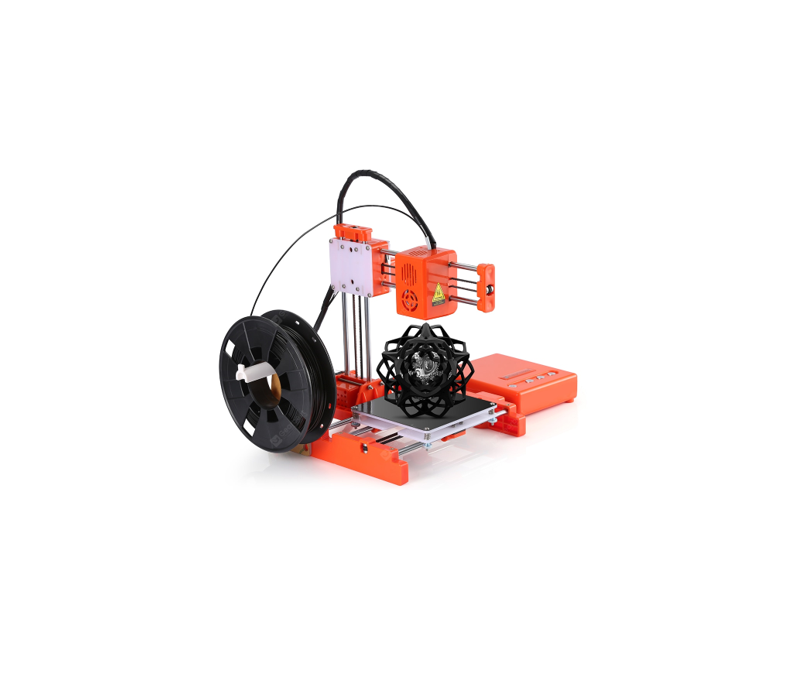

X1 Printer FAQ Manual

Problem 1: 3D Printer not print |

||

|

Probable Cause |

solution |

picture |

|

1. gcode file not correct |

3D printer can only print gcode file, the file name cannot have special symbols, only numbers or letters |

|

|

2. format the TF card |

format the TF card to FAT |

|

|

3. If the nozzle is not heated or the temperature is not measured, the feeding light flash all the time |

check the cable connectors, or replace the Nozzle |

|

|

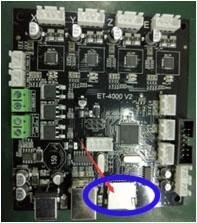

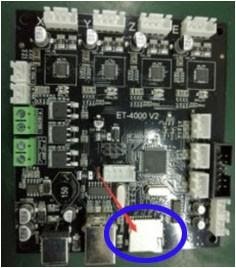

4. The card slot on the mainboard is broken |

replace motherboard |

|

Problem 2: without filament silk come out from nozzle |

||

|

Probable Cause |

solution |

picture |

|

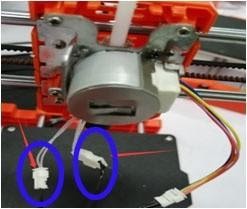

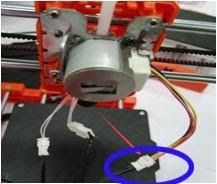

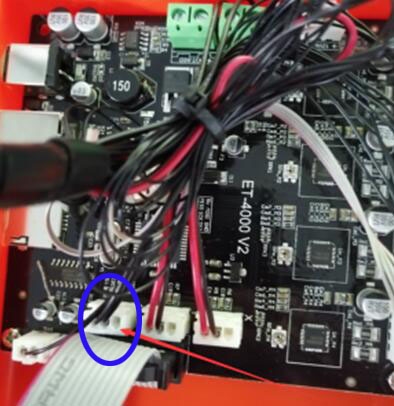

1. The E motor cable is not connected properly |

check the cable connector |

|

|

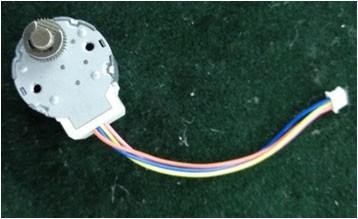

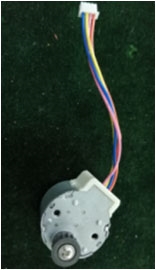

2. The E motor damaged |

replace the Extruder motor |

|

|

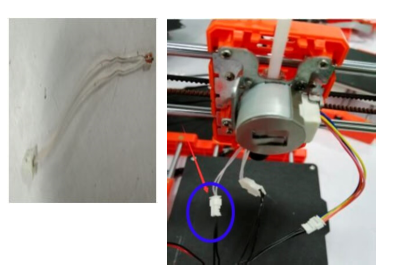

3. The wire of thermistor falls off or burns out |

check the cable connector, or replace the Nozzle |

|

|

4. The heating ring line falls off, or damaged |

check the cable connector, or replace the Nozzle |

|

Problem 3: Nozzle spit out filament is not vertical |

||

|

Probable Cause |

solution |

picture |

|

1. nozzle no good |

replace nozzle |

|

|

2. Tt is not clean inside the Teflon tube |

replace Teflon tube |

|

|

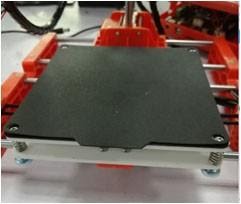

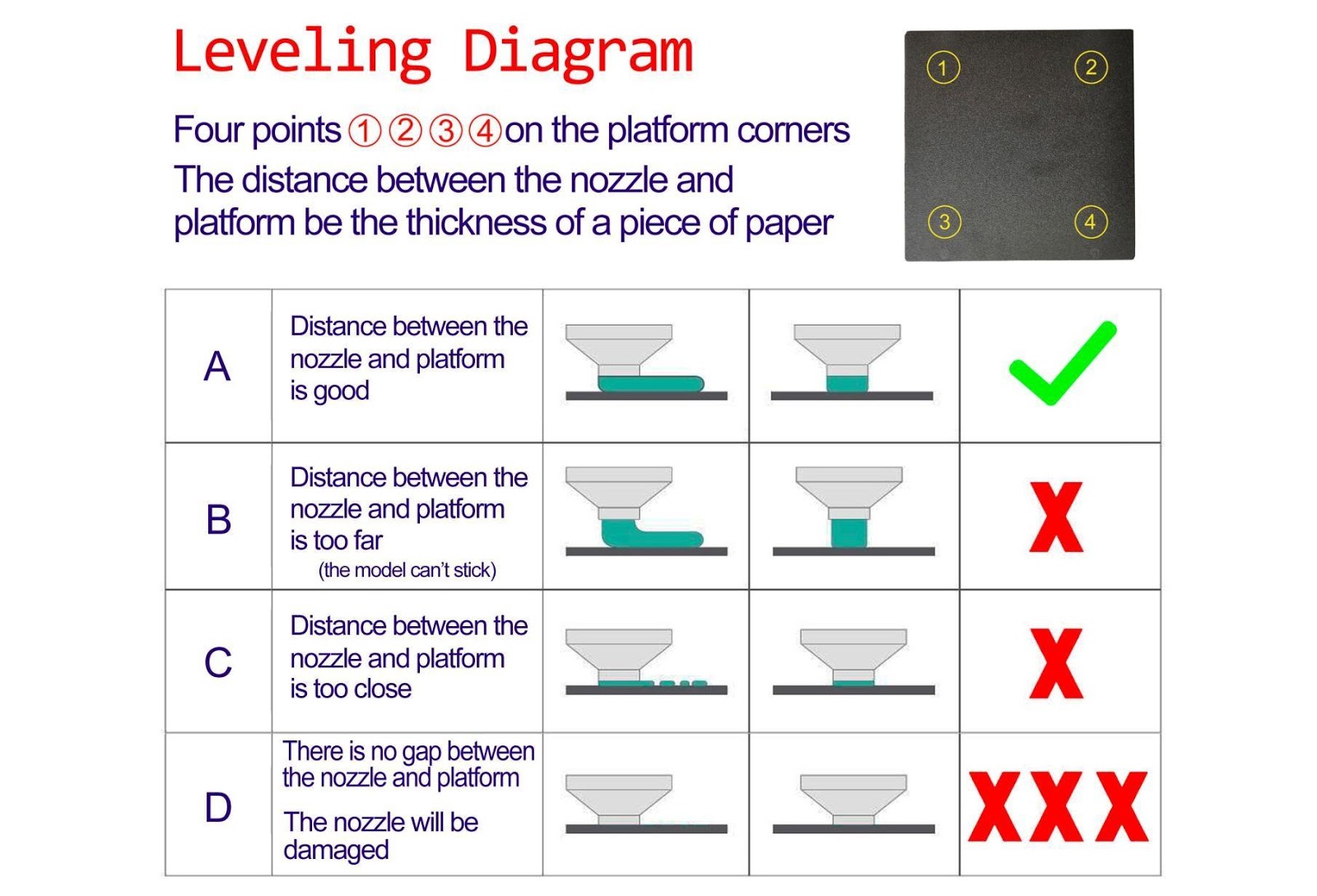

3. The platform is not leveled properly. The nozzle and platform collide during printing, and the nozzle is damaged |

Prevent the nozzle from scraping the platform before print |

|

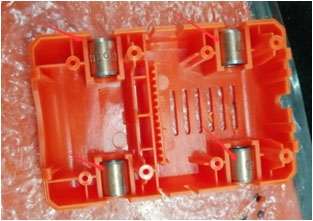

Problem 4: X Axis not work, or print shift |

||

|

Probable Cause |

solution |

picture |

|

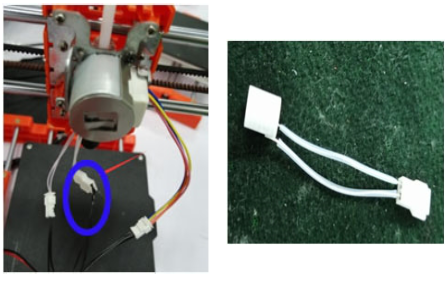

1. X Axis cable connect loose |

check the cable connector |

|

|

2. X motor dead |

replace the Y motor |

|

|

3. X limit switch wire connect loose |

open the control box to check this it loose or not |

|

|

4. Belt too loose may cause print shift, Belt too tight may cause hard to move |

Adjust belt tightness 1),loose 4 screws, just loose2), Use a tool to push the x-axis, and adjust the belt tightness3), fix the top four screws tightly again |

|

|

5. X axle sleeve too tight |

replace axle sleeve or Add some lubricating oil. |

|

Problem 5: Y Axis not work, or print shift |

||

|

Probable Cause |

solution |

picture |

|

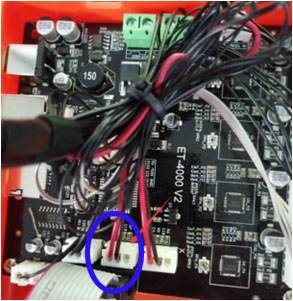

1. Y Axis cable connect loose |

check the cable connector |

|

|

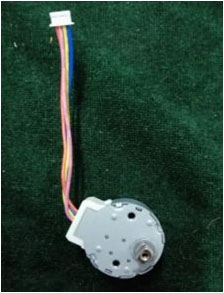

2. Y motor dead |

replace the Y motor |

|

|

3. Y limit switch wire connect loose |

open the control box to check this it loose or not |

|

|

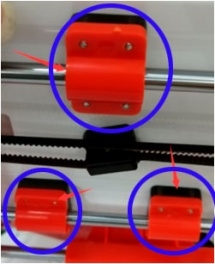

4. Belt too loose may cause print shift, Belt too tight may cause hard to move |

Adjust belt tightness |

|

|

5. Y axle sleeve too tight |

replace axle sleeve or Add some lubricating oil. |

|

Problem 6: Z Axis not work |

||

|

Probable Cause |

solution |

picture |

|

1. the power connector may loose |

check the connector |

|

|

2. Z motor dead |

replace Z motor |

|

|

3. Z limit switch wire connect loose |

open the control box to check this it loose or not |

|

|

4. Z Belt too loose |

Adjust belt tightness 1),loose 4 screws, just loose 2), Use a tool to push the x-axis, and adjust the belt tightness 3), fix the top four screws tightly again |

|

Problem 7: Printer not work, no function |

||

|

Probable Cause |

solution |

picture |

|

1. check if the power adaptor is good or not |

check if the light is on |

|

|

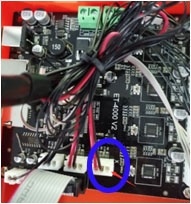

2. firmware problem |

update firmware |

|

|

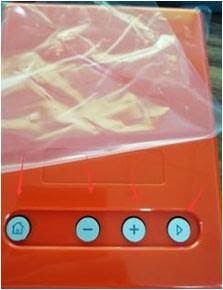

3. The button board is damaged, no response to the button |

replace the control board |

|

|

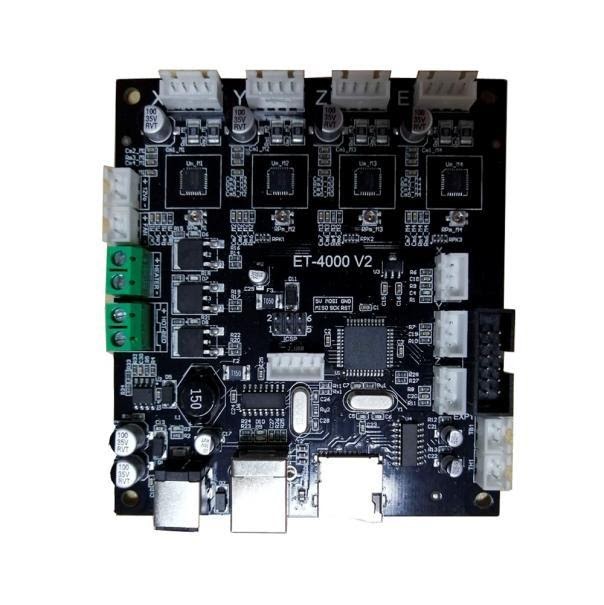

4. The mainboard is burnt out |

replace the mainboard |

|

Common FAQ for 3D Printer

1). Why is the printing model not adhesive to the printing bed.

A1: The nozzle is too far away from the bed, the proper distance between the nozzle and bed is the thickness of a piece of A4 paper .

2). Why the filament do not come out from the nozzle.

A1: Check the filament extruder gear rotates or not. and check if filament feeder Extruder motor is connected well or not. A2, Check the temperature of sliced gcode. Printing nozzle temperature of PLA material range s from 180-230℃.

A3, Check if the nozzle is blocked. Do feeding, use your hand help to push the filament gently, if there is no filament come out , then need to clean the nozzle or replace it.

A4, Check if nozzle is too close to platform, if so, the filament can not come out, then need do right leveling again.

3). The problem of print model shift X or Y direction.

A1, The model did not slice properly, need to re-slice or change the model position to generate new Gcode file. A2, The model file problem, If you print ather models has no problem, Perhaps the original file problem.

4). Why the printing effect is low.

A1, There is a lot of filament piled up on the model surface

A1.1, Nozzle temperature is too high, filament melt too fast and caused overflowing.

A1.2, The filament flow is too large, there is filament flow setting in slice software, change the default value 100% to be 80%.

A1.3, Filament diameter setting problem, it’s in slice software, the default settings are different, there are both 1.75mm and 3mm filament on the market, for 1.75mm, the diameter should be 1.75, but for 3mm, the diameter should be 2.85 or 2.95.

A2, Poor surface after removing the support for FDM technology, The support density should be as lower as possible, 10% is proper, it’s easy to remove.

A3, The filament quality is poor

X1 Printer FAQ Manual – X1 Printer FAQ Manual –

[xyz-ips snippet=”download-snippet”]