Powr-Flite PFS28 Phantom Automatic Scrubber User Manual

WARNING: OPERATOR MUST READ AND UNDERSTAND THIS MANUAL COMPLETELY BEFORE OPERATING THIS EQUIPMENT.

Save These Instructions

The customer must make sure that the operators have read or are aware of the contents of this manual and that they adhere strictly to the indications listed. The manufacturer does not accept any responsibility for damage caused to persons and/or property, or to the equipment itself if the conditions described below are not respected. This manual is an integral part of the machine; it must be carefully preserved for the lifetime of the machine, right up to decommissioning. Do not alter or remove the label affixed to the machine. This manual describes a battery powered floor cleaner and dryer. It has been designed for ease of use, manageability and safety. Maintenance has been simplified and reduced to a minimum in order to allow even untrained staff to carry necessary servicing operations.

THE PRINCIPLE CHARACTERISTICS ARE:

- Painted sheet steel bodywork formed to give maximum strength at minimum weight.

- Reinforced polyethylene chassis in an elegant and indestructible design.

- Polyethylene tanks resistant to battery chemicals and to the most widely diffused industrial solvents.

- Polyurethane coated wheels.

- Reduction motor for brushes with lifetime lubrication.

- Vacuum motor for liquids with dangerous parts and electrical contacts out of reach from operator’s hands.

- Ergonomic control panel with protected switches.

- Squeegee body with LYNATEX blades.

TECHNICAL SPECIFICATIONS

| PFS28 | ||

| Units | ||

| Productivity | sq.ft./hr/m2/hr | 27,986/2600 |

| Solution tank capacity | gallons/I | 21/80 |

| Recovery tank capacity | gallons/I | 21/80 |

| Cleaning path | in./mm | 28/700 |

| Squeegee width | in./mm | 40.5/1030 |

| Brush pressure | lbs./kg | 110-154/50-70 |

| Brush motor power | W/A | 375/15.5 (x2) |

| Vacuum motor power | W/A | 550/23 |

| Drive motor power | W/A | 200/8.5 |

| Voltage | V | 24 |

| Batteries | 2 x 12V | |

| Dimensions | in./mm | 58x31x43/1460x780x1100 |

| Weight (without batteries) | lbs./kg | 304/138 |

WARNING: The floor cleaner is intended for cleaning and washing level floors in closed spaces using appropriate detergents.

IMPORTANT SAFETY INSTRUCTIONS

All operators must read, understand and practice the following safety instructions. They will be repeated occasionally throughout this manual, and additional cautions may be added for specific cases.

- CAUTION: Operators must read and understand this manual completely before operating this equipment.

- CAUTION: Make sure key switch is in the “OFF” position before installing pad.

- CAUTION: Loose objects on the floor can become dangerous projectiles if struck by the high-speed pad. Remove them before operating this machine.

- CAUTION: Keep hands and feet away from revolving pad.

- CAUTION: Keep machine moving to prevent damage to finish or floor.

- CAUTION: Make sure key switch is turned “OFF” and battery connector is unplugged from machine before performing any maintenance procedures.

- CAUTION: Maintenance and repairs must be performed by authorized personnel.

- CAUTION: Battery acid can cause burns. When working on or around batteries, wear protective clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

- CAUTION: Do not operate this equipment in bare feet or with open-toed shoes or sandals.

- CAUTION: Charging batteries generate explosive gases.

- CAUTION: Make sure the charger has turned off before disconnecting it from the batteries. Charge batteries in a well-ventilated area with the tanks in the raised and locked position.

- CAUTION: Store or park this machine on a level surface only. Remove key from switch if machine is left unattended.

- CAUTION: Do not operate machine or charger in areas where flammable liquids or gases are present. Do not use or pick up flammable chemicals or liquids with this machine.

- CAUTION: Make sure all caution, warning an instructional decals are in place and legible. Replace damaged or missing labels.

- CAUTION: These machines are designed for level floor operations only. DO NOT OPERATE on ramps or inclines unless adequate personnel are available for assistance.

- CAUTION: Do not expose electrical components to water or other liquids. To clean machine wipe down with a damp cloth.

- CAUTION: Do not draw current from the batteries with makeshift connectors, clips or contacts.

- CAUTION: Park the cleaner on a flat and level floor.

WARNING:

DO NOT OPERATE MACHINE OR CHARGER IN AREAS WHERE FLAMMABLE LIQUIDS OR GASES ARE PRESENT.

DO NOT USE OR PICK UP FLAMMABLE CHEMICALS OR LIQUIDS WITH THIS MACHINE.

DO NOT SMOKE, LIGHT FLAMES OR MAKE SPARKS.

PHANTOM AUTOMATIC SCRUBBER

This manual refers to a battery powered automatic floor scrubber. Designed to be simple, easy to operate and safe, with maneuverability and automatic variable electronic drive. Routine maintenance has been simplified and reduced to the minimum to keep equipment on the job.

WARNING:

This manual serves to guarantee the correct use of the machine thus supporting the service which we offer the customer. You are advised to adhere strictly to the instructions contained in this manual since the manufacturer does not accept responsibility for any damage caused to persons or to property, or to the machine itself if it is not used in the way described here or if the safety and maintenance instructions are not followed. The instructions set out in this manual do not substitute the safety measures and technical specifications to be applied directly to the product for installation and operation, nor the safety regulations in force in the country where it is used or the rules of common sense. The installation or maintenance personnel must report any defects or deterioration which might compromise the safety of the machine.

WARNING

The personnel responsible for operating the machine must have specific professional training or must have experience of using machines of this type. In order to prevent damage to people or to property, we advise the customer to adequately instruct the operators on any risks related to the use of this machine. The operator must always make use of the protective measures prescribed by the laws of the country in which the machine is used as well as additional protection provided by the employer (safety shoes, overalls, safety glasses, etc.).

Personnel employed for the use or maintenance of the machine must be expert, knowledgeable and mature for the tasks described and must be reliable for interpreting correctly the contents of this manual and for guaranteeing safety and attention to detail in the inspections. The appliance is not to be used by children or persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction.

The responsibilities of the personnel authorized to use the machine are at the discretion of the customer. Maintenance personnel must have the specific characteristics ( maintenance technician) necessary for correctly interpreting diagrams and instructions.

The Manufacturer declines all responsibility for damage of any kind resulting from imprudent use by expert or inexpert personnel who have not operated the machine in accordance with this manual. The installation must be carried out in accordance with the laws in force in the country where it is installed; The Manufacturer is not responsible for equipment upstream of the cleaner.

Ensure that the main power switch is in the OFF (0) position and that the batteries are disconnected before carrying out any maintenance and/or filling the tanks with detergent and/ or changing the brushes. Maintenance procedures must be carried out by authorised personnel. Do not carry out any unsafe or temporary repairs or use non-original spare parts. Regularly check the wear and deterioration of the materials and, if necessary, call out your regular supplier.

Do not leave the cleaner unattended particularly if children are present. Refrain from smoking, lighting fires or provoking sparks. Do not use flammable liquids or chemicals with this cleaner. Ensure that the instruction manual and warnings are always on hand and are legible. Replace any torn or missing pages.

This machine must only be used on flat and level surfaces.

DO NOT USE THIS UNIT ON INCLINED SURFACESDo not operate the machine in bare feet, with sandals or any kind of open footwear. Do not wet electrical components with water or any other liquid. Dry the machine with a cloth.

The electrical parking brake must be activated in the startup operation of the unit using the lever M30. In order to move the machine without batteries, it is necessary to disarm manually the brake pulling the lever back.

ATTENTION: for safety reasons, verify that the parking brake is working (pull the lever) once the batteries are connected!!.

The electromagnetic brake is automatically activated every time the unit is switched off.

The machine generates a sound pressure level (noise) in an industrial environment (warehouse/ shop floor) which is 79 dBA. However, in other surroundings, this level may be exceeded in which case the customer must provide appropriate protection (ear defenders) as well as notices to promote their use and periodic hearing examinations.

NOTE: WHEN THE MACHINE IS NOT USED, IT MUST BE TAKEN IN A DRY ENVIRONMENT Batteries disposal.

Open the recovery tank disconnect the plug of the battery themselves. Remove the screws that hold the cable to the batteries and remove them one at a time. For the disposal of the batteries refer to a disposal center; also see the notes about the disposal at the end of this manual.

It’s very important to avoid the maximum complete discharge of the batteries in order to have a longer battery life. Avoid charging the batteries after a short time of use.

The operator must not wear clothing with wide sleeves, laces or belts; they must not approach the machine with bare or wet feet; they must not pull out the plug by pulling the cable; must not smoke if the environment or products used do not allow it.

For lifting and transporting use only specialized personnel (slingers, crane operators, etc.) with proper lifting gear which is suitable for the weight of the various components.

Transport (especially by road) must be carried out in the correct way and with the adequate means so as to protect the components (especially the electronic ones) from violent shocks, humidity, vibration, etc.; the machines are supplied with wheels and therefore need to be securely anchored before beginning transportation.

During movement, suspended loads made up of machine components or parts represent a collision, risk, it is the responsibility of the customer to highlight this danger.

On specific request, the Manufacturer will pack the machines appropriately but this does not eliminate the above safety notes.

We remind you that packing material (wood, nails, paper, cellophane, metal staples, adhesive tape, straps, ropes, etc.) may cause cuts or wounds and should be handled with care. These must be removed with appropriate tools and should not be left in the care of irresponsible people (e.g. Children); the same applies to the unpacking tools (scissors, hammers, pliers, knives, etc.) The area to be cleaned: The area to be cleaned should first be swept (manually or by machine) to remove loose dirt which may quickly clog up the vacuum system.

CAUTION: This machine is designed to work in closed industrial environments on level floors or on inclines no steeper than 2%. Do not use flammable chemicals and/or explosives with this machine. Do not use or pick up flammable chemicals or liquids with this machine.

Detergent tank: The detergent tank is positioned underneath the recover tank with the water filling cap M1 (page 8) easily accessible for easy refilling. Before filling the tank with correctly diluted detergent, empty the waste collection tank as described in the following paragraph; obviously this step is not required for the first time of filling. The capacity of the detergent tank is 21 gallons. Only use the quantities and dilution recommended by the detergent supplier and use only non foaming detergents.

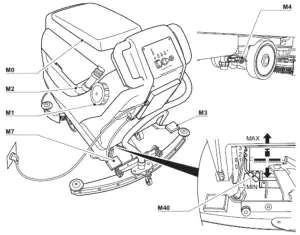

Waste tank: The waste tank should be emptied (preferably after each use) so as not to let the dirt settle; to do this, remove the cap covering the drain tube M2 (page 7) which is held in place by a retaining spring, and put in a position so that it drains. Or empty the tank and clean it with the help of the cap M0 (page 8). Always abide by the environmental regulations of the country where the machine is used.

Squeegee Assembly: The squeegee assembly serves to finish the drying operation and it is very important to ensure it is in the correct position: lower the squeegee to its working position by using the pedal to releasing the lever M3.

Do not leave any metallic tools or objects of any kind on the machine (see also IMPORTANT SAFETY INSTRUCTIONS).

Recharging the batteries: The operation must be done in an appropriate room with sufficient air recycling. Use the cable supplied to connect to the mains supply, normally 120 V 60 Hz; make sure that the supply voltage is the same as indicated on the battery charger itself. The charger will begin to charge the batteries.

Batteries : Check the electrolyte level and top up with distilled water if drops below the level of the battery elements. Keep the batteries clean and dry with anti-static cloths. Recharging must be carried out with the cell plugs removed and the cover of the machine opened so as to allow the gases generated to escape. In confined spaces these gases can be explosive, so recharging should be done in a well ventilated area.

Solution Valve: Use lever M4 (page 8) to regulate the dosage of detergent according to the amount of dirt and the speed of the machine, this will come with experience; at this point the floor cleaner will simultaneously clean and dry the floor:

Splash Guard: To replace the splash guard: Release the latch on the right side of the brush housing. Remove the screw at the opposite end of the retainer strip. Remove the retainer strip from the splash guard. Install the retainer strip in the same groove in the new splash guard. Reverse the procedure to install the splash guard.

Brush: The brush must be kept in working order; to remove a worn brush proceed as follows Turn off the machine (key switch in 0 position) and lift the brush with the pedal M7 (page 8); Unhook the brush by rotating it manually and dropping it onto the floor. Replace the brush with the new one leaving it one the floor under the unit. Turn on the machine again as described in the previous paragraph, put the speed potentiometer in the zero position. Operate the lever M8 (page 10) to turn ON the brush motor. Release the pedal M7 (page 8). If the brush isn’t hooked up immediately you have to make small side movements with the unit until the brush is hooked up.

WARNING: the use of brushes and non original spare parts can be dangerous. IN ANY CASE FOR YOUR SAFETY AFTER THE ROTATION OF THE BRUSH BE CAREFUL NOT TO COME IN TOUCH WITH MOVING PARTS OR ROTATION.

The machine is supplied with a pad driver and a red pad.The brushes pressure can be adjusted using the lever M40 (page 8). From 50 to 70Kg max;

Turn the key switch to position ON (I). In this position the machine can already move backward and forward as described below. Next press![]() button (control panel) then button

button (control panel) then button ![]() (brush). At this point the water dosage and vacuum will start automatically. If desired, they can be switched off individually

(brush). At this point the water dosage and vacuum will start automatically. If desired, they can be switched off individually ![]() with (water) and

with (water) and ![]() (vacuum ) buttons.

(vacuum ) buttons.

Pull lever M8, (page 10) the machine will go forward, keep the button![]() (forward/reverse) pressed and the machine will go backward.Release M8 (page 10) to stop the machine.Regulate the forward speed with potentiometer

(forward/reverse) pressed and the machine will go backward.Release M8 (page 10) to stop the machine.Regulate the forward speed with potentiometer![]()

The charge level of the batteries is represented by the indicator![]() When indicator

When indicator ![]() is on, the water recovery tank is full.When this indicator is lighted, the vacuum and the solution are turned OFF. The recovery tank must be emptied and the indicator reset by turning the main panel power control switch or thekey switch OFF and then back ON.

is on, the water recovery tank is full.When this indicator is lighted, the vacuum and the solution are turned OFF. The recovery tank must be emptied and the indicator reset by turning the main panel power control switch or thekey switch OFF and then back ON.

Particularly dirty floors: Certain floors or environments require particular attention or even a second pass with the cleaner

WARNING: This operation must be performed using protective gloves to protect yourself from contact with dangerous solutions.

Squeegee Assembly: Inspect and clean the squeegee assembly weekly and make sure to restore it to its working condition. If the drying action is not perfect after cleaning the squeegee assembly, remove and replace any worn rubber blades.

To replace the squeegee blades proceed as follows: drain the water from the dirty water tank, remove the squeegee hose from the dirty water tank, pull the two pins to release the squeegee assembly from the unit. Remove the wing nuts holding the squeegee retaining strap and remove the squeegee blades. Install new squeegee blades in the reverse order.

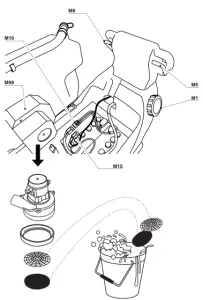

Recovery tank: weekly clean it as follows: switch off the machine, switch off the voltage, open the dirty water tank. Remove the suction motor cover M99 (page 9) . Then remove the suction motor: the filter and the net will be cleaned underneath. Drain the dirty water from the M2 (page 7) pipe. Remove the dirt that has settled in the tank. To do this, open the cap M0 (page 7) to have visibility inside the tank.

Fault diagnosis

WARNING – Before performing maintenance or making adjustments, switch off the machine and unplug from the batteries. The following simple checks may be performed by the operator.

| Trouble | Possible Cause | Possible Solution |

| The machine does not start up | Low battery Main fuse blown | Ensure battery is charged Replace fuse’ |

| The machine does not move | Defective handle switch

Blown fuse Speed control know set to low |

ChecWReplace handle switch Replace fuse

Increase speed adjustment |

| The brush does not rotate | Blown fuse | Replace fuse |

| The vacuum does not work | Blown fuse

Defective vacuum switch Recovery tank indicator is lighted. |

Replace fuse

ChecWreplace switch Reset the indicator by turning the Main Panel Power Control Switch of the Key Switch OFF and then back ON. |

| The squeegee does not recovery completely | Vacuum switched OFF

Vacuum hose blocked Recovery tank lid not sealed Recovery tank full Worn/improperly adjusted squeegee blades |

Turn ON vacuum

Clear blockages Seat tank lid Empty recovery tank Replace/adjust squeegee blades |

| No solution on the brushes | Solution tank empty

Water switch turned OFF Solution Valve closed Solution filter clogged Solenoid valve defective |

Fill solution tank

Turn water switch ON Open solution valve Clean filter Replace valve |

| Insufficient Cleaning | Incorrect brush selection Incorrect detergent selection Worn brushes | Select correct brush

Select correct detergent Replace brush |

If the fuse blows several times, the machine should be checked by an authorized Service Agent.

Warranty

For warranty information go to www.Powr-Flite.com

A Tacony Company3101 Wichita CourtFort Worth, TX 76140-17551-800-880-2913Fax: 1-817-551-0719

References

[xyz-ips snippet=”download-snippet”]