Oceanic Hydroponic Reverse Osmosis Water Filtration System

Description

Our Hydroponic System is a customized Reverse Osmosis water filter that is capable of reducing up to 99% of most contaminants. This system is designed for use with hydroponic or horticultural applications. This system is built to give the maximum amount of flow from the membrane while sending less waste water to the drain, compared to similar RO filters. Please read the following setup and maintenance guide to get the maximum results from your filter.

Precautions

- Do not install the unit where the source/inlet pressure may be more than 80 psi or there are excessive water hammer/spike problems. Keep out of direct sunlight or high intensity lights, which degrade the housing and fittings over time.

- Do not drop or place heavy objects on top of unit.

- Do not install where leakage or failure may cause damage to property.

OPERATING REQUIREMENTS

Minimum water pressure: 40 PSI,Maximum water pressure: 80 PSI,Optimal water temperature: 77*F (25*C),Maximum water temperature: 105*F (40.5*C)Typical rejection rate: 1:1.5

Filtration Stages

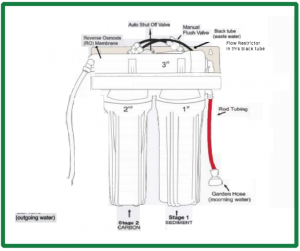

1st Stage Sediment Block, 2nd/3rd Stage Carbon Block, Final Stage Reverse Osmosis Membrane

- 1st Stage: Sediment Filter – High-Capacity Polypropylene Sediment Filter (Nominal 5 Micron Rating) – Removes dust, particles, and rust. Protects and extends the life of the reverse osmosis membrane and system.

- 2nd (and 3rd )Stage: Coconut Carbon Block: Gets rid of unpleasant chlorine, tastes, odors, cloudiness and colors. Also removes VOCs and other common chemicals from the water

- Final Stage: Reverse Osmosis Membrane: Reduces or removes Sodium, Sulfate, Calcium, Potassium, Nitrate, Iron, Zinc, Mercury, Selenium, Phosphate, Lead, Arsenic, Magnesium, Nickel, Fluoride, Manganese, Cadmium, Barium and Cyanide.

These are Standard 2.5” x 9.75” Reverse Osmosis Filters for 10” RO Housing.

Replacement Filters on OCEANICWATER.COMPRE-FILTERS – EVERY 4-6 MONTHS or sooner:3 Stage: Model # SEDCB25104 Stage: Model # SED2CB2510RO MEMBRANE- EVERY 18-24 MONTHS or sooner:Model # MEM75GPD or Model # MEM100GPD

- Upon initial startup of system, slowly turn the source water on until both the carbon and sediment filters have water in the housings. Next, open source water up all the way (do not exceed 80 psi). Flush the system for 30-45 minutes when the system is new and/or when you replace your membrane. This will flush out the food grade preservatives in the membrane.

- The first time you run water through the system please turn the inline shut-off valve to the ‘off’ position as soon as you see water flow from the blue purified water line. This will pressurize the system and is a good way to make sure that all fittings and connections are secured properly and that there are no leaks. It is also a good way to make sure that the automatic shut-off is working properly, meaning the black drain line is shutting off.

- Color Coding of Tubing:o Red Line: Water Intake from Garden Hose Connectiono Black Line: Waste Water (can be slipped down a drain) – DO NOT USE THIS WATERo Blue/White/Yellow Line: Purified Water

Please Note:It may take up to 24 hours total of running the system for the PPM & pH of the purified water to stabilize

Filter Change and Maintenance

It is essential that you change your pre-filters regularly.The carbon filter has a rated life of approximately 1,250 gallons of purified water produced.We advise changing the pre-filters at least once every 6 months or sooner if you have extremely dirty water.Dirt can become embedded and cause slower flow rates. Use the included filter wrench to loosen the clear filter housing. Be careful not to overtighten when reinstalling. It is preferable to hand tighten filter housings after a filter change.

Membrane

To install Membrane: Insert the Membrane filter into the membrane Housing with the end with the 2 black O-rings going in first. Hand Tighten the cap to the membrane housing.

The Reverse Osmosis membranes have a useful life of 6 months to 2 years depending on how high your source water PPM reading is, if there are high levels of certain contaminants (such as iron & silica), how much water you produce and regular pre-filter maintenanceIf your water is highly contaminated, then you may need to change the membranes more often. If your water is relatively clean and you keep up with your pre-filter changes it may last you 2 years+.

There are two indications as to when to change your membranes.1) test the RO and source/inlet water to see what percentage of the inlet water’s PPM the RO System is filtering out (rejection %). You should see approximately 98% of the inlet PPM’s being removed when the membrane is new. If the rejection % falls under an acceptable level (typically 90%) it’s time to change the membrane.2) When the flow rate of the product water slows down significantly. This can also happen if the pre-filters are clogged. But if you have changed your pre-filters and the product water still flows slowly, then it can indicate that the membrane should be replaced.

FAQ’s

Q: It’s Leaking, Why?A: See where the leak is coming from. Check the fittings to see if it is loose, if so then tighten it until it is firmly tightened. Make sure that the tubing is pushed all the way into the fitting. If the housing/canister is leaking, make sure that the O-ring is seated properly under the cap of the housing.

Q: The system is brand new, why is the flow rate of purified water so slow?A: The system’s GPD capacity is achieved when you have the following conditions for your source water: 77 °F, 500 PPMs, 60 PSI. If your source water is colder than this, or your inlet pressure is lower, or your PPMs are significantly higher, then you will experience less than the rated GPD flow rates.

Q: Why has the flow rate of purified water slowed down over time?A: This can be due to multiple factors, such as clogged sediment or carbon pre filter, clogged or fouled membrane, or changes to source water conditions. The quality of your water, frequency of use, and timeliness of pre-filter changes will determine how long your system performs at peak capacity.

Q: Why have the PPMs of the purified water increased over time?A: This is typically due to deterioration of the membrane as a result of exposure to chlorine. The purpose of the carbon filter is to remove chlorine from the water. If It isn’t changed on schedule, chlorine will pass through to the membrane and degrade it, causing more water to flow out of the purified line and an increase in PPMs.

Q: Why does the waste line continue to run when the purified water line is closed off?A: Over time, the Automatic Shut-Off Valve (ASOV) can accumulate scale and become clogged, causing it to malfunction. If you experience your waste line continuing to run after the purified water line is closed, please give us a call.

Q: Why is the system leaking?A: This can be due to various reasons, including Teflon tape at threaded fittings, tubing not being pushed in all the way to the quick-connect (QC) fittings, or improperly seated O-rings in pre-filter and membrane housings. It is also important to make sure the ends of the tubing have a clean cut before inserting them into the QC fittings

Q: Why did the clear pre-filter housing crack?A: This can be due to freezing conditions, excessive pressure spikes, or long term exposure to high intensity lighting.

Q: Why is the pH of the purified water higher/lower than the source water?A: The pH of the purified water depends entirely on source water chemistry. Customers can experience either slightly lower or higher pH due to their source water. This is completely normal for reverse osmosis technology.Since RO water is almost pure H2O and has no ability to buffer pH, the actual pH reading will not be accurate until you add minerals back.

Q: I have well water, what challenges can I expect?A: Here are the most common challenges when filtering well water:

- It is typically colder which will decrease your flow rates because cold water flows slower through a reverse osmosis membrane

- Often has higher PPM/TDS levels (hardness) which can decrease the life of a membrane

- Can contain high levels of sediment which can easily clog a carbon or sediment pre-filter

- Can have high levels of iron, manganese and hydrogen sulfide (rotten egg smell)

- It occasionally contains iron bacteria which is difficult to remove

- It generally has low water pressure

OCEANICWATER.COM(661) 575 – 0033[email protected]

OCEANICWATER.COM(661) 575 – 0033[email protected]

References

[xyz-ips snippet=”download-snippet”]