U-LINE UHNB115 15 Inch Nugget Ice Machine User Guide

1 Class UHNB115 / UHNP115 15″ Nugget Ice Machine

WELCOME TO U-LINECongratulations on your U-Line purchase. Your product comes from a company with over five decades of premium modular ice making, refrigeration, and wine preservation experience. U-Line creates products focused on functionality, style, and inspired innovations — paying close attention to even the smallest details. Applications include residential, outdoor, ADA height compliant, marine, and commercial. Complete product categories include Beverage Centers, Wine Refrigerators, Ice Machines, Refrigerators, Freezers, and Dispensers.Our advanced refrigeration systems, large and flexible capacities, and Built-In to Stand Out® clean integrated look allow you to preserve the right product, in the right place, at the right temperature. Since 2014, U-Line has been part of the Middleby family of brands. All products are designed, engineered, and assembled in Milwaukee, Wisconsin, USA, and select products are available worldwide.

PRODUCT INFORMATION

Looking for additional information on your product? User Guides, Spec Sheets, CAD Drawings, Compliance Documentation, and Product Warranty information are all available for reference and download at u-line.com.

PROPERTY DAMAGE / INJURY CONCERNSIn the unlikely event property damage or personal injury is suspected related to a U-Line product, please take the following steps:

- U-Line Customer Care must be contacted immediately at +1.414.354.0300.

- Service or repairs performed on the unit without prior written approval from U-Line is not permitted. If the unit ha been altered or repaired in the field without prior written approval from U-Line, claims will not be eligible.

GENERAL INQUIRIES

U-Line Corporation8900 N. 55th StreetMilwaukee, Wisconsin 53223 USAMonday – Friday 8:00 am to 4:30 pm CSTT: +1.414.354.0300Email: u-line.com

CONNECT WITH US

SERVICE & PARTS ASSISTANCE

Monday – Friday 8:00 am to 4:30 pm CSTT: +1.414.354.0300Service Email: [email protected]Parts Email: [email protected]

Designed, engineered and assembled in WI, USA

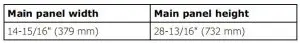

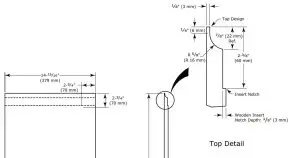

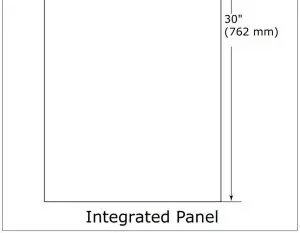

Integrated Panel Dimensions

Metric measurements rounded and optimized.

INTEGRATED PANEL

NOTICE: Due to differences in surrounding cabinetry the panel may not perfectly align with door. The procedure below is designed to provide a finished integrated panel that seamlessly integrates with surrounding cabinetry.

Panel Preparation

A full integrated door panel completely covers the door frame and provides a built-in appearance.

NOTICE

The door panel must not weigh more than 20 lbs (10 kg).It is important to ensure that all drilled holes are drilled to the correct depth in order to avoid splits in the wood when hardware is installed.

- Cut the panels to the dimensions listed in the diagram below.

- Optional: Stain or finish panel to desired stain or color. Be sure to closely follow the instructions provided by the manufacturer.

- Optional: Install handles and hardware.

NOTICEWhen applying an integrated panel to a unit, ensure that both sides are finished in order to prevent warping. In some panel installations, the panel may be visible through the glass while the door is open.

HANDLELESS INTEGRATED DOOR PANEL

The following procedure is designed to provide a finished, handleless solid panel for an 15″ (381 mm) door that seamlessly integrates with its surrounding cabinetry.

NOTE: Many cabinet manufacturers provide a ready solution for a handleless, integrated design that can be easily applied to your model. Consult your cabinet manufacturer for applicable design and installation details. The cabinet manufacturer’s solution to this design and integration detail will often result in an integrated panel solution wherein the size of the panel may result in a height dimension taller than what we specify. This can be achieved provided the additional height is positioned above the appliance door.

NOTICEThe integrated panel aligns with the surrounding cabinetry and, due to differences in cabinetry, may not align perfectly with the door.

The appliance will need up to 34-1/2″ (876 mm) to the underside of the counter to leave room for leveling adjustments.

A single prepared panel with insert must not weigh more than 20 lbs (10 kg).

Integrated Panel Preparation

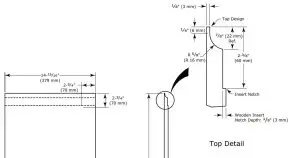

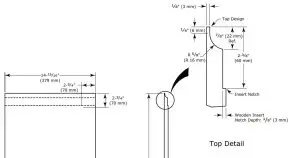

- Cut the main panel to the dimensions below. For details, see the drawings on the next page.

- Create the top design for the handleless feature and the 1/8″ (3 mm) notch for the insert(s) indicated on the Top Detail drawing, on the next page.

- Prepare the insert(s) that will back up the handleless design. Wooden Insert Cut 1/8″ (3 mm) thick wooden insert(s) to the dimensions below.

- Optional: Stain or finish panel and wooden insert to desired stain or color. Be sure to closely follow the instructions provided by the manufacturer.NOTICE If finishing panel or wooden insert, all sides must be finished to prevent warping.

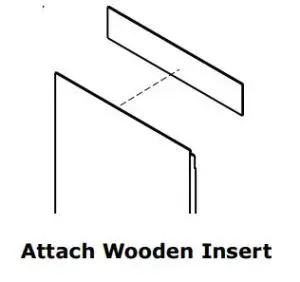

- Attach the insert to the panel. Wood glue or equivalent adhesive should be used to attach insert to panel.

Handleless Integrated Panel Dimensions

Wooden Insert Dimensions

Wooden Insert Dimensions

EXTENDED INTEGRATED PANEL

NOTICE Due to differences in surrounding cabinetry the panel may not perfectly align with door. The procedure below is designed to provide a finished panel that seamlessly integrates with surrounding cabinetry.

Panel Preparation

An extended integrated panel can be used to maintain alignment with an adjacent extended cabinet height or a reduced toe-kick/grille application.

- Cut the panels to the dimensions listed in the appropriate diagram on the next page.

- Optional: Stain or finish panel to desired stain or color. Be sure to closely follow the instructions provided by the manufacturer.

- Optional: Install handles and hardware

* Panel can extend beyond the door frame.** A minimum of 1″ (25 mm) from the floor is required for proper ventilation.

NOTICE

The door panel must not weigh more than 20 lbs (10 kg).

It is important to ensure that all drilled holes are drilled to the correct depth in order to avoid splits in the wood when hardware is installed.

Appliance will need up to 34-1/2″ (876 mm) to the underside of the counter to leave room for leveling adjustments.

When applying an integrated panel to a unit, ensure that both sides are finished in order to prevent warping. In some installations, the panel may be visible through the glass while the door is open.

Extended Integrated Panel Dimensions

* A minimum of 1″ (25 mm) is required from the floor to the bottom of the extended integrated panel/frame for proper ventilation.

* A minimum of 1″ (25 mm) is required from the floor to the bottom of the extended integrated panel/frame for proper ventilation.

Integrated GrilleIf you would like to cover the grille with an integrated panel, purchase U-Line’s adjustable grille accessories. 15” – Sales Accessory: ULAGRILLE15

Complete instructions, including dimensions of the integrated grille panel, are included with the accessory.

Integrated Panel Installation

- Fully open door.

- Starting at corner, pull gasket away from door.

- Continue to pull gasket free from gasket channel.

- Upon removal, lay gasket down on a flat surface.

- Align top of panel with top edge of door. Center panel on door. NOTICEDue to differences in floor construction or surrounding cabinetry, the panel may not sit flush with the top of the door.

- Secure integrated panel to door using clamps. A robust tape may also be used. U-Line recommends the use of bar clamps to secure the panel to the door. If using tape, be certain the tape will not damage panel finish upon removal.

- Using a 7/64″ (3 mm) drill bit, drill 6 pilot holes into the wood panel 1/2″ (12 mm) deep using the holes in the door frame as a guide. NOTICE: It is important to ensure that all drilled holes are drilled to the correct depth in order to avoid splits in the wood when hardwood is installed.

- Locate 6 of the #6x 1-1/2″ (38 mm) screws provided with your unit.

- Using a Phillips screwdriver, place one screw into each of the 6 pilot holes and screw down. Do not overtighten screws.

- Ensure the screws sit flush against the bottom of the channel.

- Remove clamps from door. NOTICE: If panel requires additional adjustment after removing clamps, slightly loosen each screw and adjust panel as necessary. Tighten screws upon completion.

- Starting at the corners, re-install the gasket into the gasket channel in the frame. Make sure the gasket is fully seated.

Grille Installation

REMOVING AND INSTALLING GRILLE

![]() Disconnect electric power to the unit before removing the grille.

Disconnect electric power to the unit before removing the grille.

When using the unit, the grille must be installed.

![]()

![]()

![]()

Removing the grille

- Disconnect power to the unit.

- Loosen the two screws (1).

- Remove grille (2) from unit.

Installing the grille

- Align cabinet and grille holes and secure, but do not over tighten grille screws (1).

- Reconnect power to the unit.

References

[xyz-ips snippet=”download-snippet”]