Installation Manual

If your pressure washer is not working properly or if there are parts missing or broken, please DO NOT RETURN IT TO THE PLACE OF PURCHASE. Contact our CustomerService Department at 1-877-362-4271 or www.simpsoncleaning.com

IMPORTANT: Please make certain that the person who is to use this equipment carefullyreads and understands these instructions before operating.

Save this manual for Future reference

SAFETY GUIDELINES – DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these symbols.

![]() DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Important Safety Instructions

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- NEVER use an engine inside homes, garages, crawlspaces or other partly enclosed areas. Deadly levels of carbon monoxide can build up in these areas. Using a fan or opening windows and doors does NOT supply enough fresh air.

- ONLY use outdoors and far away from open windows, doors and vents. These openings can pull in engine exhaust.

- Even when the engine is used correctly, CO may leak into your home. ALWAYS use a battery-powered or battery backup CO alarm in your house. Read and follow all directions for CO alarm before using. If you feel sick, dizzy or weak at anytime, move to fresh air immediately. See a doctor. You could have carbon monoxide poisoning.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Save these instructions

*NOTICE: The high pressure spray from your pressure washer is capable of causing damage to surfaces such as wood, glass, automobile paint, auto striping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the item to be cleaned to assure yourself that it is strong enough to resist damage from the force of the spray.

Changing Nozzles on Spray Wand (Fig. 6)![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Pull quick-connect coupler (E) back and insert nozzle (K). 6

- Release quick-connect coupler and twist nozzle to make sure it is secure in coupler.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

How to APPLY chemicals/cleaning solvents (FIG. 7)

Applying chemicals or cleaning solvents is a low pressure operation. NOTE: Use only soaps and chemicals designed for pressure washer use. Do not use bleach.To Apply Chemicals:

- Ensure detergent siphon hose (F, Figure 9) is attached to barbed fitting location near high pressure hose connection of pump as shown.

- Place other end of detergent siphon hose with filter on it into container holding chemical/cleaning solution. NOTE: For every 7 gallons of water pumped 1 gallon of chemical/cleaning solution will be used.

- Install low pressure (black) nozzle into quick connect fitting of spray wand, see How To Use Spray Wand paragraph in this section.

- After use of chemicals, place detergent siphon hose into container of clean water and draw clean water through chemical injection system to rinse system thoroughly. If chemicals remain in the pump, it could be damaged. Pumps damaged due to chemical residue will not be covered under warranty.

NOTE: Chemicals and soaps will not siphon if the black soap nozzle is not installed on the spray wand.

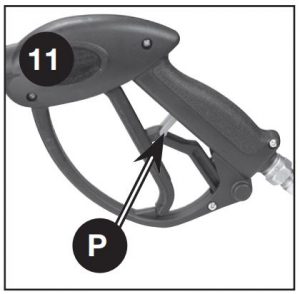

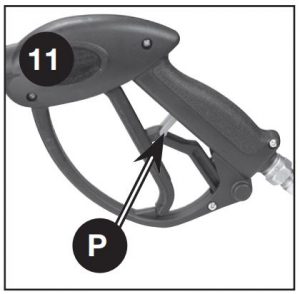

Starting (FIG. 8–11)![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Your washer operates at fluid pressures and velocities high enough to penetrate human and animal flesh, which could result in amputation or other serious injury. Leaks caused by loose fittings or worn or damaged hoses can result in injection injuries. DO NOT TREAT FLUID INJECTION AS A SIMPLE CUT! See a physician immediately!

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Breathing exhaust fumes will cause serious injury or death! Engine exhaust contains carbon monoxide, an odorless and deadly gas.

- Operate pressure washer in a well-ventilated area. Avoid enclosed areas such as garages, basements, etc.

- Never operate unit in or near a location occupied by humans or animals.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Never fill fuel tank completely. Fill tank to 1/2″ (12.7 mm) below bottom of filler neck to provide space for fuel expansion. Wipe any fuel spillage from engine and equipment before starting engine.

- DO NOT let hoses come in contact with very hot engine muffler during or immediately after use of your pressure washer. Damage to hoses from contact with hot engine surfaces will NOT be covered by warranty.

NOTICE: Risk of property damage. Never pull water supply hose to move pressurewasher. This could damage hose and/or pump inlet.

- DO NOT use hot water, use cold water only.

- Never turn water supply off while pressure washer engine is running or damage to pump will result.

- DO NOT stop spraying water for more than two minutes at a time. Pump operates in bypass mode when spray gun trigger is not pressed. If pump is left in bypass mode for more than two minutes internal components of the pump can be damaged.

If you do not understand these precautions, please contact our customer service department at www.simpsoncleaning.com

Prior to starting, refer to your engine manual for proper starting procedure.

- In a well ventilated outdoor area add fresh, high quality, unleaded gasoline with a pump octane rating of 86 or higher. Do not overfill. Wipe up spilled fuel before starting the engine. Refer to Engine Owner’s Manual for correct procedure.

NOTICE: Use of fuels with greater than 10% ethanol are not approved for use in this product per EPA regulations and will damage the unit and void the warranty.

- Check engine oil level. Refer to Engine Owner’s Manual for correct procedure.

- Check pump oil level. The oil level should come to the dot in the middle of the sight glass. Refer to the Pump paragraph under Maintenance.

- Connect the water hose to the water source. Turn the water source on to remove all air from the hose. When a steady stream of water is present, turn the water source off.

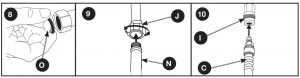

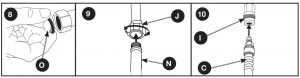

- Verify the filter screen (O) is in water inlet of pump. NOTE: Convex side faces out.

- Connect water source (N) to pump inlet (J). NOTE: Water source must provide a minimum of 5 gallons per minute at 20 PSI.

- Connect high pressure hose (C) to pump outlet (I).

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Choose the correct nozzle for the job to be performed. See How To Use spray Wand instructions in this section. NOTE: If applying a chemical or cleaning solution, see How To Apply Chemicals/Cleaning Solvents instructions in this section.

- Turn water source on.

NOTICE: Risk of property damage. Failure to do so could cause damage to the pump.

- Remove all air from the pump and high pressure hose by depressing trigger until a steady stream of water is present.

- Start engine. See Engine Owner’s Manual for correct procedure.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Depress trigger on gun to start water flow.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Release trigger to stop water flow.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Shutting down

- After each use, if you have applied chemicals, place detergent siphon hose into container of clean water and draw clean water through chemical injection system to rinse system thoroughly.

NOTICE: Risk of property damage. Failure to do so could cause damage to the pump.2. Turn engine off. See Engine Owner’s Manual.NOTICE: Risk of property damage. NEVER turn the water off with the engine running.

3. Turn water source off.4. Pull trigger on spray gun to relieve any water pressure in hose or spray gun.NOTE: Failure to release system pressure will prevent removal of high pressure hose from spray gun or pump connection.5. See Storage section in this manual for proper storage procedures.

Maintenance

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

To ensure efficient operation and longer life of your pressure washer, a routine maintenance schedule should be prepared and followed. If the pressure washer is used in unusual conditions, such as high-temperatures or dusty conditions, more frequent maintenance checks will be required.

ENGINE Consult the Engine Owner’s Manual for the manufacturer’s recommendations for any and all maintenance. NOTE: The engine drain plug is located at the rear of the unit.

PUMP (fig. 12)NOTE: The Pump was filled with oil at the factory. The preferred oil is SIMPSON® Premium Pump Crankcase Oil. If this oil is not available, an SAE 15W-40 oil may be used. Change the pump oil after the first 50 hours of operation and every 100 hours thereafter, or every 3 months.

To Check OilThe oil level should come to the dot in the middle of the sight glass (AA).

How To Change Pump Oil

- Loosen pump oil fill plug (BB).

- Place a container under the pump oil drain plug (CC).

- Remove pump oil drain plug.

- After oil is drained, replace pump oil drain plug. Tighten securely.

- Refill pump using SIMPSON® Premium Pump Crankcase Oil. If this oil is not available, an SAE 15W-40 oil may be used.

- Replace pump oil fill plug and tighten securely.

If there is a problem with the pump contact us at www.simpsoncleaning.com

ConnectionsConnections on pressure washer hoses, gun and spray wand should be cleaned regularly and lubricated with light oil or lithium grease to prevent leakage and damage to the o-rings.

NOZZLE CLEANING (fig. 13)If the nozzle becomes clogged with foreign materials, such as dirt, excessive pressure may develop. If the nozzle becomes partially clogged or restricted, the pump pressure will pulsate. Clean the nozzle immediately using the nozzle kit supplied and the following instructions:

- Shut off the pressure washer and turn off the water supply.

- Pull trigger on gun handle to relieve any water pressure.

- Disconnect the spray wand from the gun.

- Remove the high pressure nozzle (K) from the spray wand. Remove any obstructions with the nozzle cleaning tool provided and back flush with clean water.

- Direct water supply (N) into nozzle to back flush loosened particles for 30 seconds.

- Reassemble the nozzle to the wand.

- Reconnect spray wand to gun and turn on water supply.

- Start pressure washer and place spray wand into high pressure setting to test.

CLEAN THE WATER INLET FILTER (FIG. 8)This screen filter should be checked periodically and cleaned if necessary.

- Remove filter by grasping end and removing it from water inlet of pump.

- Clean filter by flushing it with water on both sides.

- Re-insert filter into water inlet of pump. NOTE: Convex side faces out.

NOTE: Do not operate the pressure washer without filter properly installed.

STORAGE

ENGINEConsult the Engine Owner’s Manual for manufacturer’s recommendations for storage.

PUMPThe manufacturer recommends using SIMPSON® / POWERWASHER® Pump Guard or equivalent when storing the unit for more than 30 days and/or when freezing temperatures are expected. SIMPSON® / POWERWASHER® Pump Guard is environmentally friendly.NOTE: Using pump guard helps provide proper lubrication to the internal seals of the pump regardless of temperature or environment.NOTICE: Risk of property damage. Use only SIMPSON® / POWERWASHER® Pump Guard or equivalent. Other products could be corrosive and/or contain alcohol which may cause pump damage.

PRESSURE WASHER

- Drain all water from high pressure hose and wrap it onto hose wrap.

- Drain all water from the spray gun and wand by holding spray gun in a vertical position with nozzle end pointing down and squeezing trigger. Store in gun holder.

- Wrap up and secure detergent siphon hose so it is protected from damage.

ACCESSORIES

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

NOTICE: The use of any other accessory not recommended for use with this tool could be hazardous. Use only accessories rated equal to or greater than the rating of the pressure washer.

Service InformationDo not return this product to your retailer. Please contact our customer service department at www.simpsoncleaning.com

LIMITED WARRANTY

The manufacturer of this product agrees to repair or replace designated parts that prove defective within the warranty period listed below at the manufacturer’s sole discretion. Specific limitations/extensions and exclusions apply.

This warranty covers defects in material and workmanship and not parts failure due to normal wear, depreciation, abuse, accidental damage, negligence, improper use, maintenance, water quality or storage. To make a claim under the terms of the warranty, all parts said to be defective must be retained and available for return upon request to a designated Warranty Service Center for warranty inspection. The judgments and decisions of the manufacturer concerning the validity of warranty claims are final.

These warranties pass through to the end user and are non-transferable. As a factory authorized and trained Warranty Service Center, the factory will honor the terms of all component warranties and satisfy claims of the appropriate warranty provisions.

Normal wear items include, but are not limited to, valves and seals, which are not covered by this warranty.

This warranty replaces all other warranties, express or implied, including without limitation any warranties of merchantability or fitness for a particular purpose and all such warranties are hereby disclaimed and excluded by the manufacturer. The manufacturer’s warranty obligation is limited to repair and replacement of defective products as provided herein and the manufacturer shall not be liable for any further loss, damages, or expenses – including damages from shipping, accident, abuse, acts of God, misuse, or neglect. Neither is damage from repairs using parts not purchased from the manufacturer or alterations performed by non-factory authorized personnel. Failure to install and operate equipment according to the guidelines put forth in the instruction manual shall void warranty.

This warranty does not cover the following: machines used for rental purposes, damage resulting from shipping (claims must be filed with freighter), accident, abuse, act of God, misuse, or neglect. Neither is damage from repairs or alterations performed by non-factory authorized personnel or failure to install and operate equipment according to the guidelines put forth in the instruction manual.

The manufacturer will not be liable to any persons for consequential damage, for personal injury, or for commercial loss.

Warranty does not apply to failures due to :

- Freight damage

- Damage due to chemical deterioration, scale build up, rust, corrosion or thermal expansion

- Freeze damage

- Damage caused by parts or accessories not obtained from an authorized dealer or not approved by the manufacturer.

- Normal wear of moving parts or components affected by moving parts.

EngineCovered by engine manufacturer warranty. See engine manual.

High Pressure Pump (defects in material and workmanship)Two (2) years from date of purchase.

Frame (defects in material and workmanship)Ten (10) year from date of purchase.

OTHER COMPONENTS (defects in material and workmanship)Includes nozzles, hoses, spray guns, wands, tires, feetNinety (90) days from date of purchase.

Trouble Shooting Guide

FNA Group, Inc.Elk Grove Village, IL 60007

Internet Address: www.simpsoncleaning.comWarranty Registration via Internet

Copyright. All Rights Reserved

Assembled in U.S.A with domestic and foreign components

Simpson Premium Pressure Washer Installation Manual – Simpson Premium Pressure Washer Installation Manual –

Questions about your Manual? Post in the comments!

[xyz-ips snippet=”download-snippet”]