TSI 4048 Flow Calibrator User Guide

http://Register.tsi.comwww.tsi.com

Copyright©

TSI Incorporated / 2016-2020 / All rights reserved.

Address

TSI Incorporated, 500 Cardigan Road, Shoreview, MN 55126 USA

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015) (For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service as described in the operator’s manual, to be free from defects in workmanship and material for 12 months, or if less, the length of time specified in the operator’s manual, from the date of shipment to the customer. This warranty period is inclusive of any statutory warranty. This limited warranty is subject to the following exclusions and exceptions:

- Hot-wire or hot-film sensors used with research anemometers, and certain other components when indicated in specifications, are warranted for 90 days from the date of shipment;

- Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

- Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship and material, under normal use, for 90 days from the date of shipment;

- Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or other consumable materials. Only the original manufacturer’s warranty applies;

- This warranty does not cover calibration requirements, and seller warrants only that the instrument or product is properly calibrated at the time of its manufacture.Instruments returned for calibration are not covered by this warranty;

- This warranty is VOID if the instrument is opened by anyone other than a factory authorized service center with the one exception where requirements set forth in the manual allow an operator to replace consumables or perform recommended cleaning;

- This warranty is VOID if the product has been misused, neglected, subjected to accidental or intentional damage, or is not properly installed, maintained, or cleaned according to the requirements of the manual. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect to, and shall have no liability in connection with, goods which are incorporated into other products or equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND THE LIMIT OF SELLER’S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be brought against Seller more than 12 months after a cause of action has accrued. The goods returned under warranty to Seller’s factory shall be at Buyer’s risk of loss, and will be returned, if at all, at Seller’s risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms waived, except by writing signed by an Officer of Seller.

Service PolicyKnowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our service policy is designed to give prompt attention to any problems. If any malfunction is discovered, please contact your nearest sales office or representative, or call TSI’s Customer Service department at (800) 680-1220 (USA) or (001 651) 490-2860 (International) or visit www.tsi.com.

Trademarks

TSI and TSI logo are registered trademarks of TSI Incorporated in the United States and may be protected under other country’s trademark registrations.

Chapter 1

Unpacking and Parts Identification

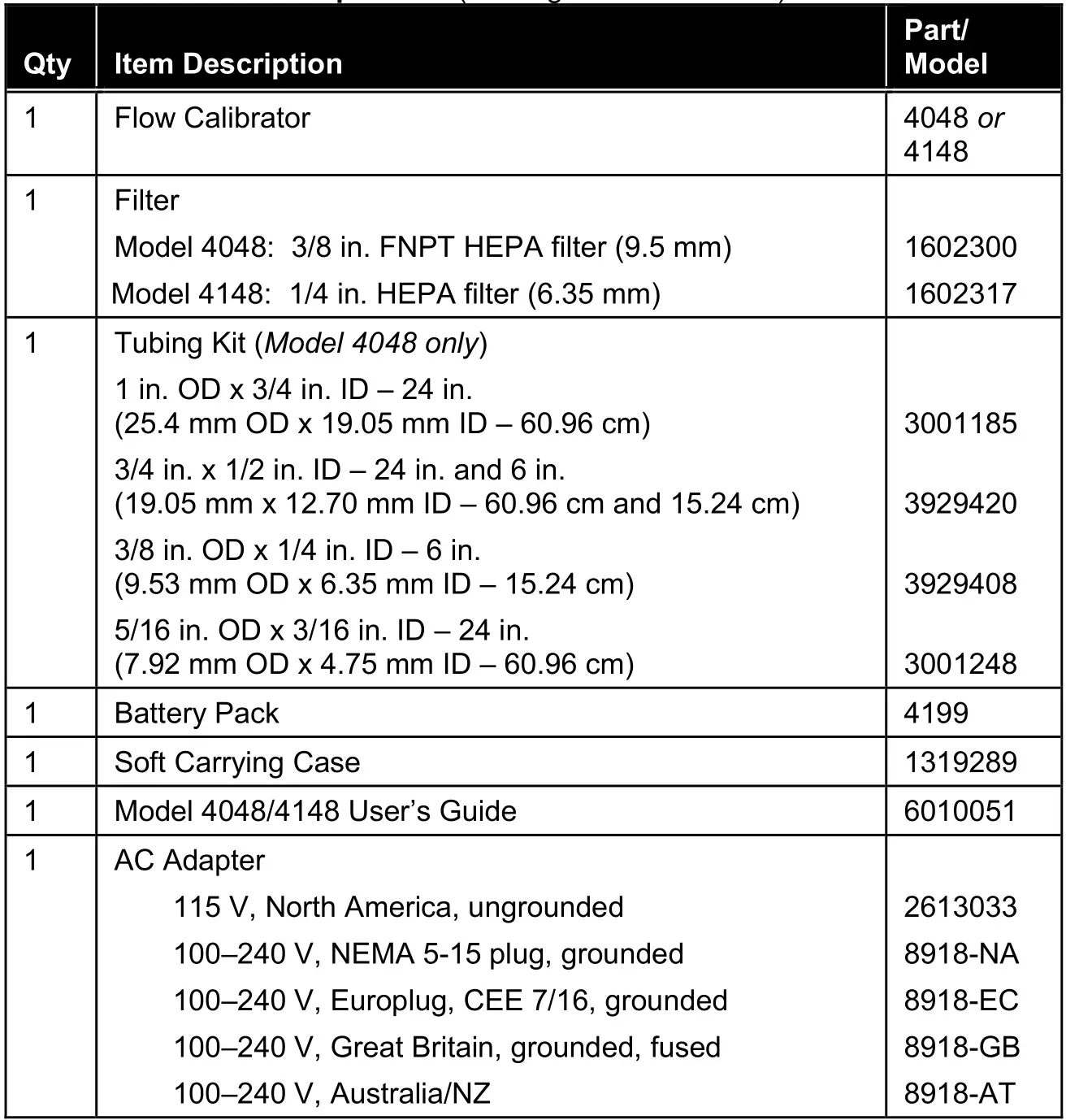

Carefully unpack the instrument and accessories from the shipping container. Check the individual parts against the list of components in Table 1. If any parts are missing or damaged, notify TSI® immediately.

Table 1-1. List of Components (see Figures 1-1 and 1-2)

Figure 1-1. Model 4048 Components

- Flow Calibrator

- Soft-Sided Carrying Case diameters and length)

- Universal Power Supply

- User’s Guide

- High-Efficiency Inlet Filter

- Tubing Kit (see Table 1-1 for

- Mounting Lugs (not shown)

- 6 AA-size Batteries (not shown)

Figure 1-2. Model 4148 Components

- Flow Calibrator

- Soft-Sided Carrying Case

- Universal Power Supply

- User’s Guide

- High-Efficiency Inlet Filter

- Mounting Lugs (not shown)

- 6 AA-size Batteries (not shown)

Chapter 2

Setting-Up

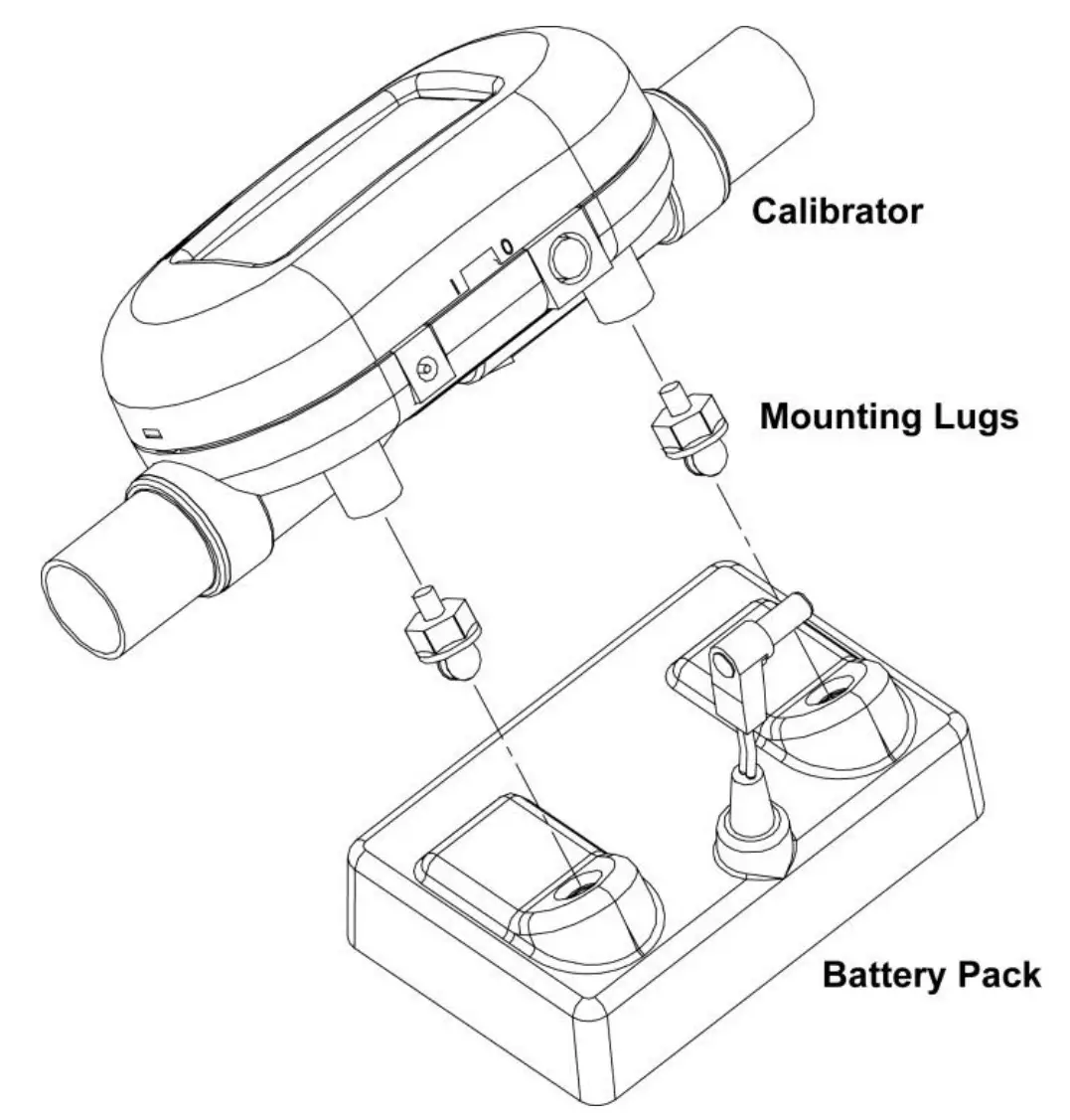

Assembly Instructions for the Flow Calibrators

The calibrator can be quickly attached to the battery pack by screwing the mounting lugs into the threaded holes in the base of the calibrator. The lugs should then be placed over the receiving holes in the top of the battery pack and snapped gently into place. Insert the connector from the battery pack to the receptacle in the back of the calibrator.The calibrator is now ready to use.

Figure 2-1. Flow Calibrator Assembly

Supplying Power

The calibrator can be powered in one of two ways: through the power jack using the supplied 4199 battery pack or using the AC adapter.The DC power input connector is shown below along with the power requirements.

Power Supply: 7.5 VDC ± 1.5 V, 300 mA maximum

Connecting Filter and Flow Tubes

The Model 4048/4148 has a thermal sensor exposed to the air flow that must be protected from foreign matter and particles. TSI® supplies a filter that should be connected to the inlet of the calibrator; however, any filter will work as long as it has a minimum efficiency of 99.9%.

NOTE

Flow direction is identified by the large arrow printed on the bottom side of the calibrator and on the bottom of the battery pack.

Attach the filter to the inlet of the calibrator using supplied tubing and/or adapters. Connecting a tube to the outlet of the calibrator will create back pressure. See for calibrator accuracy specifications when operating at various pressures. In general, minimize back pressure on the calibrator by using shorter lengths of tubing to maintain highest level of accuracy.

Figure 2-2. Typical Setup Configurations

Chapter 3

Operation

OverviewThe Model 4048/4148 Flow Calibrator measures volumetric flow rate inside the flow tube. All measurements made by the Models 4048/4148 are NIST traceable.

ON/OFF SwitchSlide the switch to the ON position. The LCD displays volumetric flow in units of liters per minute (L/min).

Flow Rate MeasurementFlow rate data will be displayed on the Model 4048/4148 through the LCD.

Volumetric flow is displayed in units of liters per minute (L/min).

Setting Flow Rates and Calibrating Instruments

The Model 4048/4148 Flow Calibrator may be used to measure or set flow rates on Condensation Particle Counters or other instrumentswhich draw an active flow sample. Be sure to follow all instrument manufacturer’s flow setting and calibration procedures.

- Start up the Model 4048/4148 Flow Calibrator and let it warm up (1 minute for Model 4048 or 10 minutes for Model 4148) prior tosetting any flow rates or conducting any calibrations.

- Connect the outlet of the Model 4048/4148 Flow Calibrator to the inlet of the active sampling instrument.NOTEPlease contact TSI® Technical Support at 800-680-1220 for instructions on connecting Model 4048 to TSI® Filter Testers.

- Follow the instrument manufacturer’s flow setting and/or calibration procedures. The volumetric flow in units of liters per minute (L/min) will be continuously displayed on the LCD of the calibrator.

Chapter 4

Maintenance

Flow SensorPeriodically inspect the flow sensor by looking into the outlet of the calibrator. Remove dust, particles and fibers from the sensor withclean, dry compressed air. The flow sensor may break if touched. NEVER RUN LIQUIDS THROUGH THE CALIBRATOR AND NEVER TOUCH THE SENSOR WITH A BRUSH. Dust or other deposits on the flow sensor will degrade the Model 4048/4148’s flow accuracy.

Re-certificationTo maintain a high degree of confidence in the measurements made by the Model 4048/4148, TSI® recommends that the instrument be returned to TSI® every 12 months for re-certification. The calibrator will be recalibrated and returned with a certificate of calibration to US National Institute of Standards Technology (NIST) traceable standards.

CasesIf the instrument case or storage case needs cleaning, wipe it off with a soft cloth dipped in isopropyl alcohol or mild detergent. NEVERsubmerge the calibrator or allow liquids to enter the flow tube.

StorageWhen storing the calibrator, always cover the ends of flow tubes with the caps provided to prevent dust or other foreign matter fromentering the tube.

Chapter 5

Troubleshooting

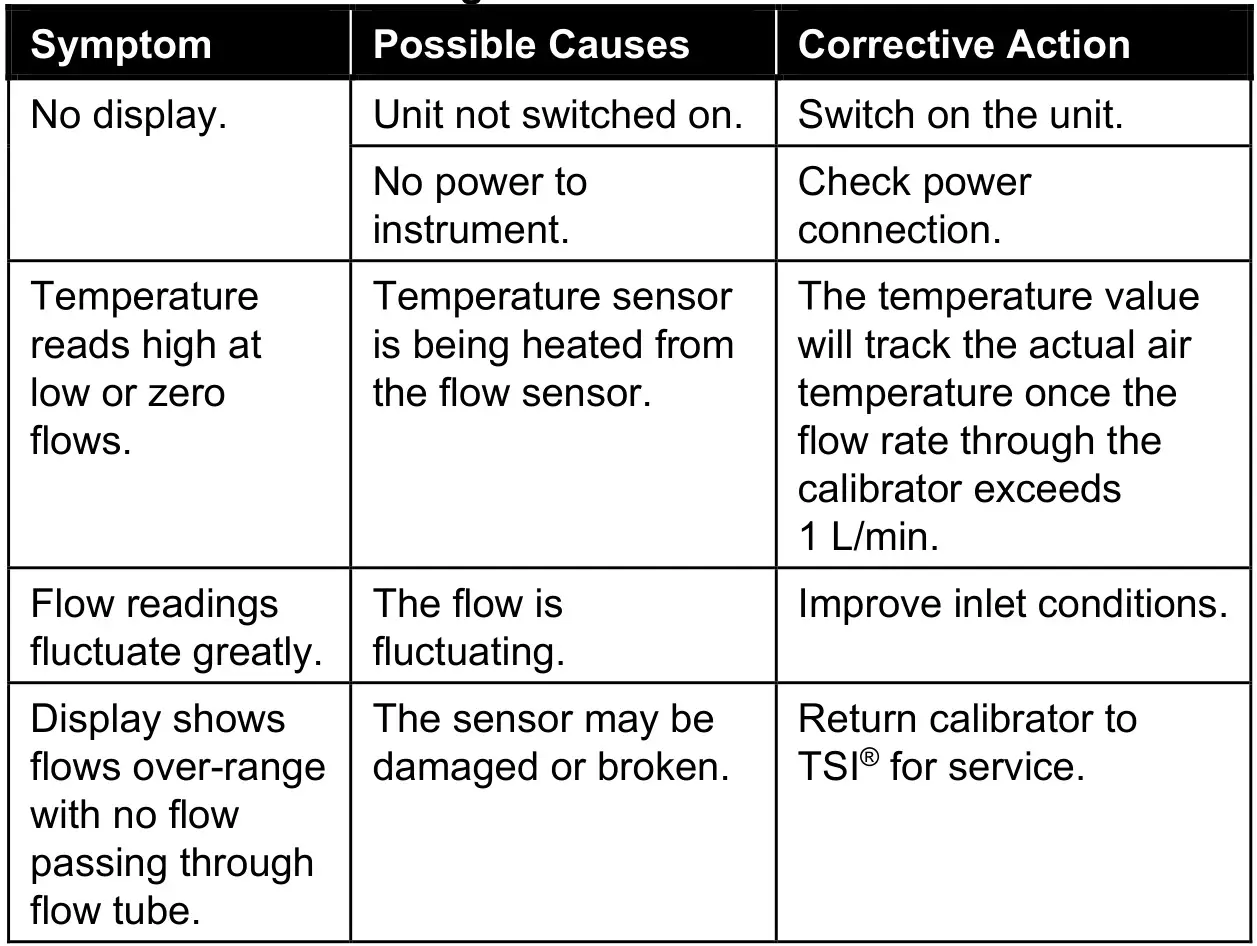

Table 3 lists the symptoms, possible causes, and recommended solutions for common problems encountered with Model 4048/4148 Flow Calibrators. If the symptom is not listed, or if none of the solutions solve the problem, please contact TSI® Technical Support at1-800-680-1220 or 651-490-2860.

Table 3. Troubleshooting

Technical Contacts

- If you have any difficulty installing the Model 4048/4148, or if you have technical or application questions about this instrument,contact an applications engineer at TSI® Incorporated, (651) 490-2860 or contact [email protected].

- If the Model 4048/4148 fails, or if you are returning it for service, visit our website at tsi.com/service or contact TSI® at:

TSI Incorporated500 Cardigan RoadShoreview, MN 55126 USAPhone: +1-800-680-1220 (USA) or +1 (651) 490-2860E-mail: [email protected]

TSI GmbHNeuköllner Strasse 452068 AachenGERMANYTelephone: +49 241-52303-0Fax: +49 241-52303-49E-mail: [email protected]

TSI Instruments Ltd.Stirling RoadCressex Business ParkHigh Wycombe, Buckinghamshire HP12 3STUNITED KINGDOMTelephone: +44 (0) 149 4 459200E-mail: [email protected]

Appendix A

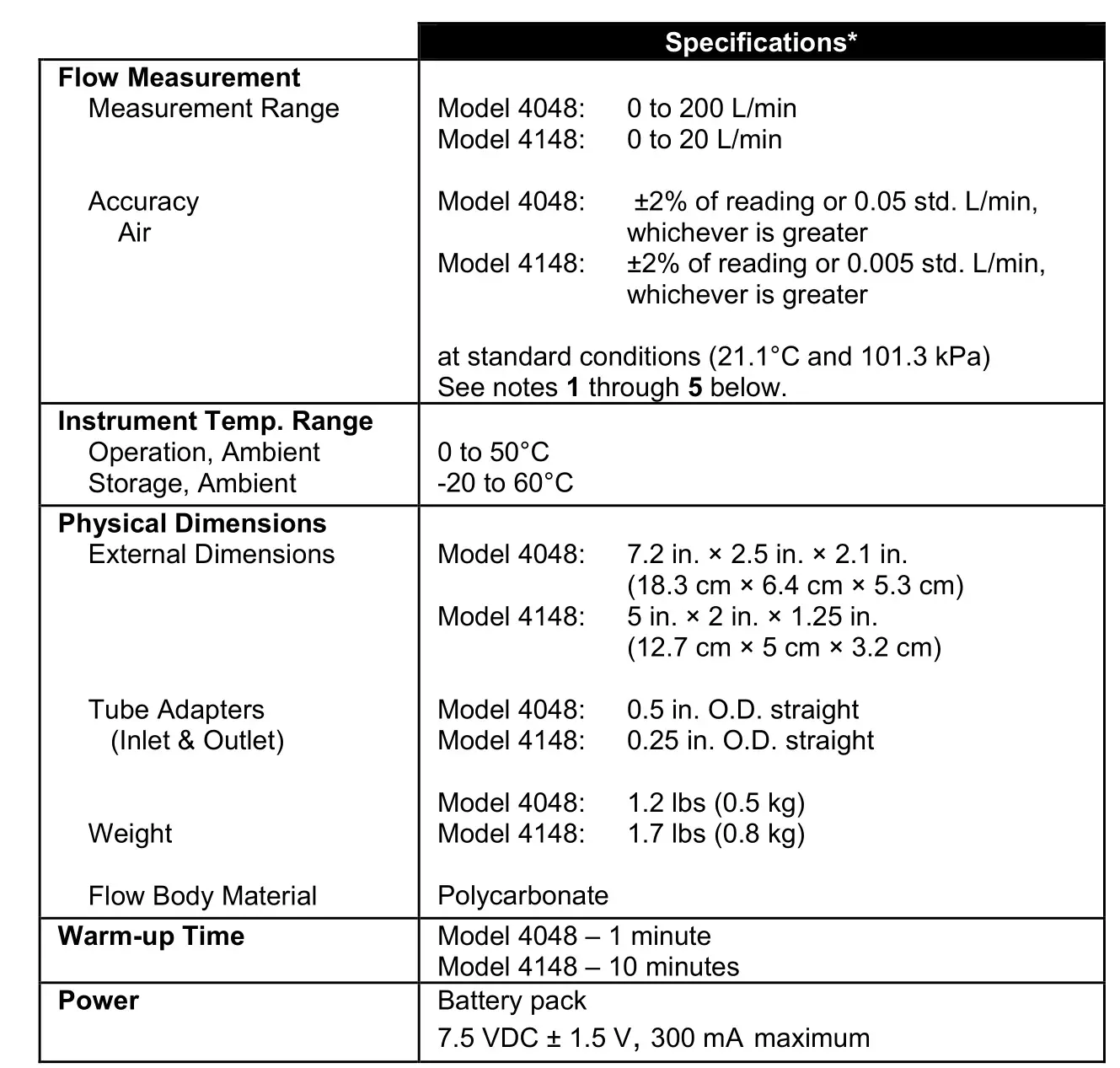

Specifications

Notes:

- Accuracy stated at standard conditions of 21.1°C and 101.3 kPa.

- Accuracy stated with air temperature and flow body temperature within ±10°C of one another.

- Accuracy stated measuring dry air (less than 10% R.H.).

- Includes ±0.5% of reading repeatability.

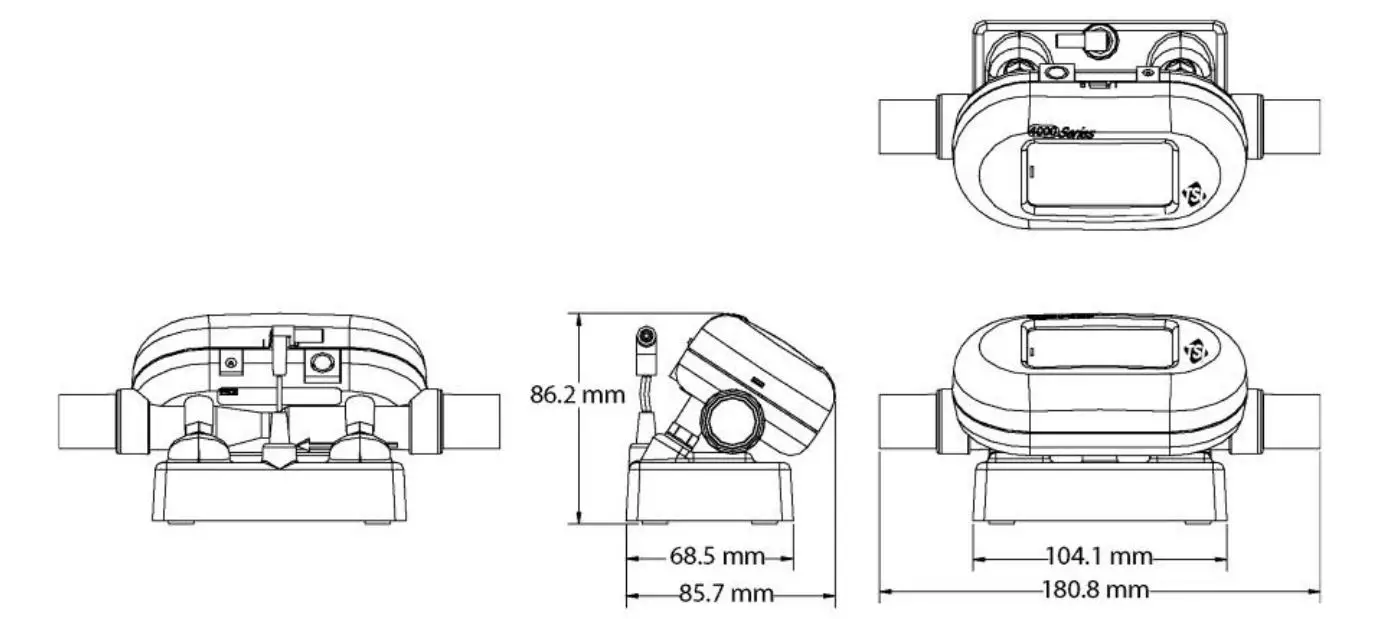

*Specifications subject to change without notice. Figure A-1. Model 4048 Dimensions

Figure A-1. Model 4048 Dimensions

Figure A-2. Model 4148 Dimensions

TSI Incorporated – Visit our website www.tsi.com for more information.

USA Tel: +1 800 680 1220UK Tel: +44 149 4 459200France Tel: +33 1 41 19 21 99Germany Tel: +49 241 523030India Tel: +91 80 67877200China Tel: +86 10 8219 7688Singapore Tel: +65 6595 6388

P/N 6010051 Rev. B ©2020 TSI Incorporated Printed in U.S.A.

[xyz-ips snippet=”download-snippet”]