ozito OSIK-30 30W Soldering Iron Kit Instruction Manual

ELECTRICAL SAFETY

WARNING! When using mains-powered tools, basic safety precautions, including the following, should always be followed to reduce risk of fire, electric shock, personal injury and material damage.

Read the whole manual carefully and make sure you know how to switch the tool off in an emergency, before operating the tool. Save these instructions and other documents supplied with this tool for future reference.The tool has been designed for 230V and 240V only. Always check that the power supply corresponds to the voltage on the rating plate.

Note: The supply of 230V and 240V on Ozito tools are interchangeable forAustralia and New Zealand.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! SOLDERING IRON WARNINGSRead all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool.Distractions can cause you to lose control.

Electrical safety

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result inpersonal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

SOLDERING IRON WARNINGS

WARNING! The appliance is not to be used by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction.

Young children should be supervised to ensure that they do not play with theappliance.

- Ensure that the tip is correctly fitted before heating the soldering iron. Ensure that it is fastened correctly and tightly with the clamping screw.

- Do not leave the soldering iron plugged in and unattended. Disconnect the toolfrom the mains power once finished with use.

- Allow the tool to cool completely before storage. Rest the tool on the providedstand or a non-flammable surface when required.

- The soldering iron must be placed on its stand when plugged in and not in use.

- A fire may result if the soldering iron is not used with care, therefore:

- be careful when using the appliance in places where there are combustible materials. Do not apply to the same place for a long time.

- do not use in presence of an explosive atmosphere

- heat may be conducted to combustible materials which are out of sight

- Do not expose to water or moisture. Ensure no liquids enters the tool.

- This tool is intended for indoor use only.

- Never start up the soldering iron without a soldering tip fitted.

- Do not touch the tip while operating the tool.

- Only solder in well ventilated areas. Toxic fumes can be produced when soldering which can lead to damage to the mucous membranes and or chronic respiratory illnesses.

- Do not eat or drink whilst soldering as solder can contain lead. Always washyour hands thoroughly after finishing work.

- Keep the hot soldering tip clear of the mains cable to prevent accidentaldamage.

- Do not use the tool if the mains cable is damaged.

STANDARD EQUIPMENT

- Soldering Iron & Tip

- Work Station & Holder

- Sponge, 5 x Soldering Tips & Solder

KNOW YOUR PRODUCT

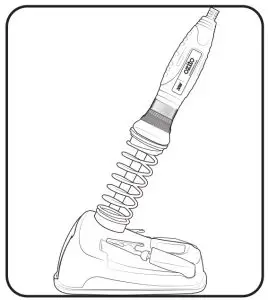

SOLDERING IRON

- Power Cord

- Handle

- Soldering Tip

- Holder

- Storage Drawer

- Work clamps

- Sponge Tray

- Clamping Screw

SETUP & PREPARATION

ASSEMBLY

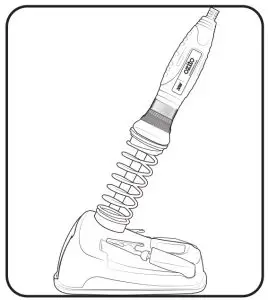

Setting Up The Stand

The work station stand provides a safe and secure way to rest the tool during and after use while the tip is hot.

WARNING! DO NOT LEAVE THE TOOL PLUGGED IN AND UNATTENDED. ALLOW IT TO COOL COMPLETELY BEFORE STORAGE.

- Align the tabs on the holder with the grooves in the work station slot.

- Push the holder into the slot until you hear it click into place.

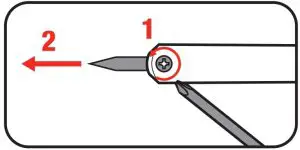

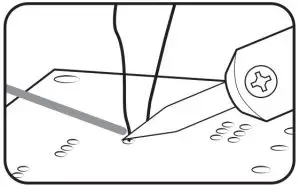

Changing Tips

WARNING! ENSURE THE TOOL IS UNPLUGGED AND COMPLETELY COOLED DOWN BEFORE CHANGING THE TIPS.

The pointed soldering tip is great for detailed soldering work such as on circuit boards or general soldering applications. This can be swapped out with the other soldering tips to better suit the application.

- Use a screwdriver (not supplied) to loosen the clamping screws.

- Remove the soldering tip.

- Insert the desired soldering tip into the barrel.

- Tighten the clamping screws to secure the tip in place.

WARNING! ENSURE THE SOLDERING TIP IS SECURE AND THE CLAMPING SCREWS ARE COMPLETELY FASTENED BEFORE USING THE TOOL.

SOLDERING

Soldering

- Rest the soldering iron on the stand.

- Wet the sponge and squeeze out any excess liquid. Place the damp sponge in the tray on the work station.

- Plug the power cord into a mains socket and allow the tool to heat up.

- Use the clamps on the work station to hold your workpieces steady.

- Use the soldering tip to heat the workpiece up.

- Hold the solder wire against the heated workpiece. The workpiece should be sufficiently heated that the solder melts and flows into the join.Note: If the solder wire doesn’t melt when touched to the workpiece, then the workpiece has not heated sufficiently. Remove the solder wire and allow the soldering iron to continue heating up the workpiece.

- Once enough solder has melted into the join, remove the solder wire and then the soldering tip from the workpiece.

- Allow the solder to cool and solidify

Usage Tips

- Ensure the solder used is appropriate for the application.

- Press the hot soldering tip into a damp sponge occasionally to remove any excess solder that may have accumulated on the tip. Do not hold it there for too long as this can burn the sponge.

WARNING! DO NOT HOLD THE SPONGE. PLACE THE SPONGE ON THE TABLE AND WIPE THE SOLDERING TIP AGAINST IT.

WARNING! DO NOT HOLD THE SPONGE. PLACE THE SPONGE ON THE TABLE AND WIPE THE SOLDERING TIP AGAINST IT. - Soldering provides an electrical connection between parts, it does not provide a strong mechanical joint. When soldering wires ensure that they are joined properly by twisting the exposed wires around each other before soldering.

- Use the soldering iron to heat the workpiece not the solder wire.Pressing the soldering tip against the solder wire will cause the solder to melt onto the tip instead of the workpiece.

- Do not use more solder than required. Use just enough to make contact between the workpieces.

- Clean the workpiece with steel wool or fine sandpaper if it is not clean. This provides a better surface for the solder to adhere to and a better electrical contact between parts.

MAINTENANCE

WARNING! BEFORE CLEANING YOUR TOOL OR CARRYING OUT ANY MAINTENANCE PROCEDURE, MAKE SURE IT IS DISCONNECTED FROM THE POWER SUPPLY TO PREVENT INJURY AND/OR ACCIDENTS.

CleaningClean the appliance regularly with a damp cloth. Do not use cleaning agents or solvents; these may be aggressive to the plastic parts in the appliance. Ensure that no water can get into the interior of the appliance.

Storage

Remove the power cord from the mains supply and allow the tool to cool completely. Allow the sponge to dry completely before storing.

Solder, spare tips and the sponge can be stored in the drawer compartment of the work station.

Store it in a dry location which is not accessible to unauthorised persons.

Power Supply

If the supply cord is damaged, it must be replaced by a qualified electrician in order to avoid a hazard.

DESCRIPTION OF SYMBOLS

|

V |

Volts |

| – |

Alternating Current |

|

°C |

Degrees Celsius |

|

Wear eye, ear & breathing protection |

|

|

Read Instruction Manual |

| Hz |

Hertz |

|

W |

Watts |

| s |

Seconds |

|

|

Regulatory Compliance Mark (RCM) |

|

Warning |

CARING FOR THE ENVIRONMENT

Power tools that are no longer usable should not be disposed of with household waste but in an environmentally friendly way. Please recycle where facilities exist. Check with your local council authority for recycling advice.

Power tools that are no longer usable should not be disposed of with household waste but in an environmentally friendly way. Please recycle where facilities exist. Check with your local council authority for recycling advice.

Recycling packaging reduces the need for landfill and raw materials. Reuse of recycled material decreases pollution in the environment. Please recycle packaging where facilities exist. Check with your local council authority for recycling advice.

Recycling packaging reduces the need for landfill and raw materials. Reuse of recycled material decreases pollution in the environment. Please recycle packaging where facilities exist. Check with your local council authority for recycling advice.

SPARE PARTS

Spare parts can be ordered from the Special Orders Desk at your local Bunnings Warehouse.

For further information, or any parts not listed here,

visit www.ozito.com.au or contact Ozito Customer Service:Australia 1800 069 486New Zealand 0508 069 486E-mail: [email protected]

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS WARRANTY YOU MUST RETURN THE PRODUCT TO YOUR NEAREST BUNNINGS WAREHOUSE WITH YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO RETURNING YOUR PRODUCT FOR WARRANTY PLEASE TELEPHONE OUR CUSTOMER SERVICE HELPLINE:

Australia: 1800 069 486New Zealand: 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE HAVE THE MODEL NUMBER AND DATE OF PURCHASE AVAILABLE. A CUSTOMER SERVICE REPRESENTATIVE WILL TAKE YOUR CALL AND ANSWER ANY QUESTIONS YOU MAY HAVE RELATING TO THE WARRANTY POLICY OR PROCEDURE.

The benefits provided under this warranty are in addition to other rights and remedies which are available to you at law.Our goods come with guarantees that cannot be excluded at law. You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Generally you will be responsible for all costs associated with a claim under this warranty, however, where you have suffered any additional direct loss as a result of a defective product you may be able to claim such expenses by contacting our customer service helpline above.

3 YEAR REPLACEMENT WARRANTY*

Your product is guaranteed for a period of 36 months from the original date of purchase. If a product is defective it will be replaced in accordance with the terms of this warranty. Warranty excludes consumable parts, for example: valve adapters andaccessories.

*This product is intended for DIY use only and replacement warranty covers domestic use.

WARNING

The following actions will result in the warranty being void.If the tool has been operated on a supply voltage other than that specified on the tool.If the tool shows signs of damage or defects caused by or resulting from abuse, accidents or alterations.Failure to perform maintenance as set out within the instruction manual.If the tool is disassembled or tampered with in any way.Professional, industrial or high frequency use.

References

[xyz-ips snippet=”download-snippet”]