1.0 HP Shallow Well PumpOwner’s Manual

Item #50299

SAVE THESE INSTRUCTIONS

Thank you very much for choosing a PowerHorse product!

For future reference, please complete the owner’s record below:

Serial Number/Lot Date Code: ________________________________

Purchase Date: ____________________________________________

Save the receipt, warranty, and this manual. It is important that you read the entire manual to become familiar with this product before you begin using it.

This pump is designed for certain applications only. Northern Tool and Equipment cannot be responsible for issues arising from modification or use of this product in an application for which it was not designed. We strongly recommend that this product not be modified and/or used for any application other than that for which it was designed.

For technical questions, please call 1-800-222-5381.

Intended Use

The PowerHorse 1.0 HP Shallow Well Pump is a single-stage domestic water pump designed for pumping potable water. Shallow well pumps are designed for applications where the water level is less than 26 feet below the pump. This pump is non-submersible.

Technical Specifications

| Property | Specification |

| Motor | 120 V, 60 Hz, Single Phase |

| Max. Flow | 978 GPH |

| Max. Head | 130 ft. |

| Max. Lift | 26 ft. |

| Max. PSI | 66.7 PSI |

| Pressure Switch | 30psi ON, 43.5 PSI OFF |

| Intake Port | 1 in. |

| Discharge Port | 1 in. |

| Pressure Tank Capacity | 6.3 Gal |

Important Safety Information

- Read and understand all instructions. Failure to follow all instructions may result in serious injury or property damage.

- The warnings, cautions, and instructions in this manual cannot cover all possible conditions or situations that could occur. Exercise common sense and caution when using this tool. Always be aware of the environment and ensure that the tool is used in a safe and responsible manner.

- Do not allow persons to operate or assemble the product until they have read this manual and have developed a thorough understanding of how it works.

- Do not modify this product in any way. Unauthorized modification may impair the function and/or safety and could affect the life of the product. There are specific applications for which the product was designed.

- Use the right tool for the job. DO NOT attempt to force small equipment to do the work of larger industrial equipment. There are certain applications for which this equipment was designed. It will do the job better and more safely at the capacity for which it was intended. DO NOT use this equipment for a purpose for which it was not intended.

- Industrial or commercial applications must follow OSHA requirements.

- This product may contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

WORK AREA SAFETY

- Inspect the work area before each use. Keep work area clean, dry, free of clutter, and well lit. Cluttered, wet, or dark work areas can result in injury. Using the product in confined work areas may put you dangerously close to other cutting tools and rotating parts.

- Do not use the product where there is a risk of causing a fire or an explosion; e.g., in the presence of flammable liquids, gases, or dust. The product can create sparks, which may ignite the flammable liquids, gases, or dust.

- Do not allow the product to come into contact with an electrical source. The tool is not insulated and contact will cause electrical shock.

- Keep children and bystanders away from the work area while operating the tool. Do not allow children to handle the product.

- Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in your work area. Some of these hazards may be hidden from your view and may cause personal injury and/or property damage if contacted.

PERSONAL SAFETY

- Stay alert, watch what you are doing, and use common sense when operating the tool. Do not use the tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the tool may result in serious personal injury.

- Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Air vents on the tool often cover moving parts and should be avoided.

- Wear the proper personal protective equipment when necessary. Wear ANSI Z87.1 compliant safety goggles or safety glasses with side shields, or when needed, a face shield. Use a dust mask in dusty work conditions. Also use non-skid safety shoes, hardhat, gloves, dust collection systems, and hearing protection when appropriate. This applies to all persons in the work area.

- Do not overreach. Keep proper footing and balance at all times.

- Do not use the tool when tired or under the influence of drugs, alcohol or medication.

- Ensure the power switch is off prior to plugging in the tool.

- Remove keys or wrenches before connecting the tool to an air supply, power supply, or turning on the tool. A wrench or key that is left attached to a rotating part of the tool may cause personal injury.

- Secure the work with clamps or a vise instead of your hand when practical. This safety precaution allows for proper tool operation using both hands.

ELECTRICAL SAFETY

- Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes and ordinances. Never remove the grounding prong or modify the plug in any way. Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user.

- Double insulated tools are equipped with a polarized plug (one blade is wider than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plugin anyway. Double insulation eliminates the need for the three wire grounded power cord and grounded power supply system.

- Do not allow the product to come into contact with an electrical source. The tool is not insulated and contact will cause electrical shock.

- Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is grounded.

- Do not abuse the power cord. Never use the power cord to carry the pump or pull the plug from an outlet. Keep the power cord away from heat, oil, sharp edges, or moving parts. Replace damaged power cords immediately. Damaged power cords increase the risk of electric shock.

- When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These extension cords are rated for outdoor use, and reduce the risk of electric shock.

PUMP USE AND CARE

- Do not force the pump. Pumps do a better and safer job when used in the manner for which they are designed. Plan your work, and use the correct product for the job.

- Check for damaged parts before each use. Carefully check that the pump will operate properly and perform its intended function. Replace damaged or worn parts immediately. Never operate the pump with a damaged part.

- Do not use a pump with a malfunctioning switch. Any pump that cannot be controlled with the power switch is dangerous and must be repaired by an authorized service representative before using.

- Disconnect the power/air supply from the pump and place the switch in the locked or off position before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

- Store the pump when it is not in use. Store it in a dry, secure place out of the reach of children. Inspect the tool for good working condition prior to storage and before re-use.

- Use only accessories that are recommended by the manufacturer for use with your pump. Accessories that may be suitable for one product may create a risk of injury when used with another tool. Never use an accessory that has a lower operating speed or operating pressure than the tool itself.

- Keep guards in place and in working order. Never operate the product without the guards in place.

Specific Operation Warnings

- Wear ANSI Z87.1 compliant goggles.

- DO NOT start pump or run pump dry. Prime pump before each use.

- Do not submerge pump in water. For indoor use only.

- Pump clean water only. DO NOT use for salt water, brine, laundry discharge or any application that may contain foreign materials and/or caustic chemicals.

- Never pump gasoline or flammable liquids with this product.

- Do not operate pump where flammable or explosive fumes or gases are present. Explosion, fire, or serious injury may result.

- Do not use this product to pump chemicals or corrosive liquids, damage to seals and moving parts will result.

- Do not run the pump with the outlet closed or blocked. The excessive pressure will cause the pump to explode and cause injury or death.

- Before using any pump, check for alignment and binding of moving parts; any broken parts or mounting fixtures; and any other condition that may affect proper operation. Any part that is damaged should be properly repaired or replaced by a qualified technician.

- Do not pump water that is hotter than 95 F.

- Electrical connections must be moved to higher ground where there is a risk of flooding.

- Unplug before servicing and when changing accessories.

- When servicing, use only identical replacement parts. Only use accessories intended for use with this pump. Approved accessories are available.

- Do not let water inside pump freeze or let frost build up on pump.

- No alterations shall be made to this product.

- Do not use in swimming pools or marine areas.

- Not for use by or around children.

ELECTRIC SHOCK HAZARD

- Always connect this product to a grounded outlet equipped with a ground fault circuit interruption device (GFCI).

- Before installing this product, have a licensed or certified electrician inspect the outlet to be sure the outlet is correctly grounded. (DO NOT remove ground pin on cord).

- Do not remove or modify the round ground prong on the power cord plug or use an adapter (cheater plug) that eliminates the ground prong. A shock hazard is created and serious injury can result.

- DO NOT plug-in power cord when wet or while standing on damp/wet ground.

- Do not use an extension cord with this product.

- Always keep one hand free when plugging this product into an electrical power cord.

- DO NOT operate if power cord or electrical components are damaged or seals are compromised.

- DO NOT attempt to service or open this product while it is connected to an electrical power supply.

- DO NOT lift this product by the electrical power cord.

Grounding

- The pump must be grounded while in use to protect the operator from electrical shock. It is equipped with an electric cord that has an equipment-grounding conductor and a grounding plug. The plug MUST be plugged into a matching receptacle that is properly installed and grounded in accordance with ALL local codes and ordinances.

- DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the receptacle, have the proper receptacle installed by qualified electrician.

- CHECK with a qualified electrician or service person if you do not completely understand the grounding instructions, or if you are not sure the tool is properly grounded.

Grounded Tools: Tools with 3-Prong Plugs

Tools marked with Grounding Required have a 3-wire cord and 3-prong grounding plug. The plug must be connected to a properly grounded outlet. If the tool should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user, reducing the risk of electric shock. (See Figure A.)The grounding prong in the plug is connected through the green wire inside the cord to the grounding system in the tool. The green wire in the cord must be the only wire connected to the tool’s grounding system and must never be attached to an electrically live terminal.Your tool must be plugged into an appropriate outlet, properly installed, and grounded in accordance with all codes and ordinances. The plug and outlet should look like those in the following illustration.

Extension Cords

- An extension is NOT recommended for use with this product. If an extension cord is used, be sure to follow the requirements listed below.

- USE A PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage, resulting in loss of power and cause overheating.

- Be sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it. Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

- Grounded tools require a 3-wire extension cord (with a three-prong plug). Double Insulated tools can use either a 2- or 3-wire extension cord.

- As the distance from the supply outlet increases, you must use a heavier gauge extension cord.Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage.

- The smaller the gauge number of the wire, the greater the capacity of the cord. For example, a 14-gauge cord can carry a higher current than a 16-gauge cord. Minimum extension cord wire size is shown in the following table:

| Minimum Wire Size Of Extension Cords | ||||

| Nameplate AMPS | Cord Length | |||

| 25′ | 50′ | 100′ | 150′ | |

| 0-6 | 18 AWG | 16 AWG | 16 AWG | 14 AWG |

| 6-10 | 18 AWG | 16 AWG | 14 AWG | 12 AWG |

| 10-12 | 16 AWG | 16 AWG | 14 AWG | 12 AWG |

| 12-16 | 14 AWG | 12 AWG | NOT RECOMMENDED |

- When using more than one extension cord to make up the total length, make sure each cord contains at least the minimum wire size required.

- If you are using one extension cord for more than one tool, add the nameplate amperes and use the sum to determine the required minimum cord size.

- If you are using an extension cord outdoors, make sure it is marked with the suffix W-A (W in Canada) to indicate it is acceptable for outdoor use.

- Make sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified electrician before using it.

- Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

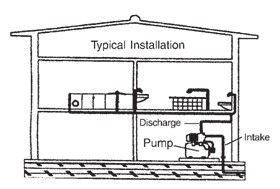

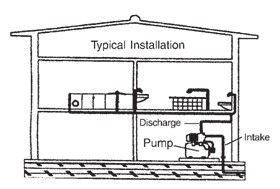

Installation

- Never install a shutoff valve in the suction or discharge of this pump. This will cause excessive friction loss and will damage the pump and void the warranty.

- All connections must be air-tight. A single leak will prevent proper operation of the pump and may cause the pump to run dry. If the pump runs dry, this will void the warranty.

- An extension cord is not recommended for use with this product. If an extension cord is required, only use a UL-certified cord that is 18 gauge wire and less than 50 ft long.

- Install the pump on a rigid, level platform above the water level. This platform must provide a solid, level surface that is capable of supporting the weight of the pump, and attached piping filled with water. Never allow the pump to become immersed in water.a. The inlet and discharge lines should not be wedged or stressed in a way that puts strain on the pump.

- The level of the intake port should not be more than 12-15 feet above the water. Pumping efficiency reduces as the height above the water level increases.

- Keep vertical lift to a minimum. Vertical delivery higher than a few feet will degrade pump efficiency.

- The intake port and discharge port must have a screen (not included) attached to prevent debris being pumped.

- ONLY pump clean water. Install the foot valve included on the suction inlet. This keeps the pump primed while not in use (not included with product).

- The foot valve must be under the pumping water level. This is the level that the waterfalls to when the pump operates.

- The pipe layout the intake and discharge pipes should have as few turns as possible to prevent air pockets within the lines. Air pockets interfere with pressure switch performance.

- Intake and discharge pipes must have a minimum of 1in. to 1-1/4in. diameter (outer diameter).

- Fill the air tank.a. The air tank must be pumped up with air between18 and 19 PSI at all times.b. On the end of the compression tank opposite the side with the pressure meter, is an air valve located under a cover. Remove the cover over the air valve and periodically monitor this air valve with an air pressure gauge to insure that the rubber bladder maintains the required 18 to 19 PSI.

Before Each Use

- Check for damaged parts before each use. Carefully check that the pump will operate properly and perform its intended function. Replace damaged or worn parts immediately. Never operate the pump with a damaged part.

- Do not use the pump where there is a risk of causing a fire or an explosion; e.g., in the presence of flammable liquids, gases, or dust. The tool can create sparks, which may ignite the dust or fumes.

- Keep children and bystanders away from the work area while operating the pump. Do not allow children to handle the pump.

- Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in your work area. Some of these hazards may be below the work surface hidden from your view and may cause personal harm or property damage if unintentionally contacted.

Prime the pump1. Remove priming valve inlet.

2. Fill the priming valve inlet with clear water.

a. If water leaks from the drain valve underneath the pump, securely close it and refill the unit.

3. Reattach the priming valve inlet and tighten.

Operating Instructions

- Stay alert, watch what you are doing, and use common sense when operating the pump. Do not use the pump while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the pump may result in serious personal injury.

- Use ANSI-approved safety goggles or safety glasses with side shields, or when needed, a face shield. Also use non-skid safety shoes, gloves, and hearing protection when appropriate.

- Do not overreach. Keep proper footing and balance at all times.

- This pump is not submersible! Do not stand the pump in water while it is plugged in, and do not get the motor wet as it could cause electrocution. Do not handle pump with wet hands.

- Do not leave the pump running unattended because the supply water may get fully drained and the pump motor can burn out. Do not allow the pump to run dry.

- Always make sure the pump is unplugged as soon as the supply water level reaches 1/4 in. deep. At water levels less than 1/4 in., the pump may begin to pump air and be EXTREMELY LOUD, which will cause the pump to overheat and burn out. Running the pump without sufficient water will damage the pump and void the pump’s warranty.

- Always use the suction strainer included with this pump to prevent debris from getting into and damaging the pump.

- Do not pump flammable or explosive liquids such as oil, gasoline, kerosene, ethanol, etc. Do not use in the presence of flammable or explosive vapors. Using this pump with or near flammable liquids can cause an explosion or fire, resulting in property damage, serious personal injury, and/or death.

- Do not touch the pump housing while it is operating, as the pump may be HOT and can cause serious skin burns. To avoid burns, unplug the pump and allow time for it to cool after periods of extended use.

- Always use the handle to lift the pump, not the power cord. Also do not suspend the pump by the discharge hose or power cord.

- Electric Shock Hazard. Make sure that the motor cover is properly closed and sealed before priming or operation. Serious injury or death could occur.

After following the installation steps:

- Make sure the intake pipe is fully submerged before operating the pump.

- Gently insert a screwdriver into the motor shaft and make sure the shaft turns freely.

- Plug the power cord in.a. Be sure that the power outlet used comes equipped with a Ground Fault Circuit Interrupter (GFCI). Have it installed by a qualified electrician. Keep the power line safely away from water.b. This is a self-starting pump that uses a pressure switch. Once the power cord is connected, the pump can be started at any time. Do not handle or perform maintenance on the pump if the power cord is plugged in.

Maintenance

- Before inspection, always unplug the pump from power and allow it to cool.

- This pump must be monitored frequently (at least once a month, possibly more frequently if used in water that is full of debris).If the pump becomes overly clogged with debris (leaves, sticks, mud, etc.), excess pressure could cause the motor seal to weaken and water could come in contact with the electric motor. If a proper GFCL outlet is not being used, hazardous shock could occur. NEVER STAND IN WATER WITH A RUNNING OR ELECTRICALLY CONNECTED PUMP!

- Use only identical replacement parts.

Maintain your pump. It is recommended that the general condition of any pump be examined before it is used. Keep your pump in good repair by adopting a program of conscientious repair and maintenance in accordance with the recommended procedures found in this manual.

- Clean the inlet screen regularly to remove accumulated debris.

- Use air pressure gauge to test air pressure in the tank’s rubber bladder. Air pressure should range between 18 and 19 PSI.

- Wipe the pump clean with a soft, damp cloth with soapy water. Do not use solvents. Do not get the electrical components wet.

- If storing the pump for a long time, store it in a dry location, and apply a light layer of oil to the metal parts prior to storage to prevent rust.

- To drain the pump, disconnect the water lines and turn it upside down.

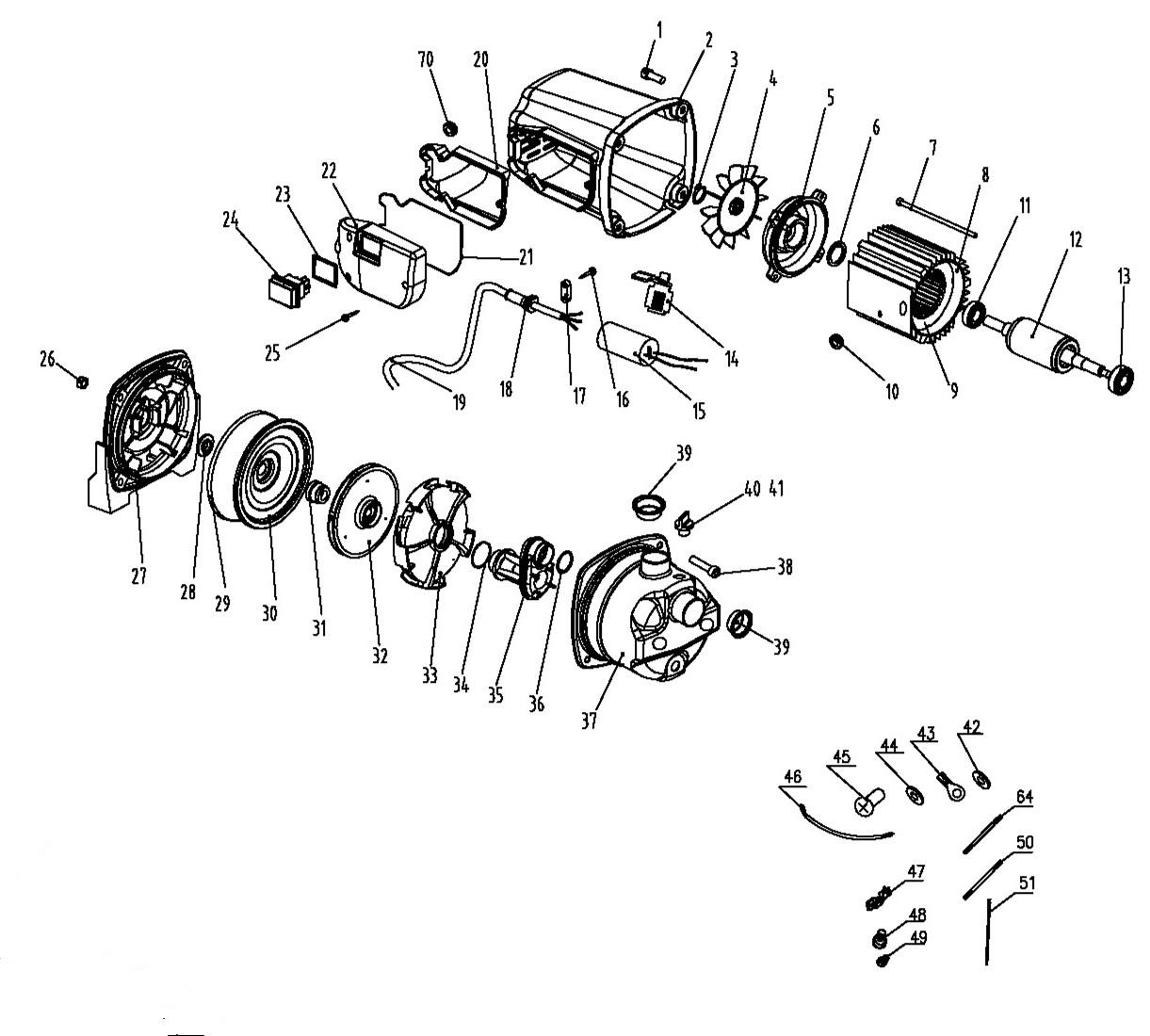

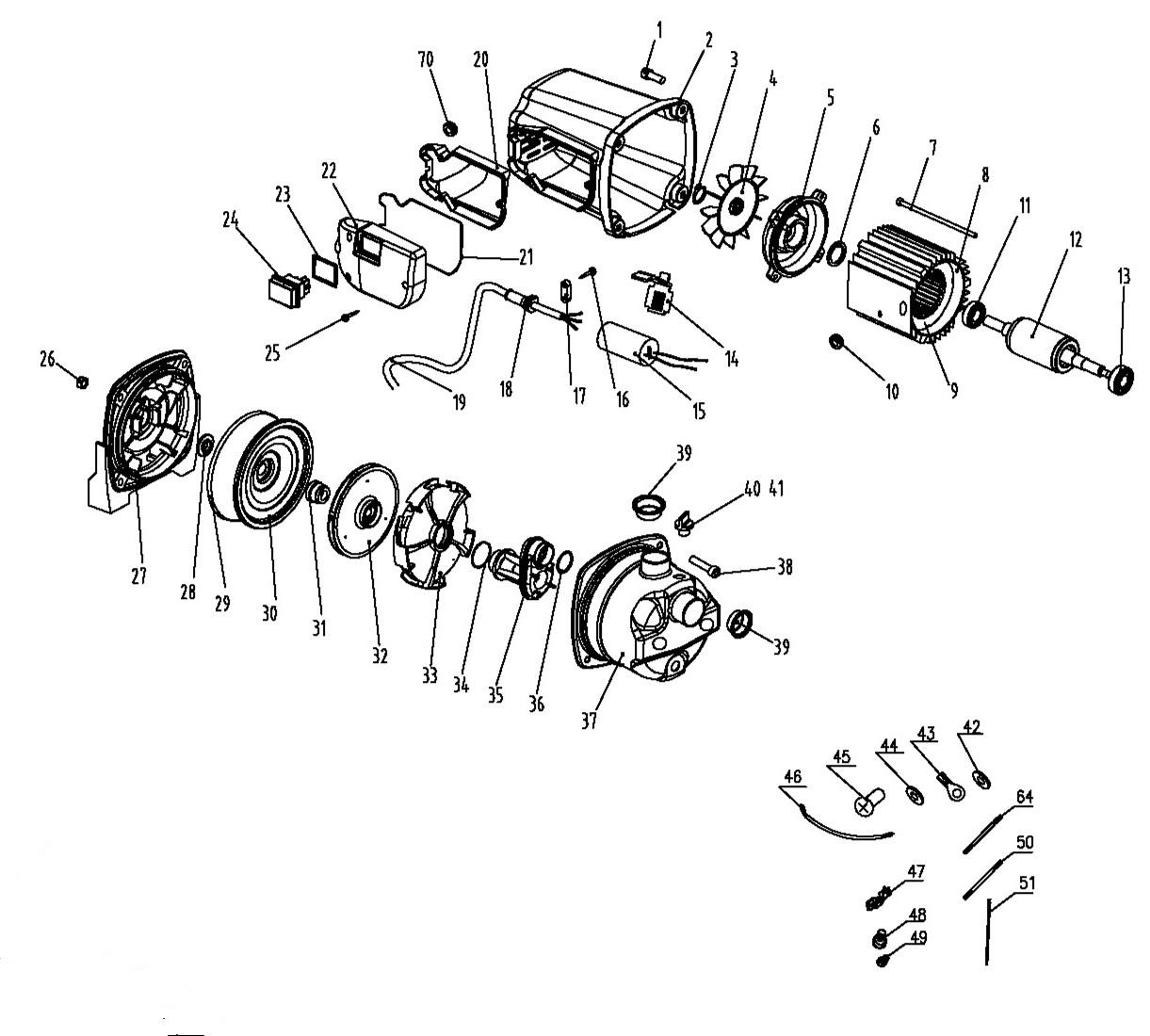

Parts Diagram

Motor

Parts List

Motor

| Part No. | Description | Quantity |

| 1 | Screw | 4 |

| 2 | Motor Housing | 1 |

| 3 | Axle retaining ring | 1 |

| 4 | Fan Blade | 1 |

| 5 | Rear Cover | 1 |

| 6 | Motor assembly | 1 |

| 7 | 4 | |

| 8 | 1 | |

| 9 | 1 | |

| 10 | 1 | |

| 11 | 1 | |

| 12 | 1 | |

| 13 | 1 | |

| 16 | Screw | 2 |

| 17 | Cable block | 1 |

| 14 | Capacitor Cover | 1 |

| 15 | Capacitor | 1 |

| 18 | Cable sleeve | 1 |

| 19 | Connection Cable | 1 |

| 20 | Waterproof Cover | 1 |

| 21 | 0-ring | 1 |

| 22 | Side Cover | 1 |

| 23 | Switch Seal Plate | 1 |

| 24 | Waterproof Switch | 1 |

| 25 | Screw 3.5’20 | 3 |

| 26 | Hex Nut M8’20 | 4 |

| 27 | Front Cover | 1 |

| 28 | Rubber Ring | 1 |

| 29 | 0-ring | 1 |

| 30 | Flange | 1 |

| 31 | Immobile Ring | 1 |

| 32 | Impeller | 1 |

| 33 | Flow Guide Plate | 1 |

| 34 | 0-ring | 1 |

| 35 | Flow Guide Assy | 1 |

| 36 | 0-ring | 1 |

| 37 | Pump Shell | 1 |

| 38 | Screw M8’20 | 4 |

| 39 | Lg.Valve Cover | 2 |

| 40 | Small Valve Cover | 1 |

| 41 | 0-ring | 2 |

| 42 | Spring washer | 1 |

| 43 | Earth pin | 1 |

| 44 | 0-ring | 1 |

| 45 | Screw M4’8 | 1 |

| 46 | Earth wire(0.25) | 1 |

| 47 | Socket | 4 |

| 48 | Nylon safety cap | 1 |

| 49 | Nylon safety cap | S |

| SO | Wire(0.3) | 1 |

| Si | Tie | 1 |

| 64 | Conducting wire(0.3) | 1 |

| 70 | Wire bushing | 2 |

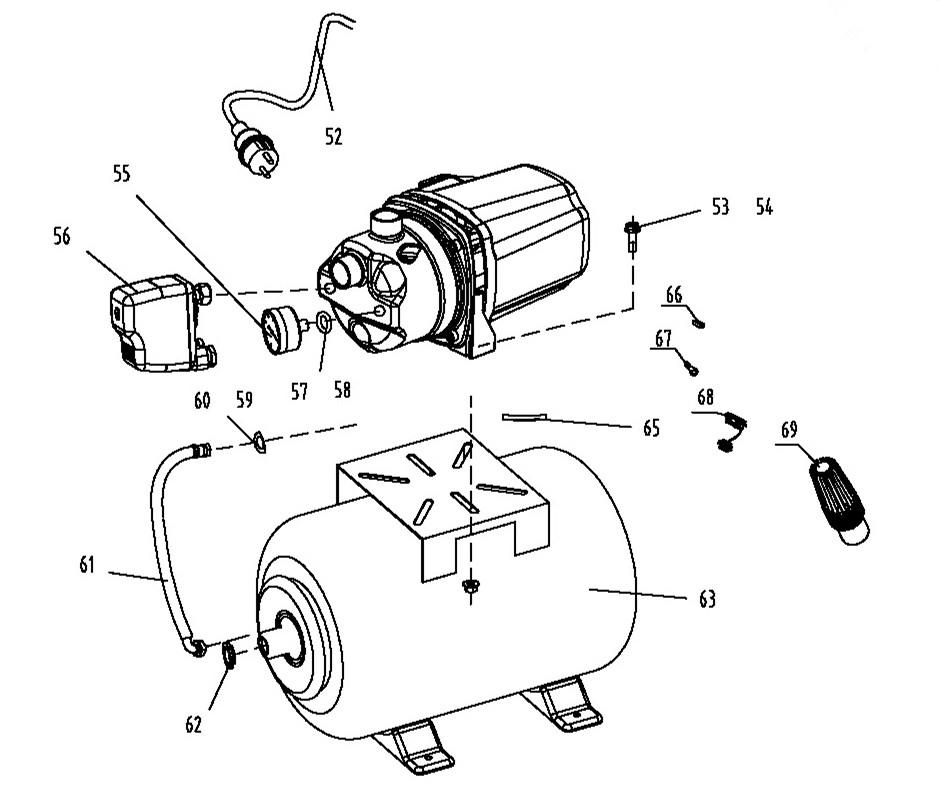

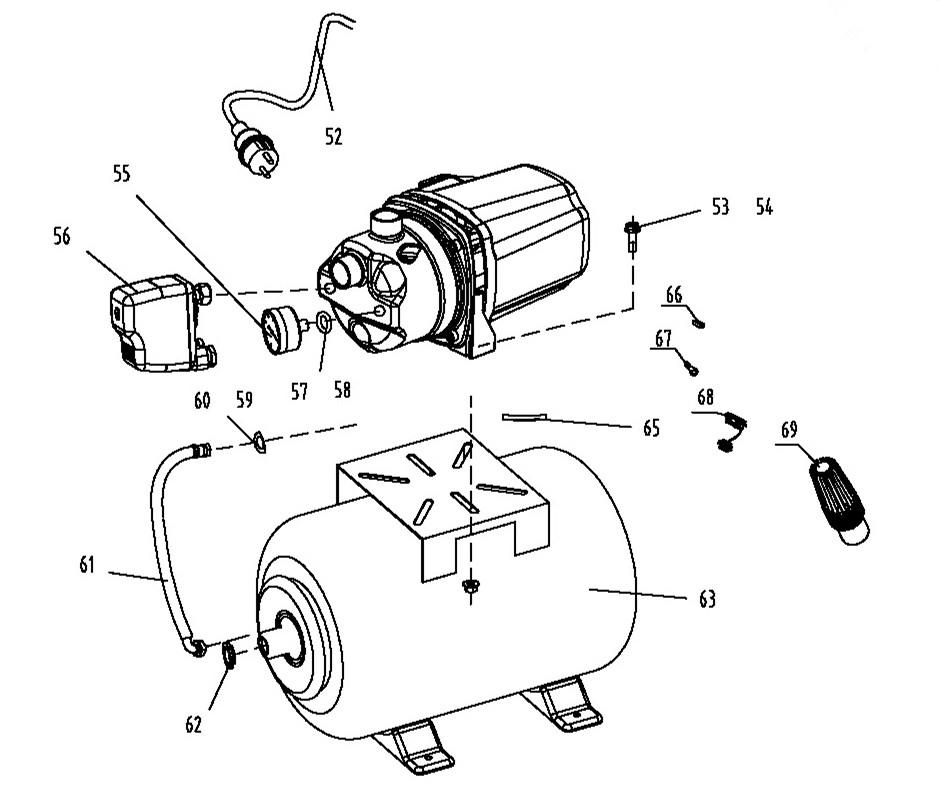

Parts Diagram

Pump

NOTE: some parts are listed and shown for illustration purposed only and are not available individually as replacement parts.

Parts List

| Part | Description | Quantity |

| 52 | Cord | 1 |

| 53 | Hex Bolt | 2 |

| 54 | Hex Nut | 2 |

| 55 | Pressure Meter | 1 |

| 56 | Switch | 1 |

| 57 | Bushing | 2 |

| 58 | 0-ring | 1 |

| 59 | Bushing | 1 |

| 60 | 0-ring | 1 |

| 61 | Tube | 1 |

| 62 | Sealed Latex | 1 |

| 63 | Compression Tank | 1 |

| 63A | Rubber Bladder | 1 |

| 65 | Sealed Latex | 1 |

| 66 | Connector pin | 4 |

| 67 | Cable retainer | 2 |

| 68 | Cable retainer | 2 |

| 69 | one-way valve | 1 |

Troubleshooting

| Problem | Cause | Solution |

| The pump won’t start | No PowerBlocked ImpellerPressure switch disconnectedThermal Protection cut out | Check connectionsFree the motor shaftCheck gaugeAllow pump to cool |

| The pump operates but it won’t discharge water | Inlet tube not submergedAir in suction pipeInlet screen cloggedLifting height exceeded | Submerge the inletCheck pipe and sealsClean screenReduce lifting height |

| Pump has low capacity | Inlet pipe is too smallLifting height exceededTank’s rubber bladderUnderinflated. | Increase pipe diameterClean screen frequentlyReduce lifting heightInflate to 18-19 PSI |

Replacement Parts

- For replacement parts and technical questions, please call Customer Service at 1-800-222-5381.

- Not all product components are available for replacement. The illustrations provided are a convenient reference to the location and position of parts in the assembly sequence.

- When ordering parts, the following will be required: Model Number, Serial Number/Lot Date Code, and Description.

- The distributor reserves the rights to make design changes and improvements to product lines and manuals without notice.

Limited Warranty

Northern Tool and Equipment Company, Inc. (“We” or “Us”) warrants to the original purchaser only (“You” or “Your”) that the PowerHorse product purchased will be free from material defects in both materials and workmanship, normal wear and tear excepted, for a period of one year from date of purchase. The foregoing warranty is valid only if the installation and use of the product is strictly in accordance with product instructions. There are no other warranties, express or implied, including the warranty of merchantability or fitness for a particular purpose. If the product does not comply with this limited warranty, Your sole and exclusive remedy is that We will, at our sole option and within a commercially reasonable time, either replace the product or product component without charge to You or refund the purchase price (less shipping). This limited warranty is not transferable.

Limitations on the WarrantyThis limited warranty does not cover: (a) normal wear and tear; (b) damage through abuse, neglect, misuse, or as a result of any accident or in any other manner; (c) damage from misapplication, overloading, or improper installation; (d) improper maintenance and repair; and (e) product alteration in any manner by anyone other than Us, with the sole exception of alterations made pursuant to product instructions and in a workmanlike manner.

Obligations of PurchaserYou must retain Your product purchase receipt to verify date of purchase and that You are the original purchaser. To make a warranty claim, contact Us at 1-800- 222-5381, identify the product by make and model number, and follow the claim instructions that will be provided. The product and the purchase receipt must be provided to Us in order to process Your warranty claim. Any returned product that is replaced or refunded by Us becomes our property. You will be responsible for return shipping costs or costs related to Your return visit to a retail store.

Remedy LimitsProduct replacement or a refund of the purchase price is Your sole remedy under this limited warranty or any other warranty related to the product. We shall not be liable for: service or labor charges or damage to Your property incurred in removing or replacing the product; any damages, including, without limitation, damages to tangible personal property or personal injury, related to Your improper use, installation, or maintenance of the product or product component; or any indirect, incidental or consequential damages of any kind for any reason.

Assumption of RiskYou acknowledge and agree that any use of the product for any purpose other than the specified use(s) stated in the product instructions is at Your own risk.

Governing LawThis limited warranty gives You specific legal rights, and You also may have other rights which vary from state to state. Some states do not allow limitations or exclusions on implied warranties or incidental or consequential damages, so the above limitations may not apply to You. This limited warranty is governed by the laws of the State of Minnesota, without regard to rules pertaining to conflicts of law. The state courts located in Dakota County, Minnesota shall have exclusive jurisdiction for any disputes relating to this warranty.

Distributed byNorthern Tool and Equipment Company, Inc.Burnsville, Minnesota 55306NorthernTool.com

Made in China

[xyz-ips snippet=”download-snippet”]