Sika AnchorFix®-1

HIGH STRENGTH, TWO COMPONENT ADHESIVE ANCHORING SYSTEM

PRODUCT DESCRIPTION

Sika AnchorFix®-1 adhesive anchoring system has been specially formulated as a high-performance, two component adhesive anchor system for threaded and reinforcing bars in uncracked concrete.

USES

As a fast curing anchoring adhesive for all grades of:

- Rebars / reinforcing steel

- Threaded rods

- Bolts and special fastening systems

Can be used on:

- Uncracked Concrete

- Solid masonry

- Hard natural stone*

- Solid rock*

* These substrates may vary greatly, in particular with regard to strength, composition and porosity. Therefore, for each application the suitability of Sika AnchorFix®-1 Adhesive must be tested by first applying Sika AnchorFix®-1 Adhesive only to a sample area. Check in particular bond strength, surface staining and discoloration.

CHARACTERISTICS / ADVANTAGES

- Fast curing

- Standard guns can be used

- Can be used at low temperatures

- High load capacity

- Non-sag, even overhead

- Styrene-free polyester resin

- Low wastage

APPROVALS / STANDARDS

- European Technical Approval (ETA) according to ETAG001-5 for threaded bars only.

PRODUCT INFORMATION

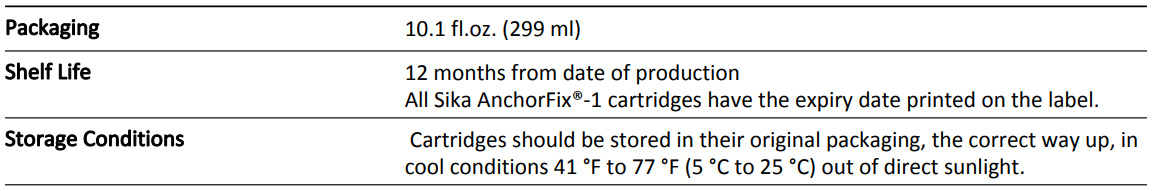

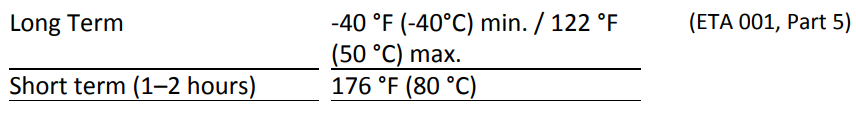

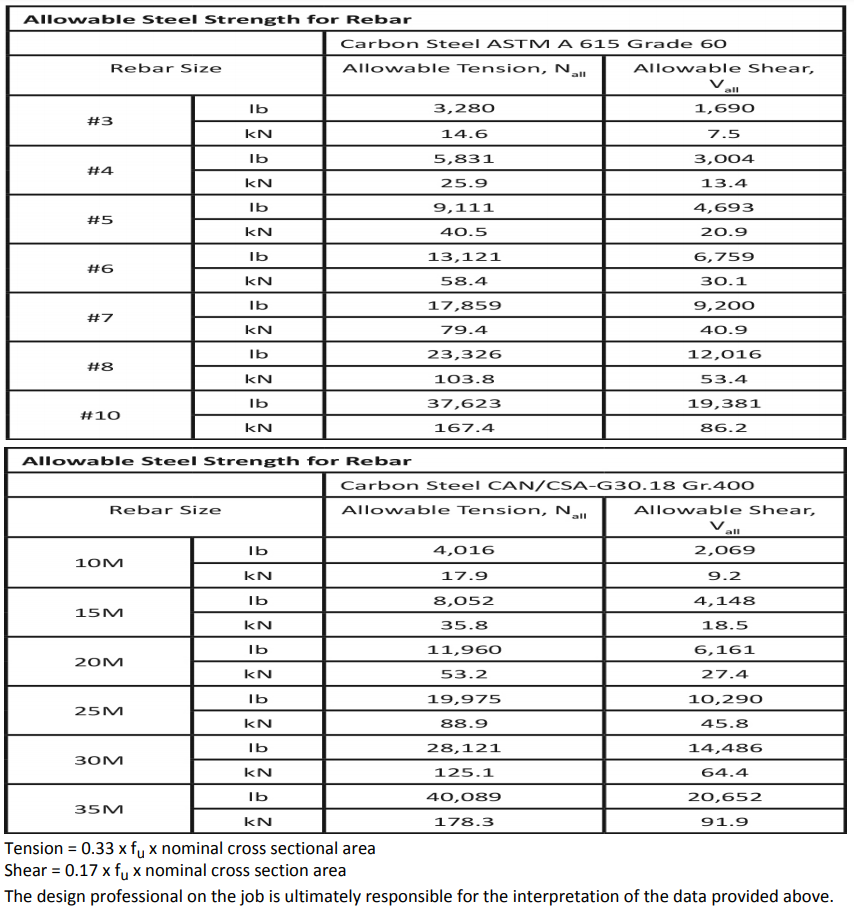

TECHNICAL INFORMATION

Tensile Adhesion Strength

Service Temperature

Design Considerations

For details about adhesive anchoring design refer to the separate documentation provided: “Technical Documentation Sika AnchorFix®-1” Ref: 870 43 01

SYSTEM INFORMATION

System Structure

APPLICATION INFORMATION

Mixing Ratio

Component A : component B = 10 : 1 by volume

Coverage

Sag Flow

Non-sag, even overhead

Product Temperature

Sika AnchorFix®-1 must be at a temperature of between 41 °F (5 °C) and 104 °F (40 °C) for application.

Dew Point

- Beware of condensation.

- Beware of frost.

Open Time

APPLICATION INSTRUCTIONS

SUBSTRATE QUALITY

- Mortar and concrete must be at the required strength. No need to be 28 days old.

- Substrate strength (concrete, masonry, natural stone) must be verified.

- Pull-out tests must be carried out if the substrate strength is unknown.

- The anchor hole must always be clean, dry, free from oil and grease etc.

- Loose particles must be removed from the holes.

- Threaded rods and rebars have to be cleaned thoroughly from any oil, grease or any other substances and particles such as dirt etc.

MIXING

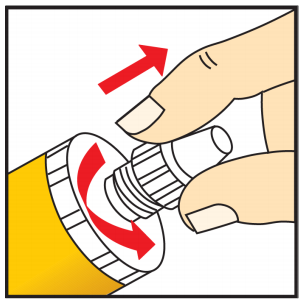

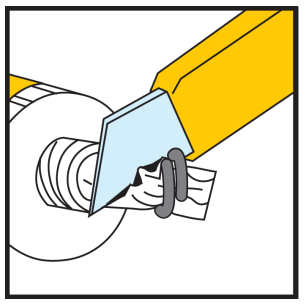

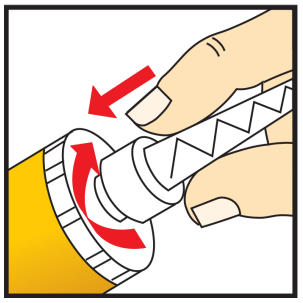

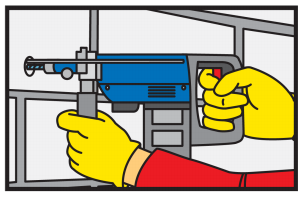

Getting the cartridge ready

1. Unscrew the cap

2. Cut the film

3. Screw on the static mixer

4. Place the cartridge into the gun and start application

When the work is interrupted the static mixer can remain on the cartridge after the gun pressure has been relieved. If the resin has hardened in the nozzle when work is resumed, a new nozzle must be attached.

APPLICATION METHOD / TOOLS

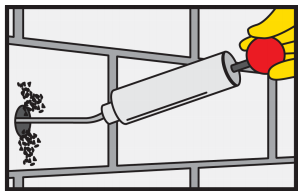

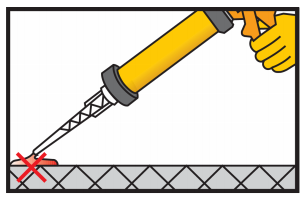

Anchors in solid masonry / concrete

Drilling of hole with an electric drill to the diameter and depth required. Drill hole diameter must be in accordance with anchor size.

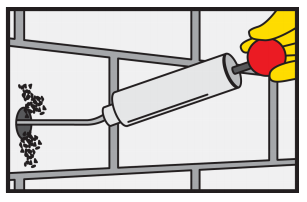

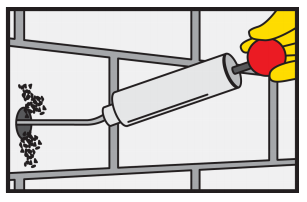

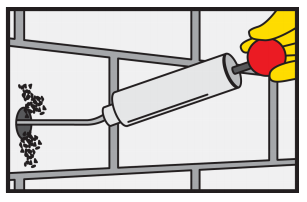

The drill hole must be cleaned with a blow pump or by compressed air, starting from the bottom of the hole. (at least 2x) Important: use oil-free compressors.

The drill hole must be thoroughly cleaned with the special steel brush (brush at least 2x). The diameter of the brush must be larger than the diameter of the drill hole.

The drill hole must be cleaned with a blow pump or by compressed air, starting from the bottom of the hole. (at least 2x) Important: use oil-free compressors.

The drill hole must be thoroughly cleaned with the special steel brush (brush at least 2x). The diameter of the brush must be larger than the diameter of the drill hole.

The drill hole must be cleaned with a blow pump or by compressed air, starting from the bottom of the hole. (at least 2x) Important: use oil-free compressors.

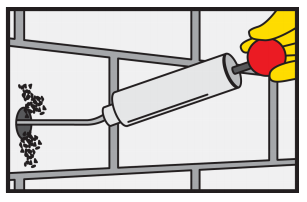

Pump approx. twice until both parts come out uniformly. Do not use this material. Release the gun pressure and clean the cartridge opening with a cloth.

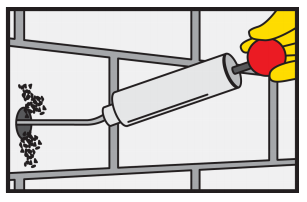

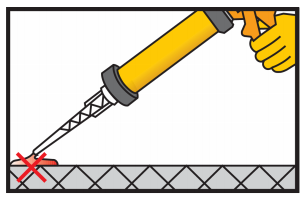

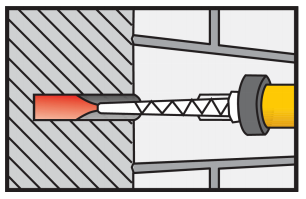

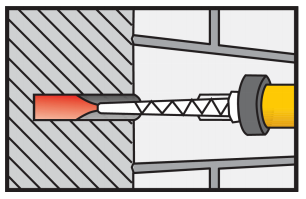

Inject the adhesive into the hole, starting from the bottom, while slowly drawing back the static mixer.In any case avoid entrapping air. For deep holes extension tubing can be used.

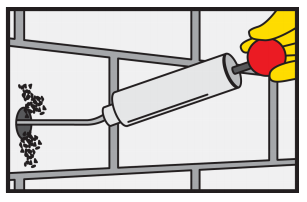

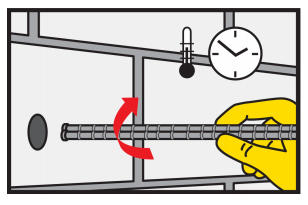

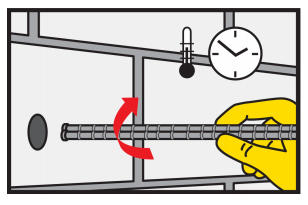

Insert the anchor with a rotary motion into the filled drill hole. Some adhesive must come out of the hole.Important: the anchor must be placed within the open time.

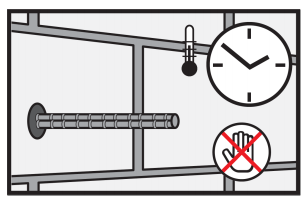

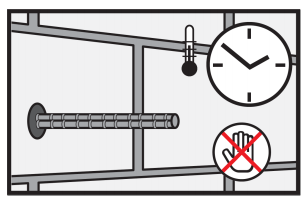

During the resin hardening time the anchor must not be moved or loaded. Wash tools immediately with Sika® Colma Cleaner.Wash hands and skin thoroughly with warm soap water.

CLEANING OF TOOLS

Tools must be cleaned as soon as possible with a clean rag.

LIMITATIONS

THE NTSB HAS STATED THAT THIS PRODUCT IS APPROVED FOR SHORT TERM LOADS ONLY AND SHOULD NOT BE USED IN SUSTAINED TENSILE LOAD ADHESIVE ANCHORING APPLICATIONS WHERE ADHESIVE FAILURE COULD RESULT IN A PUBLIC SAFETY RISK. CONSULT A DESIGN PROFESSIONAL PRIOR TO USE.

*The design professional on the job is ultimately responsible for the interpretation of the data provided on the product data sheet.

BASIS OF PRODUCT DATA

Results may differ based upon statistical variations depending upon mixing methods and equipment, temperature, application methods, test methods, actual site conditions and curing conditions.

OTHER RESTRICTIONS

See Legal Disclaimer.

ENVIRONMENTAL, HEALTH AND SAFETY

For further information and advice regarding transportation, handling, storage and disposal of chemical products, user should refer to the actual Safety Data Sheets containing physical, environmental, toxicological and other safety related data. User must read the current actual Safety Data Sheets before using any products. In case of an emergency, call CHEMTREC at 1-800-424-9300, International 703-527-3887.

LEGAL DISCLAIMER

- KEEP CONTAINER TIGHTLY CLOSED

- KEEP OUT OF REACH OF CHILDREN

- NOT FOR INTERNAL CONSUMPTION

- FOR INDUSTRIAL USE ONLY

- FOR PROFESSIONAL USE ONLY

Prior to each use of any product of Sika Corporation, its subsidiaries or affiliates (“SIKA”), the user must always read and follow the warnings and instructions on the product’s most current product label, Product Data Sheet and Safety Data Sheet which are available at usa.sika.com or by calling SIKA’s Technical Service Department at 1-800-933-7452. Nothing contained in any SIKA literature or materials relieves the user of the obligation to read and follow the warnings and instructions for each SIKA product as set forth in the current product label, Product Data Sheet and Safety Data Sheet prior to use of the SIKA product.

SIKA warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current Product Data Sheet if used as directed within the product’s shelf life. User determines suitability of product for intended use and assumes all risks. User’s and/or buyer’s sole remedy shall be limited to the purchase price or replacement of this product exclusive of any labor costs.NO OTHER WARRANTIES EXPRESS OR IMPLIED SHALL APPLY INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. SIKA SHALL NOT BE LIABLE UNDER ANY LEGAL THEORY FOR SPECIAL OR CONSEQUENTIAL DAMAGES. SIKA SHALL NOT BE RESPONSIBLE FOR THE USE OF THIS PRODUCT IN A MANNER TO INFRINGE ON ANY PATENT OR ANY OTHER INTELLECTUAL PROPERTY RIGHTS HELD BY OTHERS.

Sale of SIKA products are subject to the Terms and Conditions of Sale which are available at https://usa.sika.com/en/group/SikaCorp/termsandconditions.html or by calling 1-800-933-7452.

Sika AnchorFix-1 Datasheet – Sika AnchorFix-1 Datasheet –