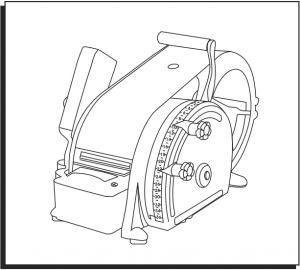

H-731 | 1-800-295-5510MANUAL KRAFT TAPE DISPENSER | uline.com

H-731 | 1-800-295-5510MANUAL KRAFT TAPE DISPENSER | uline.com

OPERATION

SET-UP

- Before using the machine for the first time, remove brushes from the tank and soak them in water for several hours or overnight. Replace brushes and slide tank into machine until the lugs on the tank bottom latch on the rod at the front of the machine.

- Fill the tank with water to the top step in the outside well. Fill the bottle with water and place the opening over the top step. Tip the bottle back into the bottle holder with neck of bottle remaining on top step.

- Set the tape guide plates in the grooves for the proper width of roll to keep the tape centered in the machine. Place the tape in the machine and thread it, gummed side down, between the plates which guide it between the feed rolls. Lift the top roll by tipping its bracket forward, slide the tape between the rolls, and release. Close the top covers.

OPERATION

On the side of the machine are two stops for use when many cartons of the same size are to be sealed. Loosen the clamp knobs, set the stops to the desired lengths and re-tighten. To feed the shorter pre-set length, hold the operating lever outward to the right as it is pulled forward. For the longer length, hold the lever inward to the left. Let the lever fly back to cut tape.

MOISTENING

- The H-731 is designed to dispense various weights of tape from lightweight kraft to heavy reinforced tape. These tapes require various combinations of water and pressure to activate their adhesives properly.

- If the tape is too wet to stick quickly, move water bottle to middle or lowest step in outside tank well.

- Located over the brushes is an adjustable platen weight. Moving the weight forward toward the end of the post increases the pressure on the tape. Pressure is decreased by moving the weight back toward the pivot rod. Heavier tapes require more pressure to fully activate their adhesives. Too much pressure will cause lighter tapes to jam in the machine.

- If necessary, the platen weight may be removed completely.

MAINTENANCE

- Wash the brushes in soap and water once a week.

- Keep the water tank clean and filled with water.

- Keep the water bottle filled to maintain water level.

- Oil moving parts occasionally with light machine oil.

0521 IH-731

[xyz-ips snippet=”download-snippet”]