SEQUENCE High Speed Champion Primer External Pond Pumps Installation Guide

INSTALLATION AND SERVICE MANUAL

CHAMPION PRIMER HIGH-SPEED CHAMPION PRIMER

| Model | 3700PRM21 | 4900PRM21 | 6600PRM24 | 6300PRM77 | 8100PRM81 | 9300PRM83 |

| INLET | 2” | 2” | 2” | 2” | 2” | 2” |

| DISCHARGE | 2” | 2” | 2” | 2” | 2” | 2” |

| MAX FLOW (GPH) | 3700 | 4900 | 6600 | 6300 | 8100 | 9300 |

| MAX HEAD (FEET) | 21’ | 21’ | 24’ | 77’ | 81’ | 83” |

| MAX POWER (WATTS) | 228 | 310 | 457 | 1496 | 1807 | 2222 |

| MAX CURRENT (AMPS) | 2.76 @115V | 3.37 @115V | 4.61 @115V | 8.7 @ 230 | 9.8 @ 230 | 11.4 @ 230 |

| VOLTS | 115/230 | 115/230 | 115/230 | 230 /115 | 230 /115 | 230 /115 |

| MOTOR HP | 1/2, 1/3 | 1/2, 1/3 | 1/2, 1/3 | 2 | 2 | 2 |

| MOTOR TYPE | 56Y | 56Y | 56Y | 56Y | 56Y | 56Y |

| MOTOR ENCLOSURE | TEFC | TEFC | TEFC | ODP | ODP | ODP |

Read this manual completely before you install or operate your new pump. This is an external “out-of-pond” pump.It is not submersible. Do not allow this pump to become submerged. Never run dry.

Read this manual completely before you install or operate your new pump. This is an external “out-of-pond” pump.It is not submersible. Do not allow this pump to become submerged. Never run dry.

Reliable. Efficient.

We congratulate you on your choice of the Sequence® Champion Primer. It has been carefully designed using the advantages of today’s technology and carefully constructed to give you the dependability of yesterday. To insure proper performance, we urge you to carefully follow the instructions in this manual. If you have any questions, please call your supplier for assistance or visit www.mdminc.com/support.

INSTALLATION

Please read carefully. When properly installed the Sequence® Champion Primer will provide dependable trouble-free service.

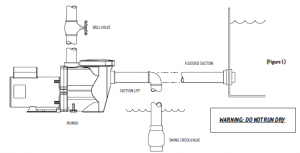

- Locate pump as near the source to be pumped as possible. A flooded suction situation is preferred. This pump is self-priming, however, there must be fluid in the pump for it to function properly. A check valve is recommended for non-flooded suction (Figure 1).

- Mount motor base to a secure, immobile foundation.

- Use only plastic fittings on both the intake and discharge ports. Seal pipe connections with Teflon® paste. These fittings should be self-supported and in neutral alignment with each port (i.e. Fittings must not be forced into alignment which may cause premature line failure or damage to the pump volute).

- Never restrict the intake. Keep both input and discharge lines as free of elbows and valves as possible. Always use pipe of adequate diameter. This will reduce friction losses and maximize output.

- Before starting pump, the priming pot must be filled with water.

WARNING: ALWAYS SHUT OFF ELECTRICAL POWER BEFORE INSTALLATION AND / OR SERVICING THIS PUMP.ALL ELECTRICAL WIRING SHOULD MEET STATE AND LOCAL ORDINANCES. IMPROPER WIRING MAY NOT ONLY BE A SAFETY HAZARD BUT MAYPERMANENTLY DAMAGE THE MOTOR AND/OR PUMP. 230V 50HZ MOTORS ARE AVAILABLE. CONTACT YOUR SUPPLIER FOR INFORMATION.

WARNING: ALWAYS SHUT OFF ELECTRICAL POWER BEFORE INSTALLATION AND / OR SERVICING THIS PUMP.ALL ELECTRICAL WIRING SHOULD MEET STATE AND LOCAL ORDINANCES. IMPROPER WIRING MAY NOT ONLY BE A SAFETY HAZARD BUT MAYPERMANENTLY DAMAGE THE MOTOR AND/OR PUMP. 230V 50HZ MOTORS ARE AVAILABLE. CONTACT YOUR SUPPLIER FOR INFORMATION.

ELECTRICAL HOOK-UP

- Check that supply voltages match the motor’s requirements.

- Check motor wiring and connect, according to instructions on motor, to match supply voltage.

- Power cord should be protected by conduit or by cable and be of proper gauge. It should be no longer than necessary.

- Power should be drawn directly from a box with circuit breaker protection or with a fused disconnect switch.

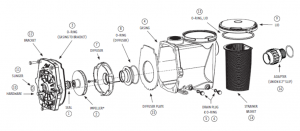

PUMP END ASSEMBLY

- Inspect all pump parts (O-ring, O-ring groove, impeller hub ID, motor shaft, etc.) and clean if necessary.

- If replacing the seal, apply sealant in bracket bore hole and around seal case according to sealant instructions. We recommend using Gasgacinch®. Silicone sealant can also be used.

- Press seal into bracket while taking care not to damage seal face.

- Place slinger (rubber washer) over motor shaft and mount bracket to motor.

- If replacing the seal, carefully lubricate the boot around ceramic piece and press it into the impeller hub making certain that the ceramic is in evenly – the sealing surface should be parallel with the impeller hub.

- Apply clean water to the carbon-graphite and seal seat sealing surfaces. Do not use silicon lubricants or grease.

- Mount bracket to motor face.

- Thread impeller onto shaft and install o-ring and screw. If required, remove motor end-cap and use a screwdriver on the back of motor shaft to prevent shaft rotation while tightening. Replace motor end cap.

- Place diffuser over impeller and tighten the allen bolts used to hold diffuser in place. Note: Be sure diffuser is in an upright position. (The word “top” appears on the diffuser as an indicator).

- Seat O-ring on diffuser. Assemble diffuser to bracket with 2 allen screws.

- Seat O-ring in bracket slot and assemble casing to bracket.

- Install drain plugs with its O-rings in casing drain holes.

DISASSEMBLY

- Shut off power to motor before disconnecting any electrical wiring.

- Close all necessary valves on inlet and discharge lines and drain the pump by removing both drain plugs. The water will drain faster if you loosen the lid.

- Disassemble bracket-motor assembly from casing by removing the nuts and bolts. (The casing may be left in-line).

- Unscrew the two allen bolts and remove diffuser. Diffuser may need to be pried off with a flathead screwdriver.

- Remove screw and O-ring from front side of impeller. Screw is a left-handed thread and loosens in a clockwise direction.

- Remove cap covering shaft at back of motor. Unscrew the impeller by twisting counterclockwise while holding the shaft with a large screwdriver to prevent shaft rotation.

- Remove ceramic piece from impeller (if replacing the seal).

- Detach bracket from motor.

- Remove seal from bracket by pressing out from the back (if replacing the seal). Do not dig out from the front.

| NO. | DESCRIPTION | P/N |

| 1 | SEAL | 1000.0414 |

| 2 | IMPELLER *DEPENDS ON MODEL | CONSULT FACTORY |

| 3 | O-RING (CASING TO BRACKET) | 8000.061 |

| 4 | CASING | 8000.070 |

| 5 | DRAIN PLUG | 1000.110 |

| 6 | O-RING (DRAIN PLUG) | 805-0112 |

| 7 | DIFFUSER | 8000.120 |

| 8 | O-RING (DIFFUSER) | 8000.121 |

| 9 | LID | 1000.771-L |

| 10 | HARDWARE KIT | 8000.502 |

| 11 | SLINGER | 1000.010V |

| 12 | BRACKET | 8000.030 |

| 13 | O-RING (LID) | 1000.771-O |

| 14 | STRAINER BASKET | 8000.778 |

| 15 | DIFFUSER PLATE | 8000.141 |

| 16 | ADAPTER, UNION X 2” SLIP | 400-5081-2B |

MAINTENANCE

LubricationMotor – Permanently Lubricated ball bearings – no service required.Rotary Seal – Requires no lubrication after assembly.

WARNING: EYE PROTECTION IS STRONGLY RECOMMENDED

WARNING: EYE PROTECTION IS STRONGLY RECOMMENDED*The pump must be drained before servicing or if stored below freezing temperatures. Periodic replacement of seals may be required due to normal carbon wear.

| SYMPTOM | PROBLEM | RESOLUTION |

|

No Flow |

Insufficient Prime | Prime system with water and purge all air from suction piping. |

| Install check valve. | ||

| Insufficient Power | Verify power supply and connection from panel to pump. | |

| Verify proper voltage. Some models are dual voltage (115/230). | ||

|

Flow Restriction |

Ensure valves are open. | |

| Ensure plumbing is clear, including suction strainers, check valves, etc. | ||

| Verify check valve orientation and direction of permitted flow. | ||

| Clean out leaves or other debris from basket strainer (if applicable). | ||

| Air leak | Fix air leaks at fittings, connections, strainer basket etc. This typically occurs on the intake side. | |

| System Incompatibility | Verify hydraulic compatibility: i.e. pump & pipe are sized for the system. | |

|

Low Flow |

Air leak | Fix air leaks at fittings, connections, strainer basket etc. This typically occurs on the intake side. |

| System Incompatibility | Verify hydraulic compatibility: i.e. pump & pipe are sized for the system. | |

| Insufficient Power | Verify power supply and connection from panel to pump. | |

| Verify proper voltage. Some models are dual voltage (115/230). | ||

|

Flow Restriction |

Ensure valves are open. | |

| Ensure plumbing is clear, including suction strainers, check valves, etc. | ||

| Clean out leaves or other debris from basket strainer (if applicable). | ||

| Insufficient Prime | Prime system with water and purge all air from suction piping. | |

|

Cavitation |

Verify airtight plumbing on the suction plumbing especially fittings. | |

| Clean out leaves or other debris from basket strainer (if applicable). | ||

| Increase pipe size where possible. | ||

| Decrease suction pipe length, reduce the number of elbows, etc. | ||

| Verify hydraulic compatibility: i.e. pump and pipe are sized for the system. | ||

|

Sporadic Operation |

Insufficient Power |

Verify power supply and connection from panel to pump. |

| Verify proper voltage. Some models are dual voltage (115/230). | ||

| Poor Ventilation | ||

| Ensure adequate airflow over motor to prevent overheating. | ||

|

Excessive Noise |

Cavitation |

Verify airtight plumbing on the suction plumbing especially fittings. |

| Clean out leaves or other debris from basket strainer (if applicable). | ||

| Increase pipe size where possible. | ||

| Decrease suction pipe length, reduce the number of elbows, etc. | ||

| Verify hydraulic compatibility: i.e. pump and pipe are sized for the system. | ||

| Insufficient Power | Verify power supply and connection from panel to pump. | |

| Verify proper voltage. Some models are dual voltage (115/230). | ||

|

Flow Restriction |

Ensure valves are open. | |

| Ensure plumbing is clear, including suction strainers, check valves, etc. | ||

| Verify check valve orientation and direction of permitted flow. |

MDM INCORPORATED

3345 N. Cascade Ave • Colorado Springs, CO • 80907Phone (719) 634-8202 • Fax (866) 425-1346www.mdminc.com •

Read More About This Manual & Download PDF:

References

[xyz-ips snippet=”download-snippet”]