Fitting Instructions Part Number(LD100) SILVERBACK LDV T60 DualCab 1pcCheck contents of kit before commencing fitment and report any discrepancies

IMPORTANT

IMPORTANT

- Do not stand/sit or rest heavy objects on Tonneau Cover

- Humans or animals are not to be under the closed Tonneau at any given time

- Securely lock tonneau Cover before operating vehicle

- Tonneau Cover is not dust or watertight

- Do not carry open volatile chemicals with Tonneau Cover installed

- If contact with volatile chemicals occur, clean Tonneau with mild detergent and water solution

Care Instructions

- Read Instructions fully before commencing installation.

- Clean Tonneau Cover with a mild detergent and water solution

- Do not use abrasive cleaners or solvents

- Refer to manufactures instructions applicable to a power drill.

- Protect Tub floor against scratches during the installation process.

Maintenance

If lubrication of the locks or hinges is required use only Graphite Powder. DO NOT use any other lubricants or oils.

Tools Required

| Pen / Marker | Masking Tape |

| Centre Punch | Scissors & Knife |

| Drill & Drill bits | Ruler |

| Phillips head screwdriver | Spanner & Socket |

| Caulking Gun | Tape measure |

| Silicon – Non-Acetic | Soapy water solution |

| Die Grinder & multi-tool | Allen Key set (Metric) |

PARTS CHECK SHEET

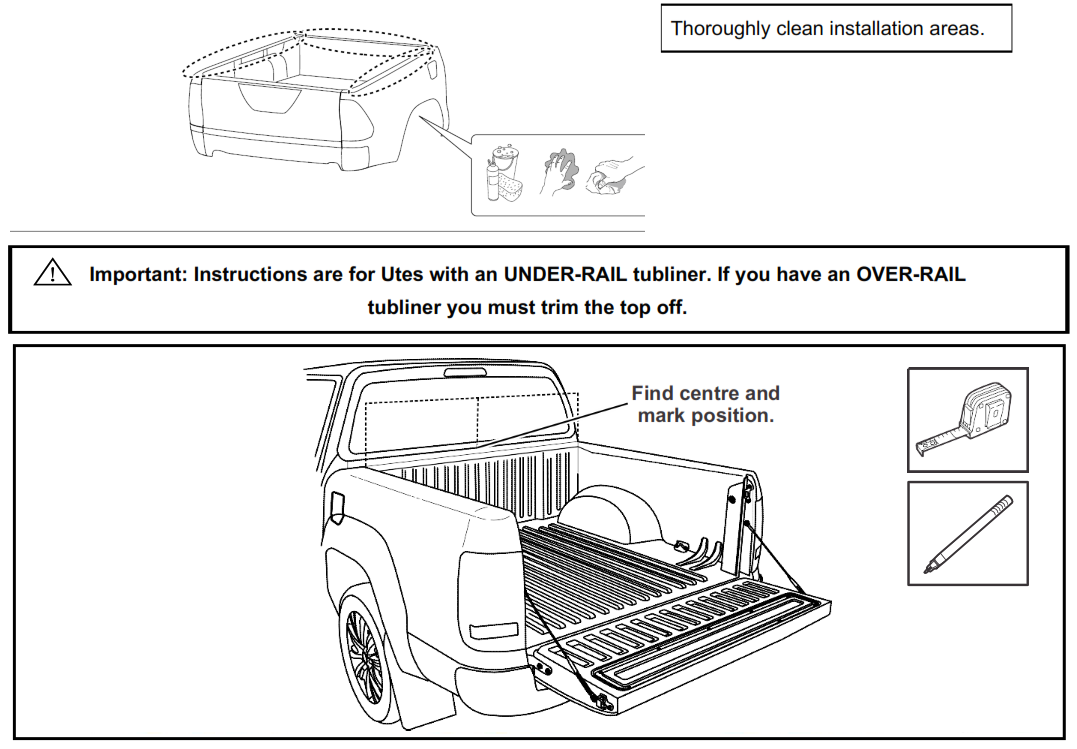

Thoroughly clean installation areas.

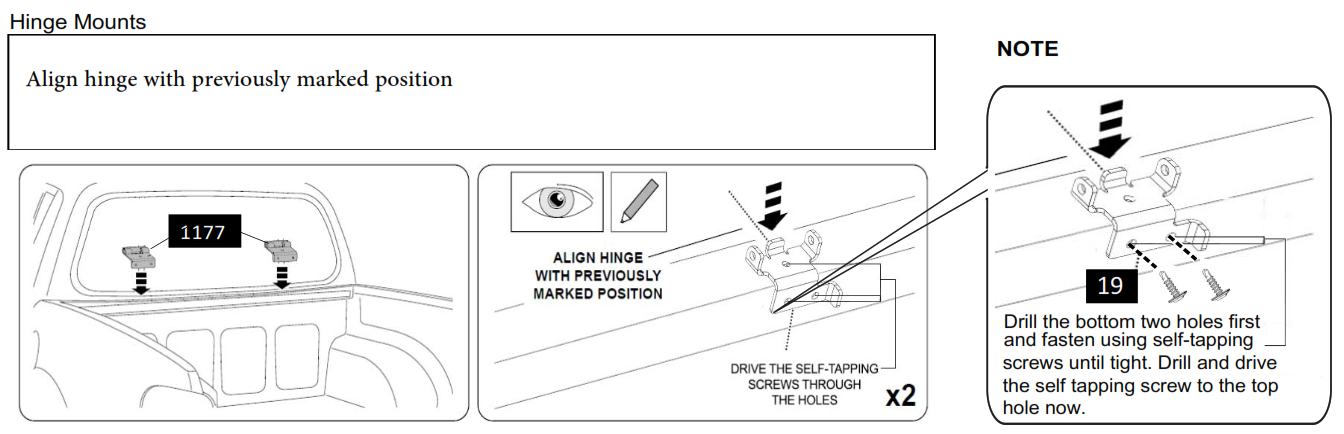

Hinge mounts:

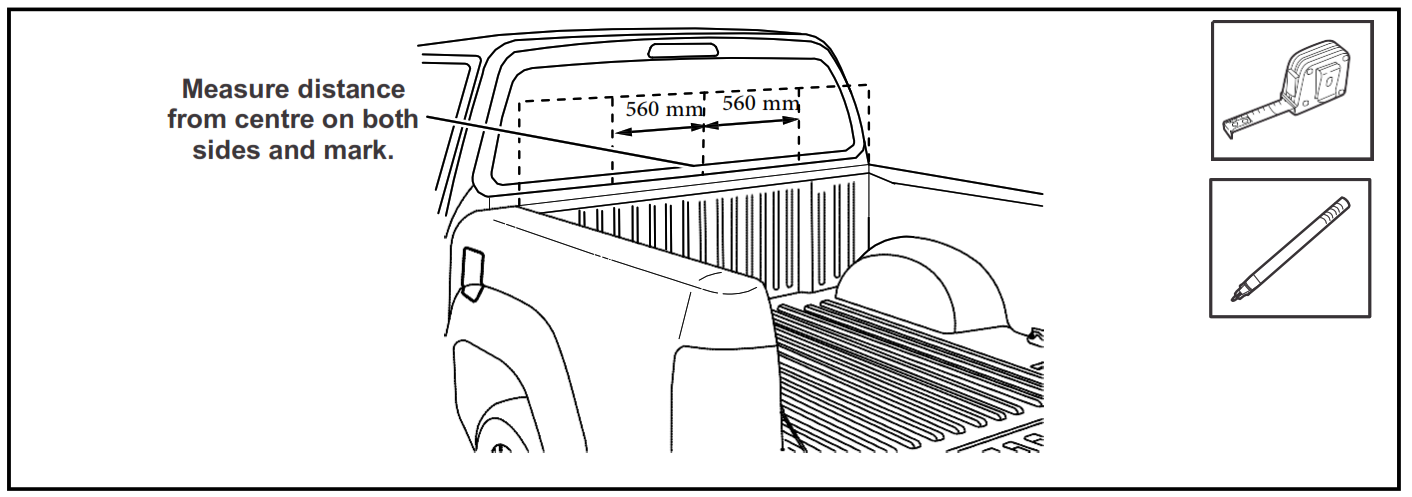

Align the hinge mounts along the front of the tray, ensuring the hinges are properly positioned from centre of tub 560 mm to centre of the hinge mount on either side along the inside of the front of the tub. Attach the hinges using self-drilling screws (supplied) through holes pre-drilled into the hinges. Apply clear or black silicone to any gaps and between the hinges and the vehicle to prevent water entry.

Measure and mark the positions as indicated above from the centre of the bed for placement of the bottom hinges.WARNING: RECHECK DIMENSIONS TO ENSURE CORRECT MEASUREMENT

Measure and mark the positions as indicated above from the centre of the bed for placement of the bottom hinges.WARNING: RECHECK DIMENSIONS TO ENSURE CORRECT MEASUREMENT

Using a 3.5MM drill bit, drill through the holes in the top and the base of the hinge plate into the tub. Remove hinge and clean any swarf, apply Cold Galvanizing compound to the holes drilled.Using the self-tapping screws fasten the hinge into the tub.

Gas Struts:

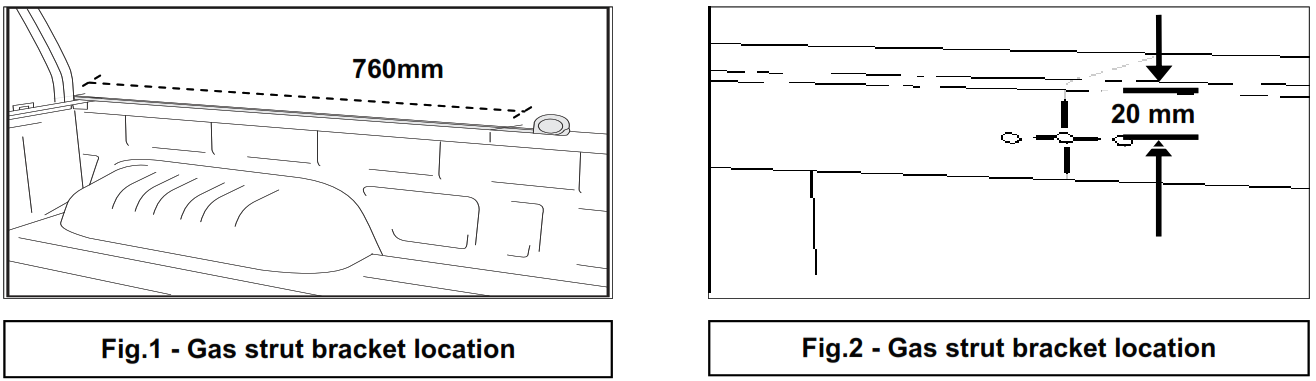

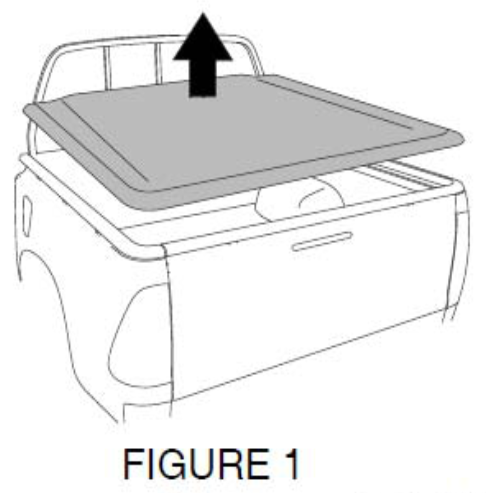

Measure from the front rail inside of the tub, measure along the top edge of tray 760 mm (windscreen end) then down 20mm and mark the position of the screws for the gas strut bracket. Position the gas strut bracket accordingly, mark two mounting holes and centre. Refer to Fig. 1 and Fig. 2

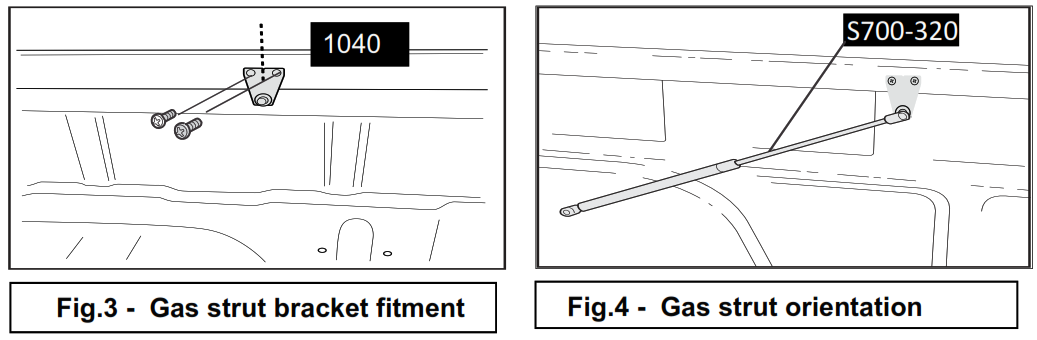

Using a 2 mm diameter drill bit set to 5 mm drill stop. Drill two pilot holes. Attach small gas strut bracket using self drilling screws provided. Repeat process on other side of tray. Refer to Fig. 2 and Fig.3

Using a 2 mm diameter drill bit set to 5 mm drill stop. Drill two pilot holes. Attach small gas strut bracket using self drilling screws provided. Repeat process on other side of tray. Refer to Fig. 2 and Fig.3

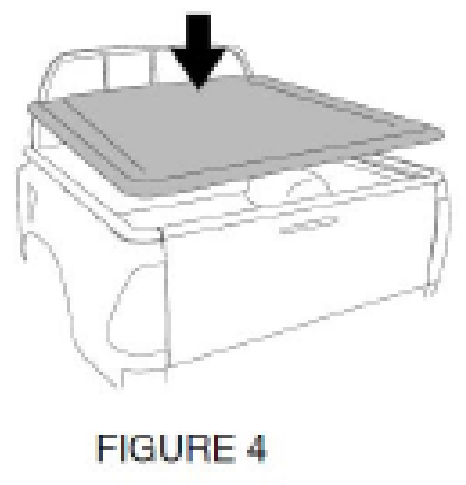

Attach small shaft end of gas strut onto gas strut brackets, by clicking them in place. Refer to Fig.4 with regard to gas strut orientation.

Important:DO NOT over tighten screws. Recommended tightening torque is 1- 3 Nm

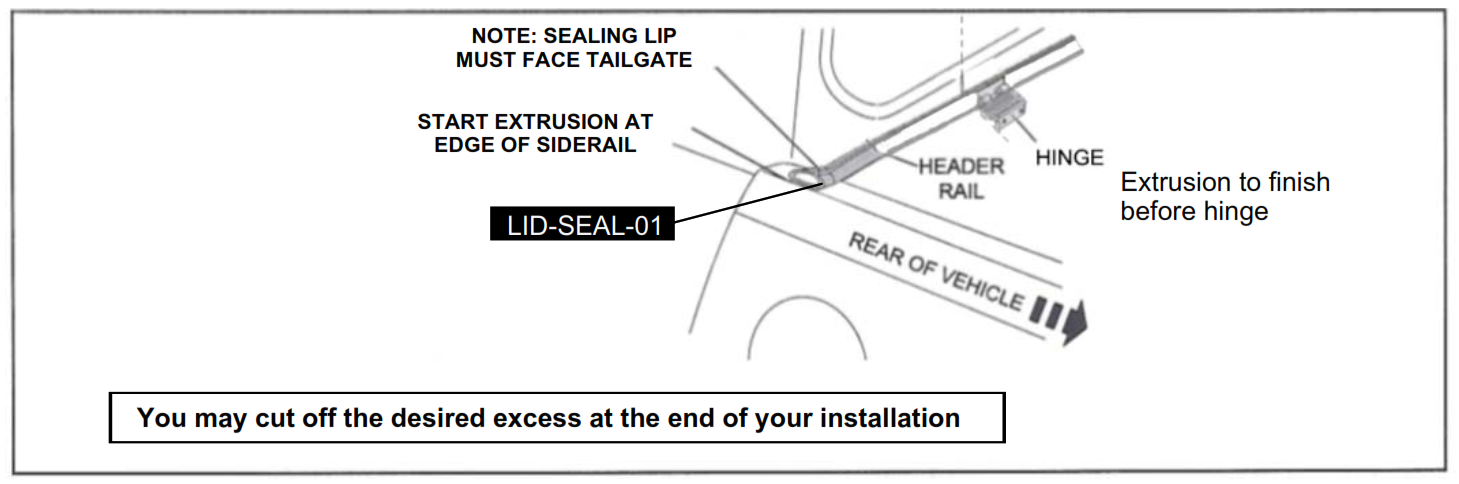

Clean header rail (where extrusion will sit) with alcohol wipes provided and wipe away the residue with a dry clean cloth. Place the extrusion tape seal along the top of the header rail with the sealing lip facing towards the tailgate. Start the extrusion at the edge of the side rail. IMPORTANT: Position extrusion as close to the header rail rear radius. Rub down firmly to ensure maximum adhesion.

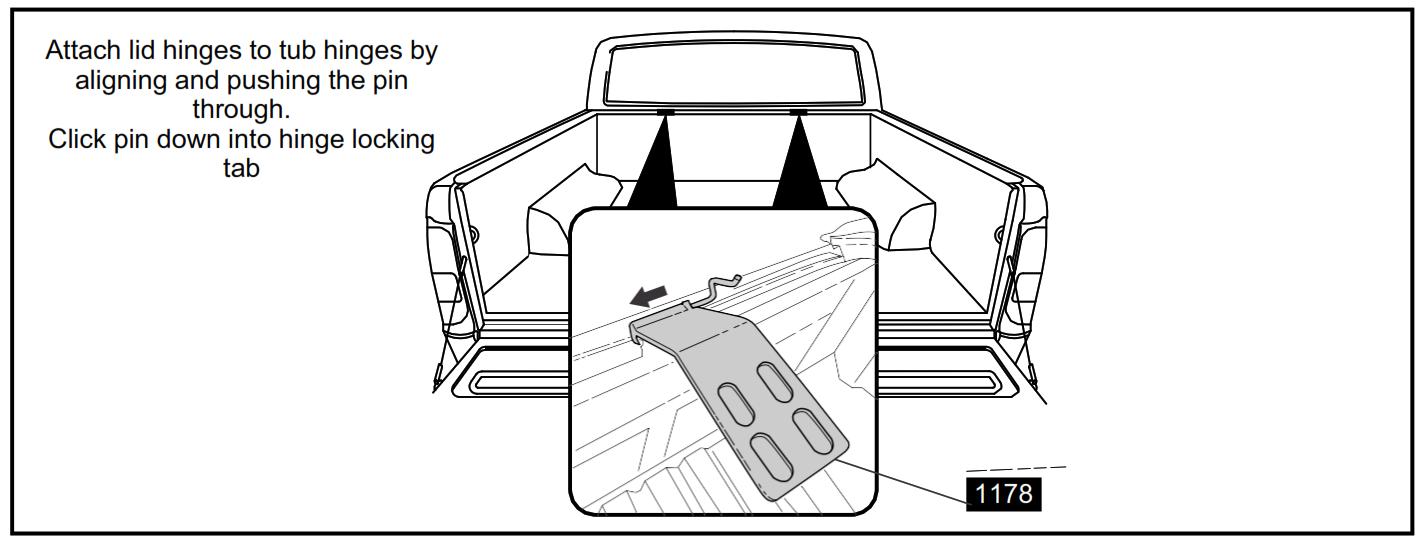

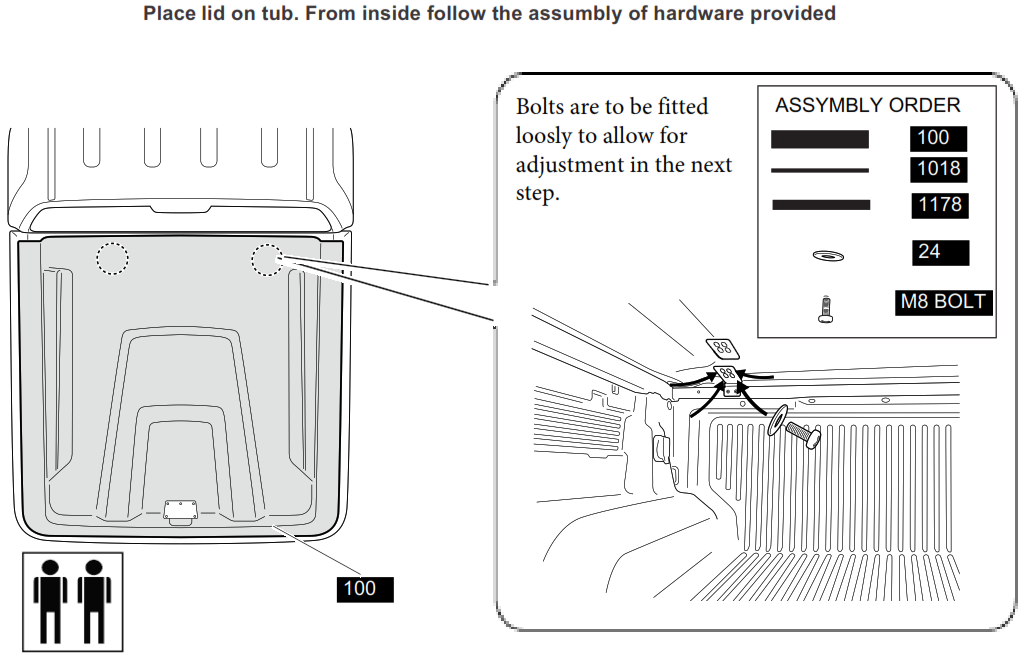

Attach lid hinges to tub hinges by aligning and pushing the pin through. Click pin down into hinge locking tabImportant:Ensure tongues are fully inserted into the hinge slots with hinge pin securely in place.Place lid on tub. From inside follow the assumbly of hardware provided

Attach lid hinges to tub hinges by aligning and pushing the pin through. Click pin down into hinge locking tabImportant:Ensure tongues are fully inserted into the hinge slots with hinge pin securely in place.Place lid on tub. From inside follow the assumbly of hardware provided Adjust Lid so it is even on both sides and pull the lid back all the way so the front of the hinge bottoms out to the inside front lip of the lid.

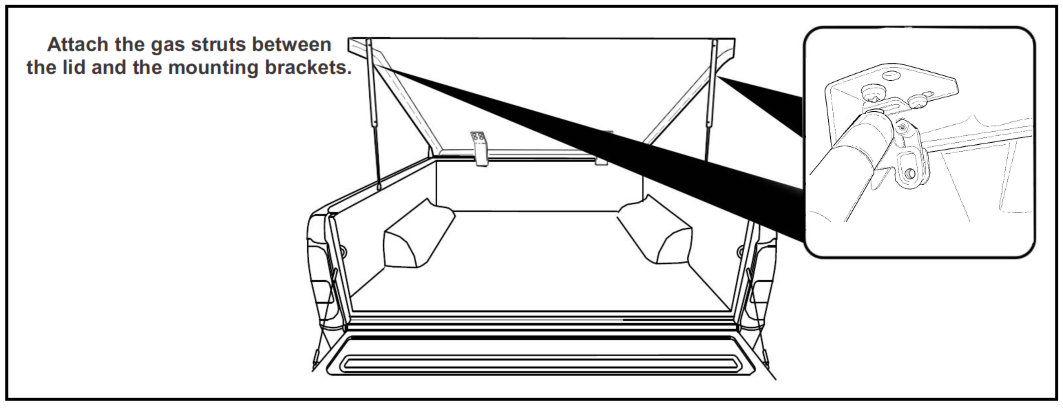

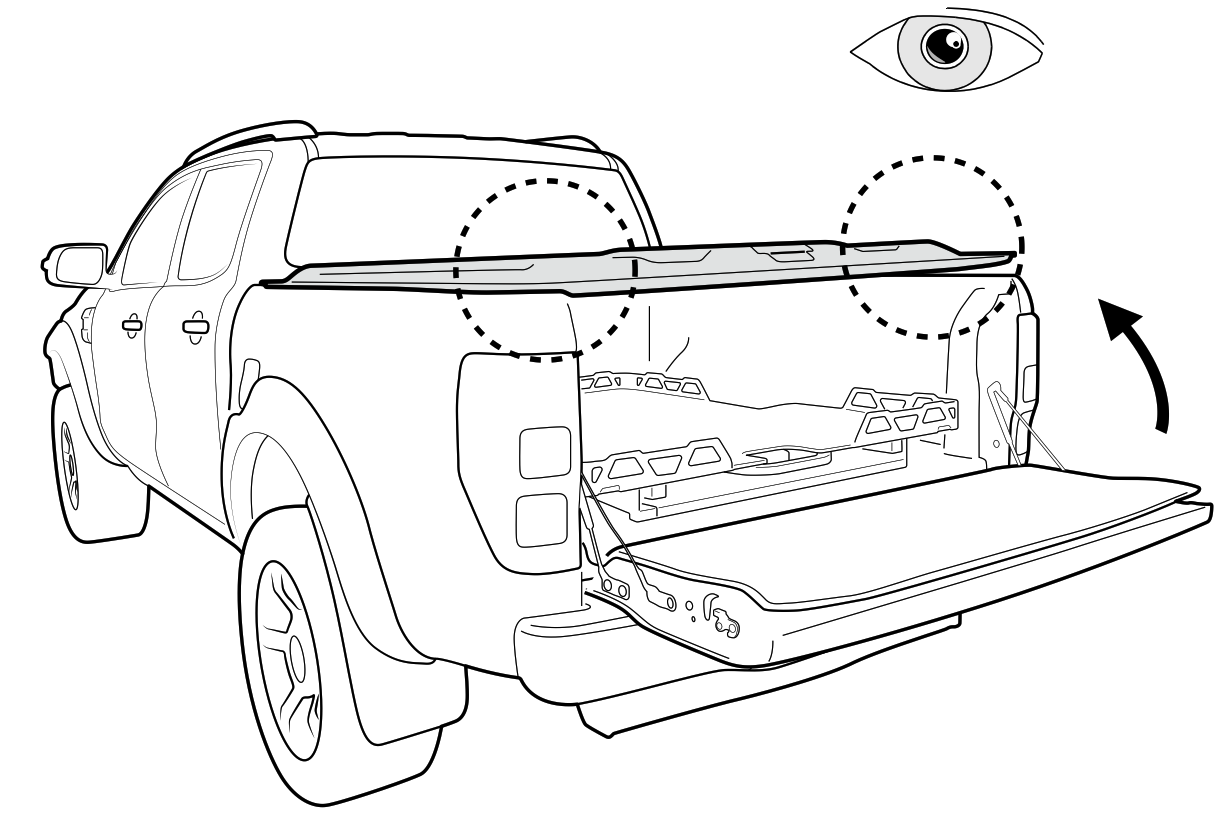

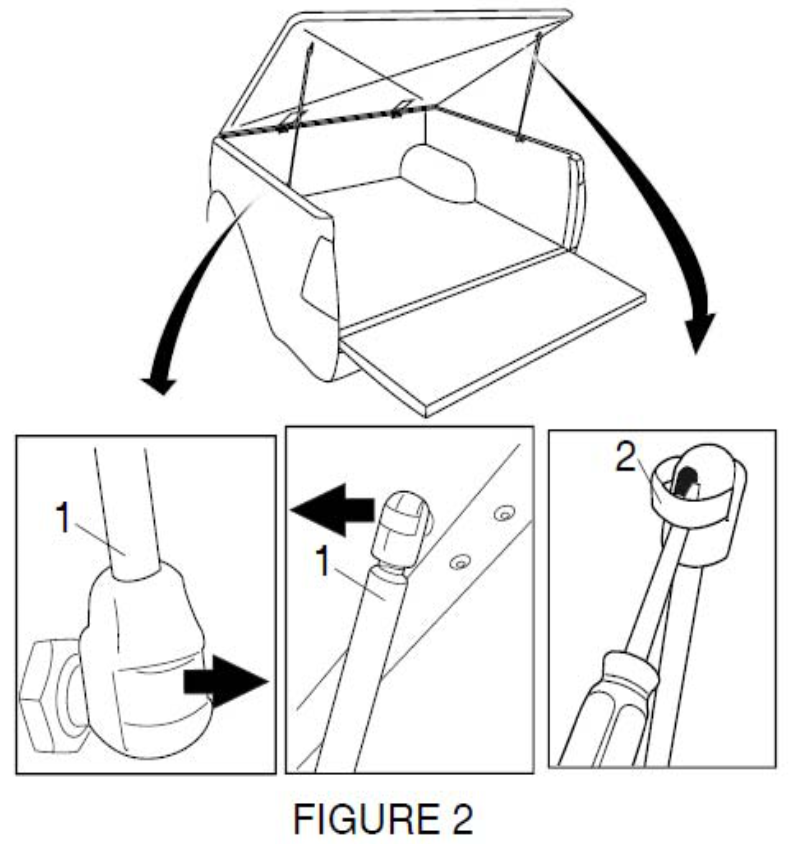

Adjust Lid so it is even on both sides and pull the lid back all the way so the front of the hinge bottoms out to the inside front lip of the lid.  With the lid in adjusted position, crawl into the tub and tighten all 8 bolts to 3nm torqueWith the Hard Tonneau Cover opened, attach the cylinder end of each gas strut onto the mounting brackets attached to the Hard Tonneau Cover by clicking into place\

With the lid in adjusted position, crawl into the tub and tighten all 8 bolts to 3nm torqueWith the Hard Tonneau Cover opened, attach the cylinder end of each gas strut onto the mounting brackets attached to the Hard Tonneau Cover by clicking into place\

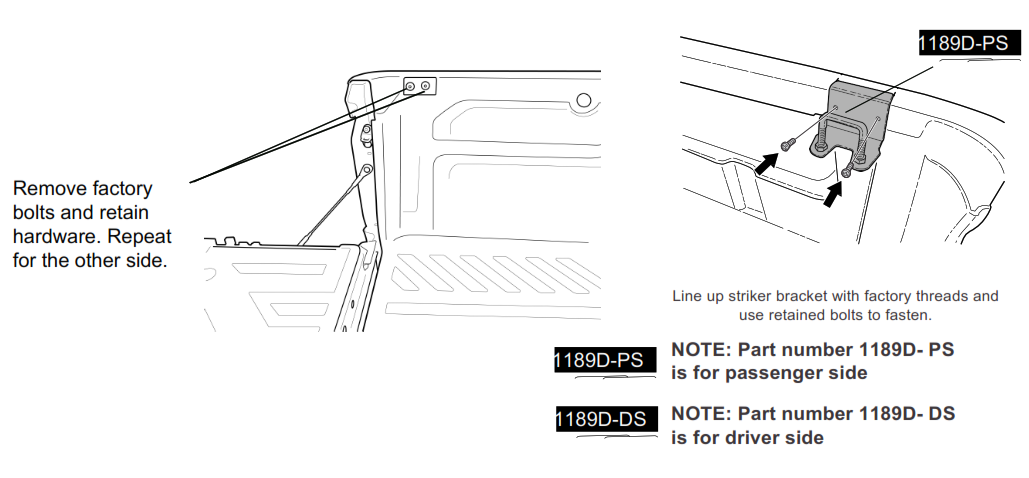

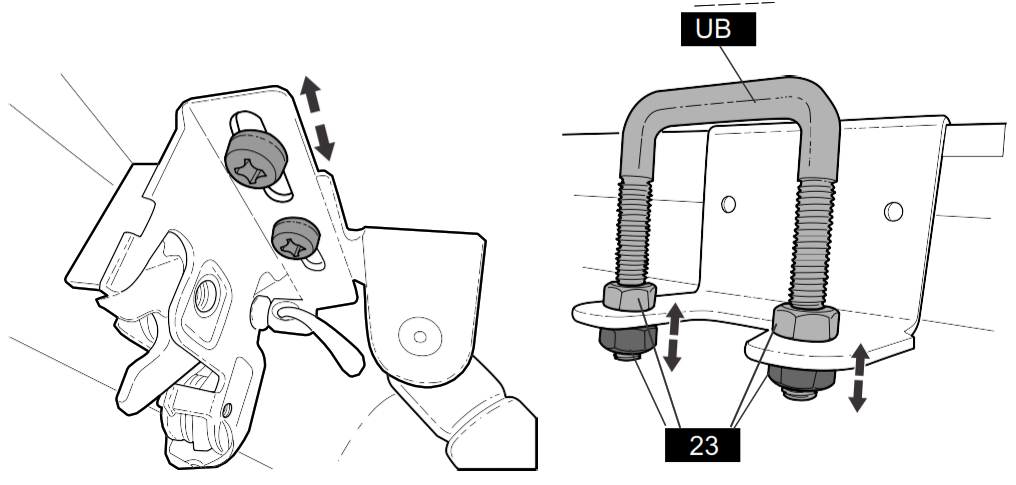

Loosen 2 screws and slide catch to align correctly with latch bar. Tighten screws to secure in place.Adjust nuts on latch bar to alter height of bar to suit. Repeat for the opposite side.

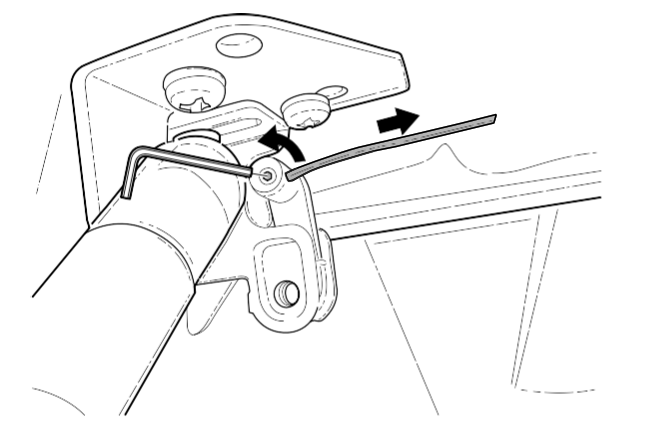

Loosen 2 screws and slide catch to align correctly with latch bar. Tighten screws to secure in place.Adjust nuts on latch bar to alter height of bar to suit. Repeat for the opposite side. Use an Allen key to loosen the hex key screw on the catch and tension cable so it is tight but doesn’t move the catch at all, then re-tighten the hex key screw.

Use an Allen key to loosen the hex key screw on the catch and tension cable so it is tight but doesn’t move the catch at all, then re-tighten the hex key screw.

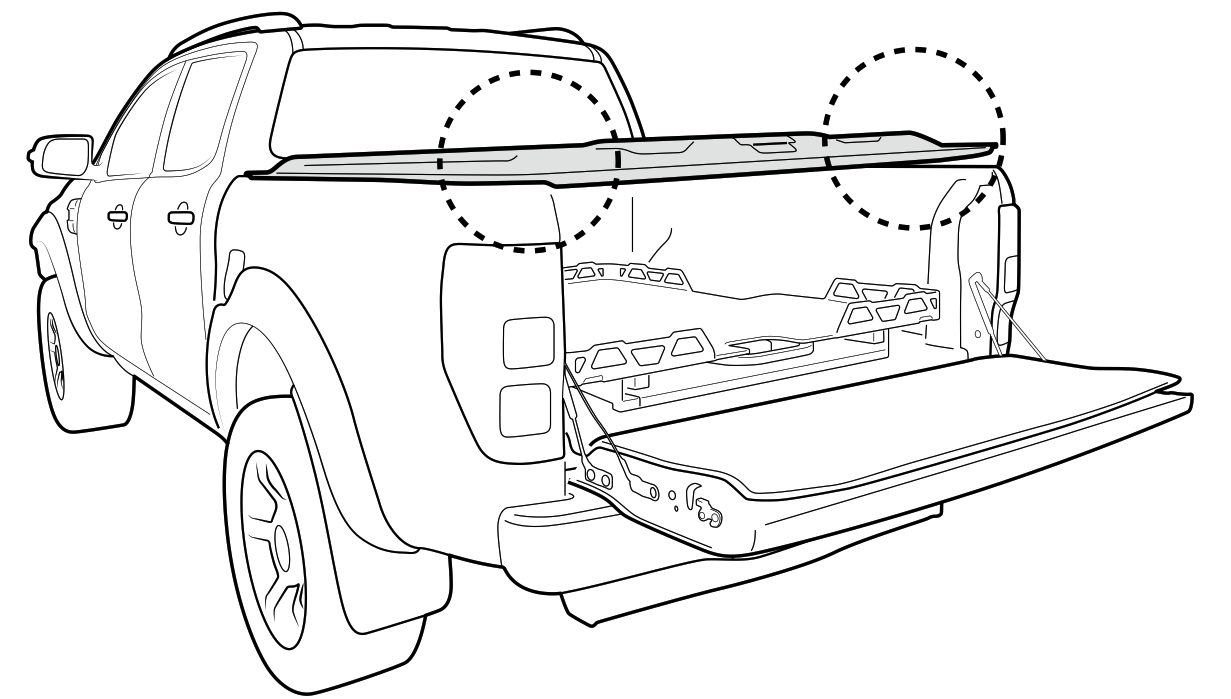

With the lid in closed position, lift the tailgate . The tailgate must close gently against the silverback lid’s seal.

With the lid in closed position, lift the tailgate . The tailgate must close gently against the silverback lid’s seal. If you find the tailgate is hard to close, put the tailgate down and adjust the U bolt up until the desired closing of tailgate is achieved.NOTE: the seal must touch and compress gently to achieve sealing.

If you find the tailgate is hard to close, put the tailgate down and adjust the U bolt up until the desired closing of tailgate is achieved.NOTE: the seal must touch and compress gently to achieve sealing.

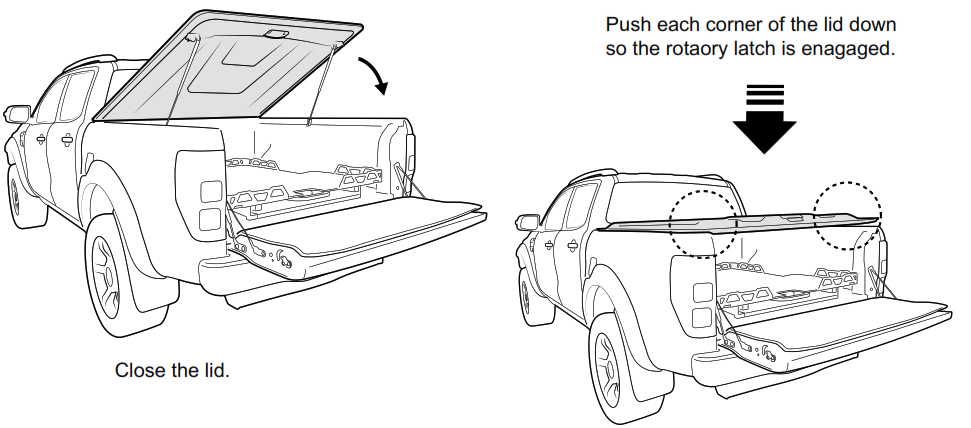

HOW TO OPERATE YOUR SILVERBACK LID

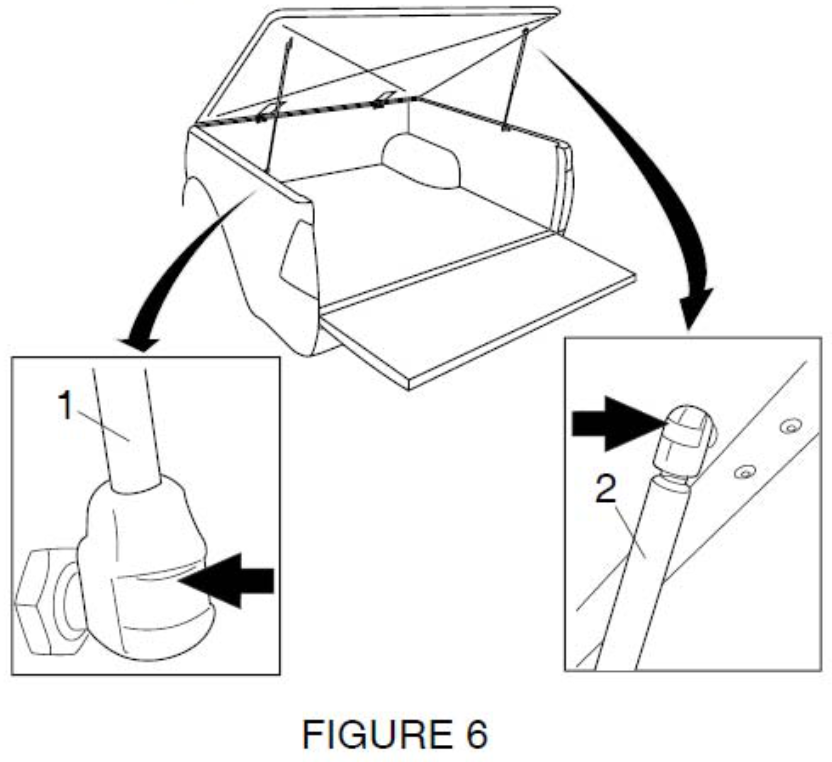

REMOVAL OF TONNEAU COVER 1. Open tonneau cover, Detach gas strut (1) by inserting a small screwdriver and adjusting the spring clip (2) on the gas strut (1). Refer to figure 2.NOTE: Do not remove the spring clip. only a small amount of lever is required to detach.

1. Open tonneau cover, Detach gas strut (1) by inserting a small screwdriver and adjusting the spring clip (2) on the gas strut (1). Refer to figure 2.NOTE: Do not remove the spring clip. only a small amount of lever is required to detach.

FIGURE 2 NOTE: 2 people are required to lift and remove the tonneau cover from the vehicle

FIGURE 2 NOTE: 2 people are required to lift and remove the tonneau cover from the vehicle

REPLACEMENT OF TONNEAU COVER

NOTE: 2 people are required to lift and fil the tonneau cover the vehicle.

NOTE: 2 people are required to lift and fil the tonneau cover the vehicle.

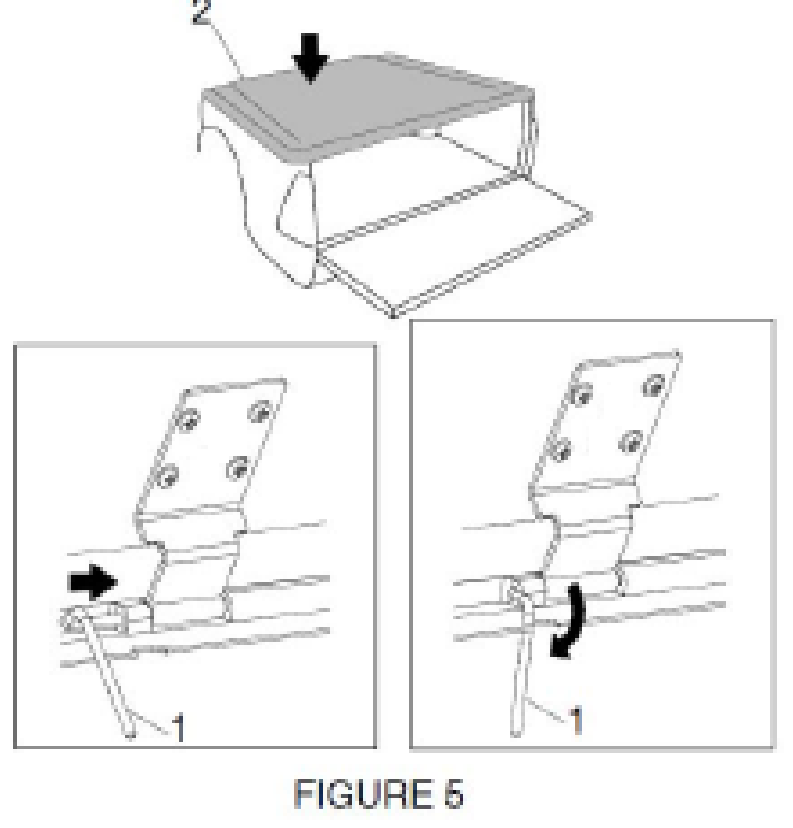

- Fil tonneau cover (2) and secure hinges with hinge pons (1). Refer to figure 5.

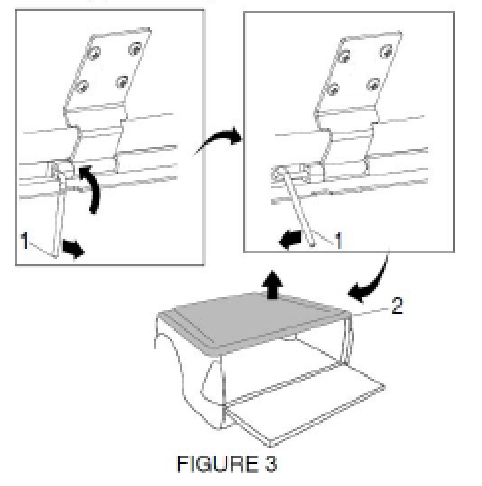

2. Remove hinge pins (1) and remove tonneau cover (2) . Refer to figure 3.

2. Remove hinge pins (1) and remove tonneau cover (2) . Refer to figure 3. 2. Attach gas struts (2) by clipping into place. Ensure narrow end (1) mounts to the vehicle. Refer to figure 6.

2. Attach gas struts (2) by clipping into place. Ensure narrow end (1) mounts to the vehicle. Refer to figure 6.

Paint care instructions:Your new painted Hard Tonneau Cover has been covered with a plastic film to protect the paint from damage. It will require cleaning and possibly light polishing after the protective film has been removed. Use polish as per new paint on a new vehicle. Wash Hard Tonneau Cover using water and normal carwash detergent and polish with an automotive polish.NOTE: Please ensure Lid is kept locked at all times when not being used, for both safety and longevity.

LD100 SILVERBACK LDVT60 Dual Cab 1pc

| Part Description | Part Number | Quantity/Length2 | CHECK LIST |

| LID FRONT HINGES | 1178 | ||

| LID TUB MOUNT WITH PINS | 1177 | 2 | |

| GAS STRUTS | 5700-320 | 2 | |

| STRUT BODY MOUNT | 1040 | 2 | |

| M8 U BOLT | UB | 2 | |

| LOCK STRICKER BRACKETS | 1189B | 2 | |

| BRACE BRACKET | 1200 | 2 | |

| SPACER BRACKET | 1018 | 2 | |

| LID NUTS & BOLTS M8 BOLTS | |||

| 25 | 8 | ||

| M8 WASHER ( 3MM THICK) | 24 | 8 | |

| SELF DRILLING SCREWS | 19 | 20 | |

| M8 NUTS | 23 | 8 | |

| M6 12MM BOLTS | 1 | 2 | |

| M6 LOCK NUT | 15 | 2 | |

| OTHER | |||

| ALLEN KEY | 42 | 1 | |

| D MOULD | LID-SEAL-01 | 2 X 300MM | |

| ALCHOLE WIPE | 1 | ||

| FITTING INSTRUCTIONS MANUAL | 1 | ||

[xyz-ips snippet=”download-snippet”]

2. Remove hinge pins (1) and remove tonneau cover (2) . Refer to figure 3.

2. Remove hinge pins (1) and remove tonneau cover (2) . Refer to figure 3. 2. Attach gas struts (2) by clipping into place. Ensure narrow end (1) mounts to the vehicle. Refer to figure 6.

2. Attach gas struts (2) by clipping into place. Ensure narrow end (1) mounts to the vehicle. Refer to figure 6.