ULINE H-7917 Flash Flood Secondary Eyewash Station

TOOLS NEEDED

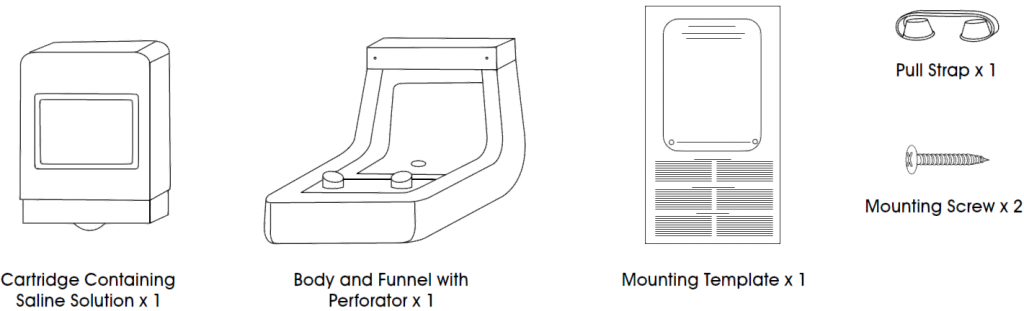

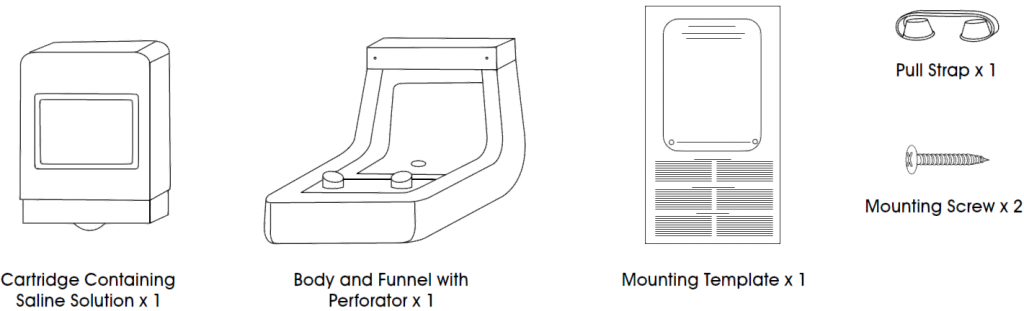

PARTS

SAFETY

WARNING!

- Emergency eyewash station is not for outside use.

- The unit must be level for proper operation.

- Employees must be instructed in the use of emergency eyewash stations.

- This unit is intended for the emergency use of victims of eye contamination until medical treatment is obtained.

- In all cases, the victim should seek medical attention immediately.

- This unit must be inspected on a monthly basis.

- Use of expired solution may result in serious personal injury.

Failure to follow and comply with all directions and cautions stated in these instructions may result in serious personal injury, blindness or death.

The ANSI Standard Z358.1-2004 requires that:

- The unit must be positioned with the nozzle(s) not less than 33″ and no greater than 45″ from the floor and 6″ minimum from the wall or nearest obstruction.

- Eyewash units must be in accessible locations that require no more than 10 seconds to reach. The eyewash must be located on the same level as the hazard and the path of travel shall be free of obstructions that may inhibit the immediate use of the equipment. For a strong acid or a strong caustic, the eyewash should be immediately adjacent to the hazard.

- Each eyewash location must be identified with a highly visible sign positioned so the sign is visible within the area served by the eyewash. The area around the eyewash must be well-lit.

INSTALLATION

This is a secondary eyewash and must be placed in an accessible location near the hazard.

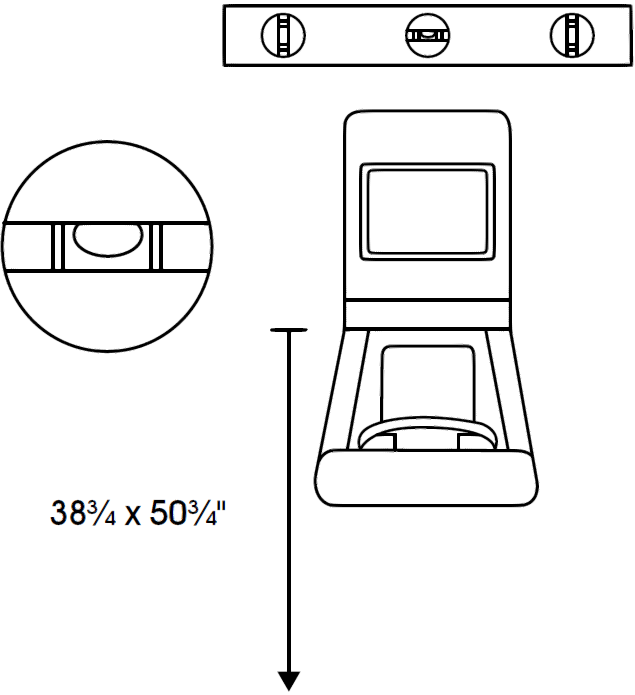

- Unit must be level.

- Mounting must support the weight of the unit (14 lbs.) plus weight of the individual leaning on it.

- Position the screw holes on unit 38¾ – 50¾” from the floor.

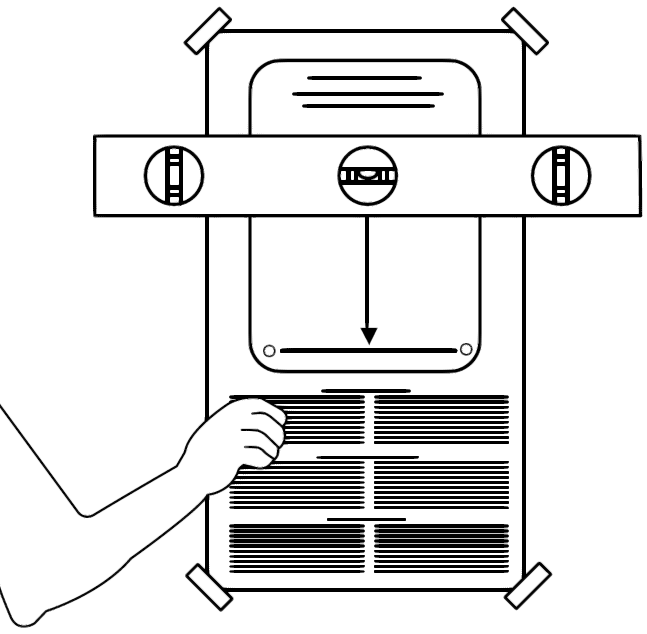

- Tape the enclosed template onto a flat, unobstructed wall surface.

- Ensure the line between mounting screws is level and template sides are square.

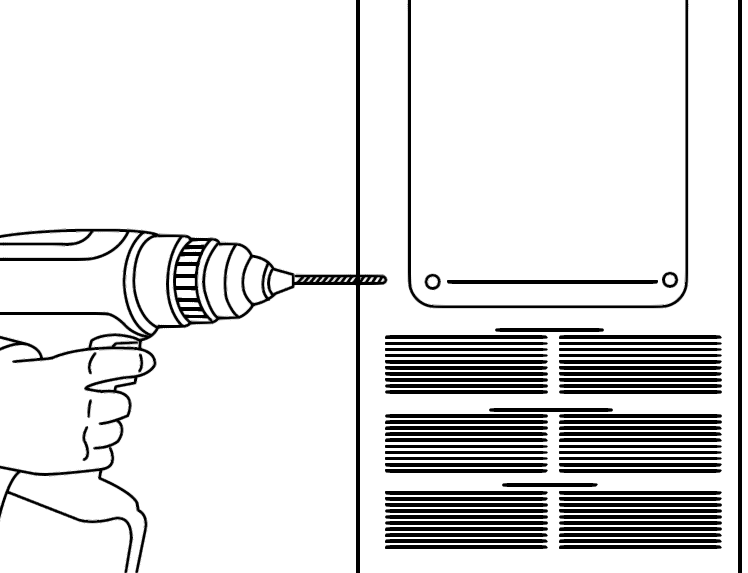

- Drill pilot holes through template using 9/64″ drill.

- Remove template.

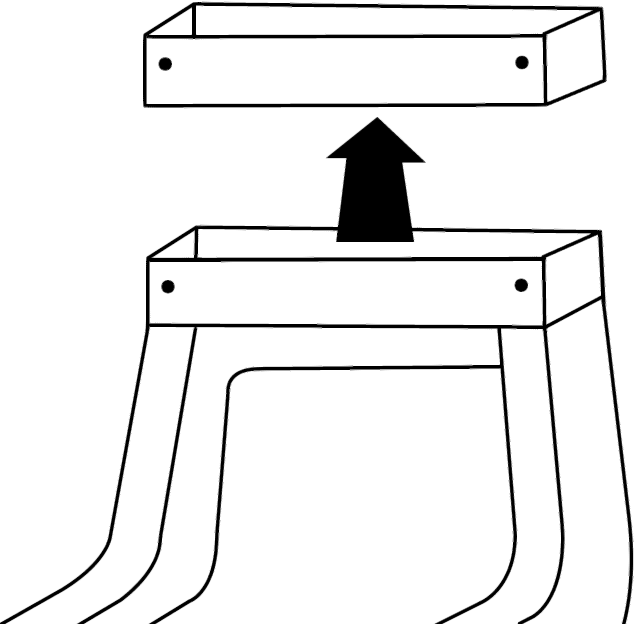

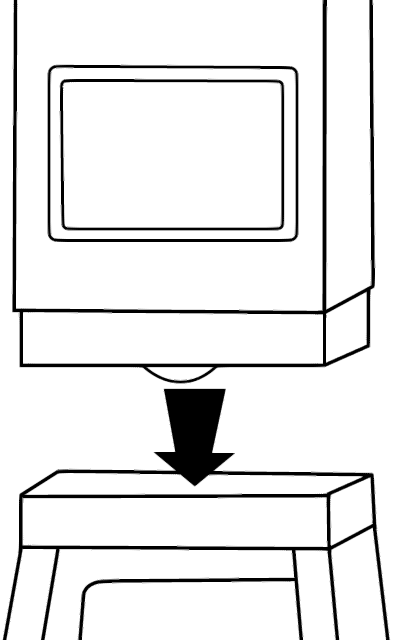

- Remove funnel with perforator from body and set aside.

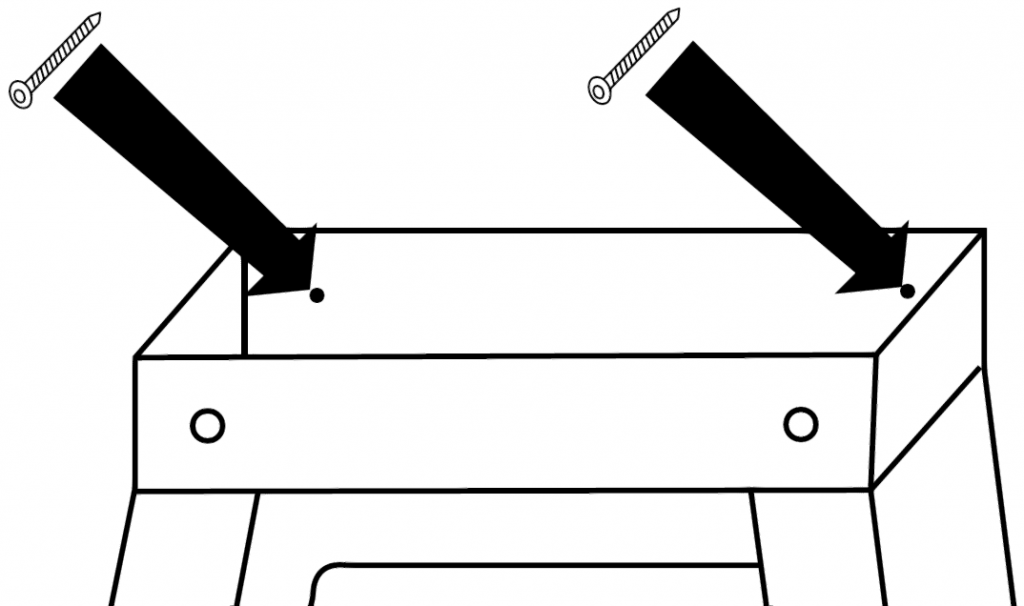

- Insert two screws through holes in back of body.

- Hold unit in place. Insert a screwdriver through holes in front of body and tighten screws into pilot holes.

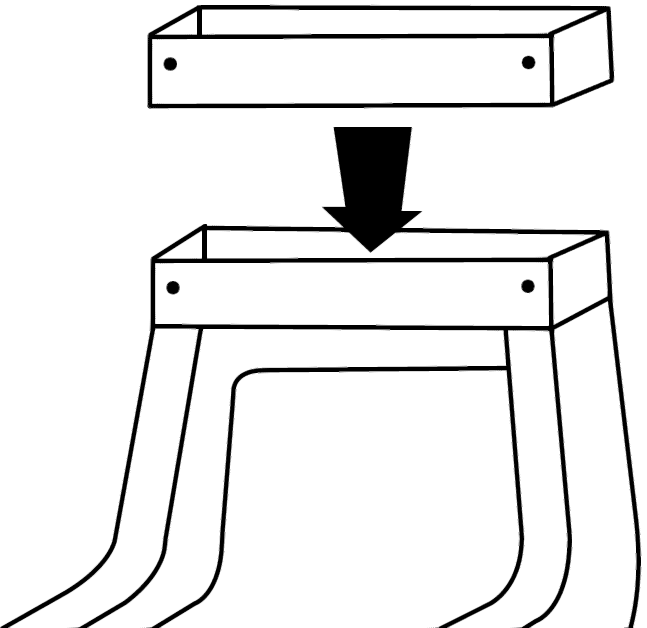

- Replace funnel with perforator on top of body.

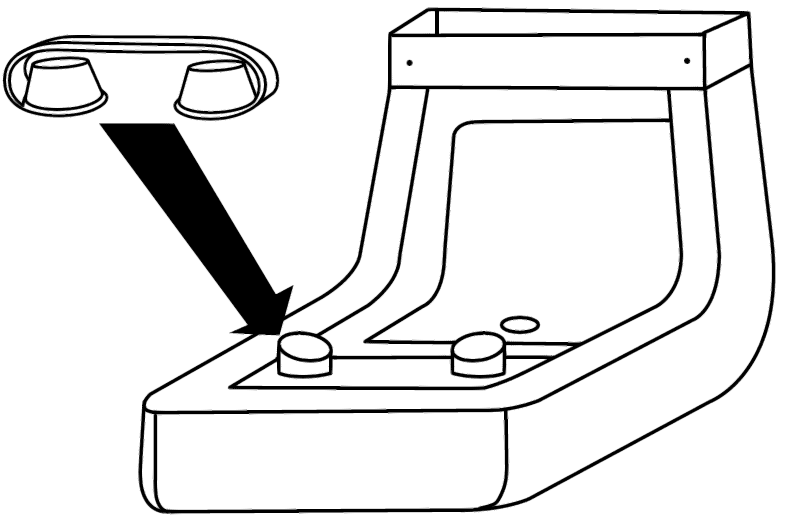

- Place pull strap over nozzles.

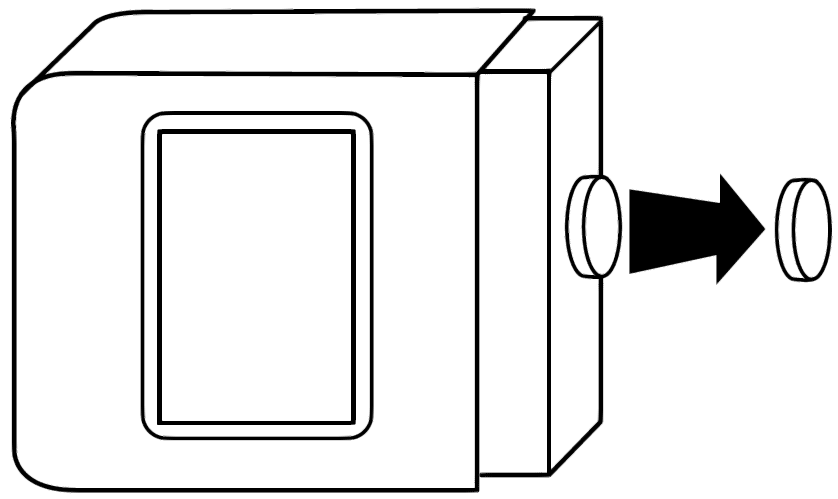

- Remove cap from cartridge, leaving foil cover intact.

- Invert cartridge and place securely into funnel.

NOTE: Solution replacement date is six months after installation.

OPERATION

Instruct employees in the use of the Eyewash Station. Regular training will keep employees aware of the location and proper use of eyewash devices.

- The sooner eyes are flushed, the less likelihood of injury.

- The unit is for emergency use only. Tampering with the eyewash station may cause it to be empty when needed.

In cases of severe eye contamination, the victim may need assistance to flush the eyes.

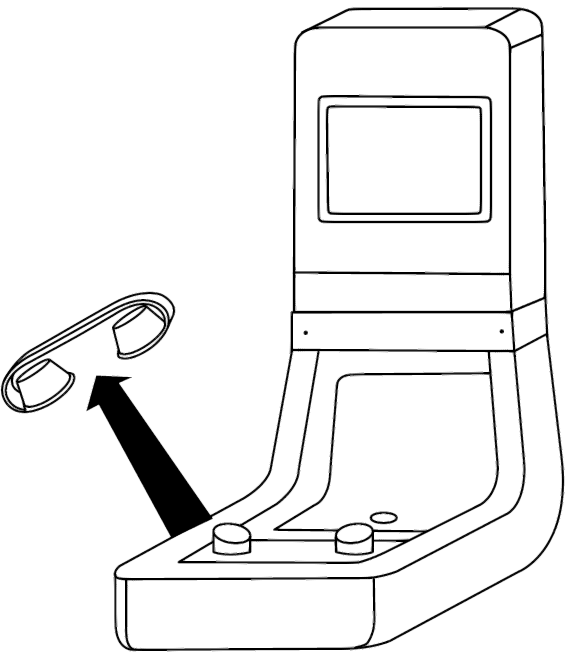

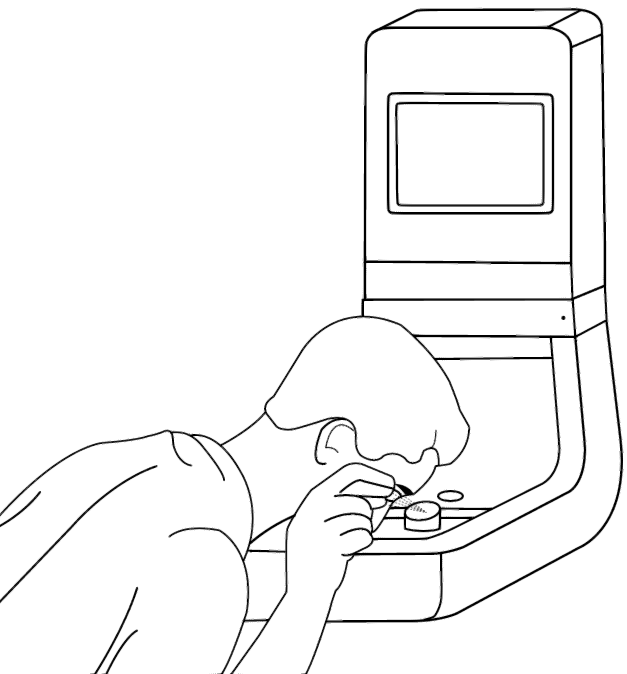

- Start the fluid by pulling strap upward.

- Lower head into flow.

- Using thumb and forefingers, fully open eyelids and flush eyes until flow stops.

- Empty cartridge can be replaced to extend flushing time.

- Victim should proceed to a primary flushing unit after initial flush with this secondary unit.

- After flushing, seek medical attention immediately.

- Replace empty unit with new cartridge.

MAINTENANCE

- Inspect all eyewash stations weekly to ensure proper operating conditions. Inspection records must be kept with the unit.

- All eyewash devices must be cleaned and drained at least once every six months to inhibit bacterial growth.

- Replace cartridge if expiration date is near or past.

- Failure to clean and drain unit may result in contaminated flushing solution.

NOTE: Saline Cartridges contain salt, which can cause a white residue on the eyewash body. Remove by wiping with a damp cloth.

To replace solution:

- Drain fluid by pulling strap and allowing it to empty.

- Remove spent cartridge.

- Place pull strap over nozzles.

- Replace cartridge as detailed in “Installation”

1-800-295-5510uline.com

[xyz-ips snippet=”download-snippet”]