ZX-180 TIRCOMBO SURFACE / UNDER MIRROR MOUNT

ZX-180 TIRCOMBO SURFACE / UNDER MIRROR MOUNT

G-ZXT180INSTRUCTION MANUALSpeedTech Lights, Inc © 2021

G-ZXT180INSTRUCTION MANUALSpeedTech Lights, Inc © 2021

Warnings and Notices for Users and Installers

This document must be delivered to and read by the end-user and installer as it serves to provide you with the required information for proper and safe use of your STL product. Before operating this or any STL products the user and installer must read this manual all the way through. You will find important information in this manual that could prevent property damage and/or serious injury to the user and installer.STL products are intended to alert pedestrians and other operators of the presence of personnel, the operation of emergency vehicles, an emergency site, and any warning needs. This does not ensure that pedestrians or drivers will react, heed, or observe emergency warning signals. Nor does the use of emergency signals grant or ensure you the right of way. It is your responsibility to make sure you can proceed safely before driving against traffic, entering an intersection, responding at a high rate of speed, or walking on or around traffic lanes.Your STL emergency vehicle devices should be tested daily to ensure the device and all its functions are operating correctly. If you experience a malfunction contact STL’s Customer Service immediately for troubleshooting options, or a warranty or service claim. You must ensure that the projection of the visual and audible signal is not blocked by vehicle components (i.e.: open trunks, visors, compartment doors), vehicles, other obstructions, or people.This is professional-grade equipment and is intended for strict use by authorized personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. You must know and be familiar with all applicable city, state, and federal laws and regulations prior to the use of emergency vehicle warning devices.SpeedTech Lights, Inc assumes no liability for any loss resulting from the use of this warning device. Proper installation is vital to the performance of the warning devices and safe operation of the emergency vehicle. Since the operator is under stressful environments the equipment must be properly wired and mounted to ensure effectiveness and safety. Therefore controllers must be properly installed and placed within convenient reach of the operator so eye contact with the roadway is never lost.The effectiveness of your STL equipment is highly dependent upon correct mounting and wiring. Improper wiring and mounting of the warning device will reduce the output and performance of the equipment. Emergency warning devices frequently require high electrical voltages and/or currents. Properly protect and use caution around live electrical connections. Grounding or shorting of electrical connections can cause high current arcing, which can cause severe personal injury and/or serious vehicle damage, including fire.Electromagnetic interference can be caused by many electronic devices used in emergency vehicles. To ensure that this doesn’t happen to you, Light Bars should be mounted a minimum of 12” – 34” from the radio antenna and do not power your equipment from the same circuit or share the same grounding circuit with radio communication equipment. After installation, test all the vehicle’s equipment together to ensure everything operates free of interference.Driver and/or passenger airbags (SRS) will impact the way you mount your equipment. Any equipment installed in the deployment area of the airbags will damage or dislodge the airbags and sensors. This will also reduce the effectiveness of the airbags to protect the passengers and therefore these areas must be avoided. Installers must make sure that this equipment along with any parts, hardware, wiring, power supplies, and switch boxes do not interfere with the airbags, SRS wiring, or sensors.All STL equipment needs to be mounted and installed according to the vehicle manufacturer’s instructions and securely attached to a part of the vehicle of sufficient strength to withstand the forces applied by the equipment. This device should be permanently mounted within the zones specified by the vehicle manufacturer. This especially applies to equipment mounted on the exterior of the vehicle to avoid dislodging. Mounting units on the interior of the vehicle by a method other than permanent mount is discouraged as it may become detached under aggressive driving conditions such as sudden braking, collision, or swerving.PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO ENSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking Your STL Product

- Unpack your unit to identify all parts including but not limited to Light Bar, switch box, brackets, screws, bolts, wiring harness, fuses, etc.

- Some parts may be in small bags.

- Some products may be packaged inside boxes of other products.

- Some parts such as Gutter Brackets, maybe in the foam protection. Double-check that no parts are left within the foam protection or left in the box.

Important Points for Your Safety and Longevity of Your Light Bar

- Installers are required to have a good understanding of automotive electronic systems and procedures for proper installation.

- Never stare directly into the LEDs as momentary blindness and/or eye damage may occur.

- Never take any lights through a car wash. Use only water to clean the outer body/lens of your equipment.

- Never use a pressure washer to clean any STL products. Inspect and test your product daily to ensure it operates properly and is mounted correctly.

- Never cut wires or work on a unit while the unit is still connected to a power source.

- Never install this product or route any wires through or in the deployment area of the airbag. Doing so may cause serious personal injury as it will damage or reduce the effectiveness of the airbag by causing the unit to become a projectile. Reference the owner’s manual for your vehicle to find the airbag deployment area. The User/Installer assumes all responsibility to determine proper mounting location, based on providing ultimate safety to all passengers in the vehicle.

- If the product requires you to drill holes, the installer must ensure that the drilling process does not damage any vehicle components or other vital parts. Check all sides of the mounting surface before beginning to drill. Make sure to deburr all drilled holes and remove any metal remnants or shards to avoid injury and wires from becoming spliced. Grommets are to be installed in all wire passage holes.

- Grommets, cable ties, looms, and other installation hardware should be used to anchor and protect all wiring. Fuses should be properly sized and located as close to the power take-off points as possible to protect the wiring and device.

- Insulation displacement connectors are not to be used.

- In order for STL products to operate at optimum efficiency, a secure and good electrical connection to the battery’s Ground Post must be made. The recommended procedure requires the unit’s ground wire be connected directly to the NEGATIVE (-) battery post. DO NOT use Circuit Breaks.

- Instruction manuals should be stored in a safe place for reference if you need to reinstall the unit or perform maintenance. They can also be found at the main site under the product listing at www.SpeedTechLights.com. If your product is no longer available on the website contact STL’s Customer Service at 800-757-2581 for assistance.

- If your product requires the use of a control box or remote device to turn on and control your equipment, make sure it is installed in a location that allows both the user and the vehicle to operate safely in any driving condition.

- Never activate or control your equipment in hazardous driving conditions.

- Use SXL type wire in the engine compartment where higher heat resistance is required according to SAE J-1128. All wires should be in accordance with the minimum wire size and other recommendations made by the manufacturer and be protected from hot surfaces and moving parts.

- FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS, WARNINGS, NOTICES, AND INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR VEHICLE THAT WILL VOID YOUR WARRANTY AND/OR CAUSE SERIOUS INJURY TO YOU AND YOUR PASSENGER.

Pre-Installation and Testing

BENCH TEST all units prior to installation by connecting the Positive Cable (Red) and Negative Cable (Black) to a power source to ensure all the features and parts of the Light Bar are functional.Test Check List:

- LED diode and LED Module functionality

- Flash patterns

- Non-volatile memory

- Physical damageIf you have trouble call Customer Service at 800-757-2581 before proceeding.

Maintenance

While STL’s Light Bars are very durable, there are some things you need to keep in mind and practice to preserve the longevity and function of your Bar.

- Never take any STL Light Bars through a car wash, such as a pressure washer, automatic car wash, brushes that will scratch your equipment, or similar car washes or equipment where chemicals, high-pressure water, and materials may scratch or damage your equipment.

- Use Water (H2O) with a soft cloth to clean your Light Bar and lenses.

- Yellowing of clear lenses may occur over time. Lenses can be purchased by calling STL Customer Service at 800-757-2581.

Wiring Diagram

| Wire Color | Function |

Red* Red* |

Positive |

Black* Black* |

Negative |

Yellow Yellow |

Flash Pattern |

* Indicates a main power cable.

| Wire Color | Function |

| Positive | |

White White |

Negative |

Blue Blue |

Flash Pattern |

NOTE: All cables except Negative contact +12 VDC.

Specifications

| Voltage | 12 VDC |

| Amps | < 0.5 |

| Optic | TIR |

| LED Count | 6 |

| Cable Length | 1′ |

| Flash Patterns | 24 |

Flash Pattern Synchronization

- Make sure all units that need to be synced together are powered On and flashing on the same pattern (see page 7 for flash pattern shortcuts).

- Connect the White cables of all units to each other.

- Connect the Yellow cables of all units to each other.

- Power all units Off and back On to verify Synchronization is complete.

Programming the Alternating Sync Flash Patterns

- Make sure all units that need to be synced together are powered On and flashing on the same pattern (see page 7 for flash pattern shortcuts).

- Divide the units into the 2 groups that you want to alternate with each other.

- Connect the White cables of all units to each other.

- Connect the Yellow cables of all units to each other.

- Connect all the Blue cables of Group A units together.

- Connect all the Blue cables of Group B units together.

- Contact all the connected Blue cables from Group A and apply it to +12VDC for about 3 seconds until half the unit steadily burns.

- Contact all the connected Blue cables from Group B and apply it to +12VDC for about 5 seconds until the other half of the unit steadily burns.

- Power all units Off and back On to verify the alternating functionality has been successfully programmed.

NOTE: Once the units have been programmed into Group A and Group B, they will keep those designations until reprogrammed.

Toggling Between Sync and Alternating Sync On The Fly

- Once you have successfully programmed your units into Group A and Group B following the alternating sync instructions, you can easily switch back and forth between alternating sync and synchronous flashing.

- Once the units are in alternate sync mode, contact all the White cables of all the units that are connected together to +12VDC for 3 seconds.This will cease Group A & B alternating sync and will sync all units to flash together.

- To go back to alternating sync mode, contact all the White cables of all the units that are connected together to +1VDC for 1 second.

NOTE: The units will remember their Group A or B designation forever until reprogrammed into a different group.

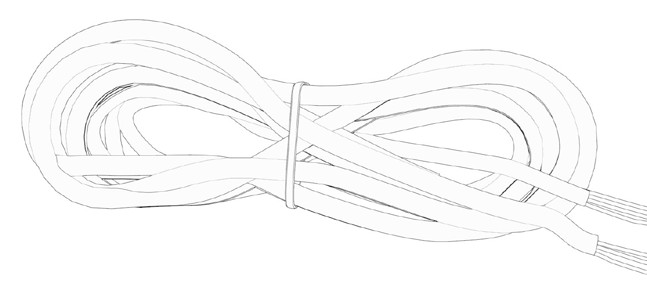

Extension Cable (Sold Separately)

- If you are extending the main cables, just add the desired length of cable to the end of the main cables coming out of the unit. You will solder and heat shrink the wire you are lengthening from the unit to each additional length of the extension cable. DO NOT cross-connect wires.

- NOTE: DO NOT leave connectors, cables, solder points exposed to heat, moisture, or debris.

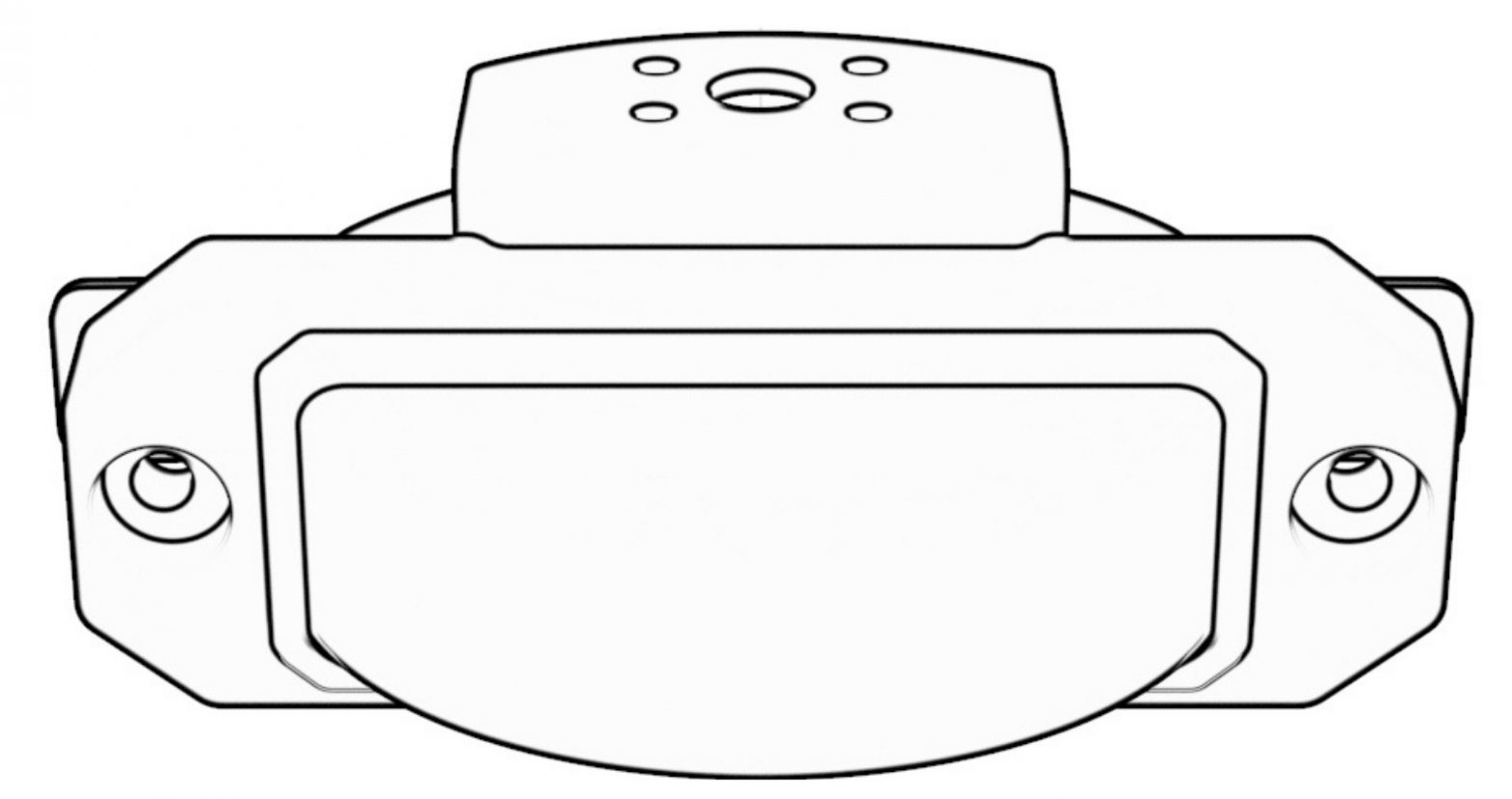

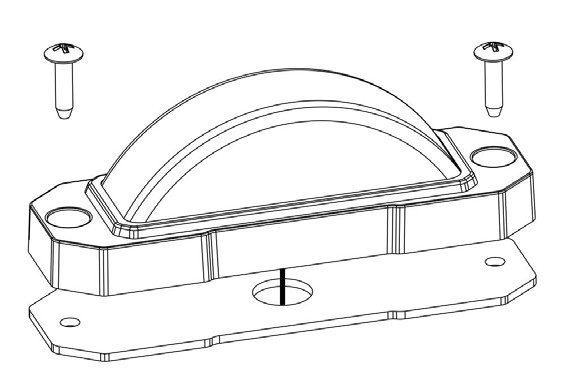

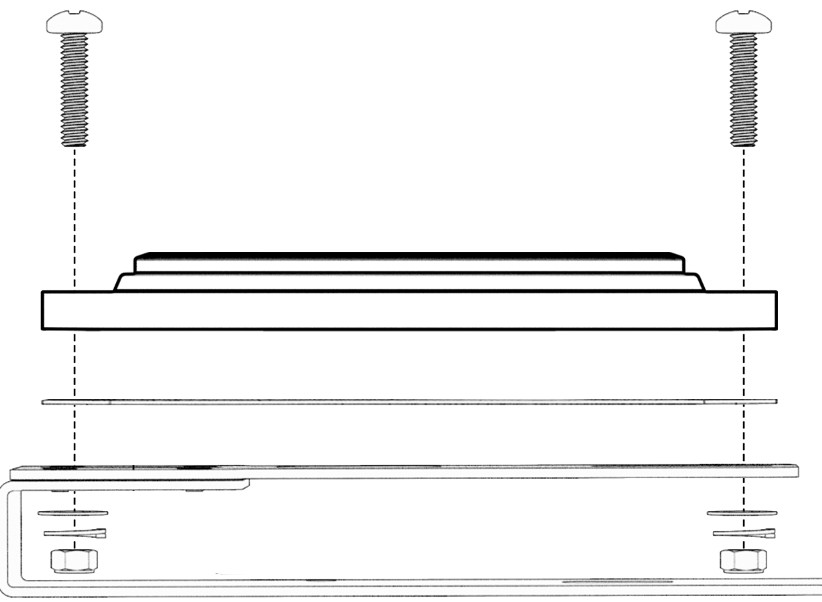

Surface Mounting w/ Flange and Foam Backing Pad (Included)

Surface Mounting w/ Flange and Foam Backing Pad (Included)

- Run cable through the Foam Pad central hole.

- Slide flange over the unit.

- Use the included hardware to mount the unit to the vehicle.

Mini L-Bracket Mount (Included)

- The mini L-bracket has two sets of holes in it.

- Use the smallest diameter hole to affix the L-bracket to the unit using the included hardware.

- Use the hardware included with the Z unit to mount the assembly to the vehicle via the larger diameter hole.

Under Mirror Mounting (Included)

- As the photo illustrates, the unit comes with a flange, a pair of small L brackets, a large mounting bracket, and a shroud.

- For under mirror mounting, the flange and the pair of small L brackets will not be used.

- Run the cables of the unit through both holes of the large mounting bracket.

- Mount the unit to the large mounting bracket via the mounting holes on the end of the unit using the smallest set of included screws.

- Mount the assembly to the bottom of the side mirror in the direction of choice using user-supplied hardware.

- Mount the shroud to the rear of the large mounting bracket using the smallest set of included screws to hide the cable.

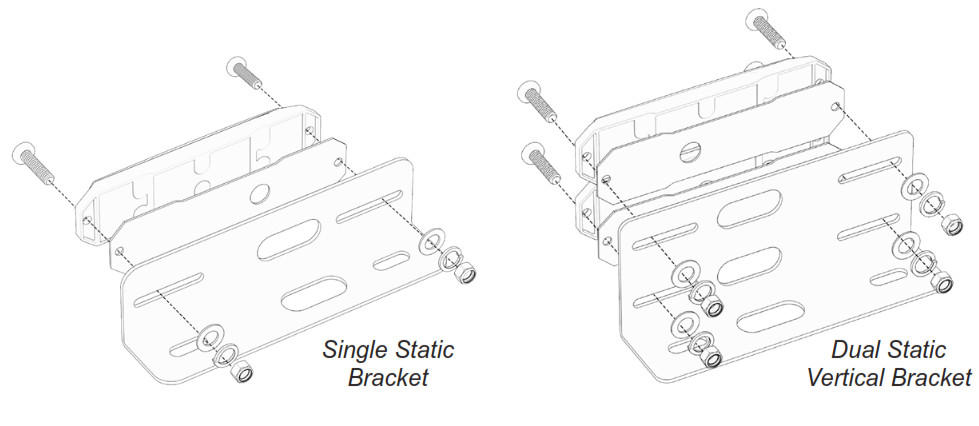

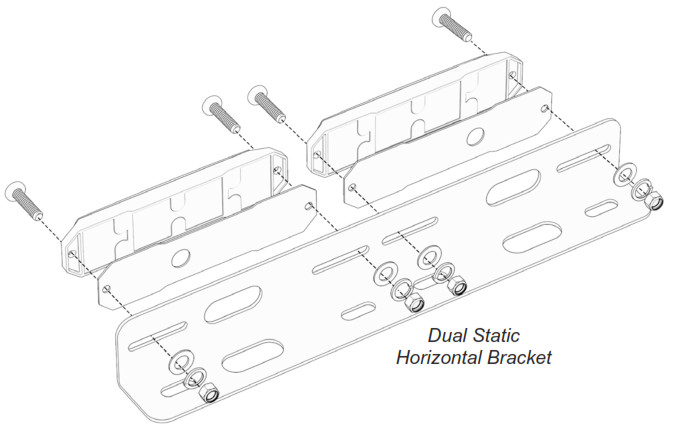

Static Mounting Bracket (Sold Separately)

- Run the cable through the Foam Pad and Bracket central holes.

- Use the hardware included with the Bracket to secure the unit to the Bracket.

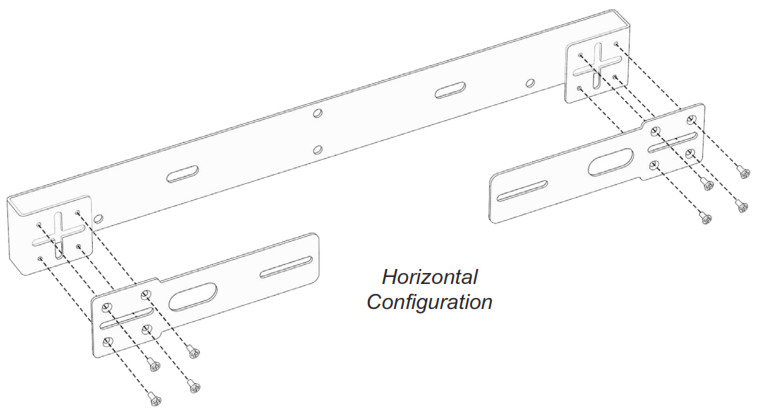

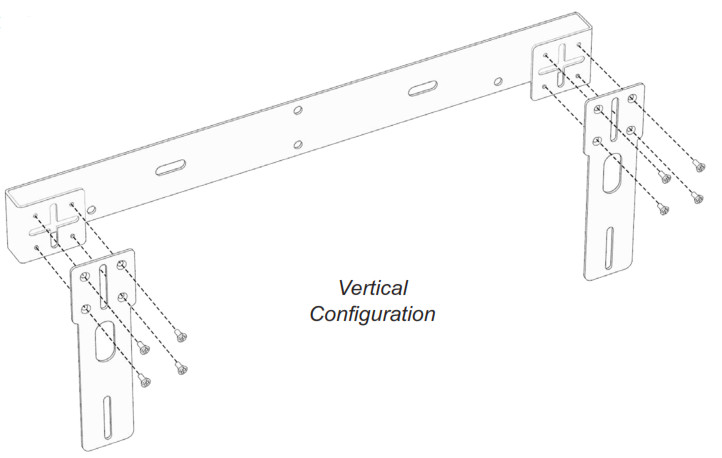

License Plate Mounting Bracket (Sold Separately)

- This kit includes hardware and (3) metal pieces: (2) short pieces and (1) long pieces.

- Use the hardware included with the Bracket to connect both short pieces to the long piece.

- Run Z unit cable through the Foam Pad and short piece central holes.

- Use the hardware included with the Bracket to secure a Z unit to each short piece.

- Use the same hardware that secures the license plate to the vehicle to mount the assembly.

- NOTE: Lights can be configured to hang vertically or horizontally.

Flash Pattern List

Flash Pattern List

|

|

Flash Pattern Shortcuts

- Hold for 2 seconds to toggle Steady Burn mode.

- Hold for 4 seconds to toggle Random pattern mode.

About Flash Patterns

- All STL LED products are equipped with a non-volatile memory that will recall the last flash pattern when the product is turned on.

- Follow the wiring diagram to identify the Flash Pattern wire to manually cycle through patterns.

All rights reserved. No part of this Instruction Manual may be reproduced, distributed, transmitted, or otherwise shared in any form or by any means, including but not limited to photocopying, recording, electronic delivery, .PDF reproduction, or any other means of reproducing all or any part thereof without the express prior written consent of SpeedTech Lights, Inc, except for non-commercial purposes as permitted by United States copyright law. Customers of SpeedTech Lights, Inc, may download and print this Instruction Manual for use with products sold to the customer by SpeedTech Lights, Inc. However, no part of this Instruction Manual may be otherwise or subsequently reproduced, downloaded, disseminated, published, or transferred, in any form or by any means, except with the prior written consent of SpeedTech Lights, Inc.

References

[xyz-ips snippet=”download-snippet”]

Flash Pattern List

Flash Pattern List