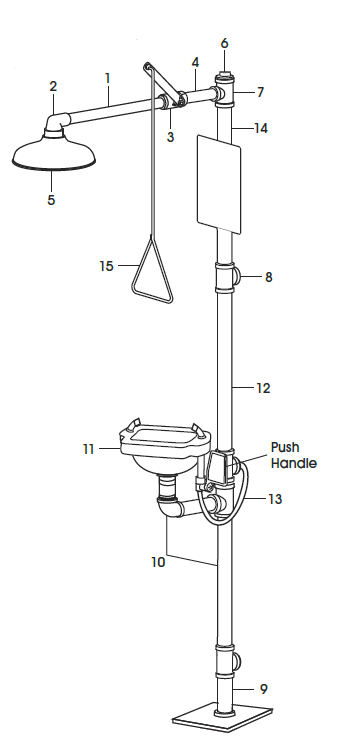

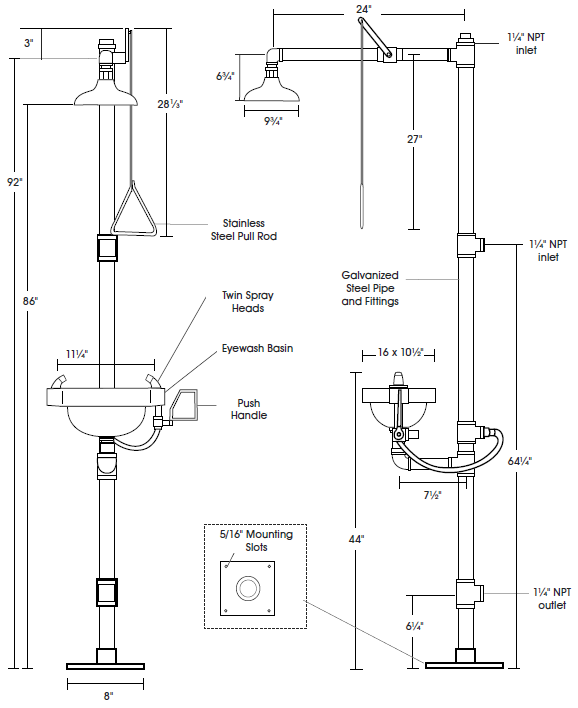

ULINE H-6697 Shower Eyewash Station

TOOL NEEDED

ASSEMBLY

NOTE: Unit is furnished with corrosion resistant epoxy coating, care must be taken to avoid damaging finish during assembly. For best results, a strap wrench should be used.NOTE: The use of a vice is recommended for proper tightening and alignment.

IMPORTANT! All threads are tapered pipe and require pipe joint compound or Teflon tape to assure watertight connection. When securing with Teflon tape, wrap tape around each thread 10-12 times for optimal seal.

- Unscrew large shower connection pipe (1) from elbow (2) and shower ball valve (3). Wrap Teflon tape around threading and reassemble.

- Unscrew small shower connection pipe (4) from shower ball valve (3). Wrap Teflon tape around threading and reassemble.

- Assemble the shower head (5) onto the elbow (2) and set assembled parts aside.

- Unscrew square head plug (6) from top inlet tee (7). Wrap Teflon tape around threading and reassemble.NOTE: If the top inlet tee (7) will be where the water source is supplied, screw square head plug (6) into side of middle inlet tee (8) instead

- Wrap tape around threading of base support unit (9) and connect to eyewash basin connection pipes (10).

- Attach eyewash basin (11) to basin connection pipes (10).

- Wrap tape around threading of middle pipe section (12) and connect to basin connection pipes (10).

- Connect hose (13) to ball valve and position for proper access by users.

- Wrap tape around threading of top pipe section (14) and assemble to top of middle inlet tee (8).

- Take assembled shower connection pipe from steps 1-3, wrap with tape, and connect to the side of the top inlet tee (7) so that the shower head (5) is facing down for proper use.

- Attach the pull handle (15) to arm of the ball valve (3).

- Connect water line to top inlet tee (7) or middle inlet tee (8) – square head plug (6) should be in the tee that doesn’t have the water supply.

- Secure unit to floor and run water through pipes to flush out any impurities and test for proper operation.

This unit complies with the requirements of ANSI Z358.1.

[xyz-ips snippet=”download-snippet”]