ULINE Fountain Roller Kit

OPERATION FOUNTAIN ROLLER KIT

INKING

- Fill the roller with the proper ink.NOTE: Only use compatible ink.

- Pump 30 to 50 strokes while rolling back and forth on a 6 x 18″ piece of oil board. Continue pumping while rolling. To get uniform distribution of ink, use extra firm pressure on the roller.NOTE: DO NOT use an absorbent material.

- To provide uniform inking around the entire surface of the roller, the inking path length must be at least 12″. This will eliminate light and dark marking.

- To test for uniformity of the ink stripe, make a test roll on a clean carton board using normal rolling pressure.

STENCILING

- Pass the roller back and forth over the stencil with straight passes.

- When more ink is needed, pump once or twice before or while stenciling.

- When stenciling a vertical surface, or if one side of the roller inks too heavily, reverse the roller. (Put the rest bar up.)

OPERATING TIPS

- To correct unequal distribution of ink due to rapid usage of ink from one area of the roller, occasionally squeeze the roller extra firmly as you roll it against a test surface.

- Do not allow the roller to become too dry.

- During continuous stenciling, pump the roller once occasionally. Occasional pumping prevents drying or flooding and oversaturation of the foam rubber.

- Fountain Roller Kits work best with .007″ thin oil boards or plastic sheets.

- Be sure to use roller cover to protect the inked roller when not in use.

CLEANING THE ROLLER

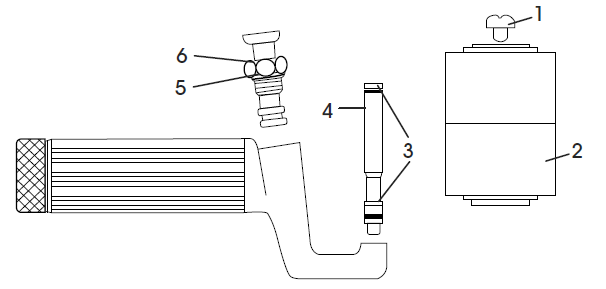

- Remove the screw (1) and carefully slide the roller (2) off the spindle (4).

- Wipe and cover the spindle with a cloth to absorb fluids. Fill the reservoir 1/4 full of the proper solvent.

- Shake vigorously and then empty the reservoir.

- Refill the reservoir 1/4 full of solvent and pump to flush the valves, ink passages and orifice.

- Drain all solvent from the fountain roller and refill with proper ink.

REPLACING THE ROLLER

- Remove the screw (1) and slide the old roller (2) off the spindle (4).NOTE: Do not pump with the roller removed. Ink will spray from the orifice.

- Wipe and lubricate the spindle (4).

- Carefully slide the new roller over the spindle and o-rings (3).

REPLACING THE PUMP

- Unscrew the hex nut (6) and remove the entire assembly.

- Lubricate the casting and the new pump (5).

- Attach the new pump assembly with the hex nut.

REPLACING THE O-RINGS

- Being careful to not damage the adjacent bearing surface, remove the o-rings (3) with a knife or other pointed tool.

- Carefully fit the new rings into place.

REPLACING THE SPINDLE

- Grasp the spindle (4) with pliers on its undercut portion.

- Unscrew it from the frame.NOTE: Handle the new spindle gently to avoid burring the orifice bearings in the center of the new spindle.

- Install the new spindle by grasping the undercut portion of the new spindle and screwing into the frame.

[xyz-ips snippet=”download-snippet”]