H-1335KIHLBERG PNEUMATIC ROLL FEED STAPLER

1-800-295-5510 – uline.com

SAFETY WARNINGS

![]()

![]()

![]()

- Wear eye protection when using tools. Always use other personal protection equipment as required, such as ear protection, hard hats, etc.

- Never use oxygen, combustible gases, CO2, steam or high-pressure gas tanks as power sources for the PN-version of this tool; the tool may explode and cause serious injury. Use only dry, clean, pressure-regulated compressed air to drive the tool.

- Always check the tool before every use.

- Always disconnect the tool from the air supply and empty the magazine when taking a break or ending work, when servicing the tool, troubleshooting or repairing. Never leave a loaded tool unattended.

- Always assume that the tool is loaded. Respect the tool as potentially dangerous. Never point the tool at yourself or anyone else, whether it contains staples or not. Always remove your finger from the trigger when not driving staples.

- Never hold your hand or another part of your body under the tool.

- Position yourself in a firmly balanced position when using or handling the tool.

- Do not modify the tool or set it up in a jig without the manufacturer’s approval.

- Use stapler with cardboard ONLY. No other use is permitted without the approval of the manufacturer.

OPERATION

ATTACH COMPRESSED AIR

![]()

![]()

![]()

![]()

Connect the tool to the compressed air system before the fastener unit is loaded.

![]()

![]()

![]()

The tool and its hose can be equipped with a connection nipple (not included) that automatically exhausts air from the tool after it has been disconnected.Ensure that the minimum internal diameter of the air hose is 10 mm (3/8″) and that of the nipple is a minimum of 5 mm (6/32″). This prevents incorrect operation due to excessive pressure drop.

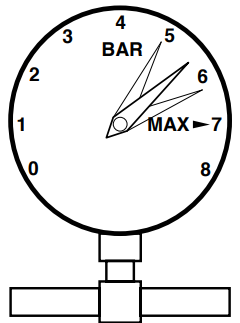

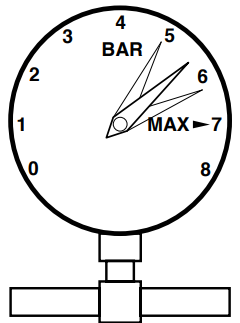

SET THE AIR PRESSURE

Adjust the air pressure to the lowest setting that will bend the staples correctly.

- Start at 5.0 bar.

- Raise this by 0.5 bar increments until you find the correct pressure for the job.

![]()

![]()

![]()

![]()

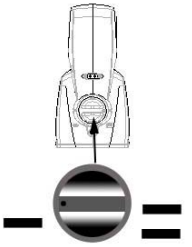

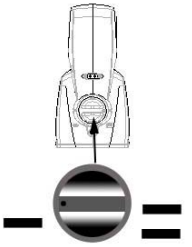

CHANGE THE STAPLE LEG LENGTH SETTING

Use the setting knob to adjust the depth of stapling claws.Press the knob in and then turn it to the required position.‘-‘ denotes shallow stapling,=’ denotes deep stapling.

ADJUST THE LEG LENGTH

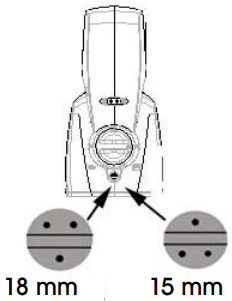

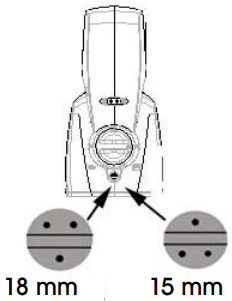

- The tool adjusts for 15 or 18 mm

- Loosen the locking screw underneath with a 2.5 mm Allen

- Set the required staple legThe side guides in the magazine are adjustable. ‘Outer’ position denotes 18 mm, ‘Internal’ denotes 15 mm.

- Tighten the locking screw.

![]()

![]()

![]()

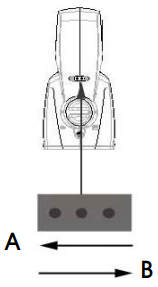

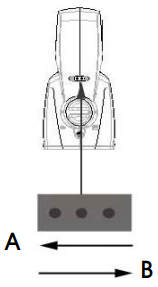

TO ADJUST THE AMOUNT THE STAPLE CLOSES

For a tighter staple closure: Turn the adjusting nut clockwise (A).For a looser staple closure: Turn the adjusting nut counterclockwise (B).

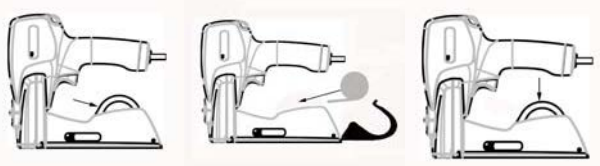

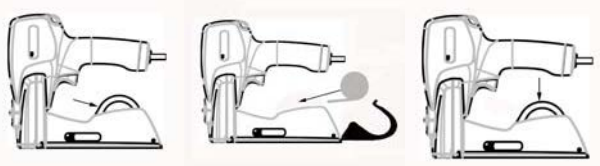

LOAD THE MAGAZINE

- Press the magazine lid backwards and release the latch. Lift the lid up and then back at the same time.

- Feed the staple strip right up to the side guides.

- Close the lid with a slight push and press it down until the lid locks.

TO OPERATE THE STAPLER

- Place the tip of the tool against the box and press until the board is compressed.

- Pull the trigger.

SERVICING THE STAPLER

MAINTENANCE![]()

![]()

![]()

- The trigger and safety yoke move freely without binding or sticking.

- All screws and nuts are securely tightened.

This tool does not require special servicing. It only needs regular cleaning with a non-aggressive (noncorrosive) cleaning agent.![]()

![]()

![]()

![]()

LUBRICATION

The tool needs a small amount of lubricating oil in the nipple each day or approximately 10 drops once a week to ensure a safe function and endurance. For high-frequency stapling, we recommend lubricating oil.Grease sliding or moving parts with multipurpose grease if they have been cleaned or replaced.

CLEARING JAMSGenerally, you will not need to disassemble any parts to clear jamming in the nozzle plate.

- Pull the locking device forwards until the nozzle plate opens.

- Carefully remove the staple with flat pliers.

- Reset the latch.

1-800-295-5510uline.com

0421 IH-1335

[xyz-ips snippet=”download-snippet”]