Triplett GSM100 Combustible Gas Detector User Manual

Introduction

Thank you for selecting the Triplett GSM100 Combustible Gas Detector. The GSM100 Combustible Gas Detector is a gas leak locating tool that is used to identify the presence of and isolate the source location of combustible gases such as methane, propane, butane, ammonia, carbon monoxide and many others (please see back of manual for a more complete list). Even low levels of combustible gas can be detected in seconds.

The GSM100 detects gas concentrations through the use of an internal sensor. This sensor is heated during operation. As the heated sensor interacts with gases, the unit immediately indicates to the user that combustible gases are present. The GSM100 indicates the presence of combustible gases with visual, audio and vibration feedback mechanisms. There are five (5) threshold levels of measurement within two (Low and High) settings of sensitivity. When the tool senses the presence of a combustible gas, it will tell the operator by blinking the appropriate light(s), triggering the appropriate audible alert or providing the appropriate vibration alert.The GSM100 comes equipped with an attached flexible 16″ probe hose.

Features

- 16″ Adjustable Probe

- Replaceable Sensor

- TRI Mode Detection

Safety

Safety Symbols

In this operator’s manual and on the product, safety symbols and signalwords are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols. This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

NOTICE indicates information that relates to the protection of property.

General Safety Rule

Warning

Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Work Area Safety

- Keep your work area clean and well lit. Cluttered or dark areas inviteaccidents.

- Do not operate equipment in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Equipment can create sparks which may ignite the dust or fumes.

- Keep children and by-standers away while operating equipment. Distractions can cause you to lose control.

Electrical Safety

- Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock if your body is earthed or grounded.

- Do not expose equipment to rain or wet conditions. Water entering equipment will increase the risk of electrical shock.

Personal Safety

- Stay alert, watch what you are doing and use common sense when operating equipment. Do not use equipment while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating equipment may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Equipment Use and Care

- Do not force equipment. Use the correct equipment for you application.The correct equipment will do the job better and safer at the rate for which itis designed.

- Do not use equipment if the switch does not turn it ON and OFF. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the batteries from the equipment before making any adjustments, changing accessories or storing. Such preventive safety measures reduce the risk of injury.

- Store idle equipment out of the reach of children and do not allow persons unfamiliar with the equipment or these instructions to operate the equipment. Equipment can be dangerous in the hands of untrained users.

- Maintain equipment. Check for misalignment or binding of moving parts, missing parts, breakage of parts and any other condition that may affect the equipment’s operation. If damaged, have the equipment repaired before use. Many accidents are caused by poorly maintained equipment.

- Use the equipment and accessories in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the equipment for operations different from those intended could result in a hazardous situation.

- Use only accessories that are recommended by the manufacturer for your equipment. Accessories that may be suitable for one piece of equipment may become hazardous when used with other equipment.

- Keep handles dry and clean; free from oil and grease. Allows for better control of the equipment.

Specific Safety Information

WarningThis section contains important safety information that is specific to this tool. Read these precautions carefully before using the GSM100 Combustible Gas Detector to reduce the risk of fire, explosion or other serious personal injury.

SAVE THESE INSTRUCTIONS!Keep this manual with the tool for use by the operator.

Combustible Gas Detector Safety

- High concentrations of combustible gases can cause explosions, fires,asphyxia and other hazards that could cause serious personal injury ordeath. Know the characteristics of the gas you are working with and useproper precautions to avoid hazardous conditions.

- Always turn on and calibrate the gas detector in an area known to be free of combustible gases. Calibration in an area containing combustible gas will result in incorrect calibration and lower than actual readings. This could result in combustible gases not being detected.

Description

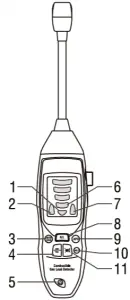

METER DESCRIPTION

- Warm Up indicator

- Low Sensitivity indicator (White)

- Auto Zero Enable/Disable

- Vibration Alert Enable/Disable

- ON/OFF

- Led Display

- High Sensitivity indicator (yellow)

- High/Low Sensitivity Selector

- Auto Power Off Enable/Disable

- Hold Enable/Disable

- Audible Alert Enable/Disable

Charging and Installing Batteries

Warning

High concentrations of combustible gases can cause explosions, fires, asphyxia and other hazards that could cause serious personal injury or death. Know the characteristics of the gas you are working with and use proper precautions to avoid hazardous conditions.

In case of unnecessary danger, it is not allowed to charge or replace batteries in the concentration of combustible gas. Set up and operate the gas detector according to these procedures to reduce the risk of fire, explosions and serious injury and incorrect measurements.

The GSM100 has an internal rechargeable battery. If the battery is low, use the 5V/0.5A adapter to charge. Please remove the battery in case battery leakage before long-term storage or transportation.

In the concentration of combustible gas, it is not allowed to replace the batteries or use the adapter, in order to reduce the risk of explosion, fire or other serious injury. It is not allowed to operate when charging.

Pre-Operation Inspection

Warning

Before each use, inspect your GSM100 and correct any problems to reducethe risk of injury or incorrect measurements.

- Clean any oil, grease or dirt from equipment. This aids inspection.

- Inspect the GSM100 for any broken, worn, missing, misaligned or binding parts, or any other condition which may prevent safe and normal operation.

- Check that the warning labels are present, firmly attached and readable.

- If any issues are found during the inspection, do not use the GSM100 until it has been properly serviced.

- Following the Set-Up and Operation instructions, turn ON and calibrate the gas detector. Once calibration is complete use a combustible gas source (such as an unlit lighter), to confirm that the gas detector senses the gas. If the gas detector does not sense the gas, do not use the unit until it has been properly serviced. Remove the gas source and allow several minutes for the sensor to stabilize prior to use.

Set-Up and Operation

Warning

High concentrations of combustible gases can cause explosions, fires, asphyxia and other hazards that could cause serious personal injury or death. Know the characteristics of the gas you are working with and use proper precautions to avoid hazardous conditions.Always turn on and calibrate the gas detector in an area known to be free of combustible gases. Calibration in an area containing combustible gas will result in incorrect calibration and lower than actual readings. This could result in combustible gases not being detected.Set up and operate the gas detector according to these procedures to reduce the risk of fire, explosions and serious injury and incorrect measurements.

Operation

- Check for an appropriate work area as indicated in the General Safety Section.

- Determine the application and confirm that you have the correct equipment. See the Specifications section for information on sensitivity, gases detected and other information.

- Make sure that all equipment has been properly inspected.

- In an area where combustible gases are known to not be present, turn on the gas detector by pressing and releasing the ON/OFF button. For one second the gas detector will vibrate, beep, and the first level red light will come on to indicate that the unit is ON. The gas detector then starts an approximately 50 second sensor heat up and calibration, during which the first level red light is blinking. Once the calibration is complete, for one second, all level lights will flash, and if the audible and vibration alerts are ON, the unit will beep and vibrate. Then either the high (yellow) or low (white) light will be ON. If the high (yellow) and low (white) sensitivity lights are ON at the same time, this indicates that the batteries need to be charged. If all display lights are ON, this indicates that the sensor has failed and that the unit needs to be serviced. If the gas detector is left ON for more than ten minutes with no activity and Auto Power Off is enable, it will automatically shut OFF to conserve the batteries.

- The Audible Alert and Vibration Alert retain the previous state the detector was last in and can be turned ON or OFF if desired. Press and release the Audible Alert button to turn it ON and OFF. The gas detector will beep once when the Audible Alert is turned ON and OFF. Press and release the Vibration Alert button to turn it ON and OFF. The gas detector will vibrate twice when turning the Vibration Alert ON and vibrate once when turning the Vibration Alert OFF.

- Enter the area to be monitored. Pay close attention to the gas level indicators (see Table 1). As gas levels increase, more red level lights will come on and the frequency of the audible alert beeping and the Vibration Alert vibration will increase. See Table 1for information on methane concentration levels and gas detector feedback.

- When the gas detector is turned ON it is in whatever sensitivity state it was last in. In the low sensitivity setting, the lowest concentration of methane detected is 100 ppm. Switch the sensitivity to the high setting by pressing the high sensitivity button (H). this will be indicated by the yellow light in the bottom right of the display. In the high sensitivity setting, the gas detector is ten times more sensitive, with the lowest concentration of methane detected at 40 ppm. Sensitivity can be changed at any time by pressing the High Sensitivity (H) or Low Sensitivity (L) buttons. If locating a leak, use the gas detector to find areas of lower gas concentration and follow back to the source. In a piping system, trace the system, stopping at the joints to monitor the gas levels.

- When gas detection is complete, turn the GSM100 OFF by pressing the ON/OFF button.

Gas Detector Feedback for Methane

Concentration Levels

| Low Sensitivity White Light ON | High Sensitivity Yellow Light ON | Level Lights | Audible Alert Beeping | ||||

| L1 | L2 | L3 | L4 | L5 | |||

| = 0 ppm | = 0 ppm | OFF | OFF | OFF | OFF | OFF | OFF |

| 1 … 100 ppm | 1 … 1000 ppm | ON | OFF | OFF | OFF | OFF | 1cyc/sec |

| 100 … 400ppm | 1000 … 4000ppm | ON | ON | OFF | OFF | OFF | 1.2 cyc/sec |

| 400 … 700ppm | 4000 … 7000ppm | ON | ON | ON | OFF | OFF | 1.65 cyc/sec |

| 700 … 1000ppm | 7000… 10000ppm | ON | ON | ON | ON | OFF | 3.25 cyc/sec |

| ≥ 1000ppm | ≥10000 ppm | ON | ON | ON | ON | ON | 6.25 cyc/sec |

NOTE: Gas Concentration levels may differ depending on the specific gas detected.

Hold Measurement

Press and release the Hold button to enable or disable. When Hold is enable, measurement is stopped and white light and yellow light stop blinking and ON. When Hold is disable, measurement is running and white light and yellow light is blinking.

Auto Zero

Press and release the Auto Zero button to enable or disable. When Auto Zero is enable, blue light under the Auto Zero button is ON. Enable Auto Zero can quickly adjust the zero point of sensor, improve the sensitivity and reduce the interference of unknown gases.

Auto Power Off

Press and release the Auto Power Off button to enable or disable. When Auto Zero is enable, blue light under the Auto Zero button is ON. If the gas detector is left ON for more than ten minutes with no activity and Auto Power Off is enable, it will automatically shut OFF to conserve the batteries.

Maintenance

Cleaning

Do not immerse the GSM100 in water. Wipe off dirt with a damp soft cloth. Do not use aggressive cleaning agents or solutions. Treat the instrument as you would a telescope or camera.

Sensor Calibration/Replacement

The GSM100 requires no calibration other than that done at regular start up. If the sensor should fail, the sensor can be replaced.

Storage

The GSM100 Combustible Gas Detector must be stored in a dry securearea between -10℃ (14℉) and 60℃ (158℉).Store the tool in a locked area out of the reach of children and people unfamiliar with the GSM100. Remove the batteries before any long period of storage or shipping to avoid battery leakage.

Disposal

Parts of the GSM100 Combustible Gas Detector contain valuable materials and can be recycled. There are companies that specialize in recycling that may be found locally. Dispose of the components in compliance with all applicable regulations. Contact your local waste management authority for more information.

Troubleshooting

|

PROBLEM |

POSSIBLE REASON |

SOLUTION |

| High (Yellow) and Low (White) sensitivity lights are ON at the same time. | The battery is discharged (unable to heat the sensor). | The batteries are low and need to be changed. |

| All display lights are ON at the same time. | The sensor (or the sensor heater) is defective. | Shut OFF unit. Sensor or entire unit should be replaced. |

Specifications

Visual Alert.5 Red LEDs: Gas Measuring Levels; Sensitivity

Audible Alert (85 db)Loud Audible Ticking Rate (w/Continuous Proportional to Gas Level)

Modulation

Vibration AlertStandard

Sensitivity< 50 ppm (methane)

Response Time< 2 Seconds

Range0 – 10000 ppm (methane)

Sensitivity Level

(methane) (HIGH)5 Levels: 100/400/700/1000/>1000ppm

(methane) (LOW)5 Levels: 1000/4000/7000/1000/>10000 ppm

Warm Up Calibration.Automatic

Warm Up Time50 Seconds Max

Operating ButtonsSeven: Power ON/OFF, High / Low

Sensitivity,

Audio Alerts,Vibration Alerts,Auto Zero,Auto Power Off,Hold

Batteries.Polymer Li-Ion Battery

Low Battery Status.Low and High Sensitivity LED Solid

Sensor ConnectionPlug-In

Expected Sensor Life5 Years

Probe.Flexible 16″/400m

Measurable Gases

| Gases Detected | Common Mixtures That Would Include or Emit More Than One Of These Gases |

| Methane | Natural Gas* Paint Thinners Industrial Solvents Dry Cleaning Fluids Gasoline |

| Hydrogen | |

| Carbon Monoxide | |

| Propane | |

| Ethylene | |

| Ethane | |

| Hexane | |

| Benzene | |

| Iso-Butane | |

| Ethanol | |

| Acetaldehyde | |

| Formaldehyde | |

| Toluene | |

| P-Xylene | |

| Ammonia | |

| Hydrogen Sulfide |

Warranty

Triplett / Jewell Instruments extends the following warranty to the original purchaser of these goods for use. Triplett warrants to the original purchaser for use that the products sold by it will be free from defects in workmanship and material for a period of (1) one year from the date of purchase. This warranty does not apply to any of our products which have been repaired or altered by unauthorized persons in any way or purchased from unauthorized distributors so as, in our sole judgment, to injure their stability or reliability, or which have been subject to misuse, abuse, misapplication, negligence, accident or which have had the serial numbers altered, defaced, or removed. Accessories, including batteries are not covered by this warranty.

Copyright © 2021 Triplettwww.triplett.com

References

[xyz-ips snippet=”download-snippet”]