INVISIBLE SERIES DISC SYSTEMDG-1 DEPTH GAUGE MANUAL

DG-1 DEPTH GAUGE

BOX CONTENTS

(1) Depth Gauge(1) Wired Measurement Probe(1) Magnetic Locator(1) Calibration Disc(1) Carrying Case READ THIS DOCUMENT IN ITS ENTIRETY BEFORE ATTEMPTING USE.

READ THIS DOCUMENT IN ITS ENTIRETY BEFORE ATTEMPTING USE.

- Read these instructions.

- Keep these instructions.

- Heed all warnings.

- Follow all instructions.

- Clean only with a dry cloth.

- Only use attachments/accessories specified by Sonance.

- Refer all servicing to qualified service personnel.

INTRODUCTION

The Sonance DISC System provides a highly accurate method for non-destructively quantifying the thickness of a finish applied on top of a Sonance invisible speaker diaphragm. The Sonance DG-1 handheld depth gauge uses a magnetic sensor to measure the distance between the top of the finished speaker and steel discs embedded in all four corners behind the speaker diaphragm of Sonance Motion Flex Invisible Speakers (Figure 1).

The depth gauge has been pre-calibrated to account for the invisible speaker’s total diaphragm thickness. Therefore, the measurement you read on the gauge will tell you the actual thickness of the finishing material on the surface of the diaphragm, in mm–assuming you have a smooth, level finish across the entire surface.

This system should be used after all drywall mud/ topping compound has been applied, feathered, leveled, cured, and sanded–but before any priming, painting, or final finishing steps are performed. This gives the installer the opportunity to verify and potentially alter the mud/finish thickness before it’s too late.

Staying within finish thickness requirements is critical for an invisible speaker’s performance and longevity. The ability to now quantify finish thickness allows the installer to achieve consistent, predictable results that unlock the full potential of fidelity and reliability that Sonance invisible speakers are capable of.BEFORE MEASURINGMeasurements must be made after the Sonance Invisible Series speaker or subwoofer has been fully installed and the surface finished according to its installation instructions but before priming, painting, wallpaper, or other final finishes have been applied.

MEASURING FINISH THICKNESS WITH THE DG-1

STEP 1Prepare depth gauge by connecting the included measurement probe and powering up the device. The depth gauge comes pre-calibrated out of the box so there is no need to calibrate before initial use.STEP 2Identify rough speaker positions by using stud locations and construction plans as a guide. Play music through the speakers and feel for the woofer motion on the wall or ceiling surface for further precision. Turn off the music before measuring.NOTE: The DG-1 depth gauge will not function while music is playing through an invisible speaker.

STEP 3

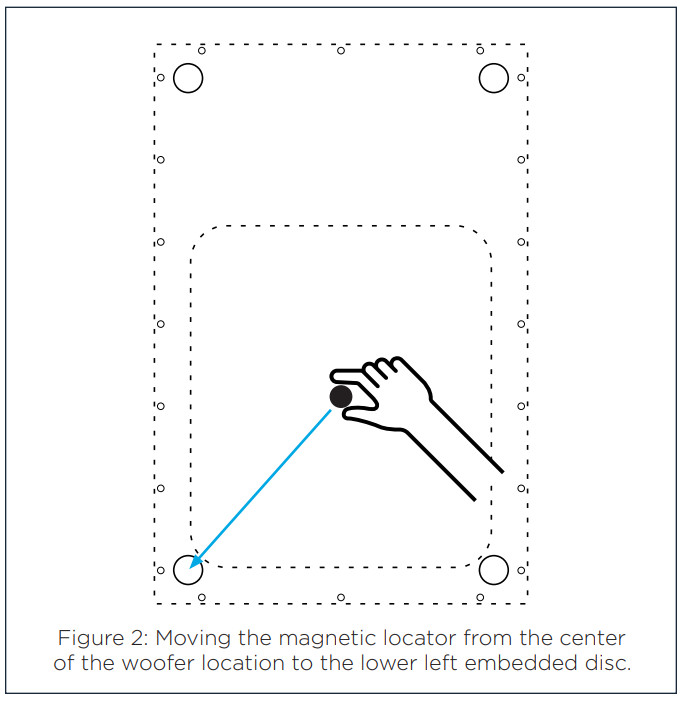

To find the embedded disc locations on each corner of the speaker, start by gently placing the included magnetic locator near the center of the woofer location and then slide diagonally across the surface downward and to the left toward the bottom left corner of the speaker (Figure 2). You will feel the magnetic locator snap firmly into place as it attracts to the edge of the embedded steel disc. This is why stainless steel screws are recommended in the mounting process for both the speaker and surrounding drywall area to minimize false detection. In order to center the locator closer to the middle of the embedded disc, we recommend sliding the locator down and to the left another 1/2″ or about 12mm. This typically results in a more accurate pinpointing of where the embedded discs are and will result in more accurate measurements.

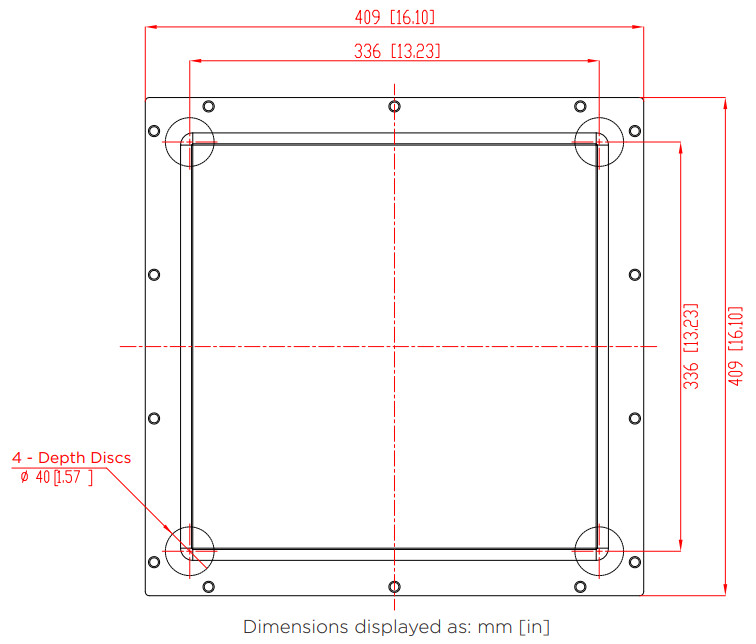

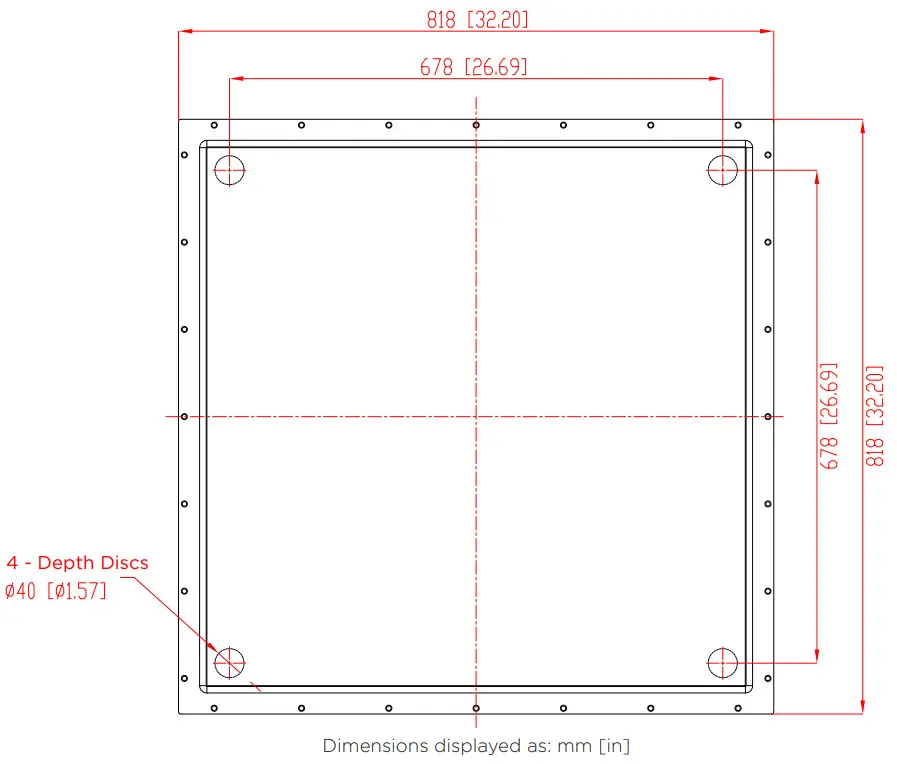

Dimensional drawings of the disc positions for Sonance invisible speakers that use the DISC system can be found on pages 67. Refer to www.sonance.com for the most recent drawings.STEP 4Mark around the perimeter of the magnetic locator using a pencil. Repeat STEP 3 & 4 for all four corners.

Alternatively, use the invisible speaker’s included cutout template (Figure 3) to quickly find the remaining three-disc locations. The cutout template makes this process much more fool-proof.NOTE: We highly recommend using the cutout template (Figure 3) that is attached to the front of every invisible speaker as a fast guide for locating discs and recording measurements at each corner location. The blue circles in each corner are punched out for easy measurement. After finding the lower-left disc location, the cutout template can be laid directly over the magnetic locator. The locator can then be removed and all four locations can be measured.

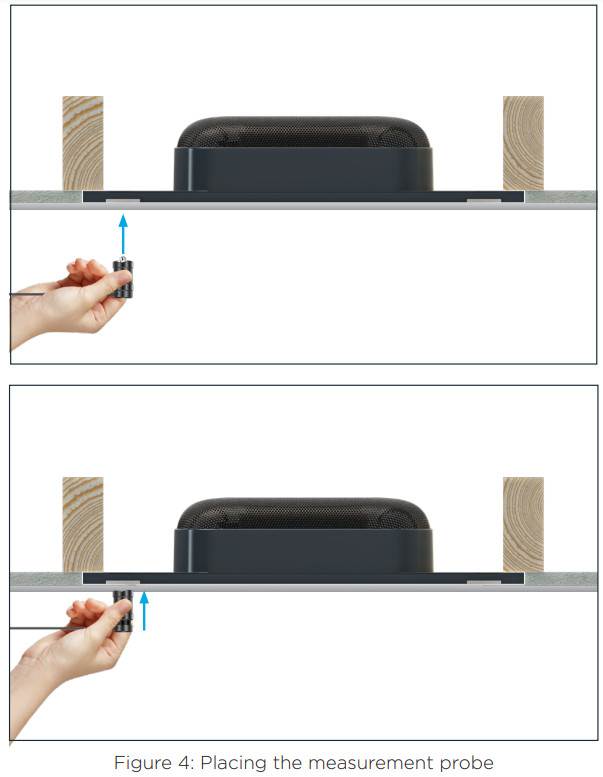

STEP 5Place the measurement probe against the wall or ceiling surface. Ensure the spring-loaded collar is touching the surface evenly (Figure 4).The best practice at this point is to slowly move the probe in a circular motion around the area you marked in STEP 4 (Figure 5).Take note of the minimum depth registered on the gauge as you move it around the marked disc area. Pause for a couple of seconds between each movement to ensure the measurement has time to update on the gauge’s display.

NOTE: As your measurement probe drifts from the center of the embedded disc, you will see the measured thickness increase which could lead to inaccurate measurements. Keep in mind that while it is possible to get a reading higher than the actual finish thickness if your alignment isn’t perfect, it is not possible to measure less than the actual thickness. That is why finding the minimum reading by circling or sweeping the probe around the area of the embedded disc is crucial.The minimum measurement should be recorded for this corner of the speaker. You can lightly mark the measurement directly on the wall with a pencil, or record the measurement onto the cutout template. We recommend you repeat these steps on the remaining three corners to ensure a consistent finish thickness. It is likely that measurements at all four corners will differ slightly. Variances of plus or minus 1/2mm are perfectly acceptable as long as the overall finished surface is smooth and level and as long as the actual measurements don’t exceed 3mm.If your measurement does exceed 3mm, sand down to target thickness (we recommend between 1.01.5mm). Ensure a smooth and even overall appearance with the rest of the installation surface and then repeat the measurement process to verify that the finish is below the 3mm maximum and close to the target thickness.

STEP 6Using a straight edge, check for surface flatness across the speaker location horizontally, vertically, and diagonally. We recommend a straight edge that will span the full height, width, and diagonal of the installed speaker.If gaps or high spots of around 1mm (about 1/32″) or more are found, or if total finish thickness exceeds 3mm, level the wall finish as needed by sanding down or adding additional material.Remember that an even, smooth surface finish will ensure a totally hidden aesthetic for your invisible speakers.

DG-1 CARE AND HANDLINGThe DG-1 is a precision tool, and though it is sturdy, it is not immune to damage if mishandled.

DG-1 CARE AND HANDLINGThe DG-1 is a precision tool, and though it is sturdy, it is not immune to damage if mishandled.

Keep the gauge in its protective case when not in use. Job sites tend to be extremely dusty. Always wipe away any dust or debris after use.

Always hold the probe by the collar. Never let it dangle or hold the probe by its cable.

“OVERFLOW” READINGOccasionally, the DG-1 may display the word “Overflow”. This usually occurs when a measurement is registered that is less than zero. The depth gauge is calibrated, or “zeroed”, to account for the thickness of the speaker’s diaphragm.If the DG-1 repeatedly displays this message, you can quickly recalibrate it using the instructions below.

CALIBRATION

Your DG-1 comes pre-calibrated; however, you may wish to re-calibrate from time to time to ensure consistent accuracy. To begin recalibration, connect the probe to the depth gauge, power it on, and wait for it to fully boot.Prior to calibrating, it is recommended to clear out any existing calibration data.

Press the Left Directional button to enter the “Root” menu. Scroll down to the “Calibration” option and press the Left Directional button to enter the Calibration menu. Scroll down to “Clear All” and press the Left Directional button once to select, and again to confirm that you want to clear the current calibration data.

Press the Right Directional button twice to exit the menu.

Fully depress the probe onto the black side of the included calibration disc (Figure 6).

Press and hold the upper rightmost key (the zero key) on the depth gauge (Figure 7). You will hear a single beep as soon as you press the button. Hold until you hear two more rapid beeps then release.

The two beeps indicate that the gauge has been zeroed out, and the display should read 0.000 with the word “ZERO” flashing at the bottom of the display.Press the zero key once more to exit calibration mode. The word “ZERO” should now disappear, and you are ready to continue using the DG-1 depth gauge.

EMBEDDED DISC LOCATIONS

IS6

IS8/IS8T/IS10W EMBEDDED DISC LOCATIONSIS10

EMBEDDED DISC LOCATIONSIS10 IS15W

IS15W

LIMITED TWO (2) YEAR WARRANTY

Sonance warrants to the first end-user purchaser that this Sonance-brand product (“Product”), when purchased from an authorized Sonance Dealer/Distributor, will be free from defective workmanship and materials for the period stated below. Sonance will at its option and expense during the warranty period, either repair the defect or replace the Product with a new or remanufactured Product or a reasonable equivalent.

EXCLUSIONS TO THE EXTENT PERMITTED BY LAW, THE WARRANTY SET FORTH ABOVE IS IN LIEU OF, AND EXCLUSIVE OF, ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED BY SONANCE. ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY, IMPLIED WARRANTY OF FITNESS FOR USE, AND IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE ARE SPECIFICALLY EXCLUDED.

No one is authorized to make or modify any warranties on behalf of Sonance. The warranty stated above is the sole and exclusive remedy, and Sonance’s performance shall constitute full and final satisfaction of all obligations, liabilities, and claims with respect to the Product.

IN ANY EVENT, SONANCE SHALL NOT BE LIABLE FOR CONSEQUENTIAL, INCIDENTAL, ECONOMIC, PROPERTY, BODILY INJURY, OR PERSONAL INJURY DAMAGES ARISING FROM THE PRODUCT, ANY BREACH OF THIS WARRANTY, OR OTHERWISE.

This warranty statement gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not allow the exclusion of implied warranties or limitations of remedies, so the above exclusions and limitations may not apply. If your state does not allow the disclaimer of implied warranties, the duration of such implied warranties is limited to a period of Sonance’s express warranty. Your Product Model and Description: DG-1 Depth Gauge. Warranty Period for this Product: Two (2) years from the date on the original sales receipt or invoice or other satisfactory proof of purchase. Additional Limitations and Exclusions from Warranty Coverage: The warranty described above is non-transferable, applies only to the initial installation of the Product, does not include installation of any repaired or replaced Product, does not include damage to allied or associated equipment which may result in any reason from use with this Product, and does not include labor or parts caused by accident, disaster, negligence, improper installation, misuse (e.g. overdriving the amplifier or speaker, excessive heat, cold or humidity, mishandling, etc.), or from service or repair which has not been authorized by Sonance. Obtaining Authorized Service: To qualify for the warranty, you must contact your authorized Sonance Dealer/Installer or call Sonance Customer Service at (949) 492-7777 within the warranty period, must obtain a return merchandise number (RMA), and must deliver the Product to Sonance shipping prepaid during the warranty period, together with the original sales receipt, or invoice or other satisfactory proof of purchase.

©2020 Sonance. All rights reserved. Sonance is a registered trademark of Dana Innovations. Due to continuous product improvement,all features and specifications are subject to change without notice. For the latest Sonance product specification information visit ourwebsite: www.sonance.comSONANCE · 991 Calle Amanecer · San Clemente, CA 92673 USA PHONE: (949) 492-7777 · FAX: (949) 361-5151 ·Technical Support: (949) 492-7777 · www.sonance.com12.09.2020

©2020 Sonance. All rights reserved. Sonance is a registered trademark of Dana Innovations. Due to continuous product improvement,all features and specifications are subject to change without notice. For the latest Sonance product specification information visit ourwebsite: www.sonance.comSONANCE · 991 Calle Amanecer · San Clemente, CA 92673 USA PHONE: (949) 492-7777 · FAX: (949) 361-5151 ·Technical Support: (949) 492-7777 · www.sonance.com12.09.2020

References

[xyz-ips snippet=”download-snippet”]