NAVAC NP12DM Vacuum Pump

INTRODUCTION AND TECHNICAL INFORMATION

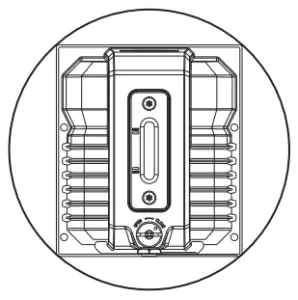

In order to make it easier to understand the components of the vacuum pump, please see the picture below.

DC INVERTER DRIVE VACUUM PUMPS

| Model | NP12DM |

| Power Supply | 115V /60Hz |

| Flow Rate ( CFM ) | 12CFM |

| Ultimate Vacuum | 5 Micron |

| Motor Power ( HP ) | 1/2 |

| Oil Capacity ( oz ) | 28 |

| Dimensions ( in ) | 16.3″x6″ x12 .1″ |

| Weight ( lbs ) | 32 |

| Inlet Port | 1/4″, 3/8″, 1/2″ Flare |

APPLICATION

NAVAC inverter drive dual-stage rotary vane vacuum pumps are used to remove air, moisture, and other non-condensable from sealed HVACR systems. The products can be used for evacuation of HVACR repair and new installations, with refrigerants including CFC, HFC, HCFC, and HCEF, such as R-12, R-22, R-41 OA, R-404A, R-32, R-134A, 1234yf, etc.

SPECIAL FEATURES

- Forced oil lubrication ensures vane sealing, cooling and high reliability.

- Large and easy to see oil-level window design help prevent oil supply shortage.

- Non-sparking design, suitable for R-32, 1234yf refrigerants.

PREPARATION PRIOR TO USING VACUUM PUMP

- Verify the power supply being used, to match the voltage on the nameplate.

- Ensure that the pump is switched off prior to connecting to the power source.

- Check for proper oil level, or change if needed.

- Remove the oil fill cap, filling oil to the level in between the two oil sight glass lines, as shown in the drawing below. For specific pump oil volume, please see the technical specification table.

Note: In order to prevent pump oil from spilling out, please add oil slowly.

Switch on the power and the pump will begin to operate. After running for approximately one minute, check the oil level. If the oil level is too low, switch off the machine and add the required extra oil. Reinstall the oil fill cap.

Note: While the pump is operating, the oil level should be in between the two oil position lines. If the oil level is too low, it will reduce the performance and could damage the pump vanes. If the oil level is too high, it could cause oil to discharge through the pump exhaust.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances

WARNING – Improper installation of the grounding plug is able to result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire.Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded. Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

SAFETY WARNINGS

WARNING: This machine should only be used for evacuation of refrigerant systems after refrigerant has been removed from the system and the system has been opened to atmosphere. This machine is not to be used as a transfer pump for liquids or any other media; doing so can damage the product. Note: In order to avoid personal injury, please carefully read and follow the instructions in this user manual and the user guide of the pump.NAVACVACUUMPUMPSARENOT ALLOWEDTOBEUSEDFORA30RFLAMMABLE REFRIGERANTS.

- NEVER CONNECT AVAUUM PUMPTOAPRESSURIZED SYSTEM. Always check to make sure that system and piping pressure is NOT ABOVE ATMOSPHERIC PRESSURE.

- When handling refrigerants, please wear an eye-protection such as safety glasses or goggles.

- Avoid direct physical contact with refrigerants, you will get burned.

- When connecting the power source, all equipment’s must be grounded in order to prevent electrical hazards.

- When the pump is in operation, the enclosure surfaces will be hot. Do not touch the oil box or the motor case. Allow adequate ventilation space for heat dissipation.

- When using R-32, 1234yf or other flammable refrigerants, use an explosion proof electrical outlet.

- Keep pump dry and away from water, mud, and dirt at all times.

- Operating pump with intake fittings open to the atmosphere must not exceed 3 minutes.

- Ambient temperature range for pump use is 30 to 104 “F(-1″C-40″C ). The pump can be used in lower ambient conditions, if warmed up inside first and run for no more than 1 minute to warm the oil prior to system evacuation.

- The pump requires 115V±10% power, and the power outlet must be grounded.

- Prior to connecting the vacuum pump to an NC-R system, please use proper methods to remove refrigerant from a pressurized system. Note that pumping refrigerants under high-pressure conditions will damage the pump, and refrigerant must be removed using a recovery machine designed for that purpose.

USE GUIDE

- When using the vacuum pump, remove the inlet protection cap from the desired (1/4″, 3/8″, or 1 /2″) connecting port, as shown in the diagram above, and connect the pump to the system or piping to be evacuated. Use shortest hoses possible for faster and more thorough evacuation.

- lnspectthe hose inlet connection, as well as all connecting hoses for proper seal. There must be no leakage or it will be impossible to draw the required deep vacuum level.

- At the beginning of the evacuation process, open the GAS BALLAST, and once the vacuum gauge reaches 2000 microns, retighten to achieve desired vacuum level.

- After evacuation is completed, shut down the pump and close the system access valves.

- Turn off the power switch on the pump and disconnect power.

- Remove the evacuation hoses.

- Close the air entry cap and the air exhaust cap tightly (with the exception of models without air exhaust cap), to prevent dirt or particulates from entering the pump.

Note:

- Always evacuate systems in conjunction with a micron vacuum gauge, such as the NAVAC NMV1 , if using the standard inverter drive pump. Micron vacuum gauges precisely measure and display system evacuation during the entire process, giving you a comprehensive view of the sealed system internal evacuation condition.

- Please pay attention to any changes in the oil level during pump operation. If the oil level falls below the center line, immediately add more vacuum pump oil to avoid damage to the pump.

- Vacuum pump and oil must be above 30°F.CAUTION-To reduce the risk of electric shock, do not expose to rain. Store indoors.EXTENSION CORDS If an extension cord must be used, be sure it is: 1.A 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that will accept the plug on the product 2.ln good condition 3.No longer than 50′ (15.2m)

- 16 gauge (AWG) or larger. (Wire size increases as gauge number decreases. 14 AWG and 12AWG may also be used. DO NOT USE 18AWG) NOTICE: Risk of Property Damage. The use of an undersized extension cord will cause voltage to drop resulting in power loss to the motor and overheating.

MAINTENANCE

- Vacuum pump oil has three major functions: pump lubricant, pump cooling, and pump sealant. During the evacuation process, the pump oil will absorb moisture being pulled from the system, causing it to be less effective as a lubricant and pump vane seal, extending evacuation time and possibly allowing the pump to overheat. We recommend that the oil be changed just before evacuating each NC-R system to insure the pump oil is in a clean condition as this is the key factor in determining if the pump can achieve the required vacuum levels. In order to maintain the optimum operation of the pump, we recommend that you use NAVAC vacuum pump oil. This oil is made using a unique process and can maintain proper viscosity during normal operation and temperatures, and it’s also helpful for cold starts. Should the NAVAC oil not be available, reputable brands of special-purpose vacuum pump oil may be used.

Note: Should the pump oil become opaque, dirty, or full of moisture, promptly change oil. This will greatly speed up evacuation, especially when there is a lot of moisture in system piping from having been left open to the atmosphere for an extended period of time

Oil change procedure:

- To ensure that the pump and oil are warm, run pump for approximately one minute prior to changing oil. Do not run longer than this, as it may be possible to damage the pump.

- While the pump is running, open one inlet port and allow oil to drain out of the pump. After turning off pump, open the oil drain plug, and drain used oil into an appropriate vessel and dispose of properly.

- As oil stops draining, tip the pump to drain any remaining oil in the bottom of the pump.

- Close oil drain valve.

- Remove oil fill cap, pour in new oil until the oil is at the proper level in the sight glass (the same procedure prior to using the pump above).

REQUIREMENTS FOR WARRANTY COVERAGE

Product warranty is provided for product quality problems for two years from date of sale. For warranty to be valid, the following conditions must be met:

- Products issues due to manufacturing defects confirmed by qualified agents.

- Products which have not been maintained or dismantled by unauthorized parties.

- Products that have been used in accordance with the User Manual. All maintenance services shall be performed during the warranty period.

Statement: Other than repairing the product defective, the manufacturer of this product will not be liable for any other costs, such as time spent in fixing the issue, refrigerant consumption,

TROUBLESHOOTING

| Malfunction | Possible Cause | Remedy |

| Low Vacuum | 1. Secondary air inlet connection cap loose on the air inlet port. | Tighten the cap. |

| 2. Damaged rubber ring inside the secondary air inlet connection cap. | Replace the rubber ring. | |

| 3. The volume of oil is insufficient | Add oil to the center line of the oil display | |

| 4. Pump oil becomes opaque or absorbed too many impurities. | Replace with new oil. | |

| 5. The pump’s oil end~ hole is clogged or the oil supply is insufficient . | Clean the oil entry hole, clean the oil filter. | |

| 6. The pump connecting hoses, manifold or system has a leak. | Inspect the connecting hose gaskets and system has a leak. system, repair leaks. | |

| 7. The pump selection is wrong. | Check the size of the container to be evacuated, recalculate and select an appropriate pump model. | |

| 8. The pump has been used for too Jong, damage and wear to components caused increased gaps between parts. | Inspect and repair, or replace the pump. | |

| Oil leak | 1. Damaged oil seal. | Replace the oil seal. |

| 2. Loose or damaged oil box connections. | Tighten the connecting screws, replace 0-rings. | |

| Oil spray | 1. Excessive oil volume. | Remove oil until the oil position line is reached. |

| 2. Inlet port pressure is excessively high for a long period. | Select an appropriate pump, increase the period. pumping speed. | |

| Start-up problems | 1. Oil temperature is too low. | Exposed the air entry hole to the external 1. Oil temperature is too low. atmosphere, and remove the oil fume filtration device. Use a screwdriver to tum the engine axle in an anti- |

| 2. Motor, power source or circus~ board malfunctions. | Inspect and repair. | |

| 3. Foreign objects entered the pump. | Inspect and remove. | |

| 4. Voltage supply is excessively low or high. | Inspect the power source voltage. | |

| 5. Overload trips. | After overload trip occurs, switch kept On. Remove the power plug, watch for approximately 30 seconds before inspecting and repairing. |

Notes:

- The pump is inverter driven and the motor has over-current/ overload protection, please troubleshoot after overload resets.

- If the above methods cannot resolve your problems, please contact your nearest distributor or take the pump to a repair center. We will do our best to provide you with a quick turnaround to keep you working.

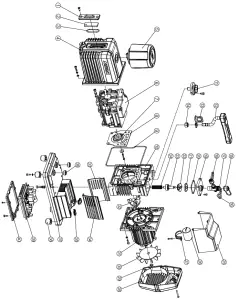

EXPLODED VIEW

REPAIR PARTS LIST

| Ref No | Part No. | Part Name |

| 1 | P012001 | Oil Lens Cover |

| 2 | P012002 | Oil Lens |

| 3 | P012003 | O-ring of Oil Lens |

| 4 | P012004 | Oil Housing |

| 5 | P012005 | Exhaust Filter and Noise Reducer |

| 6 | P012006 | Pump Body |

| 7 | P012007 | Coupling |

| 8 | P012008 | Gasket |

| 9 | P012009 | O-ring of Oil Housing |

| 10 | P012010 | Trestle |

| 11 | P012011 | Gas Ballast Assy |

| 12 | P012012 | Handle |

| 13 | P012013 | Hook |

| 14 | P012014 | Nut |

| 15 | P012015 | 1/2″Cao |

| 16 | P012016 | 1/4″ Cao |

| 17 | P012017 | Inlet Port |

| 18 | P012018 | 3/8″ Cap |

| 19 | P012019 | Base of Inlet Port |

| 20 | P012020 | O-Rina of Inlet Port |

| 21 | P012021 | Anti suck back valve oblate |

| 22 | P012022 | Anti suck back valve cap |

| 23 | P012023 | Anti suck back piston ASSY |

| 24 | P012024 | Anti suck back soring |

| 25 | P012025 | Too Cover |

| 26 | P012026 | Capacitor |

| 27 | P012027 | Capacitor hook |

| 28 | P012028 | Rear Cover Assn |

| 29 | P012029 | Elastic Collar |

| 30 | P012030 | Fan |

| 31 | P012031 | DC Motor Assn |

| 32 | P012032 | Coupling |

| 33 | P012033 | Guard Board I |

| 34 | P012034 | Guard Board II |

| 35 | P012035 | Sheath |

| 36 | P012036 | Rubber Gasket |

| 37 | P012037 | Base Plate |

| 38 | P012038 | Rubber Feet |

| 39 | P012039 | Controller Assn |

| 40 | P012040 | Cover Plate |

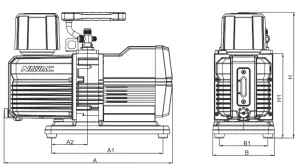

DIMENSION

|

Model |

A | A1 | A2. | B | 81 | H | H1 |

| NP12DM | 16.3 | 10.8 | 3.5 | 6 | 4.7 | 12.1 |

8.2 |

[xyz-ips snippet=”download-snippet”]