INSTRUCTION MANUAL

INSTRUCTION MANUAL

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Check that the seals between the stove and the fuel bottle are in place and in good condition before connecting the stove to the cylinder Do not use this stove if it has dunned worn seals.

- Keep stove and fuel bottle army from other heat sources. If you expose the fuel bottle to high heat, it wit explode or leak and you can be killed or seriously boned.

- Follow all savings on Fuel bottles regarding use and storage.

- Do not disassemble the stove beyond what is described in these instructions. DO NOT MODIFY THIS STOVE. Disassembly or modification of stove in only manna not consistent with these instructions voids warranty and con result in an unsafe situation where fire, bums, severe injury a death can occur.

- Do not use the stove if ports are missing or broken, or with ‘enlacement ports not specific to your stove model. Use of stove with missing or broken parts, or with replacement ports not speck to your stove model, can result in an unsafe situation where fire, bums, severe injury, or death can occur.

Cascade Designs, Inc. wants the use of appropriately sized MSRs’ brand cookware only —use of cookware other than MSR° bad cookware is at users’ own risk and discretion.

WHISPERLITE™ INTERNATIONAL INSTRUCTIONS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- before reading and fully understanding this Instruction Memel:

- if you ere not prepared or component Penang to o burning and/a hot stave at all times;

- if you observe taking fuel; or

- if you observe my condition with the stove system or in the surrounding imminent that would make the operation of an open Reined device dangerous. Failure to follow these directions can muse on unsafe situations tearing to fire, buns, severe injury, or death.

WHISPERLITE™ INTERNATIONAL STOVE

|

STOVE PARTS |

FUEL PUMP PARTS |

| A. Burner HeadB. Pot Supports/LegsC. Mixer TubeD. JetE. Rim DetentF. Shaker NeedleG. Generator TubeH. WindscreenI. Priming CupJ. Fuel Line (Brass) EndK. Catch ArmL. Heat ReflectorM. Jet and Cable Tool | N. Plunger BushingO. Plunger Bushing TabsP. PlungerQ. Fuel Pump GrooveR. Pump SealS. Pump BodyT. Check ValveU. Control Valve AssemblyV. Fuel Tube O-ringW. Fuel Tube BushingX. Pump Cup |

FUEL INFORMATION

The WhisperLiteTM International stove burns a variety of fuels by using two interchangeable Jets.

- UG Jet — White Gas and Unleaded AutoGas. This Jet is preinstalled on your stove.

- UK Jet — Kerosene. This Jet is included in the parts kit with your stove. To exchange Jets, see Cleaning the Jet and Fuel Line.

Use MSR® SuperFuel\’” (White Gas) for optimal performance. It is the highest quality fuel available for your stove. Do not use leaded fuels. Fuels other than MSR SuperFuel white gas can lead to rapid stove clogging and require more frequent Jet and Fuel Line cleanings. Also, the use of Unleaded Auto Gas may shorten stove lifespan.Visit www.msrgear.com for more information on international fuel names and safe stove transportation.

STOVE MAINTENANCE

Deposits in the Jet and Fuel Line reduce fuel flow and impair stove performance. Minor deposits in the Jet can be cleared with the Shaker Needle. Major deposits may require more extensive cleaning of the Jet and Fuel Line. At a minimum, perform the following maintenance annually or every time you perform the Pump Maintenance.CLEARING THE JET WITH THE SHAKER NEEDLE

- Close Pump Control Valve and wait 5 minutes for the stove to cool.

- Shake the stove up and down. Shaker Needle inside Jet should rattle.

- Preheat and run the stove. If performance does not improve, perform Cleaning the Jet and Fuel Line steps.

CLEANING THE JET AND FUEL LINE

|

|

- Fold Pot Supports/Legs to the packed position.

- Unscrew Priming Cup and remove Wick.

- Hold folded Pot Supports/Legs together. Remove Fuel Line from Mixer Tube.

- Unscrew Jet with Jet and Cable Tool.IMPORTANT: Do not bend Generator Tube while loosening Jet.

- Remove Shaker Needle and use it to clear Jet Orifice from top or bottom.NOTE: To exchange Jets, place Shaker Needle in new Jet and reassemble stove.

- Scour Fuel Line. Remove Cable from Fuel Line with Jet and Cable Tool. Stubborn cables can be loosened with a common lubricant (WD-40′”, Pump Cup Oil, etc.). Fully reinsert Cable into Fuel Line. Move Cable in and out with 5-inch (13-centimeter) strokes approximately 20 times Wipe Cable clean.

- Flush Fuel Line. Remove Cable. Insert Fuel Line into Pump and Fuel Bottle and secure Catch Arm on Fuel Pump Pressurize Fuel Bottle with 15 strokes. Fully open Control Valve to flush 4 spoonfuls of fuel through Fuel Line into an appropriate container. (Jet uninstalled.)DANGER: Keep away from ignition sources Close Control Valve and remove Fuel Line. Safely dispose of fuel when flushing is complete.

- Reassemble stove. If stove performance is still impaired, repeat Cleaning the Jet and Fuel Line steps.

PUMP MAINTENANCE

O-rings can become dry, cracked, or torn with use. Their lifespan is affected by dirt, debris, temperature, friction, and frequency of use. For this reason, please inspect your O-rings before every trip. Replace dry, cracked, or torn O-rings immediately, and replace all O-rings annually, regardless of appearance. Replacement O-rings and Pump Seals can be found in the Annual Maintenance Kit, or the more comprehensive Expedition Service Kit purchased separately from an MSR® dealer.

REPLACING FUEL TUBE 0-RING

- Remove Plunger. Align, twist, and pull.

- Remove Fuel Tube Bushing and 0-ring with Jet and Cable Tool. Remove the 0-ring with the end of the Fuel Line or safety pin.

- Inspect 0-ring and replace if damaged. If needed, a spare red Fuel Tube 0-ring is provided.

- Lubricate Pump Cup. Use a drop of pump cup oil or any mineral-based oil.

- Insert Plunger.Hold thumb and forefinger firmly around Arrow 1. Align Plunger Bushing Tabs with holes in Pump Body. Push Plunger/ Bushing into the Pump Body until it snaps in place.

REPLACING CONTROL VALVE 0-RING

- Unscrew Stop Nut

- turns.

- Unscrew Control Valve 6 turns.

- Unscrew Stop Nut completely and remove Control Valve Assembly.

- Inspect 0-ring and replace if damaged. Remove Control Valve Handle from the stem.Slide Stop Nut off. Remove 0-ring with a safety pin.

|

|

|

|

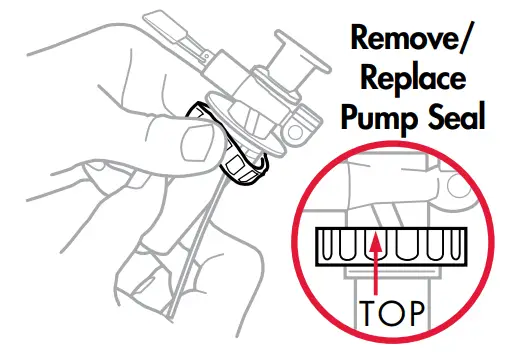

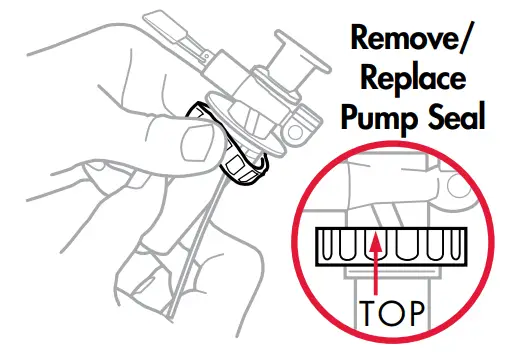

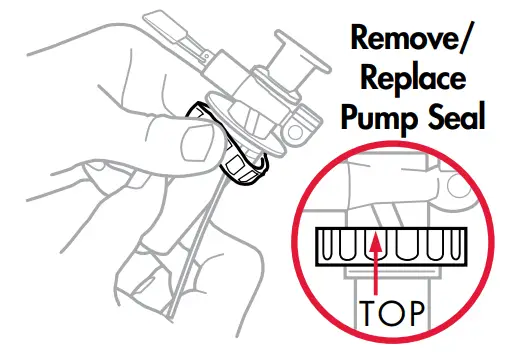

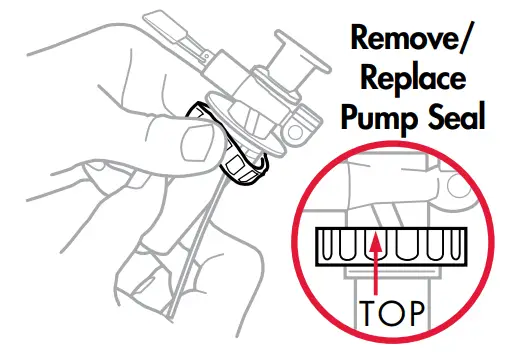

REPLACING PUMP SEALInspect Pump Seal and replace if damaged.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Turn Check Valve Assembly to remove.

- Wipe any debris from Check Valve and Pump Cavity.

- Reinsert Check Valve Assembly.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Limited Warranty details at msrgear.com/warrantyFor Troubleshooting Solutions, visit: msrgear.com/whisperlite-international

WHISPERLITETM INTERNATIONAL STOVE OPERATING INSTRUCTIONSTo avoid being killed or seriously injured, READ, UNDERSTAND, AND FOLLOW ALL instructions and warnings in this manual before using this stove.Please familiarize yourself with the parts of your WhisperLite International stove. This stove requires a priming or preheating step to convert liquid fuel into vapor to run properly. Priming or preheating the stove is addressed in Step 3.

|

STOVE PARTS |

FUEL PUMP PARTS |

| A. Burner HeadB. Pot Supports/LegsC. Mixer TubeD. JetE. Rim DetentF. Shaker NeedleG. Generator TubeH. WindscreenI. Priming CupJ. Fuel Line (Brass) EndK. Catch ArmL. Heat ReflectorM. Jet and Cable Tool | N. Plunger BushingO. Plunger Bushing TabsP. PlungerQ. Fuel Pump GrooveR. Pump SealS. Pump BodyT. Check ValveU. Control Valve AssemblyV. Fuel Tube O-ringW. Fuel Tube BushingX. Pump Cup |

FUEL BOTTLE PREPARATIONThe WhisperLite International stove is sold with two interchangeable Jets so it can burn a variety of fuels. To ensure the correct Jet is installed for the type of fuel to be used, see Fuel Information.

- Fill Fuel Bottle to fill line only. Air space is necessary for fuel expansion.

- Insert Pump into Fuel Bottle and firmly tighten.

- Check Fuel Bottle for leaks before pressurizing the bottle.

- Close the Control Valve, then stroke Plunger (20-30 strokes). Pump until firm resistance is felt. Less fuel requires more strokes or pressure.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

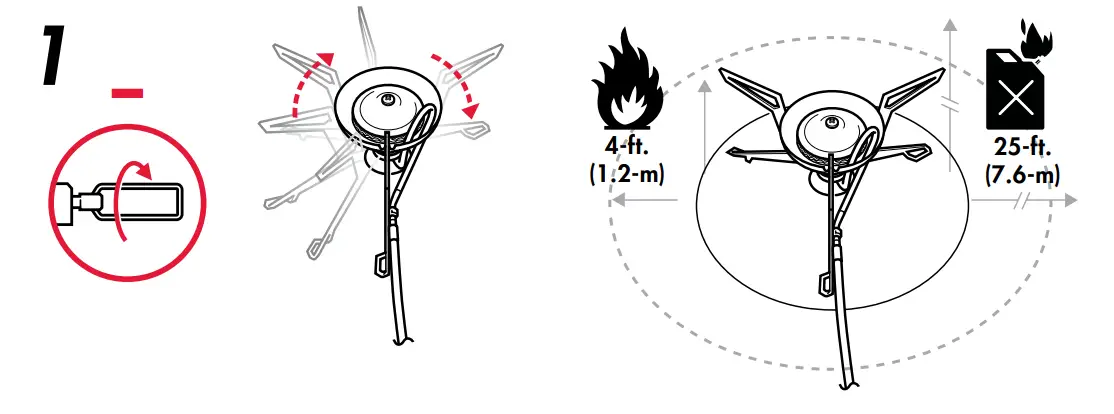

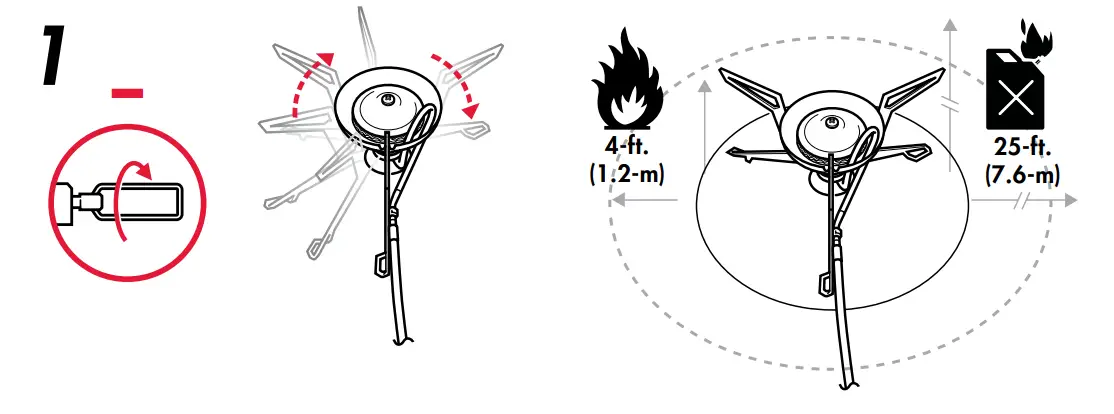

SET UP STOVE

- Unfold the 3 Pot Supports/Legs. Rotate Pot Supports/Legs fully open.

- Place stove on the center of the Heat Reflector.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

CONNECT STOVE AND PUMP

- Lubricate the entire brass end of the Fuel Line with saliva or oil.

- Completely insert the brass end of the Fuel Line into the Pump. Place Fuel Bottle on its side so Pump Control Valve points up.

- Secure the Catch Arm on Fuel Pump Groove. Keep Fuel Line straight for safety. Keep Fuel Bottle as far away from the stove as possible.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

PREHEAT STOVE

- Release only 1/2 spoonful of fuel. Open Control Valve (3/4 turn) and let fuel flow through the Jet. Close Pump Control Valve. Look for fuel in Priming Cup and on Wick.

- Light fuel in the Priming Cup. A brief soccer ball-sized flame is normal.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

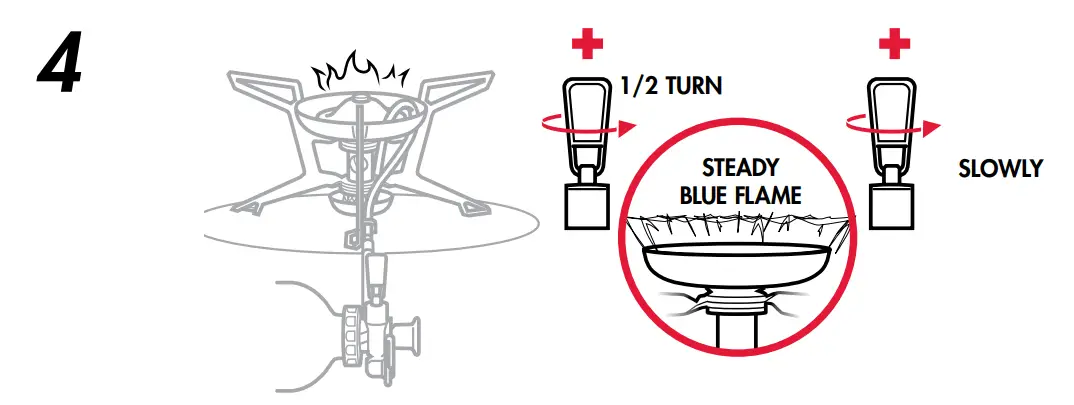

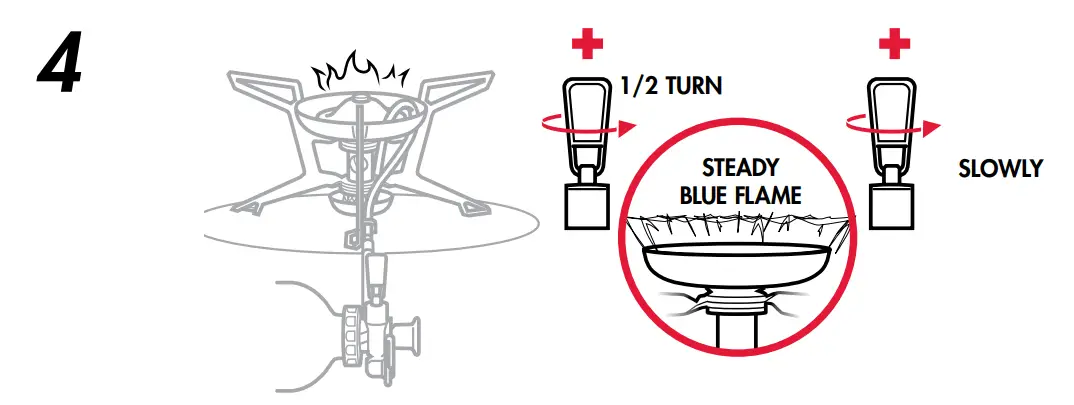

TURN STOVE ON

- Wait for preheating flame to reduce in size (approximately 2 minutes). If the flame goes out, wait 5 minutes for the stove to cool before relighting.

- Open Pump Control Valve (1/2 turn) and wait for the steady blue flame.

- Slowly open the Pump Control Valve.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

USE STOVE TO COOK

- Set up Windscreen. Fold the ends of the Windscreen together.Leave a 1-inch (2.5-cm) gap between Windscreen and pot for optimal performance. Ensure that combustion flow and ventilation air are free of any obstruction. Use Windscreen to improve performance in all conditions.

- Add appropriate food or liquid to cookware and place it on the center of the stove.

- Maintain Fuel Bottle pressure. Add approximately 10 strokes every 10 minutes to maintain performance. Hold Fuel Bottle firmly while pumping.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TURN THE STOVE OFF

- Close Pump Control Valve. Residual fuel will continue to burn with a small flame.

- After flames are out, wait 5 minutes for the stove to cool.

- Unlock Catch Arm and remove Fuel Line from Pump.

- Depressurize Fuel Bottle and repack stove. Hold Fuel Bottle upright, away from your face and any sources of heat or ignition. Slowly unscrew the pump to depressurize the Fuel Bottle.NOTICE: To transport the Fuel Bottle, the Pump may be left inside a depressurized Fuel Bottle. The Pump can also be removed and replaced with the Fuel Bottle Cap.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

TROUBLESHOOTING

|

Leaking Fuel |

Cause |

Solution |

| At Pump and Fuel Bottle Connection | Damaged or missing Pump Seal | Replace Pump Seal |

| At Pump and Fuel Line Connection | Damaged or missing Fuel Tube 0-ring | Replace Fuel Tube 0-ring |

| At Control Valve Stem | Damaged or missing Control Valve O-ring | Replace Control Valve 0-ring |

| In Pump Plunger Chamber | Obstructed Check Valve | Clean Check Valve Cavity |

|

Poor Performance |

Cause |

Solution |

| Pump not pressurizing Fuel Bottle | Loose or poorly seated Pump Damaged Pump Cup | Tighten or re-screw Pump on Fuel BottleReplace Pump Cup |

| Plunger hard to pump | Dry Pump Cup | Lubricate Pump Cup |

| Erratic yellow flames | Improper preheating | Repeat Step 3 |

| Diminished flames | Low Fuel Bottle pressure | Pump the Plunger |

| Slow boil times | Clogged Jet or Fuel Line | Clear Jet and clean Fuel Line |

| Diminished flames at altitude | Insufficient airflow | Open Windscreen slightly |

FOR OUTDOOR USE ONLY

![]()

![]()

References

[xyz-ips snippet=”download-snippet”]