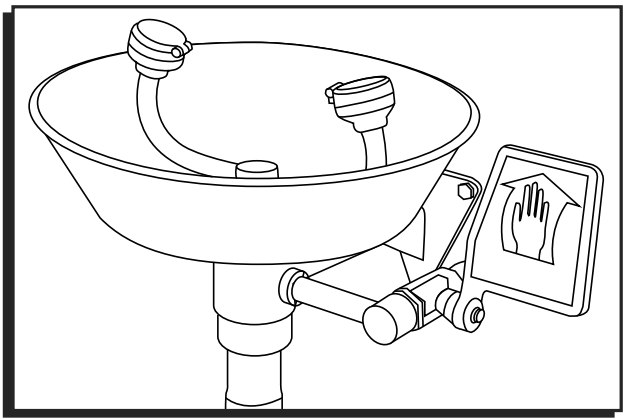

H-5457, H-5795WALL MOUNT EYEWASH STATION

1-800-295-5510uline.com

INSTALLATION AND MAINTENANCE

INSTALLATION

- The unit should be assembled in accordance with the parts diagram, installed in close proximity to hazard and should be in a clearly identified location, free of obstructions.

- A shut-off valve(s) (supplied by others) should be installed and located in accordance with the local plumbing code.

- Back flow prevention device(s) (supplied by others) should be installed and located in accordance with the local plumbing code.

- Drain location and waste discharge should be installed and located in accordance with the local plumbing code.

- Eyewash water flow pattern shall be positioned between 33 and 53 inches from the floor and at least 6 inches from the wall or nearest obstruction.

- Unit should be connected with a recommended minimum 1/2″ IPS line to a tepid, clean water source capable of supplying 30-80 PSI flowing pressure for a minimum of 15 minutes. If shut-off valves are installed inline, provisions should be made to prevent unauthorized shut-off.

NOTE: Do not use a 3/8″ nominal flex connector as flow may be insufficient.

NOTE: Do not use a 3/8″ nominal flex connector as flow may be insufficient. - Where freezing conditions exist, unit must be protected from freezing.

- Performance should be verified after installation. Check for any leaks while all valves are in the closed position. All valves should stay in the open position upon activation.

- With the eyewash valve in the fully opened position and using a test gauge, the spray pattern should meet the required pattern per ANSI Z358.1. Verify that the water is tepid, and the flow rate is at least 0.4 GPM for eyewash and 3.0 GPM for eye/face wash.

MAINTENANCE

- All units should be tested on a weekly basis to clear supply lines and verify proper activation. Units must also be inspected annually to verify the continued conformance of the required performance standards stated above.

ANSI / ISEA Z358.1 COMPLIANCE

- Location: Install eye/face wash unit within 10 seconds (approximately 55 feet) of hazard, on the same level as hazard and with unobstructed travel path. Where strong acids or caustics are being handled, emergency eye/face wash units should be located adjacent to the hazard, and an appropriate professional should be consulted for advice on the proper distance.

- Identification: Identity eye/face wash locations with highly visible signs. The area around the eye/face wash unit shall be well-lit.

- Water Temperature: Water delivered by eye/face wash shall be tepid (60-100°F).

- Training: Instruct all employees in the location and proper use of eye/face wash units.

- Maintenance/Inspection: Activate plumbed eye/ face wash units at least weekly. Inspect all eye/face wash units annually for compliance with standards.

0421 IH-5457

[xyz-ips snippet=”download-snippet”]