Removing and Installing a Hub Unit Bearing

Proper hub removal and installation procedures can enhance the performance and life of hubs, axles, wheels, brakes and other components.

Hub Unit Bearing Removal

- Raise vehicle and remove lug nuts and wheel.

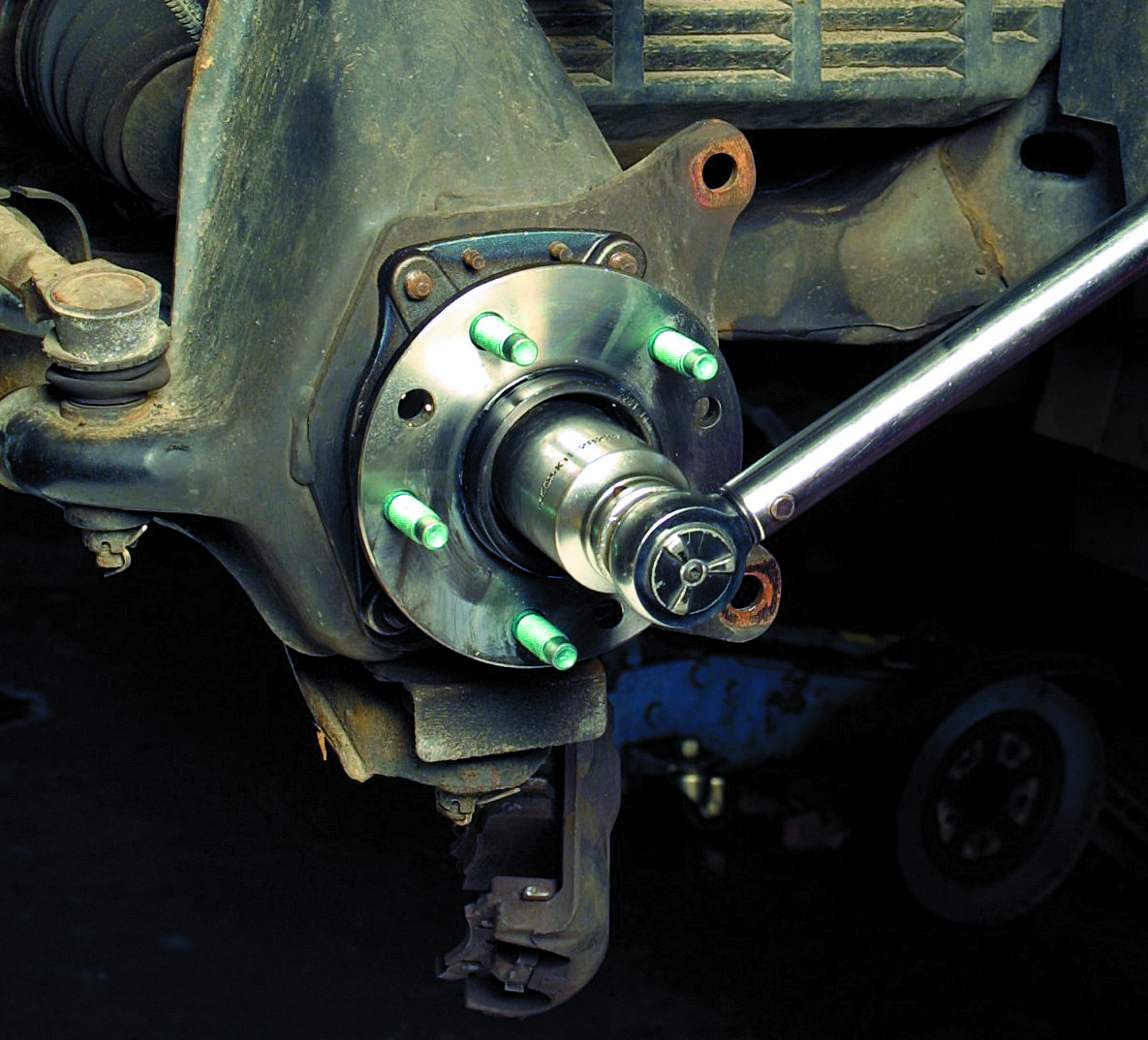

- Remove the brake caliper and rotor. Support the brake caliper with an “S” hook or a piece of wire. (Fig. 1)

- Remove the axle nut, using an axle nut socket. Follow the manufacturer’s instructions fornut replacement.

- Before removing hub unit, make a note of the proper orientation and positioning of the sensor wire and bearing. Disconnect the ABS sensor wire from its mating connector point and positioning clips. (Fig. 2)

- Remove the steering knuckle attachment bolts. You may need a puller to remove the hub assembly. Do not damage the knuckle or axle shaft.

- Clean and inspect the steering knuckle. Remove any debris, nicks or burrs using a fine file, wire brush, emery cloth or honing stone.

Hub Unit Bearing Installation

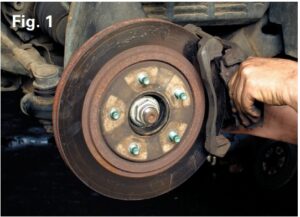

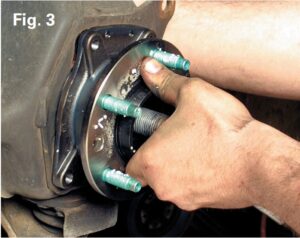

- Insert the new hub assembly into the steering knuckle. Check the positioning of the splines on the axle shaft while inserting the hub assembly. Never force the hub assembly on the shaft or strike with a hammer. (Fig. 3)

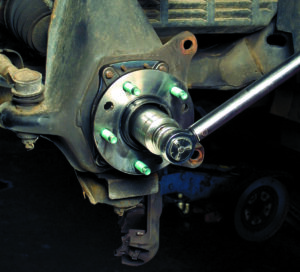

- Torque the knuckle-bearing mounting bolts to the vehicle manufacturer’s specification using a torque wrench. Do not use an impact wrench.

- Connect the new ABS sensor that comes already attached to the new bearing to its mating connection point and clips in the wheel well and frame area.

- Install the axle nut. Tighten the nut to the vehicle manufacturer’s torque specification using a torque wrench. Do not use an impact wrench. (Fig. 4)

- Replace the brake rotor and brake caliper. All components should be clean from debris and burrs. (Fig. 5)

- Replace the wheel and torque the lug nuts. Follow the vehicle manufacturer’s recommendations regarding torque specification and re torque requirements.

![]() WARNING

WARNING ![]()

![]()

![]()

CAUTIONFailure to follow these cautions may result in property damage.

The products cataloged are application specific. Any use in applications other than those intended could lead to equipment failure or to reduced equipment life.Use of improper bearing fits may cause damage to equipment.Do not use damaged bearings. The use of a damaged bearing can result in equipment damage.

TIMKEN

The Timken team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide. The company designs, makes and markets high-performance mechanical components, including bearings, gears, belts, chain and related mechanical power transmission products and services.

Removing and Installing a Hub Unit Bearing Assembly – Removing and Installing a Hub Unit Bearing Assembly –