ULINE S-17880/S-28992 S-17882 S-17883 S-17884 S-17885 Slings

OPERATION

![]() WARNING! Operator must read and understand instructions here and on sling prior to use.

WARNING! Operator must read and understand instructions here and on sling prior to use.

SAFE OPERATING PRACTICES

- Inspect slings prior to each use and do not use if damaged.

- Slings shall not be loaded in excess of their rated capacities. Rated capacities (Working Load Limits) must be shown by markings or tags attached to all slings.

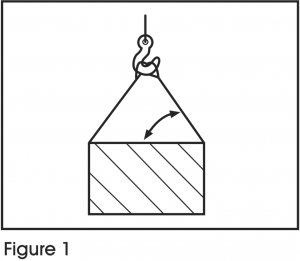

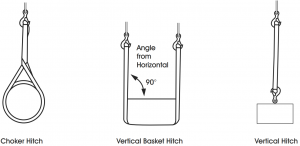

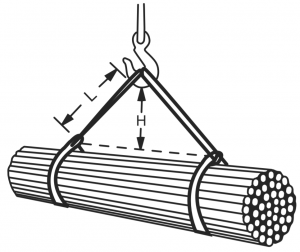

- Angle of lift must be considered in all lifts. (See Figure 1)

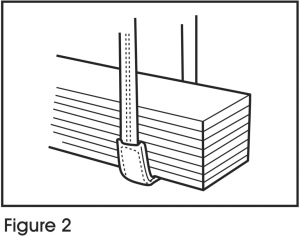

- Slings shall be padded or protected from the sharp edges of their loads. (See Figure 2)

- Loads must be rigged to prevent slippage. (See Figure 3)

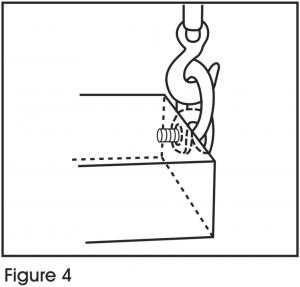

- Slings shall be securely attached to their loads. (See Figure 4)

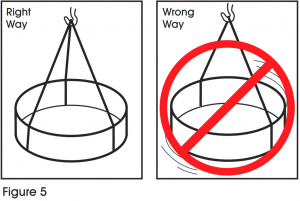

- Lift must be stable with respect to the center of gravity – balanced. (See Figure 5)

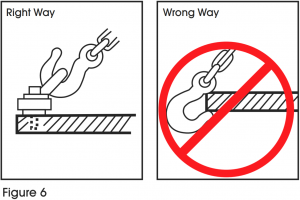

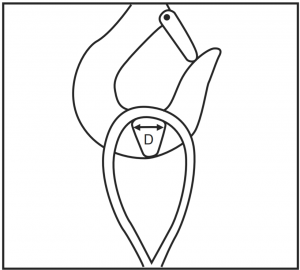

- Do not point load hooks – center load in base of hook. (See Figure 6)

- Suspended loads shall be kept clear of all obstructions.

- All persons shall be kept clear of loads to be lifted, and suspended load.

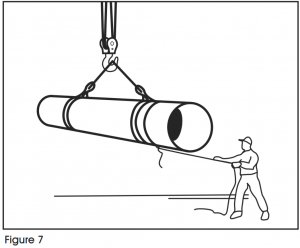

- Hands and fingers shall not be placed between the sling and load while the sling is being tightened around the load. After lifting, the load should not be pushed or guided by employees hands directly on the load. Ropes or “tag lines” should be attached for this purpose. (See Figure 7)

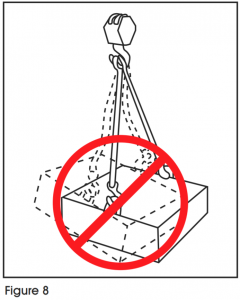

- Do not shock load. Jerking the load could overload the sling and cause it to fail. (See Figure 8)

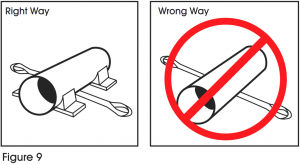

- A sling shall not be pulled from under a load when the load is resting on the sling. Before a load is lifted, a place should be prepared where it is to be put down. Lumber can be used to allow space to remove the sling and prevent shifting of the load. (See Figure 9)

- Temperature and chemical environment must be considered.

- Slings shall not be shortened with knots, bolts, or makeshift devices. (Figure 10)

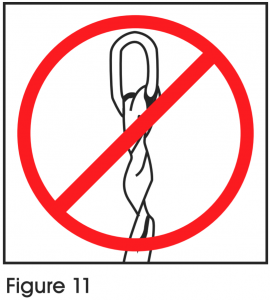

- Sling legs shall not be kinked or twisted. (See Figure 11)|

- Slings shall not be dragged on floor.

- Slings shall be stored in cool, dark, dry areas, preferably on racks

RATED CAPACITY

Using slings at an angle can become deadly if that angle is not taken into consideration when selecting the sling to be used. The tension on each leg of the sling is increased as the angle of lift, from horizontal, decreases. It is more desirable for a sling to have a larger angle of lift, approaching 90°. Lifts with angles of less than 30° from horizontal are not recommended. If you can measure the angle of lift or the length and height of the sling as rigged, you can determine the properly rated sling for your lift.

What would be the rating of each sling rigged at this angle?

* Measured from a common horizontal plane to the hoisting hook. |

What Capacity sling do I need?

* Measured from a common horizontal plane to the hoisting hook. |

REDUCED CAPACITY

Example:Vertical Choker rating of each sling = 6,000 lbs.Measured Length (L) = 6 ft.Measured Height (H) = 4 ft.Reduction Factor (RF) = 4 (H) / 6 (L) = .667(RF) x 6,000 lbs. = 4,000 lbs of lifting capacity per sling

EFFECT OF ANGLE CHART

|

REDUCTION FACTOR (RF) |

ANGLE FROM HORIZONTAL | TENSION FACTOR (TF) |

| 1.000 | 90° |

1.000 |

|

0.996 |

85° | 1.004 |

| 0.985 | 80° |

1.015 |

|

0.966 |

75° | 1.035 |

| 0.940 | 70° |

1.064 |

|

0.906 |

65° | 1.104 |

| 0.866 | 60° |

1.155 |

|

0.819 |

55° | 1.221 |

| 0.766 | 50° |

1.305 |

|

0.707 |

45° | 1.414 |

| 0.643 | 40° |

1.555 |

|

0.574 |

35° | 1.742 |

| 0.500 | 30° |

2.000 |

INCREASING TENSION

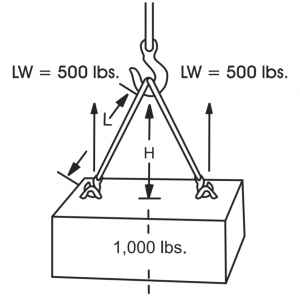

Example:Load weight = 1,000 lbs.Rigging – 2 slings in vertical hitchLifting weight (LW) per sling = 500 lbs.Measured Length (L) = 10 ft.Measured Height (H) = 5 ft.Tension Factor (TF) = 10 (L) / 5 (H) = 2.0Minimum Vertical Rated Capacity required for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs. per sling

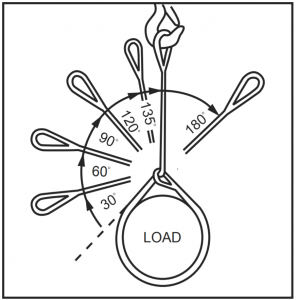

CHOKER HITCH ANGLES

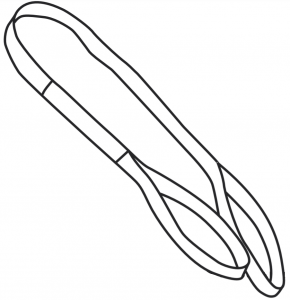

When lifting and turning a load using a choker hitch, it is not uncommon to bend the body of the sling around the choker loop and have a severe bend occur around the body at this point.

For choker angles of 120° or less, the choker rating must be reduced by multiplying the corresponding factor times the slings standard choker rated capacity.

|

ANGLE OF CHOKE |

FACTOR |

| Over 120° |

1.00 |

|

90° – 120° |

0.87 |

| 60° – 89° |

0.74 |

|

30° – 59° |

0.62 |

| 0° – 29° |

0.49 |

Sling capacity decreases as choke angle decreases.

Effect of Anchor Shackle Pin or Crane Hook on Sling EyeDamage to slings can occur if the wrong size pin or hook is used. The width of the pin or hook should never exceed the natural inside width of the eye.

|

PLIES OF WEB |

SLING WIDTH (IN.) | |||||||

| 1 | 2 | 3 | 4 | 6 | 8 | 10 |

12 |

|

|

1 |

8½ | 10 | 11 | 12 | 16 | 20 | 24 | 24 |

| 2 | 8½ | 10 | 11 | 12 | 16 | 20 | 24 |

24 |

|

3 |

10 | 12 | 14 | 16 | 18 | 24 | 24 | 24 |

| 4 | 10 | 12 | 14 | 16 | 18 | 24 | 24 |

24 |

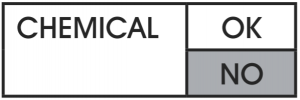

ENVIRONMENTAL CONSIDERATIONS

Polyester is seriously degraded at temperatures above 200° F.Prolonged exposure to ultraviolet light adversely affects polyester. Slings become bleached and stiff when exposed to sunlight or arc welding.Many chemicals have an adverse effect on polyester.

|

POLYESTER |

| Acids |

* |

| Alcohols |

OK |

| Aldehydes |

NO |

| Strong Alkalis |

** |

| Bleaching Agents |

OK |

| Dry Cleaning Solvents |

OK |

| Ethers |

OK |

| Halogenated Hydro-Carbons |

OK |

| Hydro-Carbons |

OK |

| Ketones |

OK |

| Oils Crude |

OK |

| Oils Lubricating |

OK |

| Soap & Detergents |

OK |

| Water & Seawater |

OK |

| Weak Alkalis |

OK |

* Disintegrated by concentrated sulfuric acid.** Degraded by strong alkalis at elevated temperatures.

INSPECTION CRITERIA

![]() WARNING! All slings should be inspected for damage prior to each use to assure that their strength has not been compromised.

WARNING! All slings should be inspected for damage prior to each use to assure that their strength has not been compromised.

|

THE DAMAGE |

WHAT TO LOOK FOR |

TO PREVENT |

| Surface and Edge Cuts – It is important to realize that all of the fibers in web slings contribute to the strength of that sling. When there have been a significant number of fibers broken in a web sling, that sling should be taken out of service. | Broken fibers of equal length indicate that the sling has been cut by an edge. Red core warning yarns may or may not be visible with cuts and are not required to show before removing slings from service. | Use wear pads between the sling and all edges that come in contact with the sling. |

| Holes/Snags/Pulls | Punctures or areas where fibers stand out from the rest of the sling surface. | Avoid sling contact with protrusions, both during lifts and while transporting or storing. |

| Abrasion | Areas of the sling that look and feel fuzzy indicate that the fibers have been broken by being subject to contact and movement against a rough surface. Affected areas are usually stained. | Never drag slings along the ground. Never pull slings from under loads that are resting on the sling. Use wear pads between slings and rough surface loads. |

| Heat/Chemical | Melted or charred fibers anywhere along the sling. Heat and chemical damage can look similar and they both have the effect of damaging sling fibers and compromising the slings strength. Look for discoloration and/ or fibers that have been fused together and often feel hard or crunchy. | Never use polyester slings where they can been exposed to temperatures in excess of 200° F. Never use nylon or polyester slings in or around chemicals without confirming that the sling material is compatible with the chemicals being used. |

| Knots compromise the strength of all slings by not allowing all fibers to contribute to the lift as designed. Knots may reduce sling strength by up to 50%. | Knots are rather obvious problems. | Never tie knots in slings and never use slings that are knotted. |

| Broken/Worn Stitching in the main stitch patterns of web slings has a direct adverse effect on the strength of a sling. The stitch patterns in web slings have been engineered to produce the most strength out of the webbing. If the stitching is not fully intact, the strength of the sling may be affected. | Loose or broken threads in the main stitch patterns. | Never pull slings from beneath loads where stitch patterns can get hung up or snagged. Never overload the slings or allow the load edge to directly contact the stitch pattern while lifting. Never place a sling eye over a hook or other attachment whose width/diameter exceeds 1/3 the eye length. |

| Illegible or Missing Tags – The information provided by the sling tag is important for knowing what sling to use and how it will function. | If you cannot find or read all of the information on a sling tag, OSHA requires that the sling shall be taken out of service. | Never set loads down on top of slings or pull sling from beneath loads if there is any resistance. Load edges should never contact sling tags during the lift. Avoid paint or chemical contact with tags. |

1-800-295-5510uline.com

[xyz-ips snippet=”download-snippet”]