PRODUCT SHEETMunters IceDry®140 Desiccant dehumidification units for a frost-free storage

Frost-free cold storage can be a reality with the installation of an IceDry dehumidifier. When an IceDry unit is installed, accumulated ice and frost will be significantly reduced or eliminated.

Features

- Thermostat controlled heating fan within the electrical panel

- Special reactivation fan in an insulated fan box with a heating cable

- Reversible panel construction (provides installation flexibility)

IceDry is the only dehumidifier that has been developed especially for installation inside cold storage areas. The tough, cold environment demands special features created to ensure reliable and energy-efficient operation of the unit.Installation of the unit is simple. The IceDry unit is placed close to a wall and ducting around the unit is minimal. Reactivation air is taken from the room next to the cold storage area. Immediately after being started, the unit will begin to reduce ice and frost.Unique benefits of the IceDry unit include:

- Reduced electrical and mechanical failures, less downtime

- Lower maintenance costs

- Reduced defrost requirements

- Increased efficiency of evaporators

Suggested specification guide

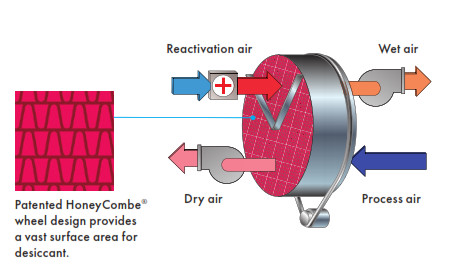

The dehumidifier shall be of the non-cycling sorption type with a single desiccant rotary structure. The unit will be equipped with an internally sealed rotor unit. The rotor casing shall be constructed of durable thermoset plastic and contain isolated sections that will provide a precise balance for dehumidification, reactivation, and heat recovery airflows. The metal frame and access panels shall be constructed from corrosion-resistant ALUZINK ®. A suitable access panel shall allow access for inspection or servicing without disconnecting ducting or electrical wiring.The rotary structure shall be a monolithic fabricated extended surface consisting of inert silicates reinforced with uniform diameter glass fibers for maximum strength. The fabricated structure shall be smooth and continuous in the direction of airflow without interruptions or sandwich layers that restrict airflow or create a leakage path at joining surfaces. Desiccants shall not channel, cake or fracture due to repeated temperature and moisture cycling. The materials of construction shall be nontoxic and NFPA 225-ASTME84 compliant.Full face contact pressure seals shall be provided to separate the process and reactivation airstreams and eliminate detrimental leakage of air or moisture with static pressure differentials of up to 3″ of water gauge.Dehumidifier shall be factory-assembled, fully automatic, complete with HoneyCombe ® desiccant wheel, reactivation heaters, reactivation energy control system, roughing filters, motors, fans, non-ratcheting desiccant drive unit, automatic controller, and all components’ auxiliaries. Reactivation Energy Modulation shall be stepless solid-state proportioning type. Dehumidifier shall be functionally tested at the manufacturer’s factory and shipped complete with all components necessary to maintain the normal operation.*Continual engineering and research for product improvement may result in design and specification changes. Consult the factory for certified technical data.

Technical Specifications*

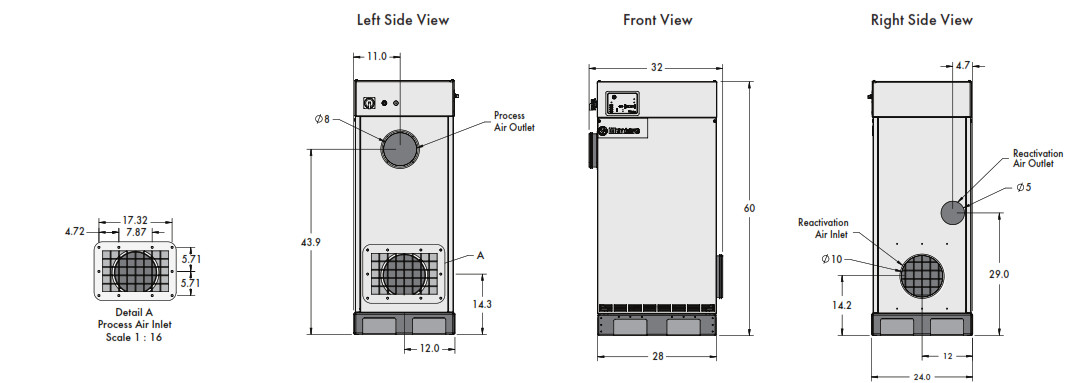

Process Volume: 825 scfmMaximum Reactivation Volume: 225 scfmMaximum FLA:24.4A @ 230V/3/60Hz13.2A @ 460V/3/60HzMaximum noise level unducted (dBA): 8030% process and reactivation filtersFan External Static Pressure (in. w.g.):Process: 1.0Reactivation: 0.5Performance:For Process Inlet Temperature ≤10°FProcess Outlet Moisture = 0.6 gr/lbProcess Temperature Rise is 16°FFor performance ≥10°F, consult the factory.

| Max length (in.) | 34 |

| Max width (in.) | 24 |

| Max height (in.) | 60 |

| Max weight (lbs.) | 350 |

Find your nearest Munters office at www.munters.comMunters reserves the right to make alterations to specifications, quantities, etc., for production or other reasons, subsequent to publication. © Munters AB, 2021

References

[xyz-ips snippet=”download-snippet”]