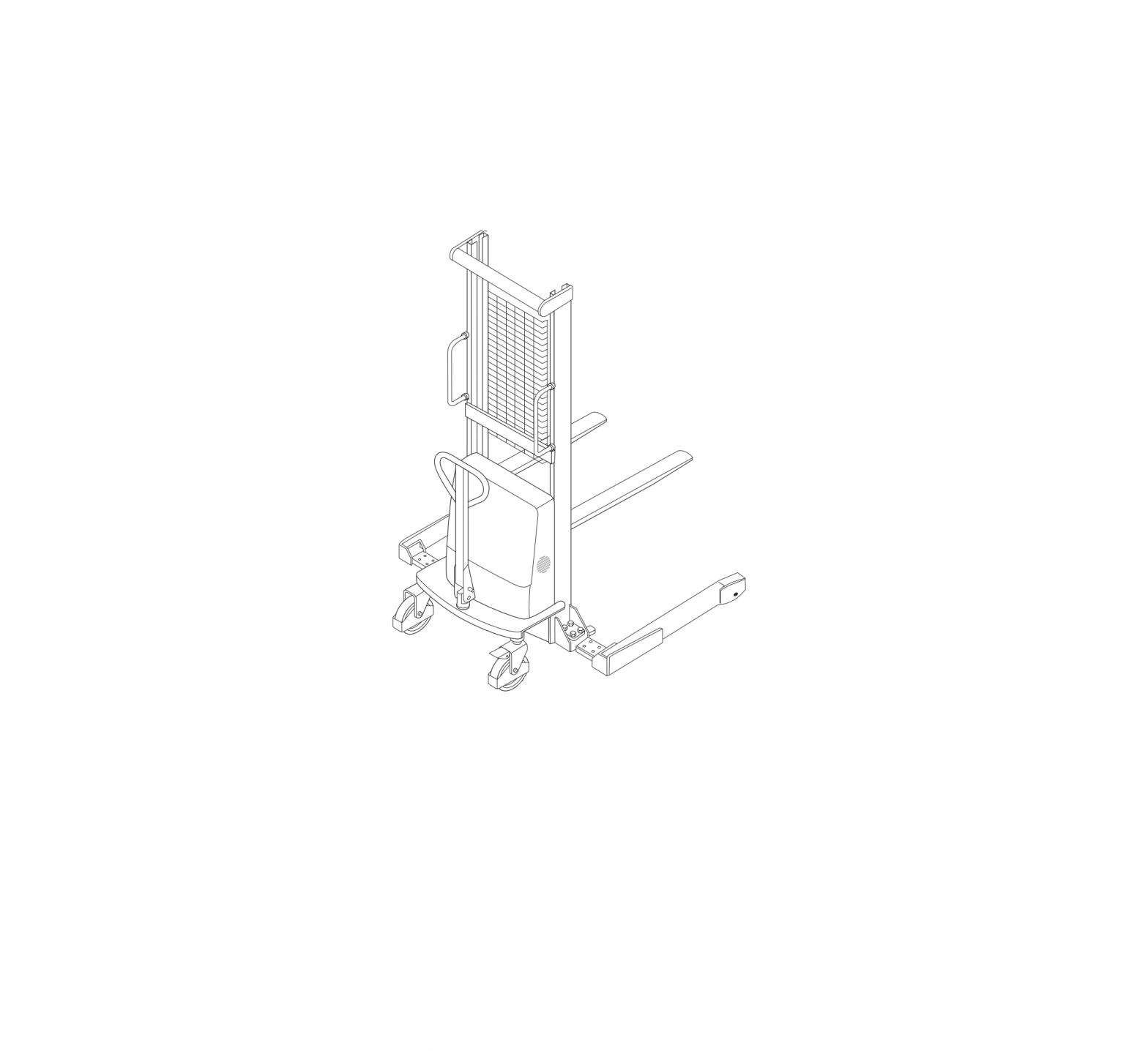

ULINE Straddle Stacker

TECHNICAL DATA

| DESCRIPTION | H-5439 | H-5440 |

| Mast Height (Lowered) |

77¾” |

91½” |

| Mast Height (Raised) |

80″ |

160″ |

| Lifting Height, Max. |

63″ |

137″ |

| Lifting Height, Min. |

21 ⁄8″ |

|

| Weight Capacity, Max. |

2,200 LBS. |

|

| Overall Length |

70″ |

|

| Overall Width |

43¾ – 54¾” |

|

| Fork Size – Length |

42″ |

|

| Fork Size – Width |

4″ |

|

| Forks Adjustable Width (Inside Dim.) |

1/2 – 20″ |

|

| Forks Adjustable Width (Outside Dim.) |

8½ – 28″ |

|

| Straddle Legs (Inside Dim.) |

36½ – 48½” |

|

| Straddle Legs (Outside Dim.) |

43¾ – 54¾” |

|

| Straddle Leg Height |

55⁄8″ |

SAFETY

- Operator should read all warning signs and instructions here and on the stacker before use

- Do not operate stacker unless you are familiar with it and have been trained or authorized to do so.

- This is a manual push truck. Operator must be able to safely move, control and stop a fully-loaded unit by themselves.

- Do not use on uneven ground or in a dangerous environment.

- Do not lift people with the stacker.

- When forks are in motion, no one should stand under the forks or pass below the forks.

- Do not move the stacker unless the forks are 12 inches or less off the ground.

- Keep a two-foot distance between the stacker andany person not operating the stacker.

- The weight of goods should be evenly distributed between the two forks.

- Do not load over the maximum capacity.

- Keep the forks in the lowest position when not in use.

- Locking caster is designed to help prevent rollingwhen unit is not in use. It is not designed to slow down or stop the unit.

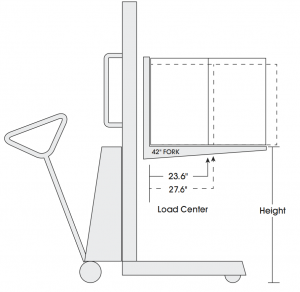

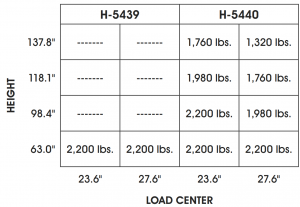

LOAD CAPACITY

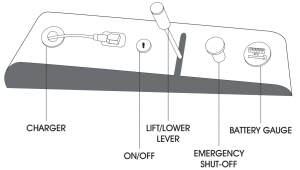

CONTROL PANEL

- Emergency Shut-Off – Press to cut power to all electric control functions, preventing forks from raising and lowering.

NOTE: This will not lock wheels in place.

NOTE: This will not lock wheels in place. - Battery Gauge – Indicates the voltage of the battery.When its voltage is low, do not use the stacker; you must charge it.

- Lift/Lower Lever – The control stick controls the lowering and lifting of the forks.

CHARGING THE BATTERY

- Charge battery when its voltage is low.

- The charging location should be ventilated and away from anything combustible.

- If the stacker is not in use for a long period of time, charge it no less than every month.

- Do not use the stacker when charging.

INSTRUCTIONS

ADJUSTING THE LEGS (SEE FIGURE 1)

- Unscrew and remove the 4 bolts and washers (11⁄16“) in the base of the stacker.

- Slide the leg to the desired position within the slot of the body.

- Reinsert the bolts and washers. Tighten.

- Repeat steps 1 through 3 for the second leg.

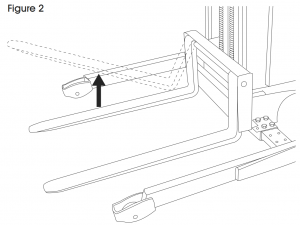

ADJUSTING THE FORKS (SEE FIGURE 2)

- Lift the front of the fork up and slide to the desired position.

- Gently lower the fork.

- Repeat steps 1 and 2 for the other fork.

MAINTENANCE

- Daily Check and Maintenance – It is necessary to check the stacker daily. Special attention should be paid to the wheels and axles. Material may block the wheels, forks, mast and chains. They should be checked for blockage.

- Hydraulic Oil – Check the oil level every six months. The hydraulic oil can be ISO VG32; its viscosity should be 32cSt at 104˚F; total volume is about 4 L.

- Lubrication – Use motor oil or grease to lubricate all movable parts.

TROUBLESHOOTING

| MALFUNCTION | PROBABLE CAUSE | CORRECTIVE ACTION |

| The forks do not go up to the maximum height. | Not enough hydraulic oil. Oil has impurities. | Pour in hydraulic oil. Change the oil. |

| The motor does not turn on. | Emergency Shut-Off is pressed down, the power is cut off.The voltage is too low.Wire connections have come loose.Connector to DC motor is bad. | Turn it clockwise, switch the power on.Charge the stacker.Check and reconnect any loose wires.Replace with a new one. |

| The forks do not go down. | Piston rod or mast is damaged, resulting from incorrect loading or overloading.Fork was kept in the up position for a long time and the piston rod rusted or is jammed.Release valve of the pump is not opened. | Replace with a new one.Lubricate piston rod. Always keep the fork in the lowest position when not in use.Check it. If damaged, replace with a new one. |

| Leaks. | Seals are worn or damaged.Piston parts are cracked or worn too small. | Replace seal(s).Replace parts as necessary. |

| Forks descend without engaging the lower lever. | Impurities in the oil caused release valve not to close tightly.Seals are worn out or damaged. Release valve is damaged. | Change the oil.Replace seal(s). Replace with a new one. |

| Battery does not charge. | Battery is bad. Charging plug is loose. | Replace with a new one.Check connection and reattach if necessary. |

| Straddle stacker is difficult to move. | Straddle legs may be uneven. | Loosen the four bolts on each straddle stacker leg.Move the straddle stacker back and forth to reset the legs.Tighten the four bolts on each straddle leg. |

| Charger quickly goes to green, but does not charge battery. | Battery too low for charger to detect. | Charge battery using external trickle charger overnight. |

| Charger LED states: RED = ChargingGREEN = Fully ChargedYELLOW = Error State | If yellow, check connections to battery and/or charger. Connections may be weak. | If connections are good, replace charger. |

1-800-295-5510uline.com

[xyz-ips snippet=”download-snippet”]