INSTALLATION INSTRUCTIONSOUTDECO USA Indoor/Outdoor PanelsFollow these instructions and recommendations for a professional installation withinwarranty, and to avoid damaging the panel.

PLEASE READ BEFORE YOU BEGIN: We recommend following best building practices for installing OUTDECO USA panelsin accordance with their intended purpose. Examples shown in this document are installation suggestions. Adjust installation configurations to meet your specific project requirements. If in doubt, consult a professional. We recommend checking with properauthorities about building codes/standards that may apply to your project.OUTDECO USA panels have a 10-Year Limited Warranty for material integrity when installed on a vertical plane, as on a wall or fence.Installations on a horizontal plane, as a roof or ceiling, are not covered by the warranty. Installers assume responsibility for the installation.

Easy to InstallSuitable for pro builders and DIY crafters. A typical project uses 12-24 panels.

OUTDECO USA Decorative Modular Panels are an engineered hardwood product similar to fencing lumber that can be cut, drilled, and sanded. Available in manageable sizes, the panels are easy to install with standard woodworking tools and methods using typical exterior decking screws, nails, and/or exterior-grade construction adhesive.OUTDECO USA panels are specifically created for outdoor vertical cladding and are weather-proof throughout North America.

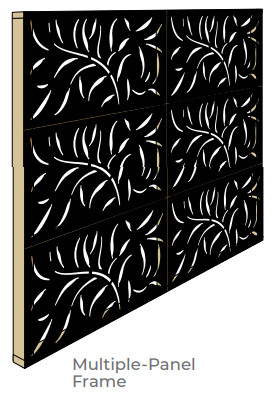

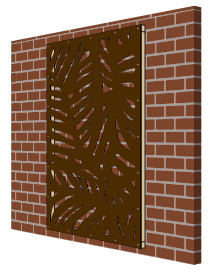

Frames & Support Structures

OUTDECO USA panels must be mounted to a frame or an existing surface or structure. They are not stand-alone structural products.Timber or metal frames can be attached to walls, fences, and other flat surfaces, or built as free-standing structures with panels mounted.

BENEFITS OF USING A FRAME

Using a frame allows for the sturdiest and most versatile panel installation and results in a professional, polished look. Frame structures can be built to almost any size, orientation, or form – as simple or sophisticated as your project requires.

- Facilitates precise panel alignment and squared edges before attaching.

- Prevents damage to surfaces when adjusting, adding, or removing panels.

- Minimizes the number of fasteners going into an existing structure and reduces the number screws or nails visible along the edges of your panels.

- Offsets panels from surfaces, allowing for air flow and expansion/contraction space; create a dimensional shadow effect and provides space for backlighting.

10-Year Limited Warranty OUTDECO panels are warranted against peeling, rotting, cracking, blistering, and warping under normal atmospheric and weather conditions. This limited warranty does not cover damage resulting from misuse, improper storage or handling,improper installation, or any horizontal roofing/ ceiling applications. (See full warranty statement at outdecousa.com.)

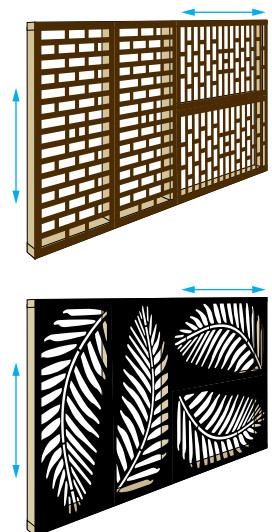

FRAME TYPES – For installations with multiple or single panels

|

|

|

| Surface-MountMount panels on fences, walls, and other flat surfaces. | Free-StandingCreate a divider or fence on aframe with posts set in cement. | Fence/Wall ExtensionMount panels above a fenceor wall for additional height. |

Mounting Styles & MethodsExamples shown are installation suggestions. Adjust for your specific project’s requirements. Some installations may require professionalassistance.

Panel SpecsFind panel weights, sizes, and other details on our website’s Patterns page and click on your panel’s pattern name.outdecousa.com/patterns

MOUNTING STYLES

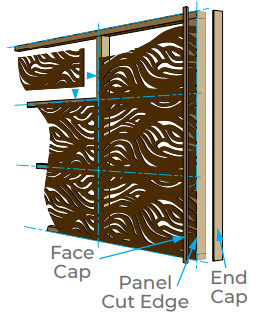

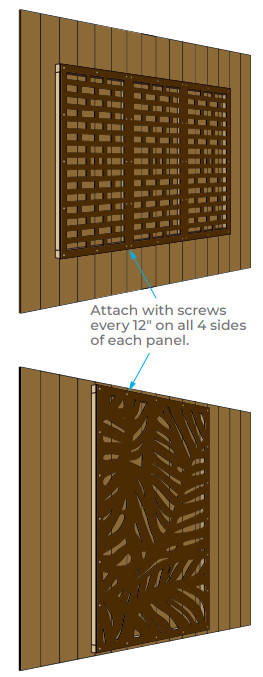

FACE-MOUNT – Attach panels to front of frame

- The easiest method for covering a fence or wall.

- Effective for making panels straight and square.

- Add a face cap piece to conceal a cut panel edge; or use an end-mounted cap to cover an exposed frame edge.

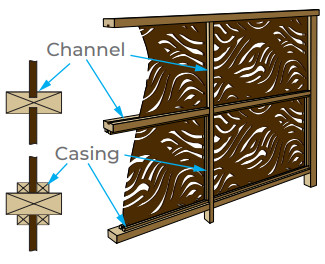

WINDOW-FRAME – Set panels inside the frameOPTION 1: Cut a recessed channel in all posts and rails to hold panel edges.OPTION 2: Build a 1″ x 1″ or 2″ x 2″ border casing and attach to the frame with the panel secured inside the casing.

WINDOW-FRAME – Set panels inside the frameOPTION 1: Cut a recessed channel in all posts and rails to hold panel edges.OPTION 2: Build a 1″ x 1″ or 2″ x 2″ border casing and attach to the frame with the panel secured inside the casing.

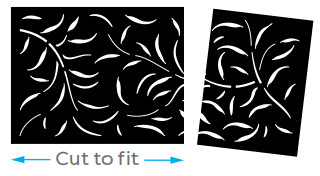

Panel Fitting  Cut panels to fit installation specs. Add a face cap to cover cut edge if desired (see top right).

Cut panels to fit installation specs. Add a face cap to cover cut edge if desired (see top right).

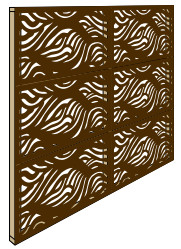

Pattern OrientationPanels can be mounted in any orientation. Check for pattern repeats and flows before cutting and installing. Learn more at outdecousa.com/patterns.

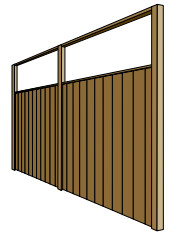

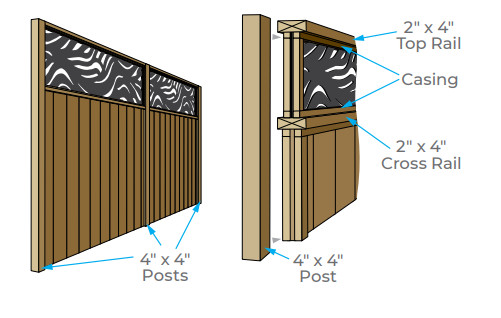

FENCE EXTENSIONS

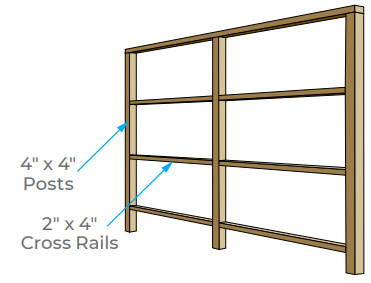

Use timber or metal posts in windy areas.OPTION 1: Fence with 4″ x 4″ posts extending above the fence

- Add 2″ x 4″ cross rails between posts to create top and bottom of extension frame

- Create a 1″ x 1″ or 2″ x 2″ border casing and attach it to the frame securing the panel between the casing.

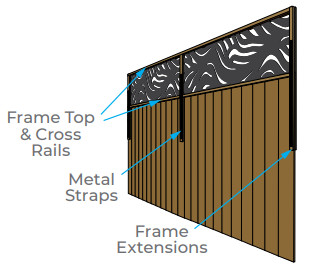

OPTION 2: Existing fence without extended posts

- Attach 2″ x 4″ timber extension posts to one or both sides of the fence extending 16″– 24″ down from top of the fence. Fasten with bolts every 12″–18″.

- Attach a 2″ x 4″ top rail to top of posts and 2″ x 4″ cross rails between posts along top of the fence to create a frame.

- Build border casing and secure panels per Option 1, #2 above.

- In non-windy areas, 1″ x 2″ or 2″ x 2″ post extensions and rails can be used to build a frame to hold panels with 16″–24″ metal straps added. Use straps on both sides of fence for a more secure installation.Fence extension installation examples are suggestions only. Modify for your fence requirements or consult a professional.

ATTACHING TO AN EXISTING MASONRY WALLCheck that wall is flat, square, and level, and can support the panels’ weight. Build a timber or metal frame. Pre-drill wall with a masonry bit and use masonry screws to attach the frame. Mount panels to frame. Use this method for mounting panels on large gates, heavy garage doors, or other sizable moving structures.ATTACHING TO A SKELETAL STRUCTURE OR STUD WALLUse the framing method above and attach your frame to the structure’s studs.

FrameConstructionPlease read through ALL instructions before starting.

FRAME MATERIALS

- For existing walls, fences, gates, garage doors, pergolas, balustrades, bench seats, or planter boxes, create a light frame using 1″ x 2″, 2″ x 2″, or 2″ x 4″ wood. Select lumber size appropriate for the number and weight of panels.

- For free-standing structures, use 4″ x 4″ timber or metal posts with 2″ x 4″ rails.

- For heavy or large gates and other moving structural or more substantial applications, use aluminum or RHS (rectangular hollow steel) for frame posts and cross rails.

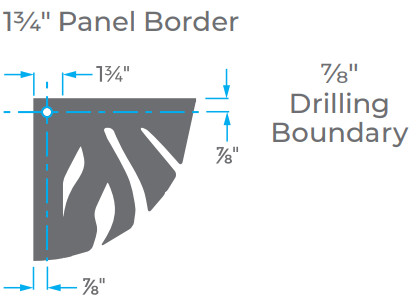

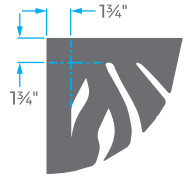

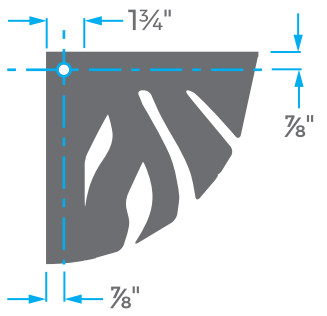

Border Spacing

All panels have a 1w” nominal border that will conceal most frames.

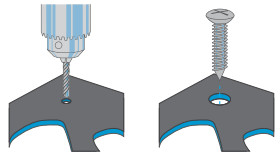

Pre-DrillingMeasure, draw-up, and pre-drill screw holes in the panel border.

Measure, draw-up, and pre-drill screw holes halfway into the panel border:

- every 12″ on all 4 sides of each panel

- ⁷/₈” from panel edge

Drilling Guide

Panel SpecsFind panel weights, sizes, and other details on our website’s Patterns page and click on your panel’s pattern name.outdecousa.com/patterns

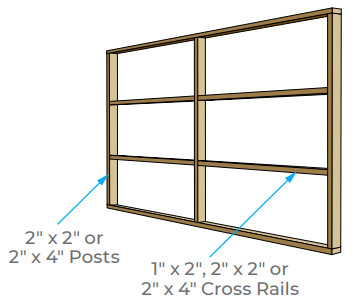

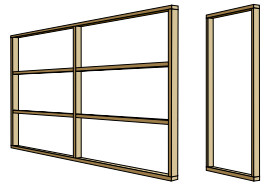

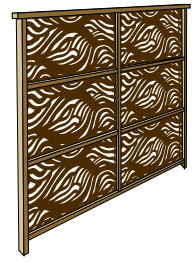

BASIC FRAME CONSTRUCTION

Build your frame laying on a flat surface so you can check dimensions, square alignment, and panel joint spacing. This allows you to easily raise/lower, reposition, or level your frame.

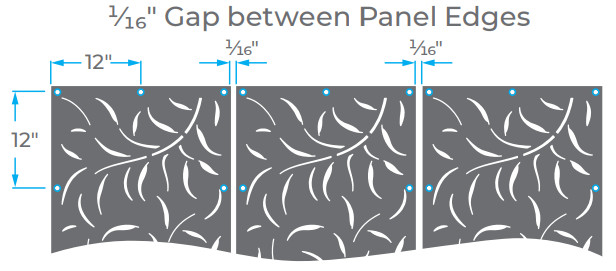

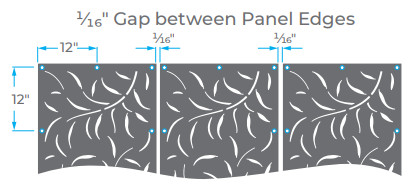

- Measure so your frame will match the exact width and height of your panel area, including a z” expansion gap between panels.

- Create a frame of vertical and horizontal studs, positioning the center lines of the interior studs where the panel edges will meet, with the z” gaps between them.

- With a helper, lift your frame into place and adjust so the entire piece is level. Attach the frame to the fence, wall, or another surface.

- Measure, draw-up, and pre-drill the panels with screw holes z” larger than your screws or nails, every 12″ on all four sides. (See border and drilling guides at left.)

- Position your panels using z” spacers to create consistent expansion joints between panels. Clamp panels to your frame and attach them. (See page 4.)

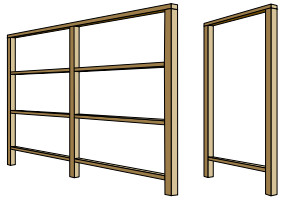

FREE-STANDING FRAME CONSTRUCTIONA free-standing installation requires a strong structural frame.OUTDECO panels are not intended for use as a free-standing structure without a frame.

Build a frame laying down on a flat surface using lumber that’s a minimum 4″ x 4″ for posts and 2″ x 4″ for rails.

- Measure so your frame will match the exact width and height of your panel area, including a z” expansion gap between panels, and add the length of post extensions for legs and footings. (Post height, weight, and footing requirements vary, so measure and consider load weight carefully. Check for any underground services and features before digging.)

- Create a frame of vertical posts and horizontal studs, positioning the center lines of the interior studs where the panel edges will meet, with the z” gaps between them.

- With a helper, lift your frame into footing holes, adjust so the entire piece is level, and add concrete.

- Position your panels using z” spacers to create consistent expansion joints between panels. Clamp panels to your frame and attach them. (See page 4.)

Attaching & Fasteners

Please read through ALL instructions before starting.Mounting hardware is not included with OUTDECO panels.

Panel SpecsFind panel weights, sizes, and other details on our website’s Patterns page and click on your panel’spattern name.outdecousa.com/patterns

SCREWS

- Use screws with a x” diameter or smaller, long enough to penetrate a minimum of 1″ into the frame.

- Good options include deck screws, Phillips wood screws, and flat-head countersink screws. Some deck screws are available in wood-like colors.

- Use galvanized screws for outdoor applications.

- Use washers where appropriate.

- Attach the frame to brick and masonry using an expansion anchor.

- For a metal frame, use pop-rivets or other suitable fasteners.

- Ask hardware professionals about the right fasteners for your frame material, panel weight, and attachment surface.

NAILS

- Pre-drill a slightly undersized hole to locate your nail spot and to prevent blistering or gouging the panel surface.

- Use galvanized nails in the appropriate size for the weight of your panel. Use nails long enough to penetrate a minimum of 1″ into the frame.

- With a nail gun, use a rubber stopper.Fire carefully leaving the heads just at or below the surface for inconspicuous nail holes.

MOUNTING WITH SCREWS OR NAILS

- Pre-drill holes before mounting. (See page 3.)

- Drill holes at least z” larger than the screw or nail diameter to allow for expansion and contraction.

- Position drill holes d” from the panel edge, in the center of the panel border, every 12″ on all four sides of each panel.

- Where multiple sheets adjoin (at sides or top/bottom), use z” spacers between panel edges on all sides to allow for thermal expansion.

- Attach panels with screws or nails every 12″ all four sides.This will secure the panels and help keep them straight.

- To avoid damaging panels, do not overtighten screws or counter-sink nails too deeply.

- For aesthetics, paint screw or nail heads to match the panel color.

- For a backlit effect, install LED light strips behind the panels, inside the frame.

MOUNTING WITH CONSTRUCTION ADHESIVE

Construction adhesive is an easy-to-use option, however, in many applications, reinforcement with additional fasteners like screws or nails may be required.

Construction adhesive is an easy-to-use option, however, in many applications, reinforcement with additional fasteners like screws or nails may be required.

- We highly recommended the use of screws in addition to the adhesive. Follow instructions #4, #5, and #6 above for attaching with screws.

- Ensure both the panel surface and the frame or mounting surface are clean and clear of dust, paint, oil, or water.

- Use a large bead (or double bead) of adhesive and sturdy clamps to ensure maximum bonding to the attachment surface.

[xyz-ips snippet=”download-snippet”]