H-8780 BULK BAG LIFTER

1-800-295-5510uline.com

OPERATION

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

USING THE LIFTER:

The bag lifter can either be carried on the forks of a forklift or be suspended from a hook.

![]()

![]()

![]()

![]()

![]()

MOUNTING LIFTER ON FORKS

- Adjust the positions of the forks on their carriage to match the location of the fork brackets on the underside of the lifter.

- Insert forks through all four fork brackets.

- Adjust location of the lifter on the forks as necessary to accommodate a bulk bag.

- Attach carriage strap to fork carriage without slack.

- Elevate the forks.

- Attach the fabric hopper/bulk bag. Attach each of the four straps of the bag to one of the arms of the lifter. Slide the straps over the retainers and seat them into strap slots.

SUSPENDING LIFTER FROM A LOAD HOOK

1. Attach load hook to bale.2. If hook is part of another fork/front end attachment (of a forklift), fasten carriage strap to fork carriage without slack.

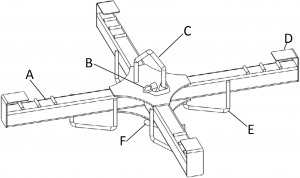

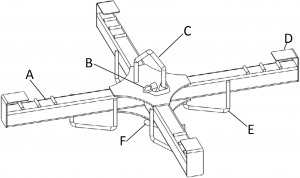

A. Strap SlotB. Carriage Strap with snap hookC. Bale: Connects to load hookD. RetainerE. Fork bracket: Insert forks through all four brackets when mounting lifter directly to forklift.F. Bag liner gatherer: Press top of the plastic bag liner (if applicable) into gatherer.

3. Attach fabric hopper/bulk bag. Attach each of four straps of bag to one of arms of lifter. Slide straps over retainers and seat them into strap slots.

![]()

![]()

![]()

![]()

![]()

SAFETY

RECORD OF SATISFACTORY CONDITION

Before putting lifter into service, record its appearance. Thoroughly photograph unit so that all features are clearly visible. Take close-range photographs of each label and/or tag as well as nylon carriage strap and snap hook. Collate photographs into a single file. The file is a record of the unit in satisfactory condition. Compare the results of every inspection to this record to determine whether the unit is in satisfactory condition. Do not use it unless it is in satisfactory condition. Purely cosmetic changes, like damaged surface coating (paint or powder-coat) are not changes from satisfactory condition. However, touch-up paint should be applied as soon as damage occurs.

INSPECTIONS AND MAINTENANCE

Regular inspections and maintenance are essential for keeping the unit in satisfactory condition. It is strongly recommend to acquire a copy of the most recent revision of ASME B30.20 (the “Standard”) before putting lifter into service. Inspect the device as described below, and also apply inspections and maintenance recommendations from the standard.

BEFORE EACH USE, INSPECT THE FOLLOWING:

1. Frame - Inspect the bale, fork brackets and main frame for deformations, cracks, etc.2. Carriage strap - Closely examine strap, snap hook and hook at the free end of the strap. Look for thinned, frayed, torn or significantly worn areas.3. Labels and Tags - Confirm that each label and/or tag is present and easily readable from a reasonable distance.

ANNUAL INSPECTION

At least once per year, load the lifter to full capacity. Lift the load for about one minute, and then lower it and disconnect the load from the lifting hook. Closely inspect the lifter for metal fatigue, cracks, warps and other damage. If any significant damage is observed, permanently remove the unit from service.

![]()

![]()

- Read and understand the entire instructions before installing, using or servicing the product. Read them whenever necessary to better understand proper use and maintenance procedures.

- Review safety messages included in the manuals of devices used with this bulk bag lifter, e.g. crane, trolley, hoist, forklift or forklift attachment.

- Always inspect lifter before each use according to inspection procedures described in the most recent revision of ASME B30.20 “Below-the-Hook Lifting Devices”. B30.20 also describes inspections that should be performed frequently and periodically. Conduct these inspections as detailed in the standard and with recommended frequency.

- Properly maintain the lifter according to Inspections and Maintenance procedures listed in these instructions. These procedures supplement the inspection and maintenance recommendations in ASME B30.20.

- Always attach lifter to a safety hook, i.e. a hook with a self-closing latch, to prevent accidental detachment from the hook. Do not connect the lifter to a damaged or malfunctioning safety hook.

- Ensure that the travel path is clear.

- Do not remove or obscure any label. Before using the lifter, confirm that all labels are in place and easily readable from a reasonable distance.

- Do not allow people to ride in bulk bag or on lifter.

- Do not lift more than the rated load of the lifter or bulk bag, whichever is smaller. The capacity of the lifter is 4,000 pounds. If the capacity of bulk bag is 3,300 pounds, do not attempt to lift any more than 3,300 pounds.

- Do not lift a load higher than necessary. Always travel with the bulk bag elevated only as high as necessary to avoid contact with the ground. Travel slowly. Avoid sudden stops to minimize load swing. Turn slowly and carefully.

- Do not modify this product in any way. Modifications automatically void the limited warranty and might make the device unsafe to use.

1-800-295-5510uline.com

0721 IH-8780

[xyz-ips snippet=”download-snippet”]