NAVAC NRD24M 30M Dual-Stage Oil-sealed Rotary Vane Vacuum Pump

Use information

Dear distinguished customer,Thanks for choosing NAVAC vacuum pump of high reliability (Hereinafter referred to as “the pump”).

Please check carefully whether the product received is the same as you ordered and the accessories, spare parts & operating manual are attached as well. Please also check if there’s any damage occurred during transportation. If needed, contact the local distributor or our sales team.

In order to maintain a stable performance level of the pump, read this operating manual carefully to fully understand the safety instructions, technical data as well as operating procedures before installation, operation, repair and maintenance of the pump.

|

|

To reduce the risk of electric shock, do not expose to rain. Store indoors. |

|

|

Failure to observe the terms could result in serious personal injury. |

|

|

Failure to observe the terms could result in damage to the pump |

|

This warning label indicates risk of electrical shock. Disconnect the pump from the power supply before beginning with connections, repair and maintenance. Make sure the cover of junction box is properly installed before running. |

|

This warning label indicates high temperature hazard. Do not touch the pump when the pump is in operation. |

|

The product should be placed steadily on the floor without any incline. |

|

|

Put the plug of power supply cord into the outlet and fasten the metal clasp to prevent falling off when the product is prepared for normal use. If it has finished its job , please get the plug off and keep the pump housing dustproof by covering a clean film plastic bag on it. |

|

|

Read the operating manual carefully and follow the operating procedures. We reserve the right to modify the design and technical data of the pump without notice which may have discrepancies in the manual. Add vacuum oil as requested before starting the new pump. |

Attention

In order to ensure the personal safety, read the operating manual carefully before installation, operation, repair and maintenance.

|

|

According to the technical guidelines and wiring regulations for electrical equipment, the power supply must match with the information shown on the pump nameplate and the electrical connections must be performed by a skilled electrician. |

|

|

To prevent electrical hazards and sudden start up hazard which may result in personal injury, disconnect the power supply before checking or repairing the pump. |

|

|

Before starting the pump, the motor must be effectively grounded and properly connected with a rated motor protection switch. |

|

|

The pump is strictly prohibited to pump dusty, active toxic, corrosive, flammable and explosive gases. |

|

|

Do not place obstacles which may affect the ventilation of the motor to avoid bum hazard and fire caused by abnormal temperature rise. |

|

|

The exhaust passage must be unimpeded during operation. Make sure that the gas flow from the exhaust port is not blocked or restricted in any way |

|

|

The pump must be operated at ambient temperature between 10 – 40 ‘C. |

|

|

Check the oil level before running. Do not operate the pump without oil or short of oil. Otherwise it will result in pump failure. |

|

|

Check oil leakage of the pump to prevent slip hazard caused by spilled oil. |

|

|

Running without oil lubrication or wrong rotation direction of the motor may cause pump failure. |

|

|

Do not connect the intake port with an overpressure device. Make sure the size of the exhaust passage with absolute pressure is not more than 1.35 bar (relative pressure is not more than 0.35 bar). |

|

|

Handling of used oil and other parts must be in compliance with local relevant environmental laws and regulations. |

|

|

Handling of used oil and other parts must be in compliance with local relevant environmental laws and regulations. |

|

|

While pumping a small amount of dust and condensable gases, an installation of corresponding filters is required. Otherwise it will cause pump failure or sharp drop of performance. |

Description

NRD series vacuum pump is a high speed, motor direct drive dual-stage oil sealed rotary vane pump. It is an basic equipment to obtain vacuum and can be used to pump inactive gas within the scope of low vacuum and a small amount of non-condensable gas.

The pump is specially suitable for coating, refrigeration, freeze drying, sterilization, instruments analysis, leak detection equipment, heat treatment metallurgy, etc. It can be used as a backing pump for roots pumps as well.

The pump has a reasonable structure design (Refer to Fig. 1) for long failure-free operation. It features high reliability, high flow rate, -low ultimate pressure and low noise level. The pump has no oil spray, no leak and easy to maintain.

- Outlet

- Junction box cover

- Junction box

- Intake port

- Gas ballast

- Exhaust port

- Oil fill plug

- Oil housing assy

- Sight glass

- Oil drain plug

- Pump feet

- Support

- Motor

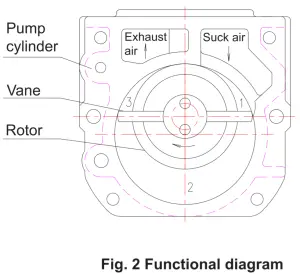

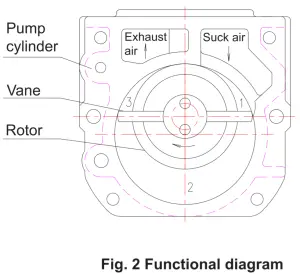

Principle of Operation

Refer to Fig. 2, the rotor mounted eccentrically in the pump cylinder, has two vanes which divide the pump chamber into three changeable compartments. When the rotor rotates clockwise, gas is sucked into chamber 1 gradually, transferred by chamber 2, and compressed and exhausted by chamber 3. The working cycle is repeated to achieve the vacuum of the system. The exhausted gas from the first stage goes into the second stage (low-vacuum stage) through air channel, and is compressed again before discharging into atmosphere to achieve a lower ultimate vacuum pressure.

Principle of Gas Ballast

The controllable gas (generally dry air at room temperature) is admitted into the pump chamber. It is mixed with pumped vapor during the gas compression process.This increases the percentage of non-condensable gas such that the partial pressure of the vapor being pumped is below its saturated vapor pressure when the exhaust valve opens. The vapor is then discharged from the pump without liquefaction. The more vapor contained in the pumped gas, the more dry air is required (See Fig. 7 Gas ballast valve).

Technical Parameters

| Model | NRD24M | NRD30M | |

| Flow Rate | CFM | 18 | 23 |

| Ultimate Vacuum | micron | 3 | 3 |

| Ultimate Vacuum Gas Ballast | micron | 6 | 6 |

| Water Vapor Capacity | lbs/h | 1.1 | 1.1 |

| Motor Power | hp | 1.5 | 1.5 |

| Oil Capacity | Quart | 2.1 | 2.1 |

| Inlet and Exhaust Flange | KF25 | KF25 | |

| Noise Level | dB | ≤58 | ≤58 |

| Net Weight | lbs | 77 | 77 |

| Dimensions | in | 20.5×7.4×10.7 | 20.5×7.4×10.7 |

Table 1

Pumping speed characteristics

Transport and Storage

|

|

Do not move the pump unless it’s switched off and the power supply is disconnected. |

|

|

Make sure that the lifting eye is tightened before lifting the pump. |

|

|

Check carefully if there’s any packaging damage during transportation. |

|

|

Move the pump with care. Any negligence will cause pump damage during transportation. In order to avoid oil spilling, move the pump fully filled with oil in horizontal direction. |

|

|

Handling of used packing material shall be in compliance with local environmental laws and regulations. |

|

|

For long term storage, clean the pump and empty the oil inside. Store the pump in a dry place at room temperature. |

Installation and Connection

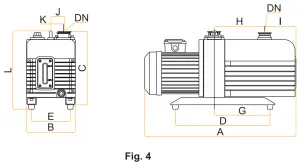

Installation Dimensions

|

Model |

A | B | C | D | E | G | H | J | K | L |

ON |

|

|

NRD24M |

567 | 188 | 272 | 320 | 148 | 160 | 185 | 82 | 59 | 47 | 295 | KF25 |

| NRD30M | 567 | 188 | 272 | 320 | 148 | 160 | 185 | 82 | 59 | 47 | 295 |

KF25 |

Table 2

Connection to System

|

|

The pump is strictly forbidden to operate in areas with risk of fire and explosion |

|

|

Make sure the gas flow at the exhaust port is not blocked or restricted in any way. Check to ensure the exhaust line is not obstructed by deposits before start-up. |

|

|

The exhaust pressure shall not be 1.15 bar higher than the absolute pressure (relative pressure 0.15 bar) but not be lower than atmospheric pressure. |

|

|

Take the following into account to choose the pump installation site: convenient for installation, maintenance, disassembly and electrical connections as well as good ventilation. |

|

|

Place the pump feet horizontally or fix the feet with bolts while connecting the pump to vacuum system. |

|

|

Oblique installation may result in pump’s vibration, high noise or even damage. The pump shall be set up on a flat and firm surface. |

|

|

The length of connecting line between pump and vacuum system shall be as short as possible. The diameter of the connecting line shall be the same as that of intake port. |

|

|

The hoop at intake port is available for connection with vacuum hose or regular vacuum pipe. No any stress generated by the pipe on the hoop is allowed while connecting. |

|

|

The exhaust line should be laid so that it slopes down so as to prevent condensate from backstreaming into the pump and contaminating the oil. Drain the oil in the exhaust line periodically to avoid block of exhaust line. If the exhaust line slopes up, the installation of a condensate trap is necessary. Check leak of the connection between pipe and flange. Vacuum tightness is essential for the achievement of ultimate pressure of the pump. |

Symbols for Switch that Controls the Motor

|

|

NRD24M/30M employs an automatically reset thermal limiter which can shut off the entire product. In the event that the thermal limiter operates, nothing is need to do but waiting for the motor to restart automatically if it has been cooled to the temperature which is specified by the thermal limiter type. Of course. users can also choose to cut off the power supply and re-energize it until the motor has been cooled to the ambient temperature. |

Grounding instructions

|

|

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances. |

|

|

Improper installation of the grounding plug is able to result in a risk of electric shock. When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat blade terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire |

|

|

Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded. Do not modify the plug provided; if it does not fit the outlet, have thev proper outlet installed by a qualified electrician. |

|

|

This product is factory-equipped with a specific electric cord and plug for connection to a proper electric circuit. Only connect the product to an outlet having the same configuration as the plug. Do not use an adapter with this product. When the product must be reconnected for use on a different type of electric circuit, the reconnection shall be made by qualified service personnel. |

Initial Start and Operation

Start-up

|

|

Make sure the gas flow at the exhaust port is not blocked or restricted in any way. Do not start the pump if the exhaust port is blocked. |

|

|

The oil level shall be kept between position MAX and MIN of oil sight glass. Excessive or insufficient oil will decrease the pump performance or even cause malfunction. The pump must be stopped before adding oil. |

|

|

Make sure the gas flow at the exhaust port is not blocked or restricted in anyway. Do not start the pump if the exhaust port is blocked. |

|

|

The operating ambient temperature is 10 – 40 C and humidity should be less than 85%. |

Operation

|

|

High temperature hazard! Do not touch the surface! The surface of the pump could be very hot during operation and after shutdown within one hour. |

Pumping non-condensable gases

Close the gas ballast to pump non-condensable gases (Set the gas ballast to position C, refer to Fig. 7). The ultimate pressure will rise (loss of vacuum) with gas ballast opened.

Pumping condensable gases and vapor

If the vacuum system contains a small amount of condensable gas, open the gas ballast valve (Set the gas ballast to position I or II, refer to Fig. 7) and keep the pump running for at least 30 minutes to pump the condensable gas effectively. Close the gas ballast valve when the vacuum system pressure is reduced to a certain value. If the pump operates at low temperature, condensable gas may be dissolved in the pump oil. The oil may be emulsified or deteriorated which will affect the pump performance, even cause corrosion of the pump body.The rise of oil level during pump operation is a sign of condensable gas contained in the vacuum system.Do not switch off the pump immediately when the process is finished. Keep the pump running with gas ballast open and intake port closed until all gases dissolved in the oil are removed.

Inspection and Maintenance

|

|

All checks and maintenance must be performed by trained personnel in accordance with local safety rules and regulations. |

|

|

In case of presence of hazardous substances due to oil decomposition or media sucked into the pump, it’s necessary to define the hazard and take all necessary safety precautions. |

|

|

In the presence of hazardous substances, determine the hazard in the first time and follow all appropriate safety procedures. If the potential hazard still exists, the pump must be decontaminated before any maintenance. |

Routine inspection

| Content | Operation | Interval | Remarks |

| Oil level | Visual inspection | Every three days | 8.2.1 |

| Oil color | Visual inspection | Every three days | 8.2.1 |

| Pump noise | Acoustic inspection | Every three days | 8.2.2 |

| Pump vibration | Visual inspection | Every three days | Check the pump feet or feet bolts in case of abnormal vibration. |

| Pump temperature | Temperature meter | Every one week | Check and clean fan of the pump and motor for deposits. |

| Seal & O-ring | Visual inspection | Every one month | Replace it if necessary |

| Dirt trap | Visual inspection | Every one month | Check and clean the foreign matter. Dry it by compressed air. |

Table 3

Maintenance

Checking oil level

- The oil level shall be always kept between position MAX and MIN of oil sight glass during operation (refer to Fig. 6). Add oil when the oil level is lower than position MIN and discharge oil by removing the oil drain plug (refer to Fig. 1) when the oil level is above position MAX.

- Check the oil color. Replace the oil if the color is other than clear and transparent.

Checking pump’s noise

The pump noise shall be continuous and stable during operation. If any abnormal noise is found, refer to Table 4 Troubleshooting.

Changing oil

- Change the oil when the pump is switched off and cooled down.

- Remove the oil drain plug (Fig. 1) and drain the used oil into a suitable receptacle. When the flow of oil stops, screw on the oil drain plug and start the pump shortly (10 seconds). Switch off the pump, remove the plug again and drain the residual oil.Screw on the oil drain plug (Check O-ring, replace it if necessary). Remove the oil fill plug (Fig. 1) and fill in fresh pump oil which is specified or provided by the manufacturer.

- After oil changing, handle the used oil stored in an assigned container according to local relevant environmental laws and regulations.

Regularly checking intake filter and anti-suckback valve

Regularly take down the intake port and clean the filter by compressed air. Check the seal position of anti-suckback valve for cleanness, damage, hardening and height.

Regularly checking fan cover and motor fan

Regularly remove the clean the fan cover and motor fan. Clean them by compressed air and reinstall them properly before pump operation.

Troubleshooting

| Fault | Possible reason | Remedy | |

| Pump cannot start | 1. Wiring is malfunctioning. | 1. Check and repair wiring. | |

| 2. Operation voltage is abnormal. | 2. Make sure the voltage is within rated voltage’s tolerance of ±10%. | ||

| 3. Motor is malfunctioning . | 3. Replace the motor. | ||

| 4. Overload protector is active. | 4. Check the ambient temperature or pumped gases temperature. | ||

| 5. Oil temperature is below 10°C | 5. Increase the ambient temperature. | ||

| 6. Pump is jammed. | 6. Repair the pump. | ||

| 7. Out of operating for long. | 7. Repair the pump. | ||

| 8. Oil is too viscous. | 8. Change the oil. | ||

| 9. Exhaust filter or exhaust line is clogged. | 9. Replace the filter or clean the exhaust line. | ||

| 10. Pump inner parts are damaged. | 10. Repair the pump. | ||

| Pump cannot reach ultimate pressure. | 1. Vacuum system configuration is unreasonable. | 1. Choose a suitable pump. | |

| 2. Vacuum system leak. | 2. Check the system. | ||

| 3. Measuring technique or gauge is unsuitable. | 3. Use correct measuring technique and gauge. Measure the pressure directly at pump’s intake port. | ||

| 4. Poor lubrication. | |||

| 4.1 Oil filter is obstructed. | 4.1 Change the oil filter. | ||

| 4.2 Oil is unsuitable. | 4.2 Change the oil. | ||

| 4.3 Oil channel is obstructed. | 4.3 Clean the channel. | ||

| 4.4 Oil is insufficient. | 4.4 Add the oil to the level as requested. | ||

| 5. Anti-suckback oil valve is malfunctioning. | 5. Repair anti-suckback oil valve. | ||

| 6. Intake line is dirty. | 6. Clean vacuum lines. | ||

| Pumping speed is too low. | 1. Intake port line is clogged. | 1. Clean the intake port line. | |

| 2. Connecting lines are too narrow or too long. | 2. Use adequately wide and short connecting lines. | ||

| 3. Exhaust line is clogged. | 3. Keep exhaust port line unobstructed. | ||

| 4. Oil mist filter is clogged. | 4. Change the oil mist filter. | ||

| 5. Anti-suckback oil valve is

malfunctioning. |

5. Repair anti-suckback oil valve. | ||

| Noise is abnormal. | 1. Operation voltage is abnormal. | 1.1 Check the power supply, switches and wiring connection. | |

| 1.2 Make sure the voltage is within rated voltage’s tolerance of ±10%. | |||

| 2. Foreign matters entering into the pump. | 2. Repair the pump. | ||

| 3. The oil level of the pump is too low. | 3. Add the oil to the level as requested. | ||

| 4. The pump inner parts are

damaged. |

4. Disassembly and replace the parts. | ||

| Pump gets hotter than usually observed. | 1. Poor ventilation | . | 1. Improve ventilation environment. |

| 2 . The fan is damaged . | 2. Change the fan . | ||

| 3. Pumped gas temperature

is too high. |

3. Add cold trap at intake port. | ||

| 4. Poor lubrication . | |||

| 4.1 The oil filter or exhaust | 4 . 1 Replace oil filter or clean the exhaust line. | ||

| line is clogged. | |||

| 4.2 Oil is unsuitable . | 4.2 Change the oil. | ||

| 4.3 Oil channel is obstructed . | 4.3 Clean the channel. | ||

| 4.4 Oil is insufficient. | 4.4 Add the oil to the level as requested. | ||

| 5. The condensator is dirty. | 5. Clean the condensator. | ||

| 6. Ambient temperature is | 6. Reduce ambient temperature . |

| Fault | Possible reason | Remedy |

|

Oil in the intake line or in vacuum vessel. |

1. Oil comes from the vacuum system. | 1. Check the vacuum system. |

| 2. Anti-suckback valve spring is obstructed . | 2. Replace anti-suckback valve spring. | |

| 3. Anti-suckback valve plate is obstructed . | 3. Replace anti-suckback valve plate. | |

| Vacuum pressure in system rises too fast when pump stops. | 4. Oil level is high. | 4. Drain the excess oil. |

| 1. Vacuum system leak. | 1. Check the system. | |

| 2. Anti-suckback valve is malfunctioning . | 2. Repair anti-suckback valve. | |

| Too much oil in the exhaust port. | 1. Too much oil in the pump. | 1. Drain some oil. |

| 2. Continuous operation under high pressure in the intake port. | 2. Shorten exhaust time. | |

| 3. Oil mist filter is obstructed. | 3. Replace oil mist filter. | |

| Sealing surface leak | 1. The seal is damaged. | 1. Replace the seal. |

| 2. Seal ring is damaged. | 2. Replace the seal ring. |

Warranty

NRD series vacuum pumps have one year guarantee from the date of purchase. Spare parts will be provided free of charge within the period of guarantee in condition that the pump is operated according to the operating manual. The following failures will be charged for repair:

- Malfunction caused by nature disasters or artificial factors

- Malfunction caused by special operating environment

- Damage of wear parts

- Malfunction caused by abnormal operation or incorrect use identified by our engineers

Before the pump is delivered to our company for maintenance, it is required to acquire the information if the pump is contaminated (and which kind of pollutants) or hazardous substances exist inside the pump. Without receiving this statement in advance, the pump will be returned to the address of the sender.

Accessories

To ensure the stability of the pump, it is recommended to use genuine spare parts and accessories provided by the manufacturer.If you need further assistance, please contact us.The accessories below are for your selection:

- Wear parts. Check the exploded view and spare parts list to select the required spare parts with corresponding item numbers.

- Intake port/exhaust port other than default one

- Dust filter

NRD Exploded View

NRD24M/30M Spare Parts List

|

NO. |

Item | Material |

Code |

Position |

Qty. |

|

|

NRD24M |

NRD30M |

|||||

|

1 |

Washer | Card board | 320220101 | 320220101 | Motor | 1 |

| 2 | Spider | Rubber | 320050101 | 320050101 | Coupling |

1 |

|

3 |

Seal | FKM | 300281601 | 300281601 | Oil pump cover | 1 |

| 4 | O ring | FKM | 300310072 | 300310072 | Front stator |

1 |

|

5 |

O ring | FKM | 300310137 | 300310137 | Front rotor | 1 |

| 6 | Spring | SUS | 320110204 | 320110204 | Trestle |

1 |

|

7 |

O ring | FKM | 300310074 | 300310074 | Anti-suckback cover | 1 |

| 8 | Seal | FKM | 300280902 | 300280902 | Anti-suckback cover |

1 |

|

9 |

Valve | FKM | 320510101 | 320510101 | Anti-suckback cove | 1 |

| 10 | O ring | FKM | 300310073 | 300310073 | Intake port |

1 |

|

11 |

Filter | SUS | 320340102 | 320340102 | Intake port | 1 |

| 12 | O ring | FKM | KF25:300310070 | KF25:300310070 | Intake/outlet port |

2 |

|

13 |

Spring | SUS | 320110302 | 320110302 | Gas ballast | 1 |

| 14 | Washer | FKM | 320230101 | 320230101 | Gas ballast |

1 |

|

15 |

O ring | FKM | 300310079 | 300310079 | Support | 1 |

| 16 | Gasket | Paper | 320210101 | 320210101 | Front chanter |

1 |

|

17 |

Seal | FKM | 300280602 | 300280602 | Front chanter | 1 |

| 18 | Spring | SUS | 320110104 | 320110104 | Front/rear rotor |

5 |

|

19 |

Vane | Resin board | 320100301 | 320100301 | Front rotor | 2 |

| 20 | Valve | SUS | 320240101 | 320240101 | Rear chanter |

1 |

|

21 |

Spring | SUS | 310080301 | 310080301 | Rear chanter | 1 |

| 22 | Valve | FKM | 311150103 | 311150103 | Rear chanter |

1 |

|

23 |

Resin board | Resin board | 320100201 | 320100201 | Rear rotor | 2 |

| 24 | Paper | Paper | 320200101 | 320200101 | Outlet port |

1 |

|

25 |

O ring | FKM | 300310081 | 300310081 | Oil-drain screw | 2 |

| 26 | O ring | FKM | 320160101 | 320160101 | Oil sight |

1 |

|

27 |

Oil sight | Glass | 320170101 | 320170101 | Oil sight | 1 |

| 28 | Washer | FKM | 320190101 | 320190101 | Oil sight |

1 |

Table 5

REMARK:1) Please refer to the exploding drawing for the relationships of each spare part.2) We reserve the right to modify the design and specified data in this operating manual without notice.

References

[xyz-ips snippet=”download-snippet”]