USER MANUAL

Rankam Turkey Fryer SetAssembly, Use and CareModel: TF2246501-RG-00

- To installer or person assembling this appliance: Leave this manual with this appliance for future reference.

- This instruction manual contains important information necessary for the proper assembly and safe use of the appliance.

- Read and follow all warnings and instructions before assembling and using the appliance.

- Follow all warnings and instructions when using the appliance.

- Keep this manual for further reference.

SAFETY SYMBOLS:

The symbols and boxes shown below explain what each heading means. Read and follow all of the messages found throughout the manual.DANGER: Indicates an imminent hazardous situation which if not avoided will result in death or serious injury.WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury.

DANGER

If you smell gas:

- Shut off gas to the appliance.

- Extinguish any open flame.

- If odor continues, keep away from the appliance and immediately call your gas supplier or fire department. Failure to follow these instructions could result in fire or explosion which could cause property damage, personal injury or death.

- Never operate this appliance unattended.

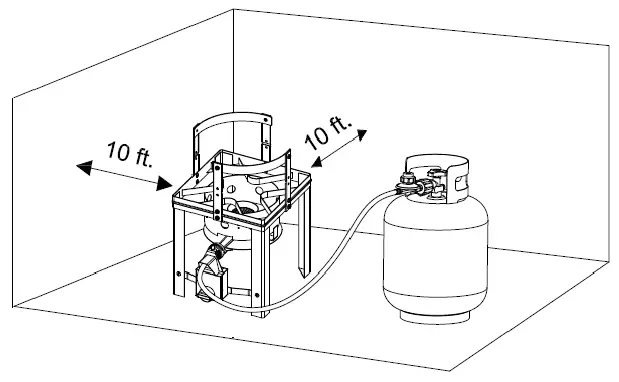

- Never operate this appliance within 10 ft (3.0 m) of any structure, combustible material or other gas cylinder.

- Never operate this appliance within 25 ft (7.5 m) of any flammable liquid.

- Do not fill cooking vessel beyond maximum fill-line.

- Never allow oil or grease to get hotter than 400°F or 200°C. If the temperature exceeds 400°F (200°C) or if oil begins to smoke, immediately turn the burner or gas supply OFF.

- Heated liquids remain at scalding temperatures long after the cooking process. Never touch cooking appliance until liquids have cooled to 115°F (45 °C) or less.

- If a fire should occur, keep away from the appliance and immediately call your fire department. Do not attempt to extinguish an oil or grease fire with water.

Failure to follow these instructions could result in fire or explosion which could cause property damage, personal injury or death.

WARNING

Combustion by-products when using this product contain chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

This Appliance is not intended for commercial use.

- Never leave the appliance unattended. Keep children and pets away from the appliance at all times.

- The use of alcohol, prescription or non-prescription drugs may impair the consumer’s ability to properly assemble or safely operate the appliance.

- This appliance is for OUTDOOR USE ONLY. DO NOT use in building, garage or any other enclosed area.

- This appliance is not intended to be installed in or on a boat. This appliance is not intended to be installed in or on recreational vehicles.

- This appliance is not intended for and should never be used as a heater.

- This appliance must not intended or and should never be used as a heater.

- When cooking, the fryer / boiler must be on a level, stable noncombustible surface in an area clear of combustible material. Asphalt surface (blacktop) may not be acceptable for this purpose.

- Keep the fuel supply hose away from any heated surface.

- When cooking with oil or grease, the thermometer provided MUST be used. Follow instructions in this manual for proper installation and use of the thermometer. If the thermometer supplied with this fryer has been lost or damaged. A replacement thermometer must be one specified by the appliance manufacturer.

- If the temperature exceeds 400° F (200°C) or if oil begins to smoke, immediately turn the burner or gas supply OFF and wait for the temperature to decrease to less than 350°F (176°C) before relighting burner according to the manufacturer’s instructions. If there is a lid (cover), do not remove the lid.

- When cooking with oil or grease, have a type BC or ABC fire extinguisher readily available. In the event of an oil or grease fire do not attempt to extinguish with water. Immediately call the fire department. A Type BC or ABC fire extinguisher may, in some circumstances contain the fire.

- Never overfill the cooking vessel with oil, grease or water. Follow instructions in this manual for establishing proper oil, grease or water levels.

- . Introduction of water or ice from any source into the oil/grease may cause overflow and severe burns from hot oil and water splatter. When frying with oil/grease, all food products MUST be completely thawed and towel dried before being immersed in the fryer.

- Do not place empty cooking vessel on the appliance while in operation. Use caution when placing anything in cooking vessel while the appliance is in operation.

- In the event of rain, snow, hail, sleet or other forms of precipitation while cooking with oil or grease, cover the cooking vessel immediately and turn off appliance burners and gas supply. Do not attempt to move the appliance or cooking vessel.

- Do not move the appliance when in use. Allow the cooking vessel to cool to 115°F (45°C) before moving or storing.

- Do not leave the appliance unattended, keep children and pets away from the appliance at all times.

Installation Safety Precautions.

- Use appliance only with LP (propane) gas and the regulator/ valve assembly supplied.

- Installation must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, Storage and Handling of Liquefied Petroleum Gases, ANSI/NFPA 58; or Natural Gas and Propane Installation Code, CSA B1 49.1

- This appliance shall be used only outdoors, and shall not be used in a building, garage or any other enclosed area.

- Use appliance at least 10 ft. from any wall or surface. Maintain 10 ft clearance to objects that can catch fire or source of ignition such as pilot lights on water heaters, live electrical appliances, etc. Never use under balconies made of wood or ANY overhead construction.

- Apartment Dwellers: Check with management to learn the requirements and fire codes for using an LP Gas appliance at an apartment. If allowed use outside at an apartment. If allowed, use outside on the ground floor with a ten(10) foot clearance form walls or rails.

- Before opening LP tank valve, check the coupling nut for tightness. When appliance is not in use , turn off control knob and LP tank valve.

- Never move appliance while in operation or still hot.

- If you notice grease or other hot material dripping from appliance onto valve, hose or regulator, turn off gas supply at once. Determine the cause, correct, clean and inspect valve, hose and regulator before continuing. Perform a leak test.

- The regulator may make a humming or whistling noise during operation. This will not affect safety or use of appliance.

- Clean and inspect the hose before each use of the appliance. If there is evidence of abrasion, wear, cuts or leaks, the hose must be replaced prior to the appliance being put into operation.

- Never use a cooking vessel larger than 30 qts. Diameter greater than 11-3/4 inches and taller than 15-1/2 inches.

- Never fill pot above upper fill line. Oil can splatter causing staining or discoloration to ground surface.

- Never place empty cooking vessel on the appliance while in operation. Use caution when placing anything in the cooking vessel while the appliance is in operation.

- Never move the appliance when in use. Allow the cooking vessel to cool before moving or storing.

- Never leave the appliance unattended. Keep children and pet away from the appliance at all times.

Keep the fuel supply hose away from any heated surface

- This appliance is not intended for and should never be used as a heater.

- Never operate appliance with LP tanks out of correct position specified in assembly instructions.

- Always close LP tank valve and remove coupling nut before moving LP tank from specified operating position.

- Appliance shall not be used for commercial cooking.

- This appliance will be hot during and after use. Use insulated oven mitts or gloves for protection from hot surfaces or splatter from cooking liquids.

- Avoid bumping of or impact with the appliance to prevent spillage or splashing of hot cooking liquid.

- Never drop food or accessories into hot cooking liquid. Lower food and accessories slowly into the cooking liquid in order to prevent splashing or overflow. When removing food from the appliance care should be taken to avoid burns from hot cooking liquids.

DANGER

- The safety relief valve on the LP tank could activate releasing gas and cause an intense fire with risk of death or serious injury. Therefore, follow instructions bulleted below exactly.(a) Do not store a spare LP-gas cylinder under or near this appliance.(b) Never fill the cylinder beyond 80 percent full; and(c) If the instructions in (a) and (b) are not followed exactly, a fire causing death or serious injury may occur.

- If you see, smell, or hear escaping gas, immediately get away from the LP tank/appliance and call your fire department.

- All spare LP tanks must have safety caps installed on the LP tank outlet.

LP Tank Removal, Transport and Storage

- Turn OFF all control knobs and LP tank valve. Turn coupling nut counterclockwise by hand only – do not use tools to disconnect. Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may result in leakage of propane.

- A disconnected LP tank in storage or being transported must have a safety cap installed (as shown). Do not store an LP tank in enclosed spaces such as a carport, garage, porch, covered patio or other building. Never leave an LP tank inside a vehicle which may become overheated by the sun.

- Do not store LP tanks in an area where children play.

LP TankThe LP tank used with your appliance must meet the following requirements:

- Purchase LP tanks only with these required measurements: 12” (30.5cm) ( diameter) x 18”(45.7cm)(tall) with 20lb.(9kg). Capacity maximum.

- The LP-gas supply cylinder to be used must be constructed and marked in accordance with the specifications for LP-gas cylinders of the US Department of Transportation (DOT) or the National Standard of Canada, CAN/CSA-B339, Cylinders, Spheres and Tubes for the Transportation of Dangerous Goods.

LP tank valve must have:

- Type 1 outlet compatible with regulator or appliance.

- Safety relief valve.

- UL listed Overfill Protection Device(OPD). This OPD safety feature is identified by a unique triangular hand wheel. Use only tanks equipped with this type of valve.

LP tank must be arranged for vapor withdrawal and include collar to protect LP tank valve.

LP(Liquefied Petroleum Gas)

- LP gas is non toxic, odorless and colorless when produced. For your safety, LP gas has been given an odor (similar to rotten cabbage) so that it can be smelled.

- LP gas is highly flammable and may ignite unexpectedly when mixed with air.

LP Tank Filling

- Use only licensed and experienced dealers.

- LP dealer must purge tanks before filling.

- Dealer should NEVER fill LP tank more than 80% of LP tank volume. Volume of propane in tanks will vary by temperature.

- A frosty regulator indicates gas overfill. Immediately close LP tank valve and call LP gas dealer for assistance.

- Do not release liquid propane (LP) gas into the atmosphere. This is a hazardous practice.

- To remove gas from LP tank, contact an LP dealer or call a local fire department for assistance. Check the telephone directory under” GAS Companies” for nearest certified LP dealers.

LP Tank Exchange

- Many retailers that sell appliances offer you the option of replacing your empty LP tanks through an exchange service, Use only those reputable exchange companies that inspect, precision fill, test and certify their cylinders. Exchange your tank only for an OPD safety feature-equipped tanks as described in the “LP Tank” section of this manual.

- Always keep new and exchanged LP tanks in upright position during use, transit or storage.

- Leak test new and exchanged LP tanks BEFORE connecting to appliance.

LP Tank Leak

Test For your safety

- Leak test must be repeated each time LP tank is exchanged or refilled.

- Do not smoke during leak test.

- Do not use an open flame to check for gas leaks.

LP tank must be leak checked outdoors in well-ventilated area, away from open flames or sparks.

Use a clean paint brush and 50/50 soap and water solution.Use mild soap and water. Do not use household cleaning agents. Damage to gas train components can result.

Brush soapy solution onto all weld seams and entire valve area.

WARNING

If “growing” bubbles appear, do not use or move the LP tank. Contact an LP gas supplier or your fire department.

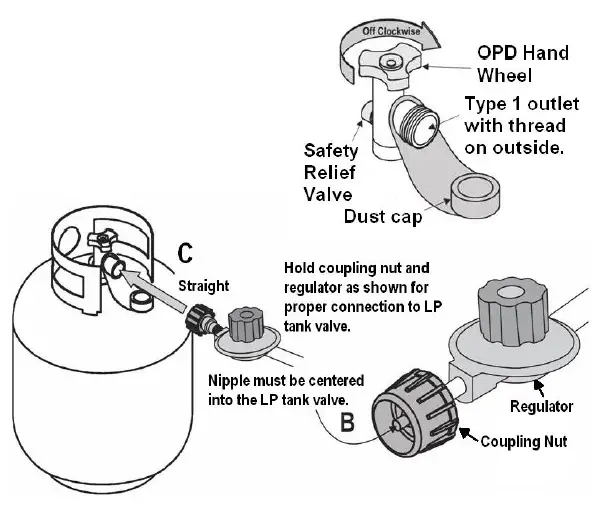

Connecting Regulator to the LP Tank

- Place LP tank on a secure, level, and stable surface.

- Turn control knob to the OFF position.

- Turn LP tank OFF by turning OPD hand wheel clockwise to a full stop.

- Remove the protective cap from the LP tank valve. Always use dust cap and strapsupplied with valve.

- Hold regulator, insert nipple (B) into LP tank valve. Hand tighten coupling nut, holding regulator in a straight line (C) with LP tank valve so as not to cross thread the connection.

- Turn the coupling nut clockwise to tighten to a full solid stop. The regulator will seal on the back-check feature in the LP tank valve, resulting in some resistance. An additional one-half to three quarters turn is required to complete connection. Tighten by hand only – do not use tools.

NOTE: If you cannot complete connection, disconnect regulator and repeat step 5 and 6. If you are still unable to complete the connection, do not use this regulator!

WARNING

- Do not insert any tool or foreign object into the valve outlet or safety relief valve. You may damage the valve and cause a leak. Leaking propane may result in explosion, fire, severe personal injury, or death.

- Never attempt to attach this appliance to the self-contained LP gas system of a camper, trailer or motorhome.

- The pressure regulator and hose assembly supplied with the appliance must be used. Replacement pressure regulator and hose assemblies must be those specified by the appliance manufacturer.

WARNING

- Do not use appliance until leak checked.

- If leak is detected at any time, STOP.

- If you cannot stop a gas leak, immediately close LP tank valve, leave area of appliance, and call LP gas supplier or your fire department!

Leak Testing Valves, Hoses and Regulator

- Turn all control knob(s) to OFF.

- Be sure regulator is tightly connected to LP tanks.

- Completely open LP tank valve by turning OPD hand wheel counterclockwise. If you hear a rushing sound, turn gas off immediately. There is a major leak at the connection. Correct before proceeding.

- Brush soapy solution onto indicated connections shown at right in A and B.

- If ‘growing” bubbles appear, there is a leak. Close LP tank valve immediately and retighten connections. If leaks cannot be stopped, do not try to repair. Call for replacement parts. Order new parts by giving the serial number, model number and name of items needed to the Customer Service Center at (888) 837-1380 or email at Use only replacement parts specified by manufacturer.

- Always close LP tank valve after performing tank leak test by turning OPD hand wheelclockwise

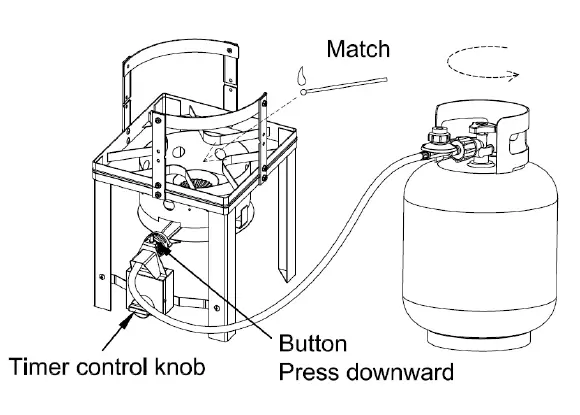

Lighting Instructions

Do not lean over LP cooker while lighting.

- Read all instructions before lighting.

- Turn regulator control valve to OFF position.

- Fully turn timer control knob clockwise.

- Fully open LP bottle valve.

- Light match and place it over burner. PRESS and HOLD push button of safety valve. Slowly turn ON the regulator control valve. DO NOT stand with head or arms over cooker.

- When burner is lit, still HOLD the push button for 10 seconds and then release.

- If ignition does not occur in 5 seconds, turn the burner control(s) off,

Note: Cycle time for timer is around 15 minutes. If the timer is not reset within around 15 minutes, the burner will shut OFF automatically. If this occurs, please follow lighting instructions and continue to cook.

CAUTIONIf burner does not light OR if burner flame is accidentally extinguished, turn knob to OFF, wait 5 minutes, try again. If the burner does not ignite with valve open OR if burner flame is accidentally extinguished after lighting, gas will continue to flow out of the burner and could accidentally ignite with risk of injury.

Burner Flame Check

- Light burner, rotate regulator knob from HIGH to LOW. You should see a smaller flame in LOW position than seen on HIGH. Always check flame prior to each use. The air damper (D) mounted on the back of your burner helps to control the amount of primary air that mixes with the LP gas. A blue flame with little or no yellow flame provides the best heat. Adjust the air damper by turning it clockwise or counterclockwise until the desired flame is achieved.

Turning LP Cooker Off

- Turn all knobs to OFF position, Turn LP tank OFF by turning OPD hand wheel clockwise to a full stop.

Hose Check

- Before each use, check to see if there is evidence of abrasion, wear, cuts or leaks, the hose must be replaced prior to the appliance being put into operation. The replacement hose assembly shall be that specified by the manufacturer.

Cleaning the Burner

CAUTION

- Checking and cleaning burner / venture tubes for insect nests. A clogged tube can lead to fire beneath the appliances.

- Spiders’ nests or wasps’ mud inside the burner may cause fire at the air damper. If a fire occurs, immediately turn off gas supply at LP tank valve.

Note:Spiders and small insects can spin webs and build nests inside the burner. This especially occurs in late summer and fall before frost when spiders are most active. These nests can obstruct gas flow and cause a fire in and around the burner and orifice. Such a fire can cause operator injury and serious damage to the appliance.

To help prevent a blockage and ensure full heat output, clean and inspect burner tube often (once or twice a month). NOTE: Water or air pressure will not normally clear a spider web.

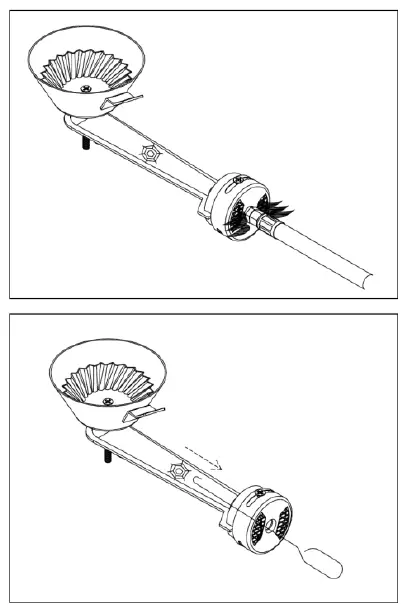

Steps for Cleaning the Burner:

- Remove orifice/hose from the burner.

- Look inside the burner tube for nests, webs, or mud.

- To remove the above obstructions, use an accessory flexible venture brush or bend a small hook on one end of a long flexible wire such as the one in small picture.

- Inspect and clean the burner if needed.

- Reattach orifice/hose to burner.

Cleaning and Maintenance

- Keep appliance area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

- Do not block holes in bottom or sides of appliance.

- Check burner flames regularly.

- Use appliance only in well-ventilated space. NEVER use in enclosed space such as carport, garage, porch, covered patio, or under ANY overhead construction.

- Completely thaw meat and poultry prior to placing in hot oil.

- To minimize splattering, dry surfaces of meat and poultry prior to placing in hot oil.

- When LP tank is connected to appliance, store outdoors in well-ventilated space and out of reach of children.

- Store appliance indoors ONLY if LP tank is turned off, disconnected and removed from appliance then stored outdoors.

- Keep the appliance clear and free from gasoline and other flammable vapors and liquids.

- Do not obstruct the flow of combustion and ventilation air.

- Keeping the ventilation opening(s) of the cylinder enclosed free and clear from debris.

- Clean all cooking surfaces of vessels, aluminum pots and pan with warm, soapy water and a nylon cleaning pad to avoid oxidation, corrosion and rusting.

CAUTIONAll cleaning and maintenance should only be done when the appliance is cool and with the fuel supply turned off at the LP tank. DO NOT clean any part in a self-cleaning oven. The extreme heat will damage the finish.

Correct care and maintenance will keep your appliance operating smoothly. Clean regularly as determined by the amount of use. NOTE: Clean the entire appliance each year and tighten all hardware on a regular basis (1-2 times a year or more depending on usage). Cleaning should be done where detergents won’t harm patio, lawn or the like.

Suggested Cleaning Materials:

- Mild dish washing liquid detergent

- Hot water

- Wire brush

- Paper clip

- Nylon cleaning pad

- Soft brass bristled brush

Component Cleaning:

- Burner: Use wire brush to loosen corrosion from burner exterior. Clean clogged gas port holes with an opened paper clip. Replace corroded or damaged burners that would emit excess gas.

- Cooking surfaces, pots and pans: Clean the cooking surface with soapy water and a nylon cleaning pad.

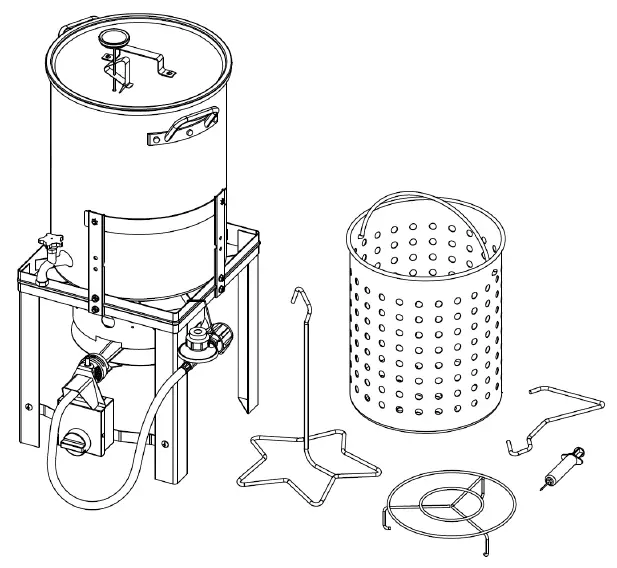

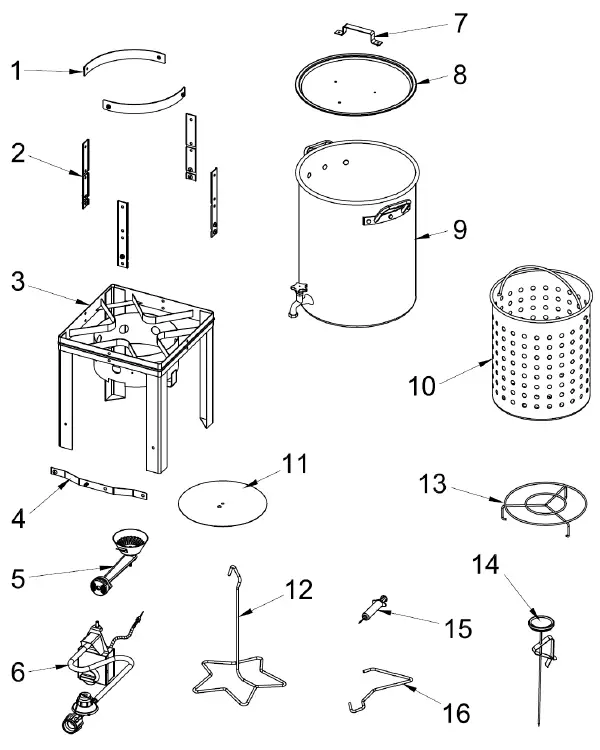

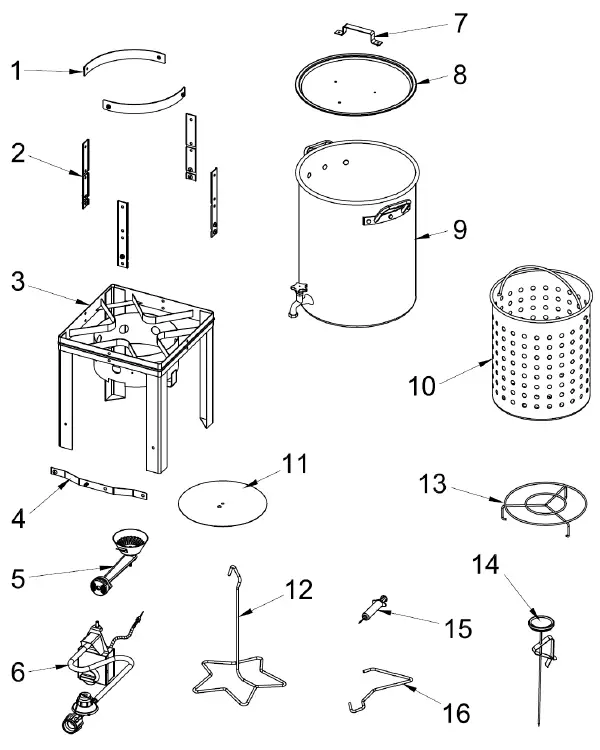

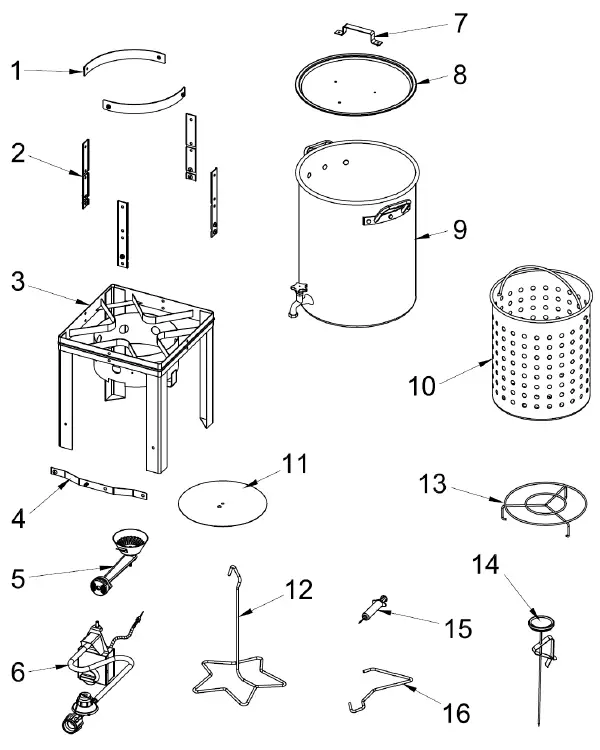

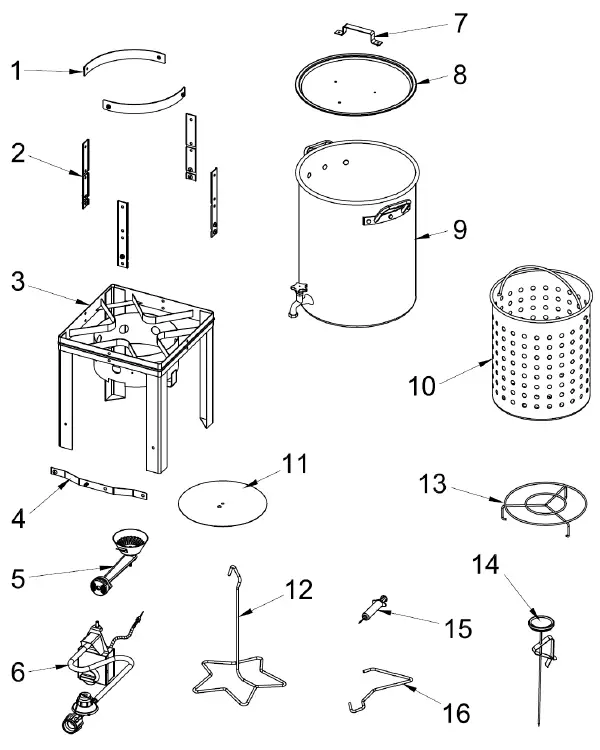

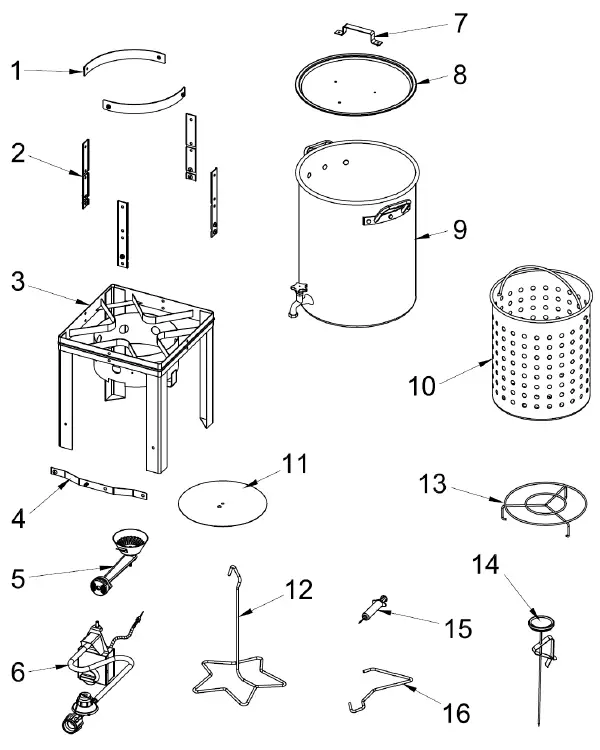

Product Diagram

Component List

Assembly Instructions:

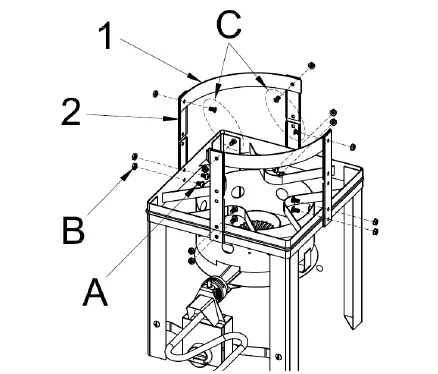

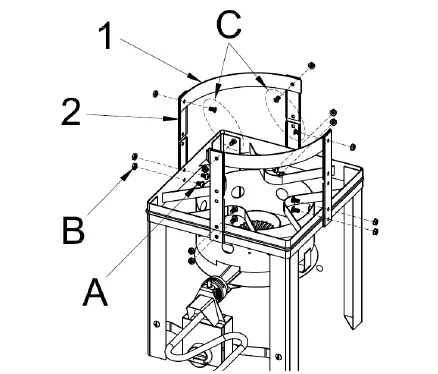

1. Attach the burner (5) to automatic shut off valve in the timer control box (6) by turning the burner clockwise. Do not fully tighten the burner to the valve, tighten until 3 threads remain visible on the valve.

2. Attach thermocouple (D) to thermocouple bracket (E) which has been fixed to the burner.Attach thermocouple (D) as per right drawing and tighten the nut (Y).

3. Insert the burner through the bottom of the stand (3), in between wind shield (F) (side with rectangle lip) and burner support bar (G).

4. Unscrew the pre-assembled nut from the threaded pin of the burner (5). Align timer control box (6) to the timer box support bar (4) and fix it with 2 pieces M6x12 screws by going through the support bar (4) and then to the time box (6). Then align burner (5) base to burner support bar (G). Align holes on heat shield (11) with threaded pin and alignment pin of the burner (5) through hole in burner support bar (G), then through small hole of heat shield (11). The alignment pin on bottom of burner (5) must be inserted through the large hole of the heat shield (11), Tighten hex nut onto bolt of the burner (5). Finally, fix the support bar (4) to legs of stand with 2 pieces M6x12 screw by going through the holes on legs and then through the holes of support bar (4). Tighten the screws with 2 pieces M6 nuts.

5. Align the tip guard support (2) with 4th and 5th holes to stand and tighten with bolt and nut.Tighten align the tip guard (1) to the 1st hole of support (2) and tighten it with crosshead bolt and nut.

6. Unscrew the pre-assembled bolt and nut from the pot lid handle (7).Attach the pot lid handle to the pot lid (8) by using the bolt and nut.

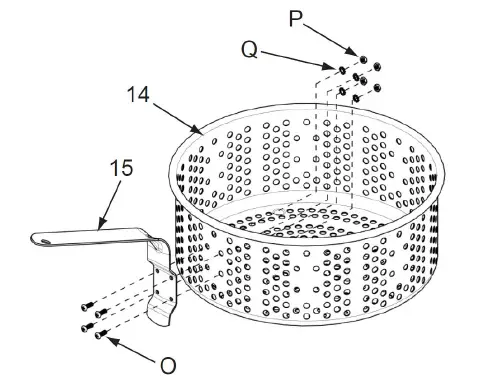

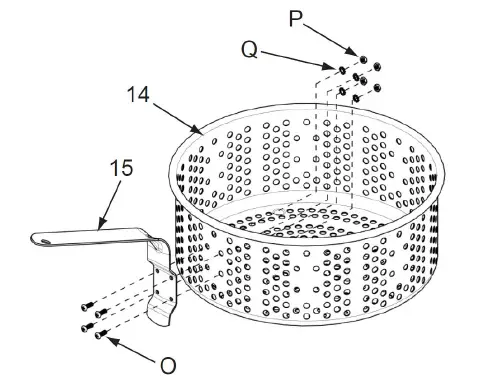

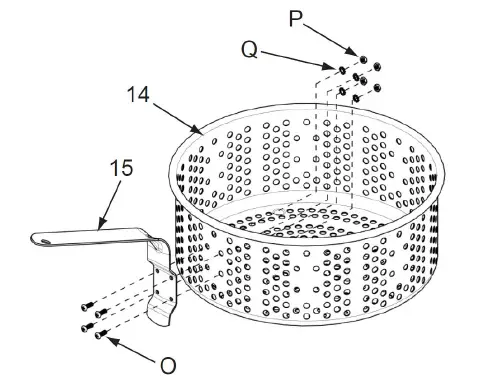

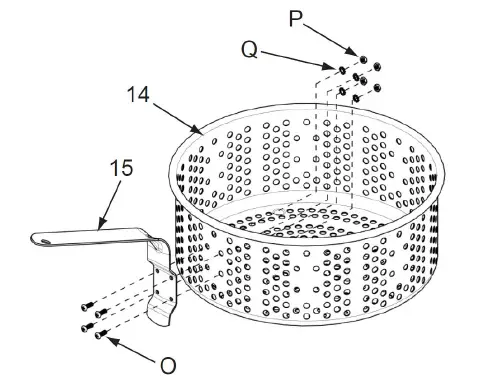

7. Attach the fish basket handle (15) to the fish basket (14) by using the bolt, nut and tooth washer

8. When transporting or storing LP cooker without tank attached, hook regulator onto burner or cooker stand to prevent damage to regulator.

Using Your Thermometer

Check the thermometer before each use by inserting into a pot of boiling water and ensuring that it registers approximately 212°F +/- 20°F (100°C +/- 10°C). If it does not function properly, obtain a replacement thermometer specified by the manufacturer before using the appliance.

Prior to lighting, position thermometer clip so that at least 2.75” of thermometer tip is submerged in oil. Reposition thermometer as necessary to cook. Continue to use thermometer until burner is turned off.

The following safety measures are recommended when using your fry set.

LOCATION MATTERS

Select a safe place to fry your turkey. It should be in an open area, outside, and on a cement or brick surface. Place the liquid propane gas tank and fryer so that if any wind blows the heat from the fryer will blow away from the LP gas tank. Never use your fryer in an enclosed area, near a wall or on a wooden deck. Keep a minimum clearance of 10 feet from the sides, front and back of the fryer to any construction.

PREPARE PROPERLY

Remove and discard any thermometer buttons, leg holders and giblet packs contained inside the completely thawed turkey. Do not attempt to fry a frozen or partially frozen turkey. Ensure your turkey is completely thawed prior to proceeding. The USDA recommends thawing 24 hours (1 day) for every 4-5 pounds in refrigerator.

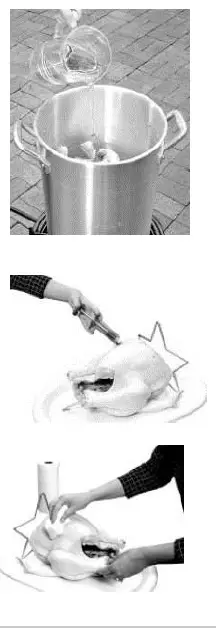

Insert the T-Star stand up through the cavity of turkey so that the legs are at the top.

Determining the maximum fill level when using a vessel without a maximum fill line:

- Place the turkey (or other food product) on the lifter.

- Place the turkey and lifter into the empty pot.

- Fill the pot with water just until the turkey is completely submerged. There must be a minimum of 3 inches or 8 cm between the water level and top of the pot.

- Remove the turkey from the pot and either mark the water level on the side of the pot or measure the amount of water in the pot.

- Remove the water and completely dry the pot and the turkey.

- This is the amount of peanut oil the pot is to be filled with to cook the turkey

- Use marinade by injecting it into the thicker areas of the turkey breasts and thighs.

- To use, load the injector with marinade and insert the needle into the turkey. Withdraw the needle slowly while pushing the plunger, minimizing large pockets of marinade and spreading it more evenly. Discard any unused marinade.

- Completely pat dry the inside and outside surfaces of the turkey. This is very important as it reduces the splattering of oil. After patting the turkey dry, add herb rubs or seasonings to the skin

FRY WITH CARE

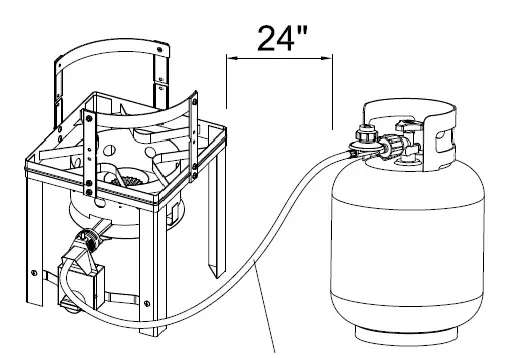

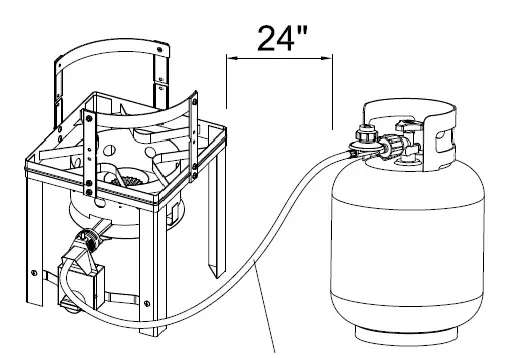

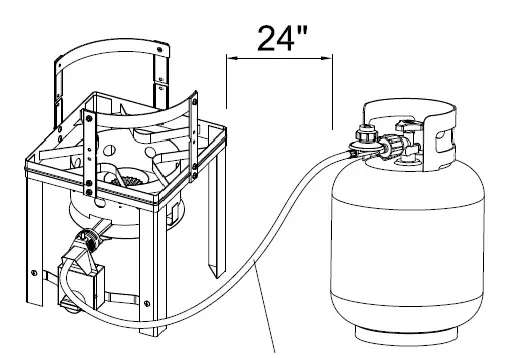

- Check your hose at both ends for proper connection. Also, place the LP tank and hose so that they are not located directly next to the fryer (see photo). Center the pot over the burner on the cooker.

- Fill the pot to the mark with peanut oil.

- Light the burner unit and heat the oil to 325°F. Never leave the fryerunattended at any time.

- Check the oil using a deep fry temperature gauge. If it has reached 325°F, you are ready to start deep frying. Monitor the temperature throughout the frying process to maintain 325°F – never let the oil temperature get hotter than 325°F.

- If the oil exceeds 400°F or if the oil begins to smoke, immediately turn the burner off.

- Wear long, insulated, flame-retardant gloves to protect your hands and arms. Use the lift handle to slowly lower the turkey into the oil. Pause at several points before reaching the bottom of the pot.

- Never drop food or accessories into hot cooking liquid. Lower food andaccessories slowly into the cooking liquid in order to prevent splashing or overflow. When removing food from the appliance, care shall be taken to avoid burns from hot cooking liquids.

- Adjust the burner to maintain 325°F. Monitor the fryer during the entire process to assure a safe frying experience. Do not leave fryer unattended.

- Cook until a golden brown color is achieved. Normal cooking time is 3 1/2 minutes per pound

DANGER

- Do not fill past the maximum fill line marked on the pot.

- An oil overflow may occur resulting in a fire which could cause property damage, personal injury or death. Follow directions above to prevent this.

WARNING

- Avoid bumping of or impact with the appliance to prevent spillage or splashing of hot cooking liquid. Introduction of water or ice from any source into the oil/grease may cause overflow and serve burns from hot oil and water splatter.

- When frying with oil/grease, all food products MUST be completely thawed and towel dried before being immersed in the fryer.

LIMITED WARRANTY

- Manufacturer warrants this Product to be free from defects in workmanship and materials for a period of Ninety (90) days from the date of purchase, PROVIDED claims are submitted, in writing, with proof of purchase.

- If any part of this item fails because of a manufacturing defect within the Limited Warranty Period, Manufacturer offers to replace such part(s) provide that such parts have not been improperly repaired, altered, or tampered with or subject to misuse, abuse or exposed to corrosive conditions. This Limited Warranty is, however, subject to certain limitations, exclusions, time limits and exceptions (Hereinafter “Conditions”) as listed below. Read these Conditions carefully.

- This Limited Warranty shall be limited to the replacement or repair of any part(s) which Manufacturer determines, after reasonable examination, to have been defective at the time of manufacturing and manufacturer’s obligation(s) shall be limited to replacement, if any, of defective part(s) which shall be shipped at Original Purchaser’s expense to Original Purchaser’s designated shipping address.

- This Limited Warranty is given to and covers the ORIGINAL PURCHASER ONLY and such coverage terminates Ninety (90) days from the date of purchase.

- DAMAGE LIMITATION WARNING: IN NO EVENT SHALL MANUFACTURER BE LIABLE FOR ANY INCIDENTIAL OR CONSEQUENTIAL DAMAGES, INCLUDING (BUT NOT LIMITED TO) LOSS OF USE OF THE PRODUCT, LOSS OF TIME, INCONVENIENCE, EXPENSES FOR TRAVEL, TRANSPORTATION LODGING EXPENSES, LOSS BY DAMAGE TO PERSONAL PROPERTY OR LOSS OF INCOME, PROFITS OR REVENUE.

- MANUFACTURER’S OBLIGATION: Manufacturer’s liability shall be limited to the delivery of a good, merchantable Product and, if necessary, the repair or replacement, at manufacturer’s option, of any defective part or unit.

- TRANSFER LIMITATIONS: This Limited Warranty is not assignable or transferable. It covers only the original purchaser.

- RESERVED RIGHT TO CHANGE: Manufacturer reserves the right to make changes or improvements to products it produces in the future without imposing on itself any obligations to install the same improvements in the products it has previously manufactured.

- This Limited Warranty gives the Original Purchaser specific legal rights but there may be other rights which vary by jurisdiction.

IF CUSTOMER SERVICE BECOME NECESSARY:

- The Original Purchaser is responsible for shipping and handling charges of the returned item(s) and replacement parts, if any.

- All parts to be replaced will need to be shipped before replacement items will be sent.

- Follow the Customer Service Representative’s instructions exactly. If a return is necessary, it must be packed carefully and shipped prepaid.

Should you encounter any problems, CONTACT US FIRSTDO NOT return product to the store!CUSTOMER SERVICE(888) 837-1380

Read More About this Manual….

Questions about your Manual? Post in the comments!

[xyz-ips snippet=”download-snippet”]