Toshiba Adjustable Speed Drives P9 User Manual

SYSTEMATIC AND PRECISE PUMP CONTROL

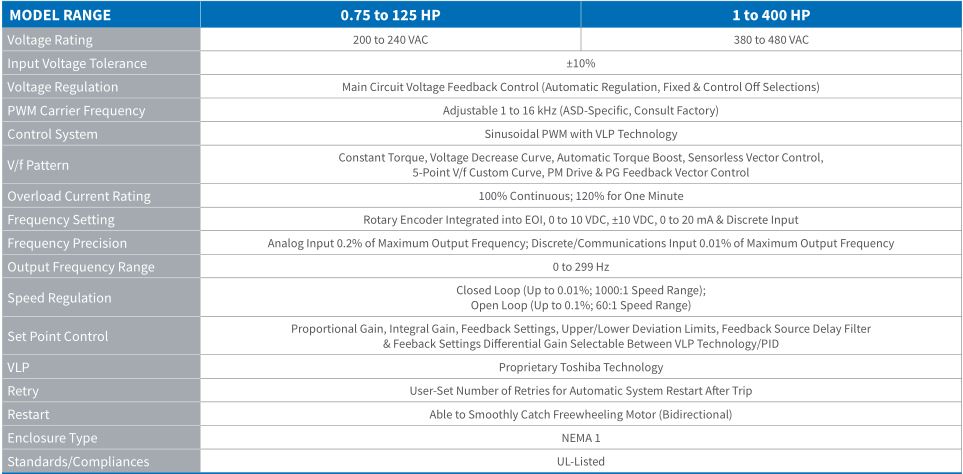

The Toshiba P9 adjustable speed drive (ASD) incorporates Toshiba’s proprietary VLP Technology®* and directly, precisely, and linearly controls pressure, temperature, level, and flow. The P9 eliminates certain obstacles users assumed were an unavoidable part of pump control.

- Linearizes Traditional Non-Linear Pump Curve, Providing Stable & Precise Control to HVAC Systems

- Solves Problem of Load-Balancing Over Multiple Fan Plenums or Pump Systems

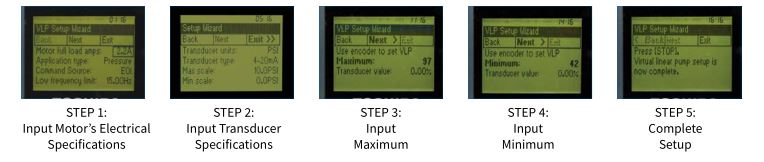

- Allows User to Configure System in Five Simple Steps, Providing Complete Control in Only Minutes

- Self-Calibrates & Eliminates Common Anomalies

- Maximizes Energy Savings on Variable Torque Loads

* VLP Technology® as used herein refers to Virtual Linear Pump technology

Start & Stop PointsDetermines when to start and stop the pump based on user-set values and system feedback on pump water levels, these points work with a delay timer to help ensure that frequent fluctuations in the system feedback do not unnecessarily start and stop the pump.

Sleep TimerShuts off fan or pump in order to reduce energy consumption and prolong the lifespan of equipment after it has run at the minimum for a user-specified amount of time.

Run External Device FeatureTurns on external booster pumps to support the primary pump when necessary in order to increase energy savings and to minimize pump and system failures.

No-Flow/Low NPSH Cut-Off FeatureStops the pump once loss of feed water or a closed output valve has been detected in order to protect against cavitation.

Sealing Water/Vacuum Priming FeatureAutomatically controls and helps to improve system reliability by monitoring water flow and water level, and starting the pump once water flows through the seal or the pump is full of water.

Toshiba’s Proprietary Windows®-Based ASD Pro SoftwareAvailable at no additional cost, this easy-to-use software can be used to program and control the P9, to download parameter sets, and to monitor real-time conditions.

PRACTICAL STARTUP CONFIGURATION

With its intuitive and user-friendly startup, the P9 allows for configuration and optimization of HVAC system’s performance.

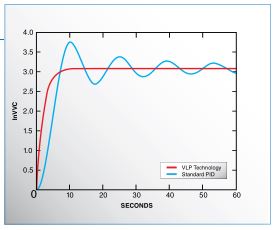

VLP TECHNOLOGY MAKES PID TUNING A THING OF THE PAST

Toshiba’s VLP Technology algorithm has taken proportional/integral/derivative gain (PID) and changed how users control pressure and flow. With this technology, after simply inputting a few values into the P9, optimum control is attained. Toshiba’s Setup Wizard effortlessly guides the user through the entire process. The setup process defines the operating boundaries by establishing a minimum point and a maximum point. By defining these points, VLP Technology creates an operating domain within the ASD that is directly and proportionately related to the specific pumping system to which it is connected. Once these points have been established, the P9 will:

- Monitor Multiple Systems for Friction Losses, Impeller Variations & Other System Variables

- Adjust Systems Accordingly to Help Ensure Only Necessary Fans or Pumps are Operating

- Balance Flow Rates for Each Operating Fan or Pump Under Different Conditions

- Maintain the Same Load for All Operating Fans or Pumps

CENTRIFUGAL PUMPS

The P9’s VLP Technology offers similar functionalities as proportional/integral/derivative gain (PID) with additional protective features for centrifugal pumping systems in numerous applicable industries. From vertical multistate pumps in a water municipality to slurry pumps in a coal mine, the P9 controls and protects centrifugal pumps with ease.

© 2020Toshiba International Corporation Motors & Drives13131 West Little York RoadHouston, Texas 77041 USATel +713-466-0277US 1-800-231-1412Rev.11ESSENCE2019

TOSHIBA MOTORS & DRIVESAdjustable Speed Drives • Motors • Motor Controls

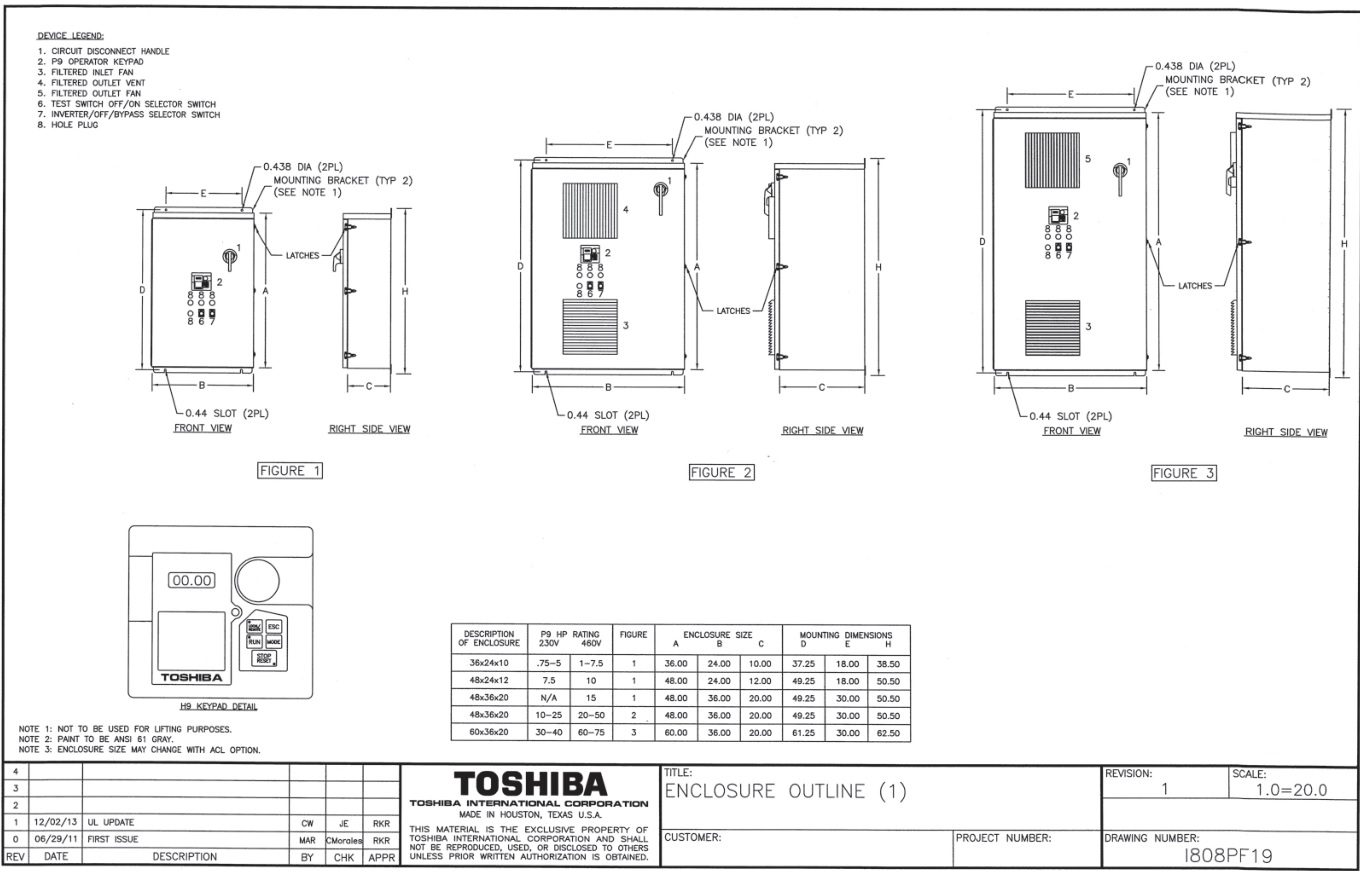

Typical Connection Diagram

Toshiba Adjustable Speed Drives P9 User Manual – Toshiba Adjustable Speed Drives P9 User Manual –

[xyz-ips snippet=”download-snippet”]