Munters GLASdek ® GX30Fire-rated evaporative cooling and humidification media

Munters GLASdek ® GX30Fire-rated evaporative cooling and humidification media

Munters is proud to introduce a new and improved generation of its fire-rated evaporative cooling media.

GLASdek ®

- High evaporative efficiency

- Fired Rated UL ® 9 0 0 , U L C – S111

- GREENGUARD Gold certified

- High face velocity, low-pressure drop, low drift

Optional TUFedg ®

- Protective edge coating

- Algae and weather resistant

- Extends the service life of evaporative pads

- Scrubbable

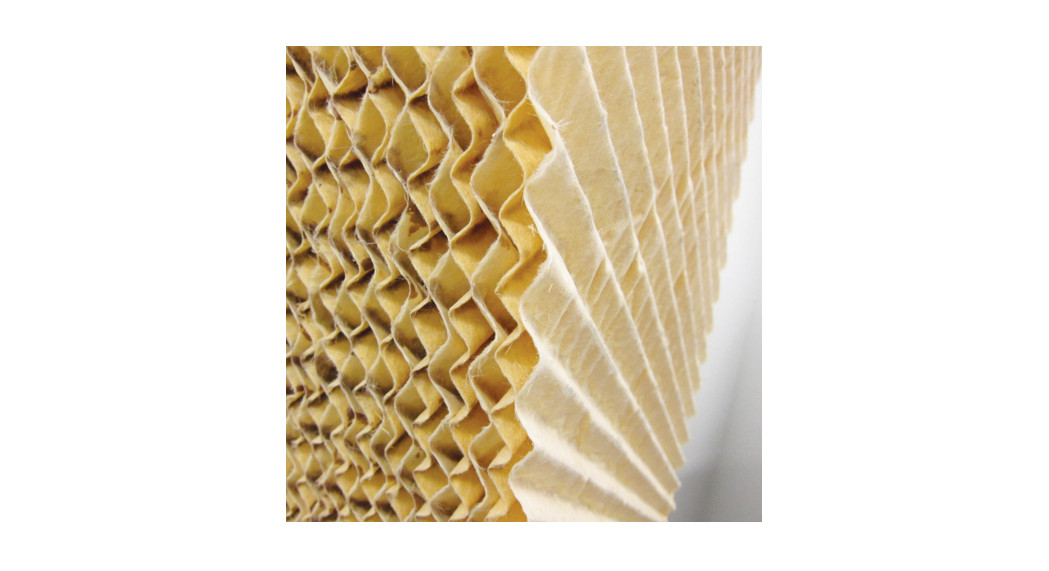

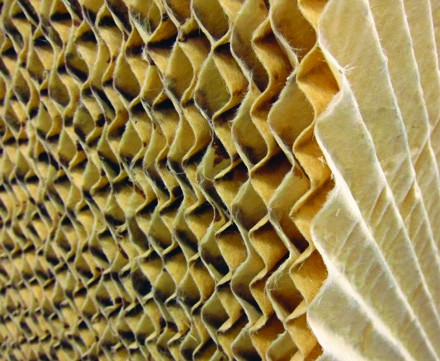

Figure 1. Munters GLASdek GX30

Figure 1. Munters GLASdek GX30

Munters GLASdek, the original evaporative media, was invented by Munters in the 1970s. The unique design has continuously been developed for maximum operating efficiency, safety, and life span. The shallow angle of Munters unequal flute design allows high-velocity air to travel through the pad without significant resistance or water droplet carry over. GLASdeks’ self-cleaning design resists clogging caused by dust, sand or other debris. By design, more water is directed toward the air entering the face of the pad, where it flushes away dirt and debris while allowing maximum cooling performance (See Figure 1).Our new-generation media, GLASdek GX30, has increased strength and durability with exceptional cooling and humidification rates due to its design, manufacturing, and materials. It is made from a flame retardant material fortified with special rigidifying agents and is the evaporative cooling and humidification media choice where strict adherence to fire codes is required. Fire Rated UL ® 9 0 0 and ULC – S111.

The new generation pad has tested better or equal in every aspect with a better resistance to supply water conditions and harsh environments as well as improved drift properties. When properly maintained, Munters GLASdek pads will provide many years of efficient cooling and humidification. GLASdek GX30 is also GREENGUARD Gold certified under UL’s certification program, as having low chemical emissions, validating that it meets the highest industry standards globally.

Design considerations

The water flow needed is based on the depth and height of the media used. GLASdek typically uses about 1.5 gallons per minute per square foot of horizontal (top) pad surface area.Supply: the drain pan and sump should be sized to supply the system with enough water to operate at its maximum flow rate and not overflow when the system is shut down.

Maintenance

Mineral deposits can be minimized by maintaining a continuous water bleed-off, or by periodically dumping the sump. The exact amount will depend on the pH and hardness of the water supply. Munters can assist by recommending individual bleed-off rates.Early implementation of simple maintenance techniques benefits pad life. The efficiency of the pad is maintained when the air can flow uninhibited through the pad. Munters maintenance bulletins provide information to help maximize the efficiency and life of GLASdek.Standard pad sizes are availableDepth: 4″, 6″, 8″, 12″Height: 24″, 36″ 48″, 60″, 72″Width: 12″, 24″SelectionThe widths, heights, and depths of the media vary by application.Call Munters for help in determining the requirements of specific installations. GLASdek can be cut to fit any installation.

Options:TUFedg ®For extended service life, Munters offers the option of TUFedg.Tough and resilient edge treatment is applied to the air entering the face of a GLASdek pad. It has been formulated to withstand repeated cleaning without damaging the pad.Munters TUFedg is non-porous and quick drying. It prevents algae and minerals from anchoring themselves into the substrate of the pad, so they slough off when dried. TUFedg also protects GLASdek pads from the damaging effects of severe weather and long-term exposure to UV light. This protective edge coating extends the life of the pad.

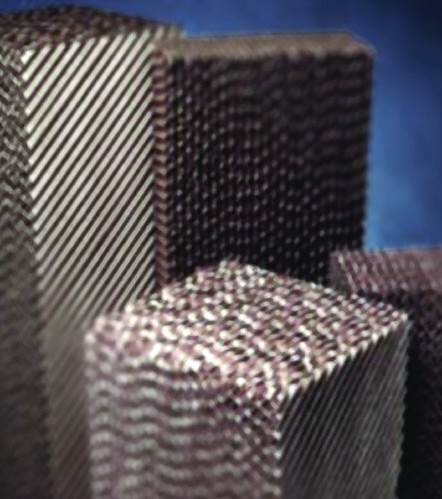

DISTRIBUTION PADS

These pads disperse water laterally and evenly across the top of the pad. These specially designed pads are also protected with Munters patented edge treatment.

Find your nearest Munters office at www.munters.comMunters reserves the right to make alterations to specifications, quantities, etc., for production or other reasons, subsequent to publication. © Munters AB, 2021

Find your nearest Munters office at www.munters.comMunters reserves the right to make alterations to specifications, quantities, etc., for production or other reasons, subsequent to publication. © Munters AB, 2021

References

[xyz-ips snippet=”download-snippet”]