of the above options.Please thoroughly read this user manual. Follow all instructions and heed all safety and cautionary notices below. Use of this motor is only permitted for persons that have read and understood these user instructions. Minors may use this motor only under adult supervision.ATTENTION: Never run the motor out of the water, as this may result in injuries from the rotating propeller. The motor should be disconnected from the power source when it is not in use or is off the water. When connecting the power-supply cables of the motor to the battery, ensure that they are not kinked or subject to chafe and route them in such a way that persons cannot trip over them. Before using the motor make sure that the insulation of the power cables is not damaged. Disregarding these safety precautions may result in electric shorts of battery(s) and/or motor. Always disconnect motor from battery(s) before cleaning or checking the propeller. Avoid submerging the complete motor as water may enter the lower unit through control head and shaft. If the motor is used while water is present in the lower unit considerable damage to the motor can occur. This damage will not be covered by warranty.CAUTION: Take care that neither you nor other persons approach the turning propeller too closely, neither with body parts nor with objects. The motor is powerful and may endanger or injure you or others. While the motor is running watch out for persons swimming and for fl oating objects. Persons whose ability to run the motor or whose reactions are impaired by alcohol, drugs, medication, or other substances are not permitted to use this motor. This motor is not suitable for use in strong currents. The constant noise pressure level of the motor during use is less than 70dB(A). The overall vibration level does not exceed 2,5m/sec2. |

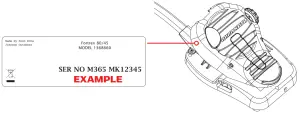

| LOCATING YOUR SERIAL NUMBER Your Minn Kota 11-character serial number is very important. It helps to determine the specific model and year of manufacture. When contacting Consumer Service or registering your product, you will need to know your product’s serial number. We recommend that you write the serial number down in the space provided below so that you have it available for future reference

|

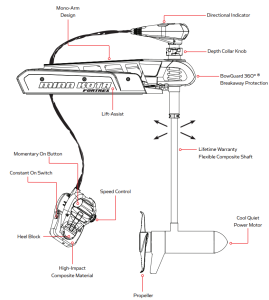

FEATURES

MOUNT INSTALLATION

TOOLS AND RESOURCES REQUIRED:

- Phillips Screw Driver

- 1/4″ Allen Wrench

- Drill · 9/32″ Drill Bit

- 7/16″ Box End Wrench

- A second person to help with the installation

ASSEMBLY OF MOTOR TO MOUNT

- Place the mount on an elevated surface such as a workbench or tailgate of pickup.

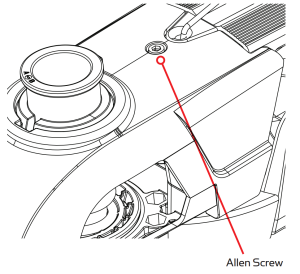

- Remove the 5/16″ Allen screw and lock washer from the mount using an Allen wrench.

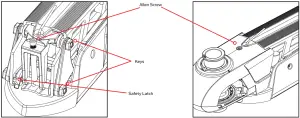

- Align the key ways on the inside of the Bowguard with the end links on the mount. Lower the motor assembly straight down until seated.

- Install the 5/16″ Allen screw / lock washer and tighten to 10-12 ft/lbs. 5

- Stow the motor into the flat position by pulling the rope/handle to disengage the latch bar, allowing the motor to fold into theflat position.

- Once in the stowed or flat position, the gas spring pin can be installed. Follow the steps below to install the gas spring pinand spacers:● Locate the upper gas spring pin and spacers in bag assembly● Align the end of the gas spring with the holes in the outer arm.● Install pin, spacers and Phillips flat head screws,● Tighten screws until the heads are flush with the outer arm.NOTE: Screws have a pre-applied thread locker, DO NOT apply additional thread locker to screws as that may prevent future removal

- Motor / mount can now be installed onto the boat. Proceed to next page for mounting instructions. ATTENTION: The 5/16″ Allen screw must be tight when installed and periodically tightened to 10-12 ft/lbs (Step 4), which will allow the motor to be stowed properly. Tighten the Allen screw when the mount is in the deployed position.

INSTALLATION OF THE BOW-MOUNT

We recommend that you have another person help with this procedure.

- For installation, DO NOT REMOVE THE SHAFT/MOTOR FROM THE BOWGUARD. The Bowguard spring is under tension and must always remain secured.

- Place the mount, with the motor in the fully stowed (flat) position, on the deck of the boat:

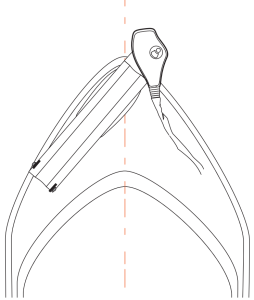

● The motor should be mounted as close to the centerline of the boat as possible when it is deployed (see illustration).● Make sure bow area under the chosen location is clear and unobstructed for drilling.● Make sure the motor rest is positioned far enough beyond the edge of the boat. The motor, as it is lowered into the water or raised into the boat, must not encounter any obstructions

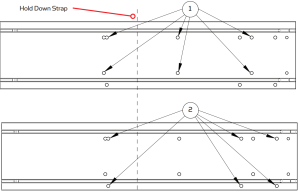

● The motor should be mounted as close to the centerline of the boat as possible when it is deployed (see illustration).● Make sure bow area under the chosen location is clear and unobstructed for drilling.● Make sure the motor rest is positioned far enough beyond the edge of the boat. The motor, as it is lowered into the water or raised into the boat, must not encounter any obstructions - Once in position, determine which bolt pattern to use (see below), mark at least 4 of the holes (2 on each side) in the bow plate and drill through with a 9/32″ drill bit. Either pattern may be used when installing the motor.– Pattern 1: Minnkota 3″ bolt pattern standard motors.– Pattern 2: Alternate 4″ bolt pattern commonly used. NOTE: If pattern 2 is to be used, the right side plate must be removed to access the mounting holes in the bow plate.

- Install hold down strap between the motor and deck of boat between second and third set of mounting holes.

- Mount the plate to the bow through the drilled holes using the provided (1/4-20 x 3-1/2″) bolts, nuts and washers.NOTE: If possible, secure all sets of mounting bolts, nuts and washers.

- Install the bow mount stabilizer (if included). See next section for installation instructions.

WARNING: The gas assist lift mechanism in this unit is under HIGH SPRING PRESSURE when the motor is in the deployed position. DO NOT remove the Bowguard assembly from the mount without disconnecting one end of the gas spring (see Removal of Bowguard section). Failure to do this can create a condition where accidental pulling of the rope may cause the mount to spring open rapidly, striking anyone or anything in the direct path.

INSTALLING THE BOWMOUNT STABILIZER

- Place motor in the stowed position.

- Unthread the composite rod from the bracket and attach bracket to the bottom of the Bowguard using the 5/16″ cap screws and nuts. The nuts fit into pocket on the inside of the Bowguard behind the spring.NOTE: The bracket can be installed on the left or right side of the Bowguard.

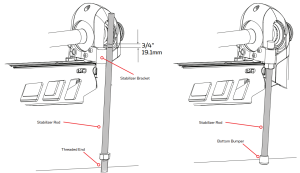

- Pull the bumper off the stabilizer rod and place the rod next to the bracket as shown in illustration.

- Place the threaded end down onto the deck surface and mark the rod 3/4″ above the top of the bracket.

- Cut the rod to the mark and round the cut edge with a file or sandpaper.

- Install the bottom bumper to the stabilizer rod and thread the rod into the bracket.

- Adjust the stabilizer rod up or down to so that the tip just touches the support surface. See illustration below. WARNING: Adjusting the rod too tightly removes the end play needed for proper pin engagement and doing so could prevent the mount from fully latching in the stowed position. If installed correctly, the rod tip should lift off the deck about 1/4″ without the mount unlatching.

- Once adjusted, tighten the jam nut against the bracket, which will prevent the rod from turning.

- Install top cap if threads are exposed.

REMOVAL OF THE BOWGUARD

WARNING: The gas assist lift mechanism in this unit is under HIGH SPRING PRESSURE when the motor is in the deployed position. DO NOT remove the Bowguard assembly from the mount without disconnecting one end of the gas spring. Failure to do this can create a condition where accidental pulling of the rope may cause the mount to spring open rapidly, striking anyone or anything in the direct path.

A) DISCONNECT THE GAS SPRING:

You must disconnect the gas spring before removing the Bowguard assembly from the motor mount. To disconnect the gas springs, follow the instructions below:

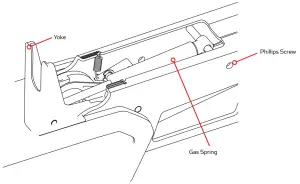

- With the mount in the stowed position, locate the upper cylinder pin.

- Using two Phillips screwdrivers, remove 1 of the Phillips flat head screws.

- Remove pin and spacers from outer arm.

- Now it is safe to deploy the motor and remove the motor assembly.

B) REMOVE THE BOWGUARD

- Once you disconnect the gas spring, place the motor in the deployed position.

- Remove the 5/16″ cap screw and lock washer located on the top of the Bowguard, in front of the pull rope.

- Lift motor/Bowguard assembly straight up until Bowguard is free from mount.NOTE: Rope and latch bar should never be pulled with the motor removed as the assembly is under HIGH PRESSURE.

C) RE-ASSEMBLING THE BOWGUARD

- Align the key ways on the inside of the Bowguard with the ends links on the mount.Lower the assembly straight down until seated Re-install the 5/16″ cap screw and washer and tighten.

- Reconnect the gas spring by following the steps below:● Locate the upper gas spring pin and spacers.● Align the end of the gas spring with the holes in the outer arm.● Install pin, spacers and Phillips flat head screws,● Tighten screws until the heads are flush with the outer arm.NOTE: Screws have a pre-applied thread locker, DO NOT apply additional thread locker to screws as that may prevent future removal.

WARNING: Moving parts can crush or cut. Gas assist lift mechanism is under pressure. Disconnect gas spring before removing motor from mount. Do not pull rope until gas spring is disconnected.

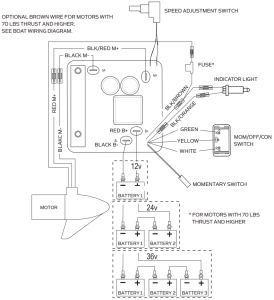

BATTERY WIRING & INSTALLATION

BOAT RIGGING & PRODUCT INSTALLATION

For safety and compliance reasons, we recommend that you follow American Boat and Yacht Council (ABYC) standards when rigging your boat. Altering boat wiring should be completed by a qualified marine technician. The following specifications are for general guidelines only:CAUTION: These guidelines apply to general rigging to support your Minn Kota motor. Powering multiple motors or additional electrical devices from the same power circuit may impact the recommended conductor gauge and circuit breaker size. If you are using wire longer than that provided with your unit, follow the conductor gauge and circuit breaker sizing table below. If your wire extension length is more than 25 feet, we recommend that you contact a qualified marine technician.An over-current protection device (circuit breaker or fuse) must be used. Coast Guard requirements dictate that each ungrounded current-carrying conductor must be protected by a manually reset, trip-free circuit breaker or fuse. The type (voltage and current rating) of the fuse or circuit breaker must be sized accordingly to the trolling motor used. The table below gives recommended guidelines for circuit breaker sizing.Reference: United States Code of Federal Regulations: 33 CFR 183 Boats and Associated Equipment ABYC E-11: AC and DC Electrical Systems on Boats

CONDUCTOR GAUGE AND CIRCUIT BREAKER SIZING TABLE

|

Motor Thrust / Model |

Max Amp Draw | Circuit Breaker | Wire Extension Length * | ||||

| 5 feet | 10 feet | 15 feet | 20 feet |

25 feet |

|||

|

30 lb. |

30 | 50 Amp @ 12 VDC | 10 AWG | 10 AWG | 8 AWG | 6 AWG | 4 AWG |

| 40 lb., 45 lb. | 42 | 10 AWG | 8 AWG | 6 AWG | 4 AWG |

4 AWG |

|

|

50 lb., 55 lb. |

50 | 60 Amp @ 12 VDC | 8 AWG | 6 AWG | 4 AWG | 4 AWG | 2 AWG |

| 70 lb. | 42 | 50 Amp @ 24 VDC | 10 AWG | 10 AWG | 8 AWG | 8 AWG |

6 AWG |

|

80 lb. |

56 | 60 Amp @ 24 VDC | 8 AWG | 8 AWG | 8 AWG | 6 AWG | 6 AWG |

| 101 lb. | 46 | 50 Amp @ 36 VDC | 8 AWG | 8 AWG | 8 AWG | 8 AWG |

8 AWG |

|

Engine Mount 101 |

50 | 60 Amp @ 36 VDC | 8 AWG | 6 AWG | 4 AWG | 4 AWG | 2 AWG |

| 112 lb. | 52 | 60 Amp @ 36 VDC | 8 AWG | 8 AWG | 8 AWG | 8 AWG |

8 AWG |

|

Engine Mount 160 |

116 | (2) x 60 Amp @ 24 VDC | 2 AWG | 2 AWG | 2 AWG | 2 AWG | 2 AWG |

| E-Drive | 40 | 50 Amp @ 48 VDC | 10 AWG | 10 AWG | 10 AWG | 10 AWG |

10 AWG |

This conductor and circuit breaker sizing table is only valid for the following assumptions:

- No more than 3 conductors are bundled together inside of a sheath or conduit outside of engine spaces.

- Each conductor has 105° C temp rated insulation.

- No more than 5% voltage drop allowed at full motor power based on published product power requirements.

*Wire Extension Length refers to the distance from the batteries to the trolling motor leads

SELECTING THE CORRECT BATTERIES

The motor will operate with any lead acid, deep cycle marine 12 volt battery/batteries. For best results, use a deep cycle, marine battery with at least a 105 ampere hour rating. Maintain battery at full charge. Proper care will ensure having battery power when you need it, and will significantly improve the battery life. Failure to recharge lead-acid batteries (within 12-24 hours) is the leading cause of premature battery failure. Use a multi-stage charger to avoid overcharging. We offer a wide selection of chargers to fit your charging needs. If you are using a crank battery to start a gasoline outboard, we recommend that you use a separate deep cycle marine battery/batteries for your Minn Kota trolling motor.

Advice Regarding Batteries:

- Never connect the (+) and the (-) terminals of the same battery together. Take care that no metal object can fall onto the battery and short the terminals. This would immediately lead to a short and extreme fire danger.

- It is highly recommended that a circuit breaker or fuse be used with this trolling motor. Refer to “Conductor Gauge and Circuit Breaker Sizing Table” in the previous section to find the appropriate circuit breaker or fuse for your motor. For motors requiring a 60-amp breaker, the Minn Kota MKR-19 60-amp circuit breaker is recommended.

CONNECTING THE BATTERIES IN SERIES (IF REQUIRED FOR YOUR MOTOR)

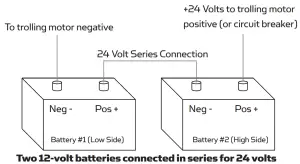

24 VOLT SYSTEMS:

+24 Volts to trolling motor

- Make sure that the motor is switched off (speed selector on “0”). To trolling motor negative positive (or circuit breaker)

- Two 12 volt batteries are required. 3. The batteries must be wired in series, only as directed in wiring 24 Volt Series Connection diagram, to provide 24 volts.a. Connect a connector cable to the positive ( + ) terminal of battery 1 and to the negative (-) terminal of battery 2.b. Connect positive ( + ) red motor lead to Neg – Pos + Neg – Pos + positive ( + ) terminal on battery 2.c. Connect negative (-) black motor lead to negative (-) terminal of battery 1.4. For safety reasons do not switch the motor on until the propeller is in the water. If installing a lead wire plug, observe proper polarity and follow instructions in your boat owner’s manual. See wiring diagram on following pages.

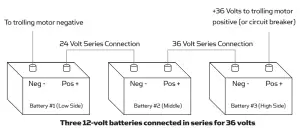

36 VOLT SYSTEMS:

- Make sure that the motor is switched off positive (or circuit breaker) (speed selector on “0”).

- Three 12 volt batteries are required.

- The batteries must be wired in series, only as directed in wiring diagram, to provide 36 volts.a. Connect a connector cable to the positive ( + ) terminal of battery 1 and to the negative ( ) terminal of battery 2 and another connector cable from the positive ( + ) terminal of battery 2 to the negative ( ) terminal of battery of battery 3.Three 12-volt batteries connected in series for 36 voltsb. Connect positive ( + ) red motor lead to positive ( + ) terminal on battery 3.c. Connect negative ( ) black motor lead to negative ( ) terminal of battery 1.

- For safety reasons do not switch the motor on until the propeller is in the water. If installing a lead wire plug, observe proper polarity and follow instructions in your boat owner’s manual. See wiring diagram on following pages.

CAUTION

- Improper wiring of 24/36 volt systems could cause battery explosion!

- Keep leadwire wing nut connections tight and solid to battery terminals.

- Locate battery in a ventilated compartment.

- For safety reasons, disconnect the motor from the battery or batteries when the motor is not in use or while the battery/batteries are being charged.

MOTOR WIRING DIAGRAM

NOTE: This is a universal, multi-voltage diagram. Double-check your motor’s voltage for proper connections. Over-Current Protection Devices not shown in this illustration.

USING AND ADJUSTING THE MOTOR

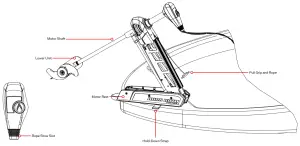

STOWING AND DEPLOYING THE MOTOR

WARNING:When raising or lowering the motor, keep fingers clear of all hinge and pivot points and all moving parts.

MOUNT FEATURES

- The motor mount is designed to fold back and lock the motor flat on the deck when not in use and to provide secure stowage for transport.

- The pull grip and rope releases the lock bar, which automatically engages when the unit is lowered or raised into position. The pull grip and rope should be used to both lower and raise the unit.

- The motor rest positions the lower unit as it comes in contact with the nose of the mount and guides it onto the motor rest.

- The yoke captures the motor shaft and keeps the lower unit centered on the motor rest. · The hold-down strap must be used to place pressure on the motor shaft to hold the lower unit tightly against the motor rest when stowed.

- The pull grip and rope can be stored by placing the pull grip into the rope stow slot on the control box of the motor.

TO DEPLOY THE MOTORSimply pull back and lift the motor off of the mount with the pull grip and rope. Lower the motor into the water using the pull grip and rope. The motor will lock into the deployed position automatically.

TO STOW THE MOTORPull back and lift the motor out of the water with the pull grip and rope. Lower the motor lower unit onto the motor rest using the pull grip and rope. The motor will lock into the stowed position automatically. Wrap the hold-down strap over top of the motor shaft to secure the motor.

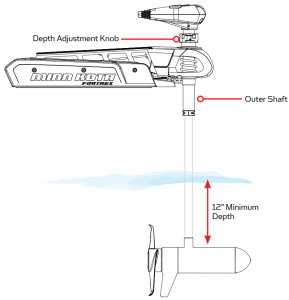

ADJUSTING THE DEPTH OF THE MOTOR

The propeller tip must be submerged at least 12″ to avoid churning or agitation of surface water.

- With the motor deployed, firmly grasp the outer shaft or control head and hold it steady.

- Loosen the depth adjustment knob until the shaft slides freely.

- Raise or lower the motor to the desired depth.

- Turn the motor control head to the desired position.

- Tighten depth adjustment knob to secure the motor in place.

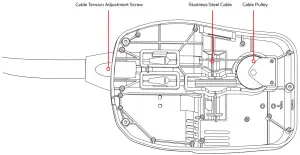

ADJUSTING THE STEERING CABLE

The steering cable tension is pre-set at the factory but will, through normal use, need occasional adjustment.

Adjust the tension of the cables by turning the cable tension adjustment screw (Phillips pan-head screw) located near the bottom of the foot pedal, just under the steering cable cover.

Turn the screw clockwise to increase tension and counter-clockwise to decrease tension.

NOTE:If the cable becomes too loose, it may disengage the wrap drum in the control box or the pulley in the foot pedal.

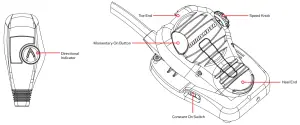

CONTROLLING SPEED & STEERING WITH THE FOOT PEDAL

Most controls on the foot pedal are easy to operate by either foot or hand:

TO ADJUST MOTOR SPEEDTurn the speed knob clockwise to increase speed and counter-clockwise to decrease speed.

TO OPERATE THE MOTOR IN MOMENTARY MODEThe default mode of operation for the foot pedal is Momentary. In this mode, the motor will only run while downward force is applied to the Momentary On button on the top of the foot pedal. A toe touch to the Momentary button on the top of the foot pedal will turn the propeller on in this mode. Removing downward force on the Momentary button will turn the propeller off.

TO OPERATE THE MOTOR IN CONSTANT MODETo switch to Constant Mode, flip the side-mounted Constant On switch until the propeller starts. In Constant Mode, the propeller will continually run, regardless of whether force is being applied to the Momentary On button on the top of the foot pedal.

TO TURN LEFT OR RIGHTPush the toe end of the foot pedal down to turn right and push the heel end of the foot pedal down to turn left. The indicator on the motor head shows the direction of the motor. The motor will not maintain its own heading. You must keep your foot on the pedal to control steering during operation.

TO REVERSE THE MOTORThe motor always travels in the direction of the indicator. You can reverse the direction of the motor by turning the motor 180° from straight ahead.

CAUTION:

- Make sure the Constant On switch is in the off position when not in use. If the motor control is left on and the propeller rotation is blocked, severe motor damage can result.

- Be sure to turn the motor off after each use.

- For safety reasons, disconnect the motor from the battery/batteries when the motor is not in use or while the battery/batteries are being charged.

SERVICE & MAINTENANCE

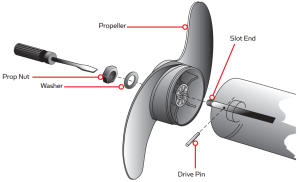

PROPELLER REPLACEMENT

TOOLS AND RESOURCES REQUIRED:

- Box End Wrench– 1/2″ for motors with 70 lbs thrust or lower.– 9/16″ for motors with 80 lbs thrust or higher.

- Screwdriver (optional)

CAUTION:Disconnect the motor from the battery before beginning any prop work or maintenance.

NOTE: The propeller on your motor may differ from the one pictured.

- Disconnect the motor from all sources of power prior to changing the propeller.

- Hold the propeller and loosen the prop nut with pliers or a wrench.

- Remove the prop nut and washer. If the drive pin is sheared or broken, you will need to hold the shaft stationary with a blade screwdriver pressed into the slot on the end of the shaft.

- Turn the old prop to horizontal (as illustrated) and pull it straight off. If drive pin falls out, push it back in.

- Align the new propeller with the drive pin.

- Install the prop washer and prop nut.

- Tighten the prop nut 1/4 turn past snug [25-35 inch lbs.] Do not over tighten as this can damage the prop.

GENERAL MAINTENANCE

- After use, the entire motor should be rinsed with freshwater. This series of motors is not equipped for saltwater exposure.

- The propeller must be inspected and cleaned from weeds and fishing line after every use.Fishing line and weeds can get behind the prop, damage the seals and allow water to enter the motor.

- Verify the prop nut is secure each time the motor is used.

- To prevent accidental damage during transportation or storage, disconnect the battery whenever the motor is off of the water.For prolonged storage, lightly coat all metal parts with an aqueous based silicone spray.

- For maximum battery life recharge the battery(s) as soon as possible after use. For maximum motor performance restore battery to full charge prior to use.

- Keep battery terminals clean with fine sandpaper or emery cloth.

- The propeller is designed to provide weed free operation with very high efficiency. To maintain this top performance, the leading edge of the blades must be kept smooth. If they are rough or nicked from use, restore to smooth by sanding with fine sandpaper.

- The rail covers on the motor rest are intended to be a wear item and may need to be a replaced periodically.

TROUBLESHOOTING & REPAIR

- Motor fails to run or lacks power:● Check battery connections for proper polarity.● Make sure terminals are clean and corrosion free. Use fine sandpaper or emery cloth to clean terminals.● Check battery water level.

- Motor loses power after a short running time: · Check battery charge. If low, restore to full charge.

- Motor is difficult to steer:● Check steering cables for proper tension. Adjust as necessary.

- You experience prop vibration during normal operation: · Remove and rotate the prop 180°. See removal instructions in the Propeller Replacement Section.

- Experiencing interference with your fish finder:● You may, in some applications, experience interference in your depth finder display. We recommend that you use a separate deep cycle marine battery for your trolling motor and that you power the depth finder from the starting/cranking battery. If problems still persist, call our service department.

NOTE: For all other malfunctions, visit an Authorized Service Center. You can search for an Authorized Service Center in your area by visiting our Authorized Service page, found online or by calling our customer service.

COMPLIANCE STATEMENTS

ENVIRONMENTAL COMPLIANCE STATEMENT:It is the intention of JOME to be a responsible corporate citizen, operating in compliance with known and applicable environmental regulations, and a good neighbor in the communities where we make or sell our products.

WEEE DIRECTIVE:EU Directive 2002/96/EC “Waste of Electrical and Electronic Equipment Directive (WEEE)” impacts most distributors, sellers, and manufacturers of consumer electronics in the European Union. The WEEE Directive requires the producer of consumer electronics to take responsibility for the management of waste from their products to achieve environmentally responsible disposal during the product life cycle.WEEE compliance may not be required in your location for electrical & electronic equipment (EEE), nor may it be required for EEE designed and intended as fixed or temporary installation in transportation vehicles such as automobiles, aircraft, and boats. In some European Union member states, these vehicles are considered outside of the scope of the Directive, and EEE for those applications can be considered excluded from the WEEE Directive requirement.  This symbol (WEEE wheelie bin) on product indicates the product must not be disposed of with other household refuse. It must be disposed of and collected for recycling and recovery of waste EEE. Johnson Outdoors Inc. will mark all EEE products in accordance with the WEEE Directive. It is our goal to comply in the collection, treatment, recovery, and environmentally sound disposal of those products; however, these requirement do vary within European Union member states. For more information about where you should dispose of your waste equipment for recycling and recovery and/or your European Union member state requirements, please contact your dealer or distributor from which your product was purchased.

This symbol (WEEE wheelie bin) on product indicates the product must not be disposed of with other household refuse. It must be disposed of and collected for recycling and recovery of waste EEE. Johnson Outdoors Inc. will mark all EEE products in accordance with the WEEE Directive. It is our goal to comply in the collection, treatment, recovery, and environmentally sound disposal of those products; however, these requirement do vary within European Union member states. For more information about where you should dispose of your waste equipment for recycling and recovery and/or your European Union member state requirements, please contact your dealer or distributor from which your product was purchased.

DISPOSAL:Minn Kota motors are not subject to the disposal regulations EAG-VO (electric devices directive) that implements the WEEE directive. Nevertheless never dispose of your Minn Kota motor in a garbage bin but at the proper place of collection of your local town council.

Never dispose of battery in a garbage bin. Comply with the disposal directions of the manufacturer or his representative and dispose of them at the proper place of collection of your local town council.

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

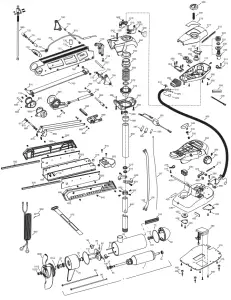

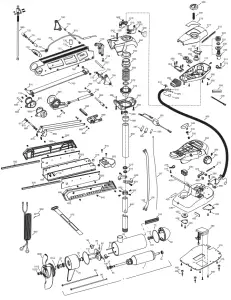

PARTS DIAGRAM

FORTREX 80

80 LBS THRUST – 24 VOLT – 45″ SHAFTThis page provides Minn Kota® WEEE compliance disassembly instructions. For more information about where you should dispose of your waste equipment for recycling and recovery and/or your European Union member state requirements, please contact your dealer or distributor from which your product was purchased.

Tools required, but not limited to: flat head screw driver, Phillips screw driver, socket set, pliers, wire cutters.

PARTS LIST

FORTREX 80

80 LBS THRUST – 24 VOLT – 45” SHAFT

|

ITEM |

QTY |

PART NUMBER |

DESCRIPTION |

|

1 |

1 |

2316216 |

24V MOTOR 45” FW |

|

1 |

2326240 |

24V MOTOR US2 45” | |

|

5 |

1 |

2-100-214 |

ARMATURE ASSEMBLY |

|

10 |

1 |

140-010 |

BEARING |

|

15 |

1 |

788-040 |

RETAINING RING |

|

20 |

2-200-160 |

CENTER HOUSING ASSEMBY | |

|

25 |

1 |

2-300-160 |

BRUSH END HOUSING ASSEMBLY |

|

30 |

1 |

421-276 |

PLAIN END HOUSING ASSEMBLY STD |

|

1 |

9421-288 |

PLAIN END HOUSING US2 45” | |

|

35 |

1 |

144-017 |

FLANGE BEARING |

|

40 |

2 |

880-025 |

SEAL |

|

50 |

2 |

188-094 |

BRUSH |

|

60 |

1 |

9-738-004 |

BRUSH PLATE ASSEMBLY |

|

65 |

2 |

975-041 |

BRUSH SPRING |

|

70 |

2 |

701-043 |

O-RING, MOTOR |

|

80 |

2 |

701-009 |

O-RING, THRU-BOLT |

|

85 |

2 |

830-027 |

SCREW, 10-32 X 2 |

|

90 |

2 |

830-094 |

THRU-BOLT |

|

95 |

2 |

990-051 |

WASHER, STEEL |

|

100 |

2 |

990-052 |

WASHER, NYLATRON |

|

110 |

2 |

973-025 |

SPACER, BRUSH PLATE |

|

115 |

2 |

992-010 |

WASHER, BELLEVILLE |

|

120 |

1 |

990-045 |

SPACER, THRUST |

|

125 |

1 |

582-013 |

CLIP, RETAINING, SHORT, US2 ONLY |

|

135 |

1 |

640-015 |

LEADWIRE, BLACK |

|

136 |

1 |

640-119 |

LEADWIRE, RED |

|

137 |

1 |

640-315 |

GROUNDWIRE, BROWN, US2 ONLY |

|

200 |

1 |

2990140 |

INDICATOR ASSEMBLY |

|

205 |

1 |

2282730 |

SPRING, INDICATOR |

|

210 |

1 |

2285605 |

DECAL, COVER 80#, FW |

|

1 |

2285606 |

DECAL, COVER 80# US2, FW | |

|

212 |

2 |

2285616 |

DECAL, CONTROL BOX, FW |

|

215 |

1 |

2280200 |

COVER, CONTROL BOX |

|

220 |

1 |

2232360 |

PULLEY, CABLE DRUM |

|

225 |

1 |

2261730 |

WASHER, NYLON |

|

230 |

1 |

2267800 |

GEAR, INDICATOR |

|

235 |

1 |

2996247 |

TOP BEARING, PINION DRIVE |

|

240 |

1 |

2301310 |

SCREW 8-18 X 1/2 |

|

245 |

1 |

2261905 |

BRACKET, INDICATOR |

|

250 |

1 |

2262221 |

INDICATOR, DRIVE |

|

255 |

2 |

2267800 |

GEAR, INDICATOR |

|

260 |

4 |

2223430 |

SCREW 8 X 3/4 |

|

265 |

1 |

2261901 |

BRACKET, CONDUIT |

|

270 |

1 |

2282500 |

CONTROL BOX |

|

274 |

1 |

2372100 |

SCREW 8-18 X 5/8 |

|

275 |

2 |

2263201 |

CLAMP, WIRE HARNESS |

|

280 |

3 |

2053414 |

8-32 X 1/2 TRI-LOBE |

|

285 |

4 |

2372100 |

SCREW 8-18 X 2/8 |

|

290 |

1 |

2265110 |

BOOT, CONTROL BOX |

|

295 |

3 |

2355410 |

SHRINK TUBE 3/8 |

|

296 |

2 |

2335400 |

SHRINK TUBE 1/2” OD X 2” |

|

297 |

1 |

2975400 |

SHRINK TUBE 1/4” OD X 1 3/4” |

|

300 |

1 |

2264015 |

LIGHT, INDICATOR |

|

305 |

1 |

2265430 |

CABLE JACKET, 5’ |

|

310 |

1 |

2261220 |

WIRE HARNESS, MAX |

|

315 |

1 |

2267505 |

CABLE ASSEMBLY, RIGHT, 5’ |

|

320 |

1 |

2267515 |

CABLE ASSEMBLY, LEFT, 5’ |

|

325 |

1 |

2211410 |

CABLE EXTENSION, US2 175” |

|

330 |

1 |

2218200 |

FUSE HOLDER ASSEMBLY US2 ONLY |

|

340 |

1 |

2993705 |

PUSH BUTTON W/ MAGNET |

|

345 |

1 |

2260810 |

CLIP, REED SENSOR |

|

350 |

1 |

2302732 |

SPRING, PEDAL BUTTON |

|

355 |

1 |

2994496 |

FOOT PEDAL W/ PLUG |

|

360 |

1 |

2263000 |

E-RING, KNOB |

|

365 |

1 |

2280115 |

KNOB, SPEED CONTROL VARS |

|

370 |

1 |

2263466 |

SCREW 1/4-20 X 2 |

|

375 |

1 |

2263210 |

BRACKET, CONDUIT ADJUSTMENT |

|

380 |

1 |

2263140 |

NYLOCK KEEPER |

|

385 |

2 |

2372100 |

SCREW 8-18 X 5/8 |

|

390 |

2 |

2261714 |

WASHER, MAX FOOT PEDAL |

|

395 |

1 |

2265115 |

BOOT, FOOT PEDAL |

|

400 |

1 |

2254031 |

SWITCH, MOM/OFF/CON |

|

415 |

1 |

2332103 |

SCREW 6-20 X 3/8 |

|

420 |

1 |

2260511 |

PIN, PIVOT, FOOT PEDAL |

|

425 |

1 |

2266610 |

DECAL, ON/OFF SWITCH |

|

430 |

1 |

2992104 |

FOOT PEDAL BASE |

|

435 |

1 |

2262301 |

PULLY, FOOT PEDAL |

|

440 |

1 |

2266401 |

COVER, PULLEY |

|

445 |

2 |

2301310 |

SCREW 8-18 X 1/2 |

|

450 |

1 |

2266413 |

TENSION SCREW |

|

455 |

2 |

2332103 |

SCREW 6-20 X 3/8 |

|

460 |

1 |

2266412 |

SWITCH PLATE, FOOT PEDAL |

|

465 |

1 |

2264056 |

CONTROL BOARD MAX 24/36 |

|

■ |

1 |

2884019 |

SWITCH-REDD, MAGNETIC W/CONNECTORS |

|

470 |

1 |

2264511 |

BOTTOM PLATE, MAX |

|

475 |

5 |

2372100 |

SCREW 8-18 X 5/8 |

|

480 |

2 |

2223455 |

SCREW 10-32 X 1/2 ZP |

|

485 |

4 |

2265126 |

BUMPER PAD, FOOT PEDAL |

|

490 |

4 |

2378600 |

POP RIVET, 3/16 X 3/4 ALUM |

|

■ |

1 |

2991550 |

CLAMP COLLAR ASSEMBLY |

|

500 |

1 |

2073102 |

NUT, 1/4-28 SS |

|

510 |

1 |

2071550 |

COLLAR CLAMP, “A” SIDE |

|

515 |

1 |

2072621 |

PIN, KNURLED |

|

520 |

1 |

2071718 |

WASHER #10 NYLON RETAINING |

|

525 |

1 |

2071555 |

COLLAR CLAMP, “B” SIDE |

|

530 |

1 |

2281505 |

KNOB – SOFT GRIP, FW |

|

535 |

1 |

2075120 |

PAD, URETHANE, DEPTH COLLAR |

|

540 |

1 |

2263422 |

SCREW 5/16-18 X 1 |

|

545 |

1 |

2281700 |

WASHER 5/16 LOCK |

|

■ |

1 |

2991754 |

BOW GUARD ASSEMBLY 45” |

|

550 |

1 |

2281942 |

BRACKET, TOP |

|

555 |

1 |

2280001 |

BEARING, TOP BRACKET |

|

560 |

1 |

2071541 |

SPRING SLEEVE, UPPER |

|

565 |

1 |

2282700 |

SPRING, BOWGUARD |

|

570 |

1 |

2281525 |

SPACER, SPRING 62” ONLY |

|

575 |

1 |

2281520 |

SPRING SLEEVE, LOWER |

|

580 |

1 |

2991725 |

BRACKET, BOTTOM |

|

585 |

3 |

2263423 |

SCREW 5/16-18 X 1 SHCS |

|

586 |

2 |

2262632 |

PIN, SPRING 1/4 X 5/8 |

|

590 |

1 |

2266000 |

BEARING, BALL, STEEL |

|

595 |

1 |

2266260 |

BEARING RACE |

|

600 |

1 |

2992085 |

TUBE W/ BEARING RACE 45” |

|

610 |

1 |

2266116 |

BEARING, CARTRIDGE |

|

615 |

1 |

2266001 |

BEARING, SPLIT RING |

|

620 |

2 |

2261622 |

COLLAR HALF |

|

625 |

2 |

2263453 |

SCREW, 1/4-20 X 1 SHCS |

|

630 |

1 |

2071560 |

COLLAR, TUBE |

|

635 |

4 |

2223468 |

SCREW 8-32 X 7/16 FLT HD |

|

640 |

1 |

2032003 |

TUBE 45” |

|

■ |

1 |

2991712 |

MNT FW 80# 45”, 112# HC 52” (SUB) |

|

700 |

1 |

2280800 |

LINK, BOWGUARD MOUNT, LEFT |

|

710 |

2 |

2287303 |

BUSHING, UPPER PINS |

|

715 |

4 |

2283411 |

SCREW, 1/4-20 X 1” FHS RIE TORX |

|

720 |

1 |

2880400 |

PULL GRIP ASSEMBLY |

|

721 |

2 |

2261732 |

WASHER |

|

725 |

1 |

2771601 |

ROPE ASSEMBLY |

|

730 |

1 |

2281516 |

SPACER, INNER ARM |

|

735 |

1 |

2281702 |

WASHER, LOCK 1/4 |

|

737 |

1 |

2284202 |

OUTER ARM |

|

740 |

1 |

2992322 |

ROPE GUIDE ASSEMBLY |

|

745 |

1 |

2281530 |

INSERT, THREADED |

|

750 |

1 |

2282608 |

PIN, 7/16 X 5 5/32 |

|

751 |

1 |

2282602 |

PIN, 3/8 X 3 3/4 |

|

752 |

2 |

2261505 |

SPACER |

|

753 |

2 |

2263011 |

E-RING, 3/8 SHAFT |

|

760 |

1 |

2223418 |

SCREW, 1/4-20 X 1/2 BHCS |

|

765 |

1 |

2993819 |

INNER ARM ASSEMBLY, SHORT |

|

770 |

1 |

2042711 |

SPRING, TORSION |

|

775 |

1 |

2283620 |

LATCH, SAFETY |

|

776 |

1 |

2282611 |

PIN, SAFETY LATCH |

|

780 |

1 |

2281704 |

WASHER 7/16 NYLON |

|

785 |

1 |

2280805 |

LINK, BOWGUARD MOUNT, RIGHT |

|

790 |

2 |

2283410 |

SCREW 1/4-20 X 1/2 PFH |

|

795 |

1 |

2288403 |

GAS SPRING (CYLINDER) |

|

796 |

2 |

2281710 |

SPACER, GAS SPRING |

|

800 |

1 |

2282610 |

PIN, UPPER, SHOCK |

|

810 |

4 |

2280005 |

BEARING, NYLINER 7/16” |

|

815 |

1 |

2282600 |

PIN, 7/16 X 4 7/8 |

|

820 |

2 |

2281932 |

BRACKET, REAR PIVOT |

|

825 |

1 |

2281501 |

YOKE, SHOCK MOUNT |

|

830 |

1 |

2282606 |

PIN, 7/16 X 4 1/2 |

|

835 |

2 |

2283402 |

SCREW, SET, 6-32 X 1/4 |

|

845 |

1 |

2282604 |

PIN, KNURLED 5/16 X 2 |

|

850 |

1 |

2283615 |

LATCH BAR |

|

855 |

1 |

2283610 |

BRACKET – LATCH/STRAP, ROPE PULL |

|

860 |

2 |

2287300 |

BUSHING, REAR PIVOT |

|

865 |

1 |

2282602 |

PIN, 3/8 X 3 3/4 |

|

870 |

2 |

2263011 |

E-RING, 3/8 SHAFT |

|

871 |

2 |

2280008 |

BEARING, IGLIDE |

|

875 |

2 |

2282720 |

SPRING, EXTENSION |

|

880 |

1 |

2773600 |

LATCH STRAP ASSEMBLY, SHORT |

|

885 |

2 |

2261732 |

WASHER 8, NYLON |

|

890 |

2 |

2373450 |

SCREW 8-18 X 3/8 |

|

■ |

1 |

2883930 |

SIDEPLATE KIT, FW, SHORT |

|

895 |

1 |

2283935 |

SIDEPLATE, LEFT, SHORT, FW |

|

900 |

1 |

2283930 |

SIDEPLATE, RIGHT, SHORT, FW |

|

905 |

4 |

2323403 |

SCREW-1/4-20 X .375 MCH SS CRPH |

|

910 |

2 |

2073408 |

SCREW 1/4-20 X 7/8 |

|

915 |

2 |

2286700 |

PLUG, SPACER |

|

920 |

1 |

2283900 |

RAMP, MOTOR |

|

925 |

2 |

2283631 |

RAIL, MACH., MOTOR REST |

|

930 |

2 |

2283920 |

COVER-RAIL, MOTOR REST (SUB) |

|

932 |

2 |

2285502 |

DECAL, SIDEPLATE, FW |

|

935 |

1 |

2281903 |

BASE-EXTRUSION SHORT, MACH |

|

940 |

6 |

2323405 |

SCREW 1/4-20 X 1/2 |

|

950 |

1 |

2256300 |

TIEWRAP |

|

955 |

1 |

2261238 |

LEADWIRE |

|

975 |

1 |

2773806 |

STRAP HOLD DOWN |

|

■ |

1378132 |

PROPELLER KIT WW2 | |

|

■ |

2994876 |

PROPELLER BAG ASSY | |

|

1000 |

1 |

2331160 |

PROPELLER WW2 |

|

1010 |

1 |

2262658 |

DRIVE PIN, LARGE |

|

1015 |

1 |

2091701 |

WASHER, PROP, LARGE |

|

1020 |

1 |

2093101 |

NUT, NYLOCK, PROP, LARGE |

|

■ |

2994887 |

MOUNTING HARDWARE BAG ASSY | |

|

■ |

2889460 |

SEAL & ORING KIT |

■ THIS ITEM IS PART OF AN ASSEMBLY.* THIS ITEM IS PART OF A KIT AND ONLY LISTED FOR VIEWING PURPOSES.

RECOMMENDED ACCESSORIES

ON-BOARD & PORTABLE BATTERY CHARGERS

Stop buying new batteries and start taking care of the ones you’ve got. Many chargers can actually damage your battery over time – creating shorter run times and shorter overall life. Digitally controlled Minn Kota chargers are designed to provide the fastest charge that protect and extend battery life.

TALON SHALLOW WATER ANCHOR

Talon deploys faster, holds stronger and runs quieter than any other shallow water anchor. Available in depths up to 12’ and bold color options including camo, it boasts an arsenal of features and innovations that no other anchor can touch:

- Vertical, Multi-Stage Deployment

- User-Selectable Anchoring Modes

- 2x Anchoring Force

- Fast Deploy

- Auto Up/Down

- Triple Debris Shields

- Built-In Wave Absorption

- Noise Dissipation

- Versatile Adjustments

MINN KOTA ACCESSORIES

We offer a wide variety of trolling motor accessories, including:

- 60-Amp Circuit Breaker

- Mounting Brackets

- Stabilizer Kits

- Premium Cable & Handles

- Battery Connectors

- Battery Boxes

- Quick Connect Plugs

[xyz-ips snippet=”download-snippet”]

The serial number on your Fortrex is located near the momentary switch underneath the side of the foot pedal.

The serial number on your Fortrex is located near the momentary switch underneath the side of the foot pedal.

● The motor should be mounted as close to the centerline of the boat as possible when it is deployed (see illustration).● Make sure bow area under the chosen location is clear and unobstructed for drilling.● Make sure the motor rest is positioned far enough beyond the edge of the boat. The motor, as it is lowered into the water or raised into the boat, must not encounter any obstructions

● The motor should be mounted as close to the centerline of the boat as possible when it is deployed (see illustration).● Make sure bow area under the chosen location is clear and unobstructed for drilling.● Make sure the motor rest is positioned far enough beyond the edge of the boat. The motor, as it is lowered into the water or raised into the boat, must not encounter any obstructions