PCW3000PCW5000/HSUSER GUIDE

Operating/safety Instructionswww.portablewinch.com

FRENCH IS THE ORIGINALLANGUAGE OF THIS DOCUMENT

INTRODUCTION

Portable Winch Co. thanks you for purchasing a Portable CapstanWinch TM. This manual was written to help you make the best use of your new machine and to use it in the most secure way.

PLEASE READ CAREFULLY BEFORE USE For any problems or questions please refer to an authorized Portable Winch Co. dealer or contact us directly.

Safety guidelines

Portable Capstan WinchesTM is designed to pull non-rolling objects, generally at angles of more or less 45 degrees relative to the horizontal. The use of a winch may present serious risks of injury, property damage, or even death.

DO NOT UNDERESTIMATE THE POTENTIAL DANGERS

1.1 Safety messages.

Your safety and the safety of others are very important. You will find important safety messages in this manual. Please read them carefully.These safety messages are warning you of potential injuries to either yourself or others. Each safety message is preceded by a warning symbol.

| SYMBOL | MEANING |

|

YOU WILL BE MORTALLY OR SEVERELY INJURED IF YOU DO NOT FOLLOW THESE INSTRUCTIONS. |

|

YOU COULD BE MORTALLY OR INJURED IF YOU DO NOT FOLLOW THESE INSTRUCTIONS. |

|

YOU COULD BE INJURED IF YOU DO NOT FOLLOW THESE INSTRUCTIONS. |

|

READ THE USER GUIDE. |

|

EYE AND HEARING PROTECTION. |

1.2 Labels

1.2.1 Serial number labelsThe serial number label can be found on the right side of the machine’s gearbox. In addition to the serial number, the fundamental specifications of your model are also found there.

1.2.2 Noise protection label

We recommend that you wear hearing protection during use of the Portable Capstan Pull WinchTM.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

INFORM ALL USERS OF THE SAFETY AND USAGEINSTRUCTIONS.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

THE ENGINE EXHAUST GASES CONTAIN POISONOUS CARBON MONOXIDE. NEVER RUN THE ENGINE IN A CLOSED BUILDING WITHOUT ADEQUATE VENTILATION.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

CLEAN AND/OR REPLACE ALL SECURITY LABELS THAT ARE DIRTY, DETERIORATED, UNREADABLE, OR TORN

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

NEVER PULL ROLLING MATERIAL THAT RISKS ROLLING OUT OF YOUR CONTROL.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

2 Checks before use.

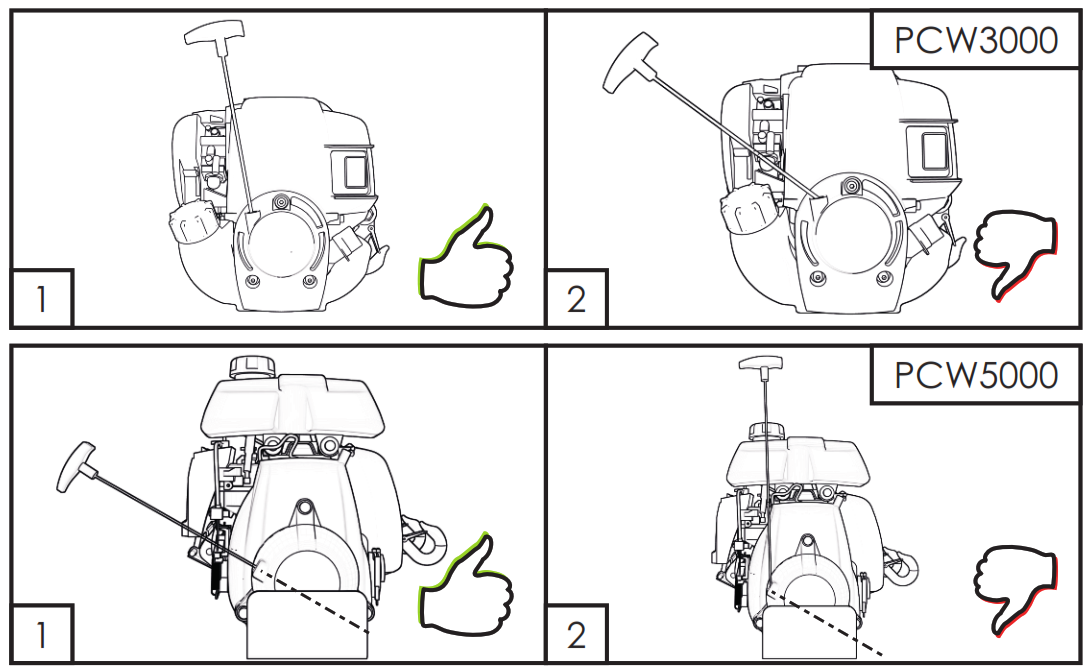

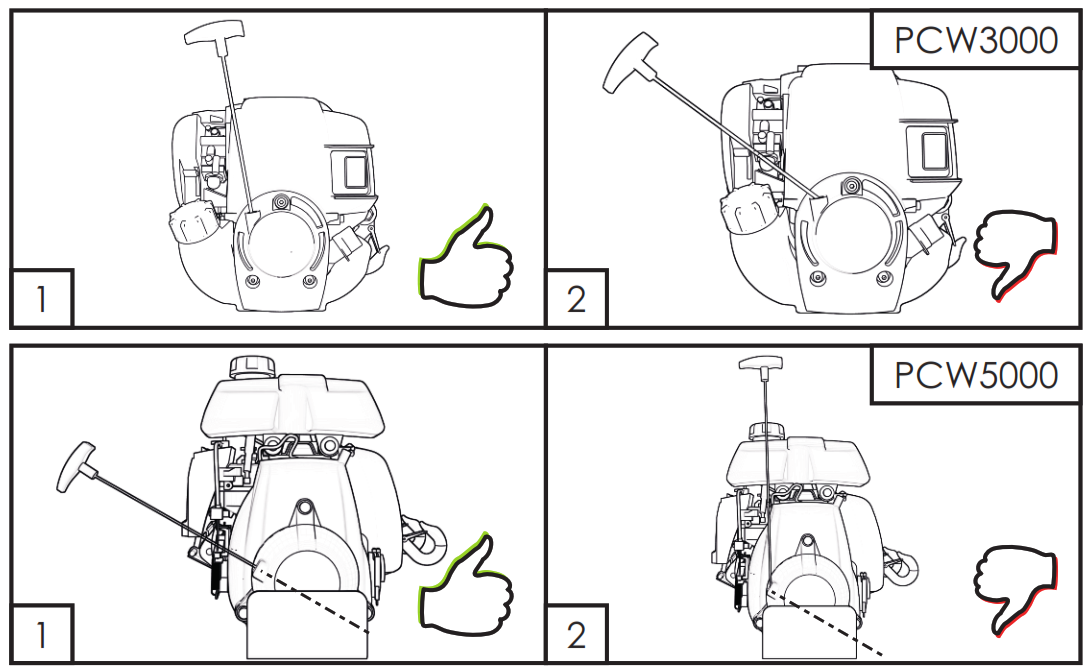

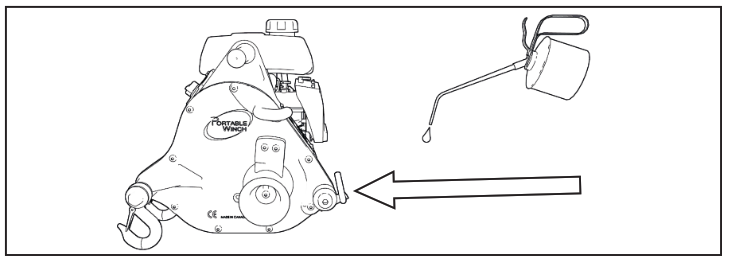

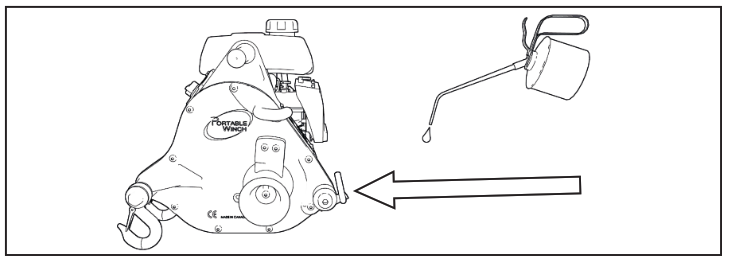

2.1 On receivingInspect the box to detect any obvious damage. If a part is missing or damaged, notify the carrier immediately.2.2 Is the engine ready?2.2.1 Oil the engineFill the Honda engine with SAE 10W-30 API SJ oil according to the quantities indicated for your model.● PCW3000: 100 ml● PCW5000: 250 ml● PCW5000-HS: 250 mlCheck the oil level on a horizontal surface. The oil level must reach the opening edge. For special uses and in extreme temperature conditions, consult the Honda engine manual.2.2.2 Gasoline.Fill the tank with UNLEADED gasoline. Never use a mixture of oil/gasoline, your Portable Capstan WinchTM is equipped with a four-stroke engine. Consult the Honda engine manual.Do not overfill.2.2.3 Starting the engineConsult the Honda engine manual for starting instructions.FIRST TIME USE: ALLOW THE ENGINE TO RUN IDLY FOR FIVE (5) MINUTES BEFORE PULLING A LOAD FOR THE FIRST TIME.Activate the engine’s on/off switch.

Take care to pull the starter grip in the output axis of the rope. If you do not pull at the correct angle, the friction of the rope on the plastic housing may damage the rope and/or the housing.

2.2.4 Capstan drums Your Portable Capstan WinchTM is equipped with the following drums.

● PCW3000: Drum 76 mm in diameter.● PCW5000: Drum 57 mm in diameter.● PCW5000-HS: Drum 85 mm in diameter.

2.2.5 Spark arrestors

In some areas, an engine may not be used without spark arrestors. Check local regulations. The PCW3000 model is fitted with internal spark arrestors.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

THE PCW5000 AND PCW5000-HS MODELS ARE NOT EQUIPPED WITH SPARK ARRESTORS.

- AN OPTIONAL SPARK ARRESTOR IS AVAILABLE FROM PORTABLE WINCH CO. AND FROM APPROVED HONDA DEALERS.

- PART NO. FROM PORTABLE WINCH CO.: PCA-1151

- PART NO. FROM HONDA: 350-2M7-801Consult the Honda engine manual for spark arrestor maintenance instructions.

Using the winch

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.1 Rope3.1.1 Type of rope

Only use a line with low elasticity. We recommend a double braid polyester line.Min., max. and recommended diameters:● PCW3000:

-

-

- Min.: 10 mm

- Max.: 12-13 mm

- Recommended: 10 mm

-

● PCW5000 and PCW5000-HS:

-

-

- Min.: 10 mm

- Max.: 16 mm

- Recommended: 12-13 mm

-

Contact us if you have any questions about rope types.

Contact us if you have any questions about rope types.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

● POLYPROPYLENE AND POLYETHYLENE LINES ARE DANGEROUS FOR PULLING DUE TO THEIR ELASTICITY AND THEIR LOW MELTING POINT.● MAKE SURE THAT THE LINE IS NOT DAMAGED AND OFFERS ADEQUATE RESISTANCE FOR THE LOAD TO BE PULLED.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

● STRETCHING THE LINE MAY CAUSE SERIOUS INJURY. BE CAREFUL WHEN RELEASING THE TENSION IN THE LINE.● ALL LINES STRETCH INCREASED LENGTH: THE MORE THE LINE IS PULLED, THE MORE IT STRETCHES.● STRETCHING THE LINE MAY CAUSE THE LOAD TO MOVE IN AN UNEXPECTED AND DANGEROUS MANNER.● STRETCHING THE LINE MAY CAUSE IT TO RELAX AND MOVE BACKWARDS QUICKLY, PULLING YOUR HAND TOWARDS THE WINCH OR CAUSING SEVERE BURNS. NEVER WIND THE LINE AROUND YOUR HAND.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.1.2 Rope maintenance

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

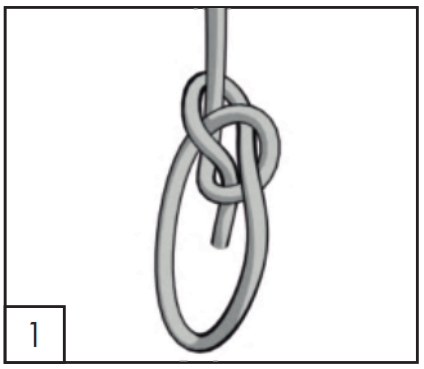

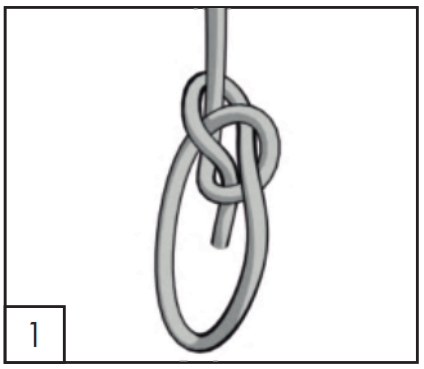

3.1.3 Recommended knots

Even better, a double bowline knot (fig. 2) allows you to maintain approx. 75% of the line’s capacity.

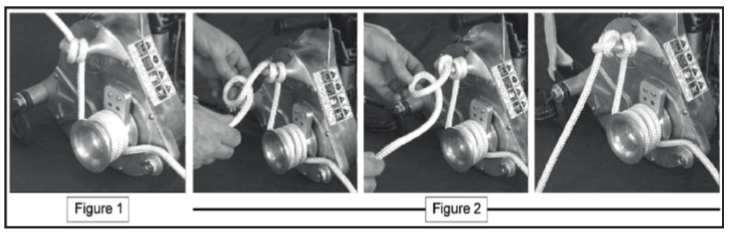

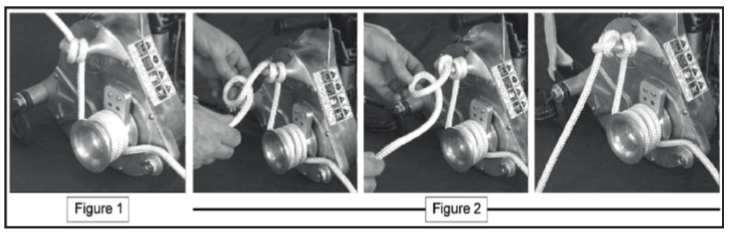

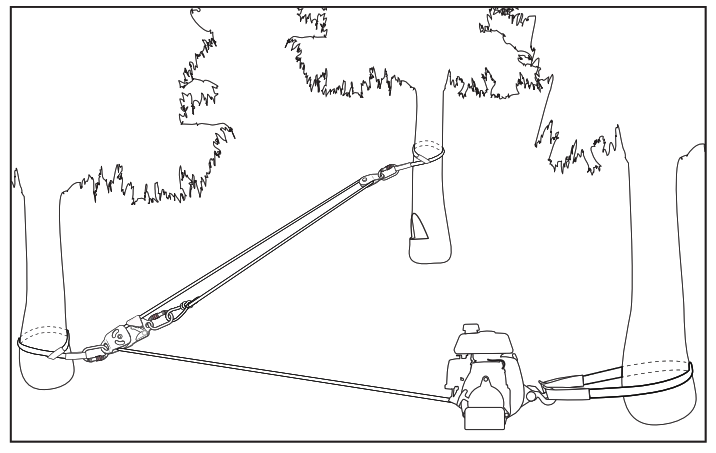

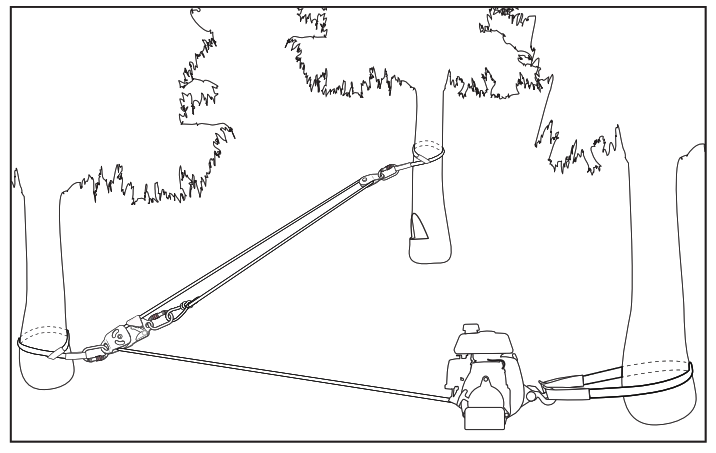

3.2 Anchoring the winchOPTION 1: In most cases, the winch is anchored to a fixed object using a polyester sling or one of our optional anchors, and the line is attached to the object you are trying to move. The latter is moved towards the winch as the winch pulls the line.OPTION 2: Sometimes, the winch can be anchored to the object you want to move and the line is attached to a fixed object. The winch and the object being moved are then pulled towards the line’s anchoring point. This method is useful when you guide the load while operating the winch. Your winch is supplied with a polyester sling measuring 2 meters. To anchor the winch, wind it around the anchoring point with the sling. Insert each end of the sling in each of the two safety hooks located on the back of the winch (fig. 1).Place the winch in the direction of the load to be pulled. When the winch is switched on, it will attempt to align itself with the load. The friction of the sling against the anchor may prevent correct alignment; in this case, release the tension in the line and move the sling so that the tension is distributed over the two books equally.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

ANCHORING AROUND A STUMP REQUIRES SPECIAL ATTENTION TO AVOID THE SLING SLIPPING OFF THE TOP OF THE STUMP.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

We also offer a wide range of anchoring accessories for our capstan winches. Visit www.portablewinch.com

3.3 Oil levelPCW5000 and PCW5000-HS: The Honda GXH-50 engine is fitted with an Oil Alert TM system that automatically shuts off the ignition when the oil level in the crankcase falls below a safe level. The Oil AlertTM system also stops the engine when the engine’s operating angle exceeds 20 degrees (± 4 degrees). Make sure that your installation keeps the winch relatively horizontal during pulling and when idling.PCW3000: The Honda GX-35 4-stroke engine is an engine for all positions. Therefore, it can be used at any angle without the engine stopping during operation.3.4 Installing the rope

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.4.1 RopeUse a line with a low elasticity in good condition with a minimum diameter of 10 mm and a maximum diameter of 16 mm (or 12 -13 mm with the PCW3000) with good knots. We highly recommend the bowline knot (see section 3.1.3). Use pulleys to divert the line and increase the pulling power when the load approaches or exceeds the winch’s pulling capacity.3.4.2 PulleyThe use of a pulley at a short distance from the winch offers several benefits:● Provides an angle allowing the load to be slightly raised to reduce friction;● Maintains the winch in a near-horizontal position;● Keeps the winch and the operator away from the load’s trajectory.3.4.3 DirectionInstall the line so that it doesn’t rub against any objects during pulling. Try to install the line so that the front of the load is slightly raised. Never pull downwards or through obstacles.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.4.4 On a slope![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.5.1 Winding the line around the capstan drum![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

B. PCW5000: Thru the hook, over the pulley and then under the drum (Fig. 2);

3. Wrap the line around the drum (3 or 4 turns);4. Take the line behind the exit hook;5. Keep your distance from the winch (approx. 1 m) and pull slowly and horizontally on the line until the line’s slack is taken up and you feel the tension in the line;6. Inspect your installation to make sure that the anchoring of the winch and the entry hook is aligned with the line;7. Check that the line is not rubbing against objects in its path;8. Increase the engine speed and pull on the line to start moving the load.3.5.2 PullingWhen pulling, position yourself so that you can see the winch and the load. Pull-on the line HORIZONTALLY. The tension you exert on the line keeps the winch level.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.5.2.1 If the line slipsIf the line slips on the drum while you are pulling, add a turn of line around the drum (4th turn). The engine will stall when the winch reaches its maximum capacity. You should then review theinstallation (add pulleys) or ”cradle” the load (see next section).3.5.2.2 To ”cradle” the loadPull until the engine nearly stalls and release the tension in the line. Then return the tension to the line and repeat as required.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.5.2.3 Taking a break during pullingSLOWLY release the tension in the line and allow it to slide over the drum.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3.5.2.5 To recommence pullingRelease some of the tension before restarting the winch’s engine. Firstly, undo the two half-knots. Allow the line to move slowly to release the tension. Then, whilst holding the line in one hand, restart the engine while pulling on the starter and increase the engine speed. You can recommence pulling.3.5.2.6 If it is essential to keep the tension in the line at startupYou can use a blocker or a Prusik knot connected to your anchoring point to maintain the tension in the line. You can also use a self-locking pulley PCA-1271 or PCA-1272. They are particularly useful for pulling rolling objects and for directional felling.

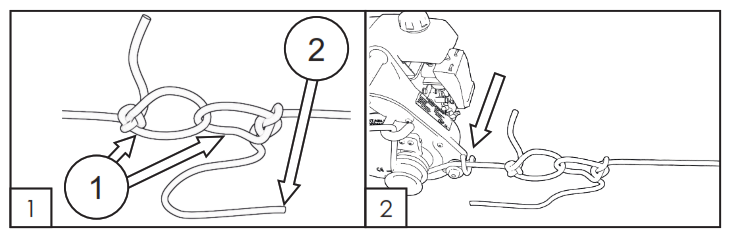

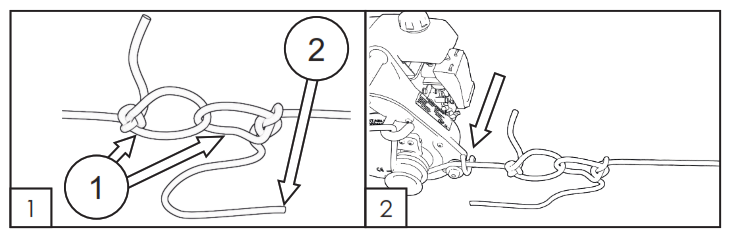

3.5.2.7 If your rope is too shortIf your line is too short, connect two lines together:1. Fig. 1-1: Use 2 bowline knots to link your two lines together.2. Fig. 1-2: Allow approx. 1 m (3′) of line to exceed the knot of the line pulling the load. This length of the line will be used for pulling when the knot is undone.3. Fig. 2: Stop the winch before the knots reach the winch; they will not be able to pass through and the line will become tangled.4. Release the tension in the line. Attach the load to a fixed point if necessary.5. Untie the line’s knot and use the remaining length to wind it around the drum and restart the winch again.

3.5.2.8 Stopping the winch

- Gradually release the tension to gradually lower the winch towards the ground;

- Lower the throttle lever to the idle position;

- Set the on/off switch to the OFF position;

- Do not touch the capstan drum after use. It may be hot and burn your skin.

4 Maintenance4.1 CleaningWhen your work is complete, clean and dry the winch.

DURING CLEANING, CHECK THE WINCH, THE HOOKS, THE LINE, AND THE POLYESTER SLING FOR ANY DAMAGE OR SIGNS OF WEARRegularly remove the capstan drum and clean around the shaft. Any accumulated debris may damage the seal. Brush the shaft with a little oil to avoid corrosion.

4.2 LubrificationThe gearbox is lubricated in the factory and thus should not require lubrication or maintenance. If oil losses become apparent, check the oil level by placing the winch on a level surface and unscrew the cap. Use an 8 mm hexagonal key.

When tipping the winch forwards, a little oil may escape through the hole. If required, you can add SAE80W90EP gear oil. PCW5000 and PCW5000-HS only:

The entry guide pulley must turn freely. Lubricate it regularly using a light oil, otherwise, there is a risk of premature wear due to dirt between the axis and the pulley. If necessary, remove it to get rid of any dirt. Use an 8 mm hexagonal key.

4.3 Honda engineMaintain the engine according to the instructions provided in the Honda engine user manual.4.4 StorageAlways store your Portable Capstan WinchTM on its base. Please consult the Honda engine user manual for storage instructions.4.5 Spark arrestorsPCW3000: Since your winch is equipped with integrated spark arrestors, you must clean them after one hundred (100) hours of operation. Consult the Honda engine manual for the cleaning procedure.PCW5000 and PCW5000-HS: If your winch is equipped with an optional spark arrestor (PCA-1151, sold separately), you should clean this every one hundred (100) operating hours to ensure that it works properly. Consult the Honda engine manual for the cleaning procedure.

5 Additional information5.1 AccessoriesA full range of accessories is available. Take a look at www.portablewinch.com.5.2 WarrantyThe Portable Winch Co. winch and accessories are guaranteed against all manufacturing defects when owned by the ”original owner” as defined here below. The “original owner” is defined as the person or entity that purchased the winch or accessories from an authorized Portable Winch Co. dealer as shown by the original invoice. The warranty is transferable if the new buyer holds a copy of the original invoice. This warranty does not apply to items sold ”as is”. The warranty does not apply to the wear parts defined as those coming into contact with the line during pulling.Portable capstan winches are covered as follows :● PCW3000Commercial use: 1 yearPrivate use: 5 years● PCW5000 et PCW5000-HSCommercial use: 1 yearPrivate use: 5 yearsServiced by Portable Winch Co. or its retailers.Engine :The Honda engine is guaranteed by Honda Motor Corporation, and the warranty period may vary from one country to another.All Honda service centers may make warranty repairs, if necessary. Please keep your proof of purchase (original invoice including the serial number of the winch). It will be used to establish the start date of the warranty period. Portable Winch Co. will replace or repair, at its discretion, any faulty products. All other Portable Winch Co. accessories are covered by a one-year (1) warranty with the exception of the lines which are covered by a 3-month warranty. If you have any questions, please consult the warranty policy at www.portablewinch.com Extend your warranty for free We want to thank you for your purchase. To do this, we are offering you AN ADDITIONAL ONE-YEAR (1) WARRANTY FOR FREE!It’s simple, just register your winch at www.portablewinch.com or over the phone on 1 888 388-7855 or + 1 819 563-2193.5.3 Troubleshooting areaIn case of problems, consult the Troubleshooting section at www.portablewinch.com in the Manuals and instructions section.5.4 Exploded-views To access the exploded view of your winch, consult Exploded views at www.portablewinch.com on the Manuals and instructions page or see the end of the manual.5.5 Technical data

| SPECIFICATIONS | PCW3000 |

| ENGINE | HONDA GX-35 4-STROKE ENGINE |

| DRUM DIMENSIONS | Ø 76 MM, UP TO 4 TURNS OF 10 MM ROPE |

| MAXIMUM PULLING FORCE(SINGLE LINE) | 700 kg |

| SPEED | 10 m/min |

| GEARBOX | HARDENED STEEL GEARS/OIL LUBRICATION |

| WEIGHT (DRY) | 9,5 kg |

| DIMENSIONS (OVERALL) | 35 cm x 28,9 cm x 26,1 cm |

| ROPE | DOUBLE BRAID POLYESTER WITH LOWELASTICITY (NOT INCLUDED) |

| LENGTH | UNLIMITED |

| MINIMUM DIAMETER | 10 mm |

| MAXIMUM DIAMETER | 12-13 mm |

| RECOMMENDED DIAMETER | 10 mm |

| Guaranteed sound power level– LWA dB(A) | 108 dB(A) |

| Uncertainty factor KwA dB(A) | 2.5 dB(A) |

| Measured sound pressure level –LpA dB(A) | 93 dB(A) |

| SPECIFICATIONS | PCW3000 |

| ENGINE | HONDA GX-35 4-STROKE ENGINE |

| DRUM DIMENSIONS | Ø 76 MM, UP TO 4 TURNS OF 10 MM ROPE |

| MAXIMUM PULLING FORCE(SINGLE LINE) | 700 kg |

| SPEED | 10 m/min |

| GEARBOX | HARDENED STEEL GEARS/OIL LUBRICATION |

| WEIGHT (DRY) | 9,5 kg |

| DIMENSIONS (OVERALL) | 35 cm x 28,9 cm x 26,1 cm |

| ROPE | DOUBLE BRAID POLYESTER WITH LOWELASTICITY (NOT INCLUDED) |

| LENGTH | UNLIMITED |

| MINIMUM DIAMETER | 10 mm |

| MAXIMUM DIAMETER | 12-13 mm |

| RECOMMENDED DIAMETER | 10 mm |

| Guaranteed sound power level – LWA dB(A) | 108 dB(A) |

| Uncertainty factor KwA dB(A) | 2.5 dB(A) |

| Measured sound pressure level – LpA dB(A) | 93 dB(A) |

6.0 CE Declaration of conformity

Declare, under our sole responsibility, that the product :Portables Capstan WinchesModels PCW3000, PCW5000 and PCW5000-HS

Designed for this use:

Pulling non-rolling objects at angles of +45º on a horizontal surface.

In compliance with the ”Machines” directive 2006/42/EC as well as the following directives:

– 2004/30/UE Electromagnetic Compatibility Directive.– 2000/14/CE Directive on Environmental Noise Emissions.

M. Gerold Vonblon,Landstrasse 28, A-6714 Nuziders is authorized to compile the technical file.Signed by:

Name: Pierre RoyPosition: Managing DirectorIn Sherbrooke, QC, CanadaFriday, 23rd November 2018.

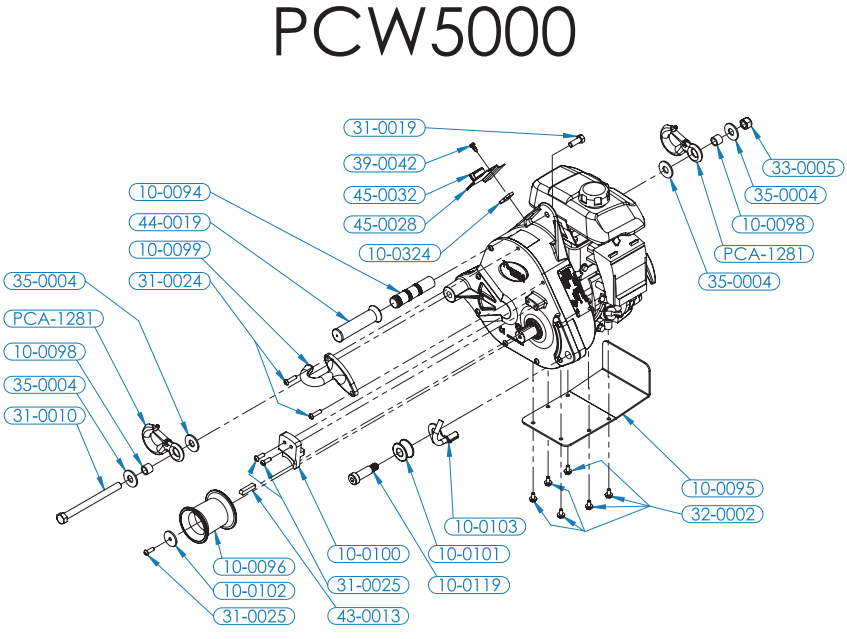

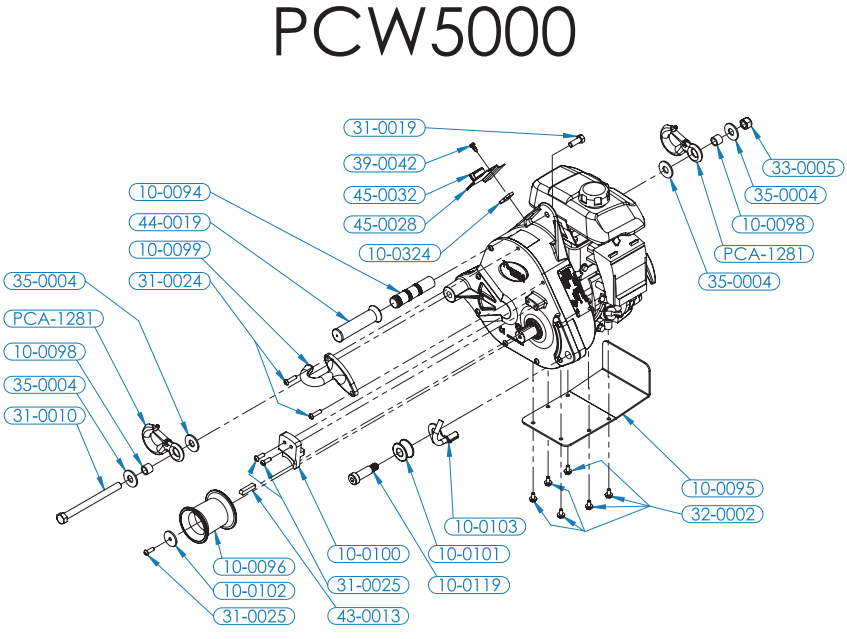

PCW3000

| PARTNUMBER | DESCRIPTION | QTY | PARTNUMBER | DESCRIPTION | QTY |

| 10-0094 | WINCH HANDLE | 1 | 31-0019 | HCS 3/8-24 X 1- Gr5 – ZN | 1 |

| 10-0095 | GUARD PLATE PCW5000 | 1 | 31-0024 | BHCS 1/4-20 X 1 – SS | 6 |

| 10-0096 | CAPSTAN DRUM 57mm | 1 | 31-0025 | BHCS 1/4-20 X 3,4 – SS | 6 |

| 10-0098 | BUSHING FOR SAFETY HOOK | 2 | 32-0002 | FLANGE BOLT SERRATED M6-1 x12mm – ZN | 6 |

| 10-0099 | ALUMINIUM ROPE EXIT HOOK | 1 | 33-0005 | NUT 1/2-13 NYLON – ZN | 1 |

| 10-0100 | ROPE GUIDE FOR CAPSTANDRUM 57mm | 1 | 35-0004 | FLAT WASHER 1/2 – ZN | 4 |

| 10-0101 | ROPE ENTRY PULLEY | 1 | 39-0042 | TAPPING SCREW-TYPE AB#10×5/8 | 1 |

| 10-0102 | RETAINING WASHER (1/4 X 1-1/4OD) – ZN | 1 | 43-0013 | KEY FOR CAPSTAN DRUMS 57MM, 85 MM & 108 MM (5/16 X1-1/2) | 1 |

| 10-0103 | ROPE KEEPER | 1 | 44-0019 | VINYL GRIP | 1 |

| 10-0119 | SHOULDER BOLT 5/8 X 1 1/2 – ZN | 45-0028 | SUPPORT PLATE FOR ON/OFFSWITCH | 1 | |

| 10-0324 | SWITCH MOUNT SPACER | 1 | 45-0032 | ON/OFF SWITCH | 1 |

| 31-0010 | HCS 1/2-13 X 6 – GR5 – ZN | 1 | PCA-1281 | SAFETY HOOK WLL: 3/4 TON | 2 |

| PARTNUMBER | DESCRIPTION | QTY | PARTNUMBER | DESCRIPTION | QTY |

| 10-0098 | BUSHING FOR SAFETY HOOK | 2 | 32-0007 | SHCS M8-1.25 X 16mm – BLACK | 2 |

| 10-0102 | DRUM RETAINING WASHER (1/4X 1-1/4 OD) – ZN | 1 | 32-0008 | HEX FLANGE SERRATED BOLTM8-1.25 X 16mm – ZN | 2 |

| 10-0129 | CAPSTAN DRUM 76mm | 1 | 32-0009 | SHCS M5-0.80 X 10mm | 1 |

| 10-0130 | GUARD PLATE PCW3000 | 1 | 32-0051 | SHCS M6-1 X 16mm – ZN | 2 |

| 10-0132 | ENGINE ALUMINUM COUPLINGPC W3000 | 1 | 32-0055 | BRCS M5-0.8 X 8mm – SS | 2 |

| 10-0133 | ENGINE COUPLING PLATE | 1 | 32-0056 | HEX FLANGE SERRATED BOLTM6-1.0 X 20mm – ZN | 4 |

| 10-0134 | THROTTLE CABLE ASSEMBLYPC W3000 | 1 | 33-0005 | NUT 1/2-13 NYLON – ZN | 1 |

| 10-0135 | ROPE EXIT HOOK PCW3000 | 1 | 33-0011 | SQUARE NUT 10-24 – ZN | 1 |

| 10-0136 | ROPE ENTRY HOOK PCW3000 | 1 | 35-0004 | FLAT WASHER 1/2 – ZN | 4 |

| 10-0137 | WINCH HANDLE PCW3000 | 1 | 39-0028 | TAPPING SCREW – TYPE B-#10×1/2 | 2 |

| 10-0415 | GEARBOX 200:1 | 1 | 43-0057 | KEY FOR CAPSTAN DRUMS 76MM (8 MM X 30 MM) | 1 |

| 10-0427 | ALUMINIUM ROPE GUIDE FORCAPSTAN DRUM 76mm | 1 | 44-0002 | THROTTLE LEVER PCW3000 | 1 |

| 31-0010 | HCS 1/2-13 X 6 – GR5 – ZN | 1 | 45-0001 | HONDA ENGINE GX-35 NT-S3 | 1 |

| 31-0038 | MACHINE SCREW PAN HEADSQUARE DRIVE 10-24 X 3/4-ZN | 1 | 70-0031 | ON/OFF SWITCH ASSY. FORPCW3000 | 1 |

| 32-0005 | BHCS M6-1 x 20mm – SS | 2 | PCA-1281 | SAFETY HOOK WLL: 3/4 TON | 2 |

www.portablewinch.com[email protected]1 888 388-7855 / +1 819 563-2193Rev: 02 (2020-06-29)44-0175Written and published in Canada

References

[xyz-ips snippet=”download-snippet”]