OPERATOR’S MANUALCarpet ExtractorPFX1380E

WARNING: OPERATOR MUST READ AND UNDERSTAND THIS MANUAL COMPLETELY BEFORE OPERATING THIS EQUIPMENT.

Save These Instructions

Congratulations on your purchase of a Midsize extractor. You are now equipped to handle any and all commercial carpet cleaning jobs. Your new unit is a high-quality, precision-made product.All parts used in the manufacturing of this unit have passed rigid quality control standards prior to assembly. Please safeguard the original receipt/invoice. If you experience any problems with your unit during the warranty period, the original receipt/invoice will act as proof of purchase.

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE USING THIS UNITRead and understand this owner’s manual and all labels on the unit before operating. Safety is a combination of common sense, staying alert, and knowing how your unit works. Use this unit only as described in this manual. Use only the manufacturer’s recommended attachments. To reduce the risk of personal injury or damage to your unit use only recommended accessories.WARNING To avoid fire, DO NOT use a flammable or combustible liquid or floor cleaner.WARNING To avoid electric shock, DO NOT expose to rain. Stored Indoors.When using this Midsize extractor, basic precautions should always be followed, including the following:

- DO NOT leave the unit when plugged in. Unplug from outlet when not in use and before servicing.

- DO NOT allow the unit to be used as a toy. Close attention is necessary when used around or near children.

- Use only as described in this manual. Use only the manufacturer’s recommended attachments.

- DO NOT use with damaged cord or plug. If the unit is not working properly because it has been dropped, dropped into water, left outdoors, or damaged in any way, contact a service center.

- DO NOT handle plug or appliance with wet hands.

- DO NOT put any objects into openings.

- DO NOT use with any opening blocked: keep free of dust, lint, hair, or anything that may reduce airflow.

- Keep hair, loose clothing, fingers, and all parts of the body away from openings and moving parts.

- DO NOT pick up anything that is smoking or burning such as cigarettes, matches, or hot ashes.

- DO NOT use to pick up hazardous chemicals.

- Turn off all controls before unplugging.

- Turn the unit off immediately if foam or liquid comes from the machine exhaust. Empty & clean out recovery (dirty) tank and use a defoamer to correct the problem.

- DO NOT use to pick up flammable or combustible liquids such as gasoline or use in areas where they may be present.

- DO NOT use where oxygen or anesthetics are used.

- Replace damaged or worn parts immediately with genuine original equipment parts to maintain safety.

- This unit must be connected to a properly grounded outlet only. See grounding instructions.

Shipping and DamageThis equipment is thoroughly inspected, tested, and packaged to provide equipment in good operating condition. It is beyond our control after the equipment is turned over to a freight carrier. The freight carrier received and signed for the equipment in good condition. Consequently, it ismost important to protect your interest by carefully complying with the following instructions:Please inspect your cartons for any damage (including concealed damage) that might have occurred during shipment. Any damage is the responsibility of the freight carrier and should be reported to the freight carrier immediately. It is your responsibility to issue a claim and to receivecompensation from the freight carrier for any damage done in transit. Damage of this sort is not warranted.

GROUNDING INSTRUCTIONS

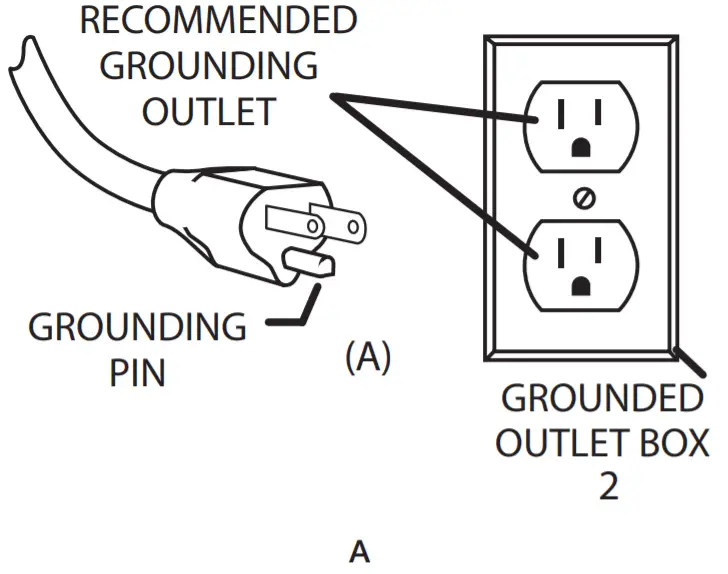

This appliance must be grounded. If it should malfunction or break down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This machine is equipped with a cord having an equipment-grounding conductor and grounding plug. Theplug must be inserted into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance – ifit will not fit the outlet, have a proper outlet installed by a qualified electrician.This appliance is for use on a nominal 115-volt circuit and has a grounding plug that looks like the plug illustrated in sketch A.

General Instructions for the Midsize Series Extractors

Follow these easy step-by-step instructions to ensure proper operating performance.

- Fill up the freshwater solution tank with tap water that is 120 °F-135° F (49° C-57° C) and approved carpet cleaning chemical if you are not pre-spraying your chemical on the carpet.

- Attach two 12 gauge extension cords, included, to each of the sockets located on the lower backside of the unit.

- Plug each extension cord into a SEPARATE and grounded 20 amp wall socket circuit, when this is accomplished the green indicator light will be lit.

- Attach the hose system to the unit and to your carpet wand.

- Turn the heater and the pump to the “ON” position, when the heater is on the orange indicator light on the switch panel will be lit.

- Turn vacuum switches to the “ON” position one at a time to begin cleaning.

- When the recovery tank is full, empty by using a drain hose at the front of the machine. If a pail is used to empty the recovery tank, do not use the same pail to fill the solution tank as this can result in putting dirt and grit into the solution line that can plug filters, orifices, and generallydegrade the solution line system (do not reuse solution).

- To empty the solution tank, detach the wand from the end of the vacuum hose and insert the vacuum hose into the solution tank. Turn the vacuum switches to the “ON” position and transfer the solution to the vacuum tank and dispose of it as outlined in #7. Clean vacuum stack filter at this time.

Maintenance

To receive reliable service from this equipment, regular daily maintenance is a requirement. Fabric cleaning, both carpet, and upholstery are very dirty environments for any equipment.The following recommendations are offered.

- Keep the equipment clean, both inside and out.

- Lubricate brass quick disconnects and drain valves with a quality lubricant such as WD-40®.

- Flush solution systems after use with clear, clean water. (A white vinegar solution may also be used). This will counter-act hard water and alkaline deposits and aid in keeping orifices clean.

- Do not allow fluid either in solution or waste tank to sit overnight. The unit should be emptied and cleaned daily.

- Clean the filters on the vacuum stack in the vacuum tank and all lint filters in the inlet or vacuum tanks daily.

- Do not use the same receptacle (pail) to fill the solution tank that has been used to remove wastewater from the vacuum tank.

- When the unit is not in use, leave the vacuum tank lid open.

- At the end of each day, run the vacuum for 3 minutes with the lid open and filter off.

Safety Precautions

These precautions are designed with the safety of the operator, the equipment, and others in mind and must be followed at all times to avoid serious personal harm and/or death, and damage to the unit.

- Never use equipment near or around flammable or explosive materials, fuels, or solvents.

- Never lift the machine by the drain hose.

- Do not allow the unit to freeze!

- The equipment was not designed to be used outdoors or in the rain.

- Do not operate in standing water.

- Wear safety equipment and clothing to protect from extremely hot water.

- Do not operate equipment under any unsafe conditions.

- Common sense is a powerful force in protecting the operator, the equipment, and others from serious damage injury, and/or death.

Storage of Equipment

- Store extractor indoors in a dry area.

- The recovery and solution tank should be empty and clean when the extractor is not in use.

- Leave the recovery lid open to air out the recovery tank.

- Do not store at freezing temperature.

- A small amount of windshield washer fluid, available at an auto supply, may be left in the pump and internal solution line for protection against freezing.

Warnings

- Do not break off or pull the grounding prong on the plug.

- Do not attempt a repair on a warranted machine unless instructions to perform it by an authorized shop are obtained from the factory.

- Do not use citrus-based (D-Limonene) cleaners in this machine.

- Do not use cleaning chemicals in this machine except those recommended for steam-type extraction equipment. The use of any chemicals with abrasive additives voids the warranty.

- Do not use any replacement parts except those specified on the parts list. The performance of the machine could be affected if substitutions are made.

- Do not use water in excess of 140° F (60° C) through the pump system. It could damage the seals and polypropylene casing of the diaphragm pump.

- Follow maintenance schedule strictly.

- Failure to comply with the above warnings instructions will void the warranty.

Troubleshooting InformationELECTRICAL SYSTEM

| PROBLEM | POSSIBLE CAUSE | SOLUTION |

| No electrical power. | 1. Defective power cord (s).2. Circuit breaker off or a fuse blown. | 1. Replace.2. Turn the circuit breaker on or replace the fuse.Unplug any equipment using the same circuit. |

| A switch is turned on.Intermittent power to the motor(s). | 1. Faulty electrical cable.2. Defective switches.3. Loose terminal. | 1. Repair or replace.2. Replace.3. Replace. |

| Electrical Shock. | 1. Equipment not grounded. | 1. Locate grounded outlet. |

| Vacuum motor on, low or no vacuum at the wand. | 1. Drain hose open.2. Defective vacuum hose Kinks in the vacuum hose.3. Vacuum disconnected.4. Damaged recovery lid.5. Lint clogging ball-type shutoff screen.6. Loose hose connection.7. Vacuum motor exhaust blocked. | 1. Close drain hose.2. Repair or replace the hose.3. Open the machine, connect the vacuum hose to the recovery tank.4. Replace the tank lid. The recovery tank lid must be closed.5. Clean out fibers and accumulated dirt from the screen.6. Check for leaks between standpipe and around clamps and cuffs vacuum motor.Replace the damaged hose(s).7. Check airflow by removing the hose from the machine and feeling the exhaust under themachine. Remove obstruction. |

| Motor running and no vacuum and no exhaust from the blow port. | 1. Faulty vacuum motor.2. Water shutoff closed. | 1. Replace.2. Clean water shutoff screen. |

| Premature closing of ball-type shutoff. Ball-type shutoff failing to release after recoverytank is drained. | 1. Dirty or clogged shut-off filter screen.2. Ball coated with detergentor other foreign material.3. Screen slightly out of round. | 1. Remove and clean screen.2. Remove and rinse the ball with clean water.3. Bend the screen by squeezing slightly by hand until there is an obvious space between the ball and the inside of the screen. |

| Foam/dirty solution coming out of vacuum exhaust port. | 1. Foam bypassing water shutoff.2. Elbow in the vacuum tank is not positioned correctly. | 1. Use an additional defoamer.2. The elbow should be pointed directly at the sidewall of the tank away from the ball-type shutoff. |

| Pump motor runs but no spray through jets. | 1. Clogged or faulty solution control valve.2. Clogged or faulty quick disconnect on housing.3. Punctured pump diaphragm.4. Clogged jets | 1. Check intake on the valve and remove lint or other foreign material.2. Depress plunger on solution hose against the inside wall of solution tank. If the solution is flowing at this point, the system is OK If no solutionflows, check the quick disconnect for lint and other foreign matter.3. Replace with a diaphragm repair kit.4. Clean jets on wand or tool. |

| Uneven spray from the jet. Spray weak or uneven. | 1. Clogged jet. | 1. Remove and clean. |

| Leaking or stuck solution valve. | 1. Foreign material in the valve.2. Loose brass hex nut.3. Valve or seals worn | 1. Remove brass hex plug, clean valve, and replace.2. Reseal hex and plug.3. Replace worn parts with solution valve repair kit. |

| The pump motor not working. | 1. Loose wiring2. Defective pump pressure switch.3. Motor burnout | 1. Tighten wiring2. Replace with new pressure switch assembly.3. Replace pump motor |

| Pump pressure low. | 1. Punctured pump diaphragm. | 1. Replace with the diaphragmrepair kit. |

| Pump pressure varies. | 1. Worn carbon brushes.2. Defective pump pressure control switch. | 1. Replace brushes.2. Replace. |

For warranty information go to www.Powr-Flite.com

A Tacony Company3101 Wichita Court • Fort Worth, TX 76140-17551-800-880-2913 • Fax: 1-817-551-0719©Tacony Corporation, All rights reservedPFX1380E-MAN 05/2021

References

[xyz-ips snippet=”download-snippet”]