After selecting Verify IDs/DTC Codes, trigger each sensor of the vehicle. In this example, the RR sensor is not triggering.

After selecting Verify IDs/DTC Codes, trigger each sensor of the vehicle. In this example, the RR sensor is not triggering.

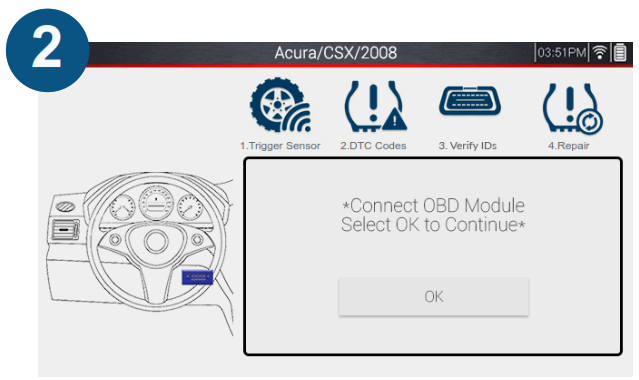

Continuing on to DTC Codes, ensure the OBDII Cable is connected to the tool and vehicle with the ignition in the ON position, Then tap “OK”.

Continuing on to DTC Codes, ensure the OBDII Cable is connected to the tool and vehicle with the ignition in the ON position, Then tap “OK”.

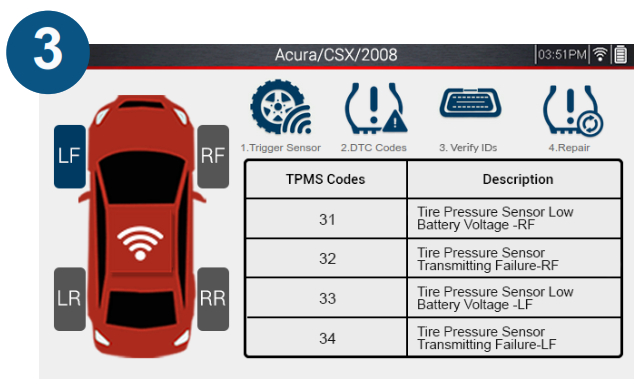

In this example, it shows that two codes are present. The first code may be the issue regarding the sensor.

In this example, it shows that two codes are present. The first code may be the issue regarding the sensor.

Continuing on to Verify IDs, this example shows that there is an ID stored in the vehicle but triggering the sensor shows no sensor detected. The sensor needs to be replaced.

Continuing on to Verify IDs, this example shows that there is an ID stored in the vehicle but triggering the sensor shows no sensor detected. The sensor needs to be replaced.

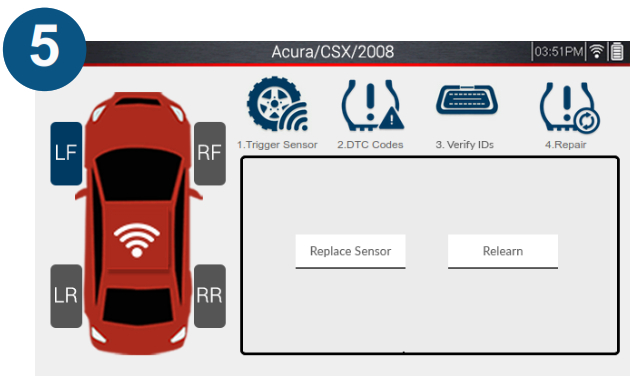

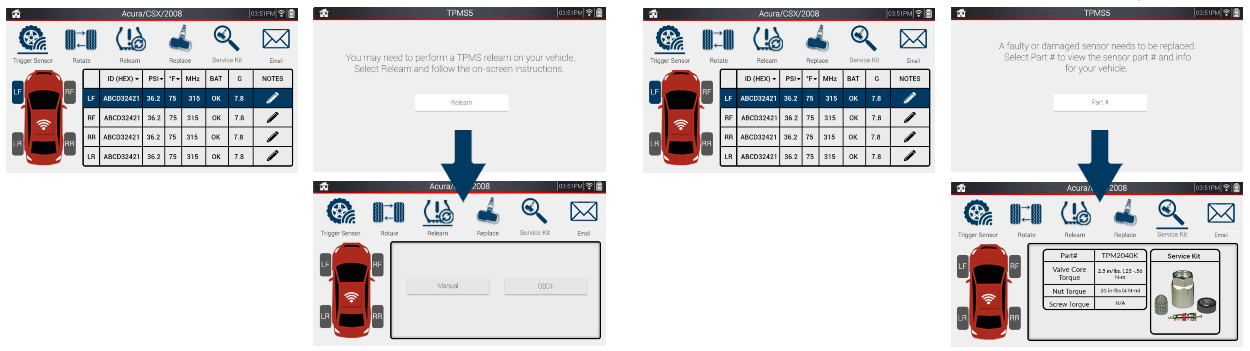

Continuing on to Repair, selecting either Replace or Relearn will take you to that screen at the main TPMS function where you can program a sensoror perform a relearn

Continuing on to Repair, selecting either Replace or Relearn will take you to that screen at the main TPMS function where you can program a sensoror perform a relearn

In this example, programming a new sensor is needed. From the program screen, a new sensor can be programmed, and a relearn can be performed if necessary. See section B-4 for programming, and B-2 for relearns

In this example, programming a new sensor is needed. From the program screen, a new sensor can be programmed, and a relearn can be performed if necessary. See section B-4 for programming, and B-2 for relearns

Note: If all sensors appear on the Verify IDs screen but the IDs do not match, a relearn is necessary to match the IDs.

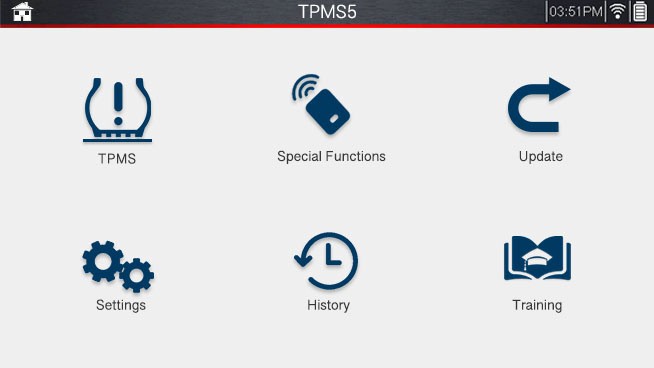

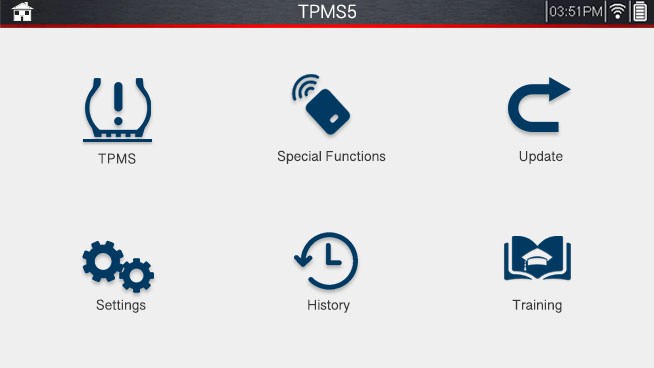

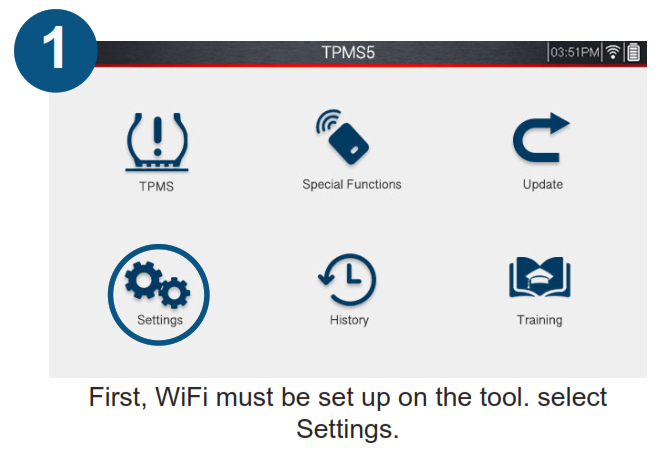

D – Settings

Within the Settings function, a variety of customizable settings can be changed for user preference. Each setting is described in the next section.

| Profile | Change internal tool information including Company Name, Address, and Phone Number. |

| Date and Time | Change Date and lime settings including Date, lime, Time Zone, set automatic Date and Time On/Off. |

| Language | Change between 10+ Languages including English, Spanish, French, and more. |

| Region | Change Region from North America, Europe, Australia, or Japan. |

| Units | Change Pressure (PSI, Bar, kPa) and Temperature (°F, °C) units. |

| Sensor ID Format | Change Sensor ID Formats from Decimal (0-9), Hexadecimal (A-F 0-9), or Auto. |

| Screen Brightness | Change Screen Brightness from 20%-100%. |

| Sound | Change Sound settings including Beep (On/Off), and Vibration (On/Off). |

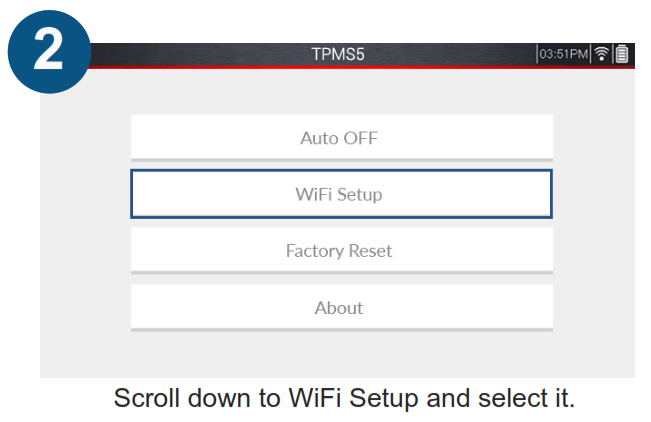

| Auto OFF | Change Auto OFF settings from 10min-60min or Off completely. |

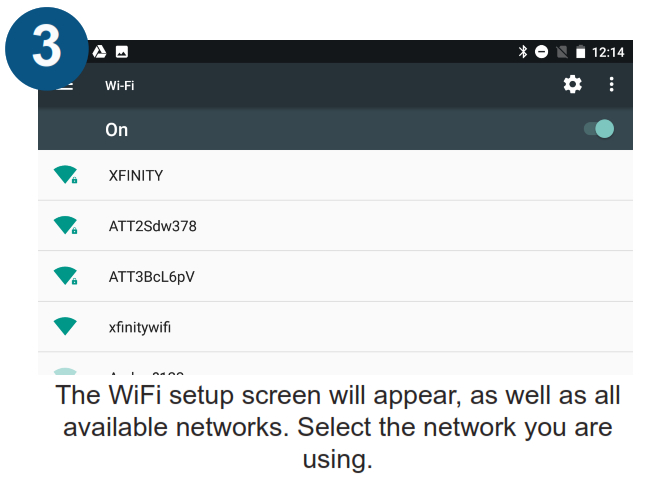

| WiFi Setup | Change Wifi Settings by scanning for available networks and connecting. (This setting is necessary for WiFi Updating and Emailing). |

| Factory Reset | Erase all data from the tool and return it to factory settings. WARNING: This will remove all Jobs, settings, and update information from the tool |

| About | View various tool information including Serial Number, Version, Copyright information, and more. |

E – History

Within the History function, view all saved jobs in the tool and revisit them. Jobs will be listed in order by date and will display customer name and vehicle Make, Model, and Year.

F – Training

Within the Training function, view a TPMS troubleshooter that takes the user through common TPMS issues to reach a solution. As well as an in-depth Demo mode that takes the user step-by-step through the main TPMS functio.

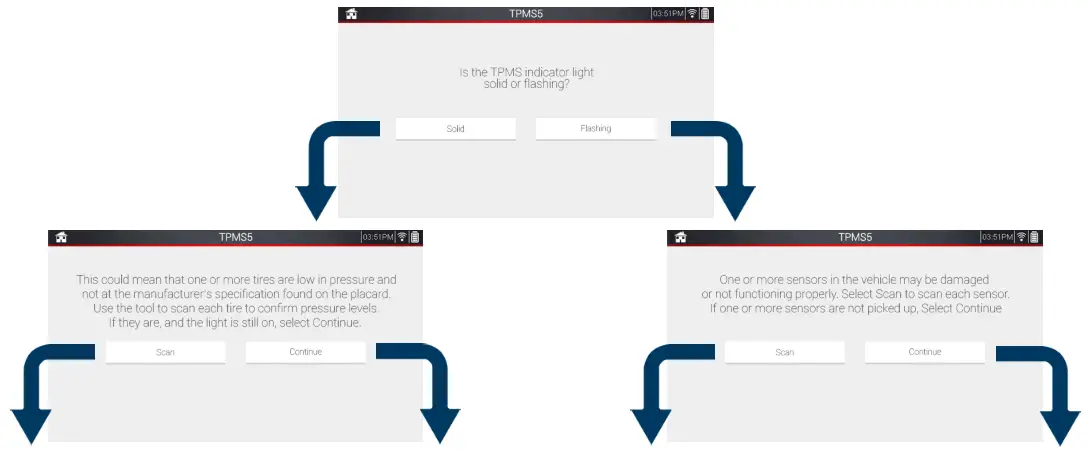

Troubleshooter

Troubleshooter

Troubleshooter allows the user to diagnose common TPMS issues. The function will ask common questions to guide the user to a solution. Tap each answer as it applies, and the tool will take the user to the screen necessary.

|

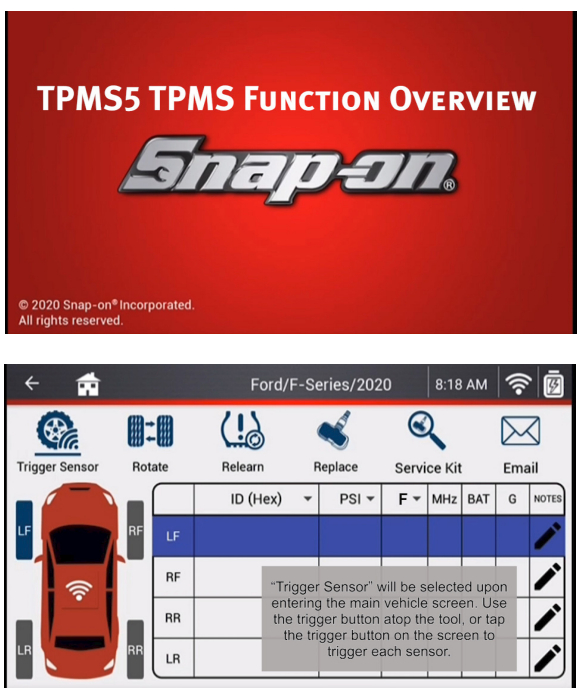

Demo

Demo

Demo mode takes the user step-by-step through the main TPMS function. From the main menu, all the way down to sending an email, the user can Demo the tool. Use this mode for practice or training purposes.Note: this mode is for Demo purposes only, any information that appears on-screen are examples and information may not match certain situations.

Chapter 3:

Updating

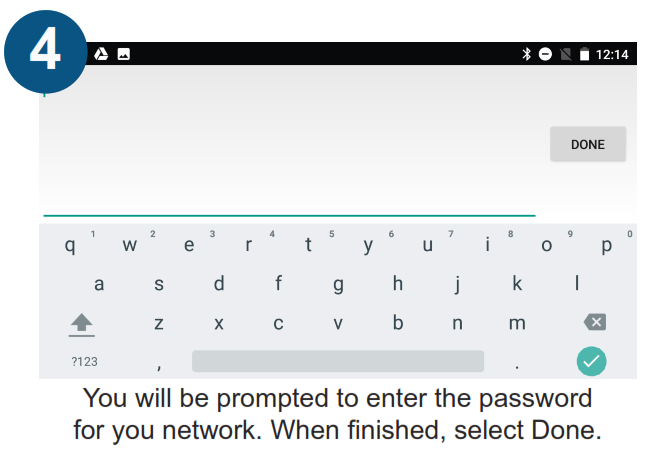

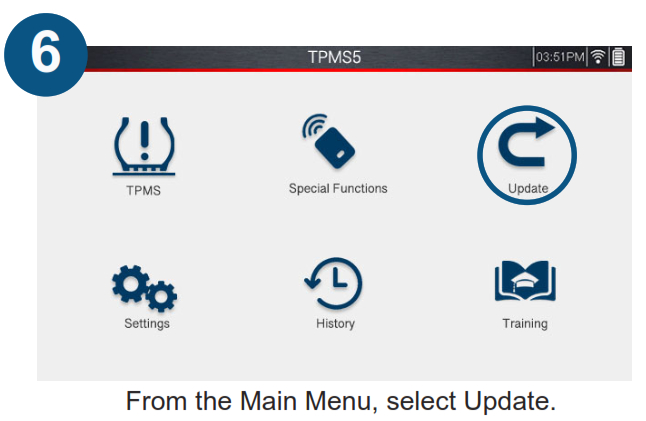

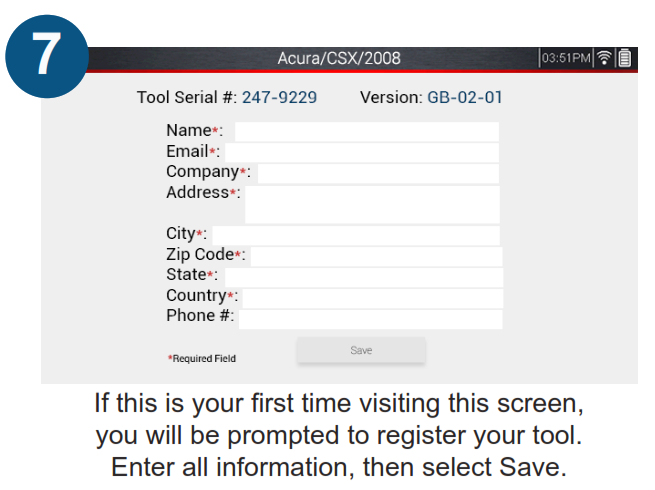

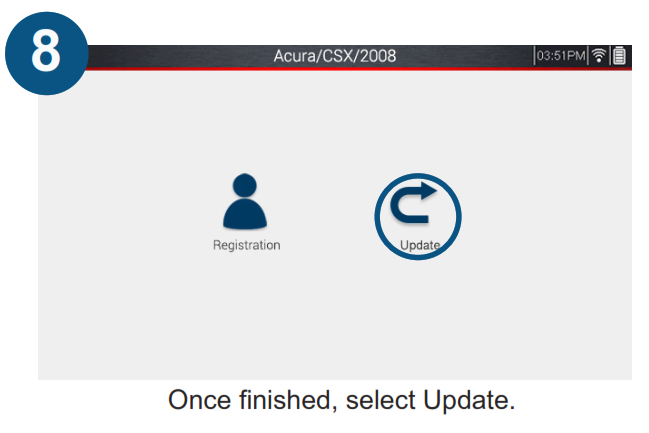

The TPMS5 can be updated directly through WiFi. Ensure the tool is plugged in and charging whenever performing an update.

A. via WiFi Connection

|

|

|

|

|

|

|

|

|

The Tool will begin updating, DO NOT interrupt this process. Once finished, the tool will restart and it will be on the latest software version. The Tool will begin updating, DO NOT interrupt this process. Once finished, the tool will restart and it will be on the latest software version. |

chapter 4:

chapter 4:

Warranty/Service and Repair

Snap-on Tools Company Limited One (1) Year Warranty

Snap-on Tools Company (the “Seller”) warrants only to original purchasers who use the Equipment in their business that under normal use, care and service, the Equipment (except as otherwise provided herein) shall be free from defects in material and workmanship for one year from the date of riginal invoice. Seller does not provide any warranty for accessories used with the Equipment that are not manufactured by Seller. SELLER’S OBLIGATIONS UNDER THIS WARRANTY ARE LIMITED SOLELY TO THE REPAIR OR, AT SELLER’S OPTION,

REPLACEMENT OF EQUIPMENT OR PARTS WHICH TO SELLER’S SATISFACTION ARE DETERMINED TO BE DEFECTIVE AND WHICH ARE NECESSARY, IN SELLER’S JUDGMENT, TO RETURN THIS EQUIPMENT TO GOOD OPERATING CONDITION. NO OTHER WARRANTIES, EXPRESS OR IMPLIED OR STATUTORY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTYOF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL APPLY AND ALL SUCH WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED.

SELLER SHALL NOT BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL COSTS OR DAMAGES INCURRED BYPURCHASERS OR OTHERS (including, without limitations, lost profits, revenues, and anticipated sales, business opportunities or goodwill, or interruption of business and any other injury or damage).

This Warranty does not cover (and separate charges for parts, labor and related expenses shall apply to) any damage to, malfunctioning, inoperability or improper operation of the Equipment caused by, resulting from or attributable to (A) abuse, misuse or tampering; (B) alteration, modification or djustment of the Equipment by other than Seller’s authorized representatives; (C) installation, repair or maintenance (other than specified operator aintenance) of the Equipment or related equipment, attachments, peripherals or optional features by other than Seller’s authorized representatives; (D) mproper or negligent use, application, operation, care, cleaning, storage or handling; (E) fire, water, wind, lightning or other natural causes; (F) adverse nvironmental conditions, including, without limitation, excessive heat, moisture, corrosive elements, dust or other air contaminants, radio frequency nterference, electric power failure, power line voltages beyond those specified for the Equipment, unusual physical, electrical or electromagnetic stress nd/or any other condition outside of Seller’s environmental specifications; (G) use of the Equipment in combination or connection with other equipment, attachments, supplies, or consumables not manufactured or supplied by Seller; or (H) failure to comply with any applicable federal, state or local regulation, requirement or specification governing emission analyzers and related supplies or consumables. Repairs or replacements qualifying under this Warranty will be performed on regular business days during Seller’s normal working hours within a reasonable time following purchaser’s request. All requests for warranty service must be made during the stated warranty period. Proof of purchase date is required to make a Warranty request. This Warranty is nontransferable.

TPMS5 Technical Support and Service

| US SERVICE AND TECH SUPPORT35990 Industrial Road,Livonia, Michigan 48150844-349-8767 | CANADA SERVICE AND TECH SUPPORT4-2355 Royal Windsor Drive, Mississauga,Ontario L5J 4S8855-455-8767 |

Email: [email protected]

Assembled in TaiwanSnap-on is a trademark, registered in the United States and other countries, of Snap-on Incorporated.©2020 Snap-on Incorporated. All Rights Reserved. All other marks are trademarks of their respective holders.Snap-on, 2801 80th Street, Kenosha, WI 53143 www.snapon.comPatents: See https://patents.snapon.com

EU Declaration of Conformity

Product Model/Product

Product Name: Tire-pressure monitoring system

Model Name: TPMS5

Name and address of the manufacturer or his authorized representative:ATEQ INSTRUMENTS (ASIA) PTE LTD.TAIWAN BRANCH (SINGAPORE) NO.3, LANE 223, SAN JIA DONG STREET, 40642, TAICHUNG, TAIWAN

This declaration of conformity is issued under the sole responsibility of the manufacturer.

The objection of the declaration

Tire-pressure monitoring systemThe object of the declaration described above is in conformity with the relevant Union harmonization legislation:Radio Equipment (RED) Directive 2014/53/EU

6. References to the relevant harmonized standards used or references to the other technical specifications in relation to which conformity is declared:RED: EN 300 328 V2.2.2, EN 301 893 V2.1.1, EN 300 330 V2.1.1, EN300 220-1 V3.1.1, EN300 220-2 V3.2.1

7. Additional information:Signed for and on behalf of:ATEQ INSTRUMENTS (ASIA) PTE LTD.TAIWAN BRANCH (SINGAPORE)Taichung, Taiwan 2020/8/19 Roger Lin / RD Manager

Roger Lin / RD Manager

References

[xyz-ips snippet=”download-snippet”]

Troubleshooter

Troubleshooter Demo

Demo