INSTRUCTIONS FOR USEPro-Ject 2 Xperience Primary

2

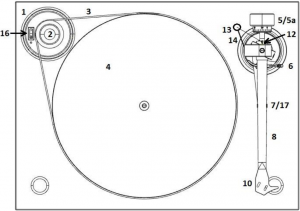

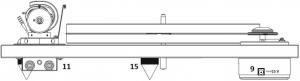

Controls, features and connections

1 Motor unit2 Stepped drive pulley3 Drive belt * 3a Hook *4 Platter & felt mat *5 Tonearm counterweight * 5a Downforce scale6 Tonearm lift lever7/17 Tonearm rest and removable transport lock8 Tonearm tube 8a Tonearm base9 Power supply socket10 Headshell with finger lift11 Phono output sockets and earth connection12 Anti-skating stub with anti-skating weight adjustment scale13 Anti-skating weight *14 Anti-skating weight support hoop15 Adjustable tip-toe feet anti-scratch cups *16 Power switchConnection cable (not shown) *Universal power supply (not shown) *Single adapter (not shown) *18 Turntable lid (not shown, only included in clear-acryl colour option)

Dear music lover,

Thank you for purchasing a Pro-Ject Audio System’s record player.

In order to achieve maximum performance and reliability, please study these instructions carefully.

![]() Warning of a hazard for the user, the unit or possible misuse

Warning of a hazard for the user, the unit or possible misuse

Important notice

The following instructions for adjusting the cartridge are provided in case the cartridge is replaced by a different model at a later date.During assembling and adjustment small parts could be lost if they are not carefully placed in a suitable receptacle. Before starting assembly make yourself acquainted with the parts listed above which are correspondingly numbered in the technical drawings above. Separately packed items are marked with an asterisk *.

3

Safety instructions

The power supply is used to connect and disconnect the unit from the mains. Make sure that the plug is easily accessible at all times. Hold the plug when unplugging the power cord. Never handle the power cord while your hands are wet or damp.

![]()

![]()

![]()

Avoid letting liquids enter the device. Never place any item containing liquid, like a flower vase, on or near the device. Never spill any liquid on the device. Never place any naked flame sources, like lighted candles, on or near the device. The product shall not be used in damp or wet locations, next to a bathtub, sink, swimming pool or any other similar conditions.Keep plastic bags away from children to prevent any risk of suffocation.

Set-up

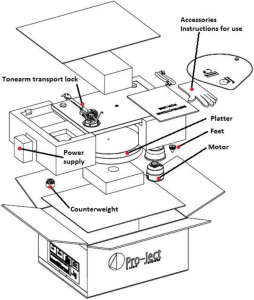

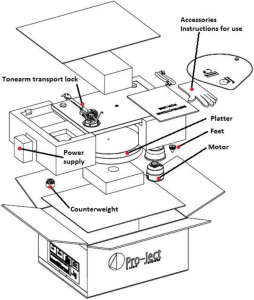

The deck is supplied partially disassembled and carefully packed for a safe transport. Remove all parts from the transport packaging carefully.

Screw the three tip-toe feet (15) onto the threaded bolts located on the underside of the plinth Make sure the surface you wish to use the turntable on is levelled (use a spirit level) before placing the turntable on it. After putting the motor unit in the place, carefully insert the platter axle into the bearing housing. Put felt mat on the platter and level the plinth using the spirit level and the adjustable feet (15).

Fit the drive belt (3) around the platter (4) and the smaller diameter part of the motor pulley (2). Avoid getting sweat or grease on the belt as these will deteriorate the performance and reduce the belt’s lifespan. Use absorbent kitchen paper to remove any oil or grease from the outer edge of the hub and the belt. Remove the transport lock (17) from the tonearm. Store it in the original packaging so they are available for any future transportation.

Cartridge downforce adjustment

The supplied counterweight (5) is suitable for cartridges weighing between 6 – 10g (counterweight no. 16). Alternative counterweights for cartridges weighing between 11 – 15g (counterweight no. 3), 8 – 11g (counterweight no. 2) or 5 – 8g (counterweight no. 9) are available as accessory parts. Adjust the downforce before installing the anti-skating weight.Following adjustments have to be done very carefully. Remove cartridge protection cap. Push and turn the counterweight (5) carefully on the rear end of the tonearm tube (8), so that the downforce scale (5a) shows towards the front of the player. Lower the arm lift and position the cartridge in the space between arm rest and platter. Rotate the counterweight (5) until the arm tube is balanced. The arm should return to the balanced position if it is moved up or down.Once the arm is balanced correctly return it to the rest. Hold the counterweight (5) without moving it and gently revolve the downforce scale ring (5a) until the zero is in line with the anti-skating stub (12). Check whether the arm still balances out.Rotate the counterweight counter clockwise (seen from the front) to adjust the downforce according to the cartridge manufacturer’s recommendations. One mark on the scale represents 1 mN (= 0,1g / 0,1 Pond) of downforce.

Adjusting the vertical tracking angle (vta)

![]()

![]()

Put a record and the record weight on the platter. When the needle is lowered into the record groove and the tonearm is not resting on the lift arm, the tube of the tonearm should be parallel to the surface of the record.If it is not, loosen both hexagon screws in the tonearm base just enough to allow vertical movement of the arm pillar without force and slide the arm up or down until it is parallel.

Retighten the hexagon screws without applying excessive force (which would deform the arm pillar) finger tight is quite sufficient.

4

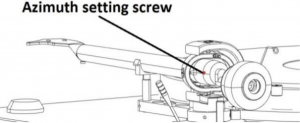

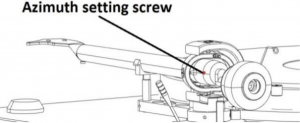

Adjusting the azimuth

The cartridge needle must be vertical in the record groove in order to trace the groove wall modulations correctly.A small screw at the bearing end of the arm allows incorrect azimuth to be corrected.Slacken off the screw just enough to be able to revolve the arm tube without applying force. Note! Do not remove this screw completely!With the aid of a good magnifying glass adjust the needle until it is vertical in the groove (i.e. perpendicular to the record’s surface). Ideally this should correspond to the top surface of the cartridge body being parallel to the record surface.When the needle is vertical, retighten the screw carefully.

Under no circumstances should the arm tube be adjusted with the needle still in the record groove! Irreparable damage may be caused to the cantilever suspension! The arm must be lifted to make each adjustment and lowered afterwards to check it.

Anti-skating force adjustment

The anti-skating force must be adjusted corresponding to the downforce as follows:

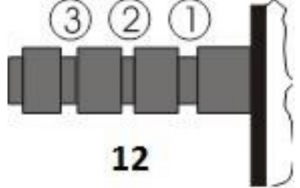

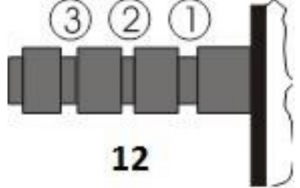

Downforce Groove in the stub (12)10 – 14mN 1st from bearing rings15 – 19mN 2nd ” ” ”20mN and bigger 3rd ” ” “

Hang the loop of the thread of the anti-skating weight into the groove of the anti-skating stub (12) corresponding to the downforce applied to your cartridge and hang the thread in the groove of the wire support (14).

Connection to the amplifier

The record player has gold plated female RCA phono sockets (11) so you can substitute the supplied interconnect cables with higher quality cables such as the Pro-Ject Connect it interconnect cables for connection to the amplifier if you wish. Use the Phono input (sometimes labelled gram, disc or RIAA) on your amplifier. Make sure that the phono input offers correct matching and amplification for the type of cartridge used. Line inputs (like CD, Tuner, Tape or Video) are not suitable.Take care about connecting the left and right channel correctly. The right channel is usually marked red, the left channel black or white. Check the manual of your amplifier for relevant information. An earthing wire may be connected to the screw terminal between the sockets if you encounter humming problems.If your amplifier does not have an input suitable for phono cartridges, a separate phono amplifier stage for MM or MC cartridges is required. It has to be connected between record player and a free line level input of the amplifier.For detailed product information regarding Pro-Ject Audio Systems interconnect cables and phono amplifiers please visit our website: www.project-audio.com

Mains power connection

A universal power supply with 3 exchangeable sockets adapters suitable for all countries is supplied. Select the correct adapter for your country and insert the adapter to the exchangeable part of the power supply.Connect the low voltage plug from the power supply to the socket (9) on the rear side of the record player before connecting the power supply to the mains.

Switching on and off

Pressing the power switch (16) alternately starts and stops the motor.

5

Changing replay speed

Use the accessory tool provided (3a), hook the belt (3) over the larger diameter part of the motor pulley (2). To revert to 33 r.p.m. repeat the proceedings using the smaller step on the pulley.

Maintenance and cleaning

Your record player requires little or no regular maintenance. Remove dust with a slightly moistened antistatic cloth. Never use a dry cloth because this will create static electricity which attract more dust! Antistatic cleaning fluids are available at specialist stores but must be applied sparingly to avoid damage to rubber parts. It is recommended to fit the needle cover before cleaning or maintenance is carried out to avoid damage. If the player is not used over a long period of time the drive belt can be removed to prevent unequal stretching.

Always disconnect the record player from the mains power supply as a precaution before maintenance!

Mounting and connecting the cartridge

All cartridges with half inch mounting holes can be mounted. Leave the needle’s protection cover on, fit the cartridge to the headshell by using the supplied screws by passing one screw through each slot in the headshell (10). Do not tighten the nuts yet.

Connect the tonearm wires with the cartridge pins as follows:

white left channel positive (L+)red right channel positive (R+)green right channel return (R-)blue left channel return (L-)

The full sound quality of the record player can only be achieved if the cartridge is adjusted correctly. Particular tools like the Pro-Ject Audio Systems alignment tool are required to accomplish this job properly. If you are not well acquainted with the adjustment of cartridges, please call for the willing help of your Pro-Ject Audio Systems dealer.

Please note: adjusting a cartridge and tonearm calls for the greatest care in order to avoid damaging the cartridge or tonearm bearings. Ask your local dealer for help if you are unsure in any of the necessary steps and precautions which must be taken.

Technical specifications PRO-JECT 2 Xperience Primary/ Pro-Ject 9cc tonearm

Nominal speeds 33/45 r.p.m.Speed variance ±0,6 %Wow and flutter ±0,13 %Signal to noise -65dBEffective tonearm mass 15gEffective tonearm length 9” (230mm)Overhang 18mmPower consumption 5W max/ >0,5W standby modeOutboard power supply 15V DC / 800m A, 90-264V AC, 47-63HzDimensions (W x H x D) 465 x 130 x 340mmWeight 6,5 kg

6

Potential incorrect use and fault conditions

Pro-Ject Audio Systems turntables are manufactured to the highest standards and undergo strict quality controls before leaving the factory. Faults that may possibly occur are not necessarily due to material or production faults but can sometimes be caused by incorrect use or unfortunate circumstances. Therefore the following list of common fault symptoms is included.

The platter does not turn although the unit is switched on:

- The unit is not connected to the mains power supply.

- No mains at the socket.

- Drive belt is not fitted or has slipped off.

No signal through one or other channel or both channels:

- No signal contact from the cartridge to the internal tonearm wiring or from that to the arm lead or from that to the phono box or between that and the amplifier. This could be due to a faulty plug, broken wire or solder joint or simply loose plug/socket connection.

- Phono input not selected at amplifier.

- Amplifier not switched on.

- Amplifier or speakers defective or muted.

- No connection to the loudspeakers.

Strong hum on phono input:

- No earth connection from cartridge or arm or arm cable to amplifier, or earth loop.

Distorted or inconsistent sound from one or both channels:

- Record player is connected to wrong input of amplifier, or MM/MC switch incorrectly set.

- Needle or cantilever damaged.

- Wrong r.p.m., drive belt overstretched or dirty, platter bearing without oil, dirty or damaged.

Service

Should you encounter a problem which you are not able to alleviate or identify despite the above information, please contact your dealer for further advice. Only if the problem cannot be solved there the unit should be sent to the responsible distributor in your country.Guarantee repairs will be accepted only if the unit is returned correctly packed in the original package. Therefore we strongly recommend keeping the original packaging.Never return a record player without making sure that it is safely disassembled and correctly packed in the original packaging according to the diagrams on the last page of this user guide. Please remove the following parts from the turntable and pack them separately: power supply socket (9), counterweight (5), anti-skating weight (13) platter (4) and belt (3). Mount the cartridge protection cap. Insert the transport lock for the tonearm (17).

Warranty

The manufacturer accepts no responsibility for damage caused by not adhering to these instructions for use and/or by transportation without the original packaging. Modification or change to any part of the product by unauthorized persons releases the manufacturer from any liability over and above the lawful rights of the customer.

Pro-Ject Audio Systems is a Registered Trademark of H. Lichtenegger.This guide was produced by: Pro-Ject Audio Systems Copyright © 2015. All rights reserved.

The information was correct at the time of going to press. The manufacturer reserves the right to make changes to the technical specification without prior notice as deemed necessary to uphold the ongoing process of technical development.

7

8

References

[xyz-ips snippet=”download-snippet”]