TSI Filtration For Respiratory Protection User Guide

Masks and respirators are diverse. What standard do I follow, and what equipment do I need to conduct testing?

The global demand for respiratory protection and barrier devices has skyrocketed during the COVID-19 pandemic. This has created significant pressure on manufacturers to produce higher volumes of devices, and even bring new devices to market.

Adding to the complexity is the issue of testing standards. While respirator testing has not changed significantly in recent years, testing for other types of devices has been undergoing change:

- Barrier face coverings1 (commonly known as facemasks) used in public spaces now have a formal testing standard to measure their performance (ASTM F3502);

- The US testing standard for medical masks (ASTM F2100) is currently (as of Q2 of 2021) undergoing revision.

Understanding which testing standards apply to which devices, and what tools can be used to conduct device testing, can be somewhat challenging in this changing environment.

This document seeks to help you find the TSI® solution for testing various respiratory protection and/or barrier devices to their appropriate standards. Table 1 summarizes which devices are tested to which standards, recommends a TSI® solution to conduct device testing, and provides guidance on purchasing relevant accessories and consumables.

1 To clarify, barrier face coverings are not the same as respirators, and are not the same as medical masks. See Reference #5.

TSI and TSI logo are registered trademarks of TSI Incorporated in the United States and may beprotected under other country’s trademark registrations.

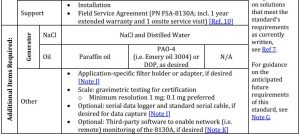

Table 1: TSI® filter testing solutions, and recommended accessories, for testing to various filtration standards for respiratory protection and barrier devices. Relevant Notes and References are indicated throughout by letters and numbers, respectively; see the Notes and References sections below.

2 Designs / appearances may vary significantly within each category. The images provided are meant to serve as a guide only, and should not be considered to be a complete representation of all device types within a certain category.3 While TSI® can provide guidance on how to test to a particular standard using TSI equipment, compliance with a given standard (and, if applicable, with other local or regional regulations) is ultimately the customer’s responsibility. This document is intended to be educational only, and should not be considered a legal reference.

TSI® Solution for Respiratory Filter Testing

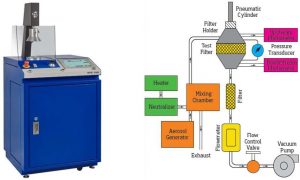

The Model 8130A Automated Filter Tester is a globally established solution for respirator testing. Because of this, and the similarity between the requirements of respirator testing and barrier face covering testing as required by ASTM F3502, the Model 8130A is also a complete solution for barrier face covering testing.

Figure 1: The Model 8130A Automated Filter Tester. Left: the tester, when viewed from the front. Right: a schematic of the tester’s internal components.

The Model 8130A generates a polydisperse NaCl or oil challenge aerosol that is detected with two solid-state photometers. Photometers are used for their excellent sensitivity and dynamic range, as well as their ability to measure the large mass concentrations required for the loading testing of respirators (see Note A). The 8130A can support flow rates of 10 to 110 L/min and can measure total filtration efficiencies up to 99.9999% during initial penetration and loading tests. Differential pressure can be measured as part of the filtration test, or alone with the aerosol generator turned off.

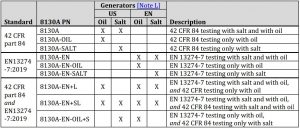

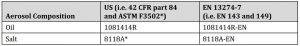

Table 2: Available generator configurations for the Model 8130A Automated Filter Tester

Several different generators are available. Use Table 2 to select the 8130A part number that includes the correct generators for your testing needs. For guidance on expanding the capabilities of an existing Model 8130A (for example, to enable an 8130A to conduct EN testing), see Note M.

Notes

- A. Respirators and loading: As with filters in any application, as respirators accumulate particles, their performance changes. A specific “loading” test is performed to investigate the performance of a respirator during significant particle accumulation. Loading tests are required in some, but not all, testing standards for respiratory protection and barrier devices. Refer to the poster “Air Filtration Basics” for more information on loading. Further, note that the specific parameters of a loading test are defined by the standard to which the testing will be conducted. Consult the relevant standard(s) for specifics.

- B. Additional requirements for some devices:o For medical masks: compliance must be demonstrated not only to ASTM F2100, but also to additional requirements set by the United States Food and Drug Administration (FDA). In the FDA Guidance Document (Surgical Masks – Premarket Notification [510(k)] Submissions, Section 8), the FDA clarifies that the test must be conducted with 0.1 μm polystyrene latex spheres (PSL) aerosol, and further specifies that the aerosol must be non-neutralized.o For surgical respirators: this special category of respirators in the US must be tested to both the 42 CFR part 84 standard and the ASTM F2100 standard. Due to having been tested for filtration efficiency and pressure drop in the 42 CFR part 84 tests, they are exempt from only the particle filtration efficiency and differential pressure portions of ASTM F2100. They must satisfy all ASTM F2100 requirements aside from the particle filtration efficiency and pressure drop.

- C Barrier face coverings: ASTM F3502-21 is a new standard – released February 2021 – that pertains to the testing of barrier face coverings. Among other performance characteristics, ASTM F3502 requires barrier face coverings to meet the performance requirements pertaining to particle filtration efficiency and pressure drop (breathability). The particle filtration efficiency test in the F3502 standard is a modified version of 42 CFR part 84 subpart K (initial efficiency only, with NaCl aerosol).The TSI® Model 8130A meets all of the technical requirements of this new standard for how barrier face coverings must be tested. In Europe, several standards are in various stages of development (e.g., CEN CWA 17553, AFNOR SPEC S76-001, others). Please refer to the application note on ASTM F3502-21 (see Ref. #5), or contact TSI® to discuss your barrier face covering testing needs.

- D. EN 14683: For medical face mask standards, EN 14683 is the relevant standard for the EU. EN 14683 requires a bacterial filtration efficiency (BFE) test and a differential pressure (dP) test (Annex C), but does not require a particulate filtration efficiency (PFE) test. TSI® does not have available solutions for the BFE test. Contact TSI® to discuss the possibility of performing the EN 14683 dP test on the Model 8130A.

- E. EN 13274-7: In EN 149:2001+A1:2009, as well as in the current draft revision of EN143:2000/A1:2006, the filter penetration test has been removed. In its place is now a reference to the methods now contained in EN 13274-7:2019: “Respiratory Protective Devices – Methods of Test – Part 7: Determination of Particle Filter Penetration.” Refer to the TSI® application note “Testing to EN13274-7:2019 with 8130A-EN” (Ref. #1).

- F. Scope of this guidance relative to 42 CFR part 84: TSI® makes an automated filter tester (the Model 8130A) that can be used for the filter efficiency and pressure drop measurements of respirators. All other measurements required by 42 CFR part 84 are beyond the scope of TSI’s solutions and guidance.Further: 42 CFR part 84 describes the testing methods for a wide variety of respirator designs. See References #6, 7, and 10 to learn more. It is the user’s responsibility to be sufficiently acquainted with the requirements of the standard for the devices the user would like to test, including aerosol composition, tester settings, and other requirements.

- G. ASTM F2100 is currently under review: As described in our application note AFT-007 (see Ref. #7), ASTM F2100 is a parent method that calls upon several other published procedures. Among them is ASTM F2299, which requires the determination of filtration efficiency using monodisperse polystyrene latex spheres (PSL). This is sometimes referred to as the particle filtration efficiency (PFE) test. A proposed revision would replace the PFE portion (F2299) with the method detailed in ASTM F3502.Regardless of any changes that may be made to ASTM F2100, in the United States the US Food and Drug Administration (FDA) has the final authority over the testing of medical masks (which includes surgical and procedural), as well as surgical respirators. Their final requirements may differ from those of any subsequent revisions of ASTM F2100.

- H. 8130A v. 8130A-EN: These two models differ in the aerosol generator and minor hardware changes. These differences are pertinent to the standards discussed in this document as follows:• 42 CFR 84 and GB2626: 8130A is fully compliant with 42 CFR 84 and GB2626.• ASTM F3502: The 8130A contains the proper aerosol generator (PN 8118A; see Note L) to use when testing barrier face coverings according to ASTM F3502-21.• EN 13274-7: Filters can be tested to EN 13274-7 (which is referred to by EN 149) using the Model 8130A-EN when using oil aerosol; see Ref. #1.To purchase a tester that can, upon delivery, meet both 42 CFR part 84 and EN 13274-7 requirements, refer to Table 2. To learn how to expand the testing capabilities of a currently-owned tester, see Note M.

- I. Data capture methods for 8130A: There are four data capture methods available for the 8130A. Choose the method preferable for your needs. Contact TSI® for further details.• Serial printer: available from TSI®.• Serial data logger: purchased from a third party. Requires a standard serial cable.• Modbus TCP (setup and penetration tests only): available from TSI®.• HTTP streaming (raw data dump only): contact TSI® for more information

- J. Custom filter holders: The standard filter holder included with the 8130A is a general-purpose flat sheet media holder with an area of 100 cm2. For any other needs, filter holders have to be customized to the type of device you are testing, or adapters need to be made. For example, cartridges often need specific adaptors and small chambers are needed for testing respirators. It is the end user’s responsibility to design and source these.

- K. Network monitoring of the 8130A: SpiderControl™ is a third-party software that enables a user to view the 8130A front panel from a networked computer. While the physical buttons to operate the chuck cannot be activated via SpiderControl™ software, all of the touchscreen-related functions can be performed. This option requires a regular Ethernet cable and a host computer. The 8130A and the host computer can be connected to each other either directly via the Ethernet cable, or via a network.

- L. Individual aerosol generators: While Table 2 describes which aerosol generators are included with purchase for the available configurations of the Model 8130A automated filter tester, each of the generators are also available for individual purchase. Individually purchasing an aerosol generator can be valuable – for example, when converting an 8130A to an 8130A-EN as described in Note M (also see Note H). Individual aerosol generators can be purchased using the part numbers shown in Table 3.

Table 3: Part numbers for ordering individual aerosol generators for use with the Model 8130A Automated Filter Tester.

*ASTM F3502 requires salt aerosol, so the 8118A is the only generator that can be used for this testing.

M. To expand the capabilities of a current tester, refer to advice below as appropriate:

- To expand the capabilities of an 8130A so that it can do EN-compliant testing, order:o The relevant EN aerosol generator(s), as shown in Note L. Be sure to be sufficiently familiar with the EN standard(s) so as to know which aerosol composition(s) will be necessary; ando A conversion kit (PN 8130A-P1233). This kit contains the EN-specific pressure gauge and rotameter to make the ‘minor hardware changes’ mentioned in Note H to fully convert to an EN-compliant tester.• To expand the capabilities of an 8130A-EN so that it can do ASTM F3502 testing, order:o The salt generator PN 8118A (see Note L).

- To expand the capabilities of an 8130A-EN so that it can do 42 CFR part 84 testing, order:o The relevant aerosol generator(s) as shown in Note L. Be sure to be sufficiently familiar with the EN standard(s) so as to know which aerosol composition. Be sure to be sufficiently familiar with the 42 CFR part 84 standard so as to know which aerosol composition(s) will be necessary for your device testing needs.

References

- “Testing to EN13274-7:2019 with 8130A-EN”. TSI® application note AFT-006, A4 and US.

- “42 CFR part 84 Standard.” TSI® application note AFT-001, US.

- “42 CFR part 84 Testing Modes.” TSI® application note AFT-002, US.

- 42 CFR part 84: Approval of respiratory protective devices. https://www.ecfr.gov/cgi-bin/text-idx?SID=6b0b69703a73ccc1c57f3084ae6a29b7&mc=true&node=pt42.1.84&rgn=div5

- “TSI Tools for Measuring Submicron Particle Filtration of Barrier Face Coverings to ASTM F3502”. TSI® application note AFT-008, A4 and US.

- ASTM F3502: Standard specification for barrier face coverings. https://www.astm.org/Standards/F3502.htm

- “TSI Tools for Measuring Submicron Particle Filtration of Medical Masks and Respirators to ASTM F2100”. TSI® application note AFT-007, A4 and US.

- ASTM F2100: Standard specification for performance of materials used in medical face masks. https://www.astm.org/Standards/F2100.htm

- CertiTest® Automated Filter Tester Model 8130A specification sheet. A4 and US.

- Model 8130A Automated Filter Tester, description of Field Service Agreement.

- “Determination of Particulate Filter Efficiency Level for N95 Series Filters Against Solid Particulates for Non-Powered, Air-Purifying Respirators”

TSI Incorporated – Visit our website www.tsi.com for more information.

USA Tel: +1 800 680 1220UK Tel: +44 149 4 459200France Tel: +33 1 41 19 21 99Germany Tel: +49 241 523030

India Tel: +91 80 67877200China Tel: +86 10 8219 7688Singapore Tel: +65 6595 6388

Application Note AFT-009 Rev. A-(A4)

©2021 TSI Incorporated

Printed in U.S.A.

[xyz-ips snippet=”download-snippet”]