Ultimaker guideHow to choose the right 3D printer

Ultimaker guideHow to choose the right 3D printer

|

|

Introduction

Advances in 3D printing make it ideal for prototyping, customized molds, manufacturing aids, and end-use parts. As a result, more companies are purchasing fused filament fabrication (FFF) 3D printers to streamline their production processes. But choosing the right 3D printer is critical.How do I choose the right 3D printer?The 3D printing market offers a multitude of 3D printers, materials, service agreements,and software across a wide price range. If you’re new to 3D printing, the number of options can be overwhelming.Even for those with some 3D printing experience, choosing the right 3D printer can be daunting. Many factors must be considered, including noise level, safety compliance, technical specifications, and production parameters.For business success, a 3D printer must be able to reliably, and affordably produce usable parts. But how do you know if you’re making the right choice?This guide covers everything you need to know before buying an FFF 3D printer. We’ve even included a sample of the questions you should ask your supplier.

Analyzing your 3D printing requirements

Before you choose an FFF 3D printer, you should define your printing needs. Will you 3D print prototypes or models? Will aesthetics or functionality be the priority? Do you need to print production volumes? Once you have this information available, you can decide on your 3D printer requirements.Build volumeHow large are your prints likely to be? 3D printers have a maximum area within which they can print, called the build volume or build envelope. This dictates the largest dimensions that a printer can produce. For example, the Ultimaker S5 has a build surface of 330 x 240 mm (13 x 9.4 inches), and can print parts up to 300 mm (11.8 inches) tall.3D printers with a large print volume usually cost more but could save you money in the long run. One of the benefits of a large build plate is that you can produce prints in higher quantities. This enables you to print parts in batches, saving you time.When deciding on your build volume needs, plan for the largest part that you regularly print. For the occasional larger object, you can either design it in multiple parts for assembly or outsource.

A bigger build volume is ideal for small-batch production or printing large parts

Print quality and speedBecause FFF prints in layers, the layer height determines surface smoothness. This is a bit like the resolution of a screen: the more pixels on a screen – or layers in a print – the more detail you see. A higher layer height can result in small but visible `steps’ on a print’s curved surfaces. To ensure your 3D printer can create smooth surfaces, check its minimum layer height – the smaller this is, the more detail can be produced.The typical layer thickness of a 3D printer is between 20 and 600 microns. A minimum thickness of 20 micron means your printer can be used for niche applications, such as creating molds for parts.Keep in mind that print quality influences print speed – printing an object with 100-micron accuracy will take much longer than 300 micron. But not all parts need the best quality finish. For a simple prototype to check fit or dimensions, a faster print is preferable. When setting up your print in software such as Ultimaker Cura, you can choose the layer thickness and speed.

Printing with a 100-micron layer height produces a smooth curved surface

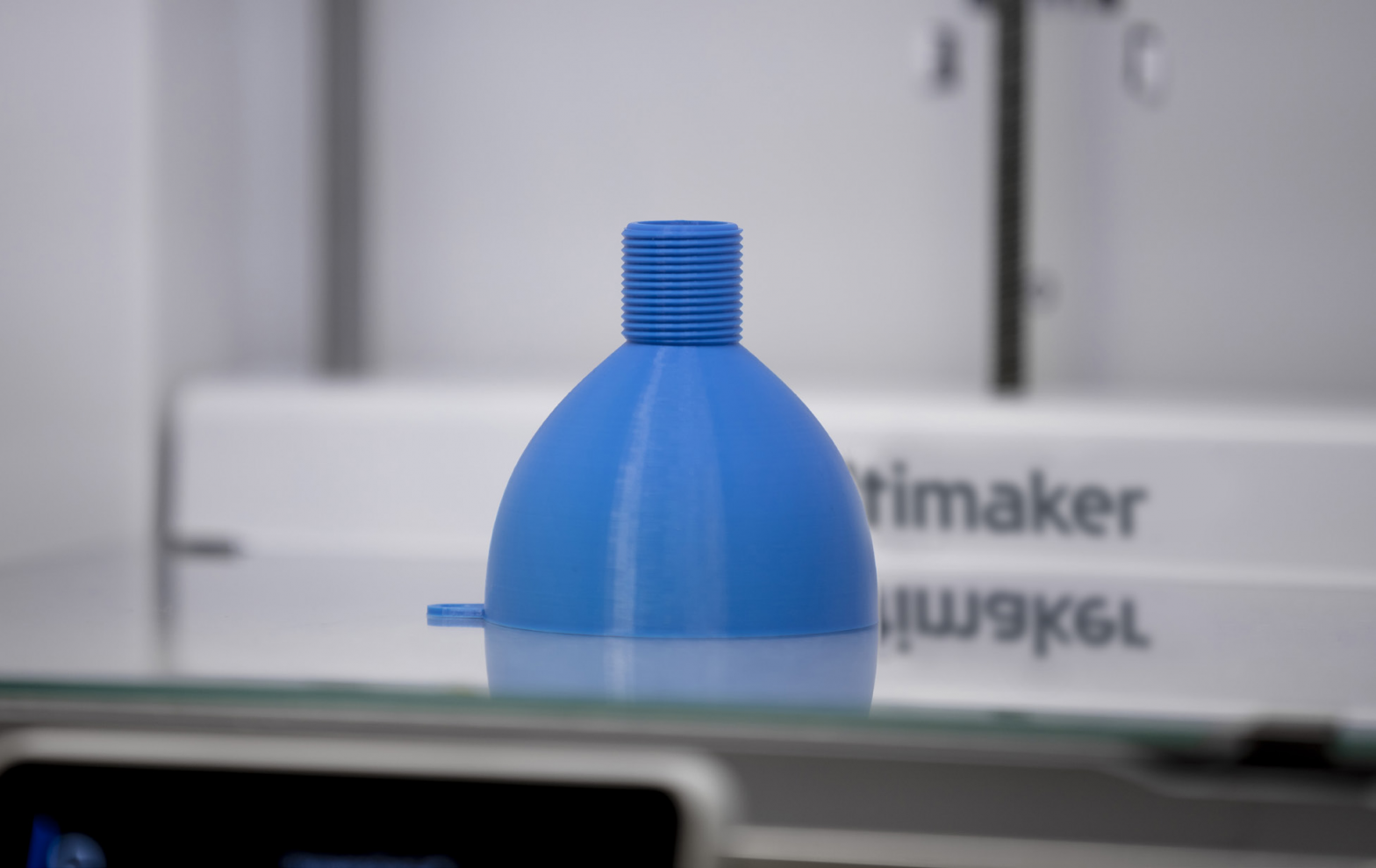

Printing multiple materialsNot all 3D printers can print multiple materials or create complex geometries, as not all of them have multiple nozzles.Many printers have only one nozzle and can print only one material (or color) at a time. This is called single extrusion. To use two colors or materials simultaneously, dual or multiple extrusion (i.e. more than one nozzle) is necessary.Because 3D printers can’t print features in mid-air, parts with overhangs or cavities need support material. This requires a separate nozzle to the one used for the build material, making a dual extrusion printer necessary. Ultimaker 3D printers use quick-swap ‘print cores’ that allow you to rapidly change between nozzles.Printing supports with material such as PVA (polyvinyl alcohol) makes it possible to create complex geometries and nested parts. PVA is easy to remove, as it dissolves in water and can be safely disposed of down a drain.

The white PVA supports the PLA part during printing and can be dissolved in water

Choosing the right materials

The characteristics of a printed part are determined by the material used, so it’s important to know which material will best suit the parts you intend to produce. Before you choose a 3D printer, you should ensure that it is compatible with the materials you plan to use.The most commonly used 3D printing material is a vegetable-based plastic called PLA, great for visual prototyping. But for parts that require mechanical properties such as flexibility, toughness, or heat resistance, different materials are necessary. Since these materials can have different requirements – the nozzle and build plate temperatures or extra-strong components – not all printers are compatible with all materials.The table below summarizes the properties of some of the most common 3D printing materials. All of these will print on an Ultimaker 3D printer. You can see our full materials range on our website.

|

Material |

Properties |

| PLA(polylactic acid) | Excellent surface quality and detail. Mechanical properties not suitable for some applications |

| ABS (acrylonitrile butadiene styrene) | Strong, ductile material with wear resistance and heat tolerance |

| Nylon(polyamide) | Strong yet flexible, with good chemical, impact, and abrasion resistance |

| CPE(copolyester) | Durable and flexible with a glossy finish and good impact and heat resistance |

| PC(polycarbonate) | Strong and tough material with heat resistance up to 110 °C |

| TPU(thermoplastic polyurethane) | Flexible material with rubber-like properties. Provides high impact and wear resistance |

| PP(polypropylene) | Durable, tough, and fatigue resistant. Retains shape after torsion, bending, or flexing |

| PVA(polyvinyl alcohol) | Water-soluble material is used to create supports for overhangs and cavities |

Open filament systemNot only are some printers incompatible with some materials, but some brands also limit you to using only their own materials. While Ultimaker’s materials are tested and optimized for use with Ultimaker printers, we also offer an open filament system. So if you have a preferred material supplier or you want to experiment with another filament, you are free to do so.Be sure to find out whether your chosen 3D printer has an open filament system that enables you to use multiple material types from multiple suppliers.

Determining software requirements

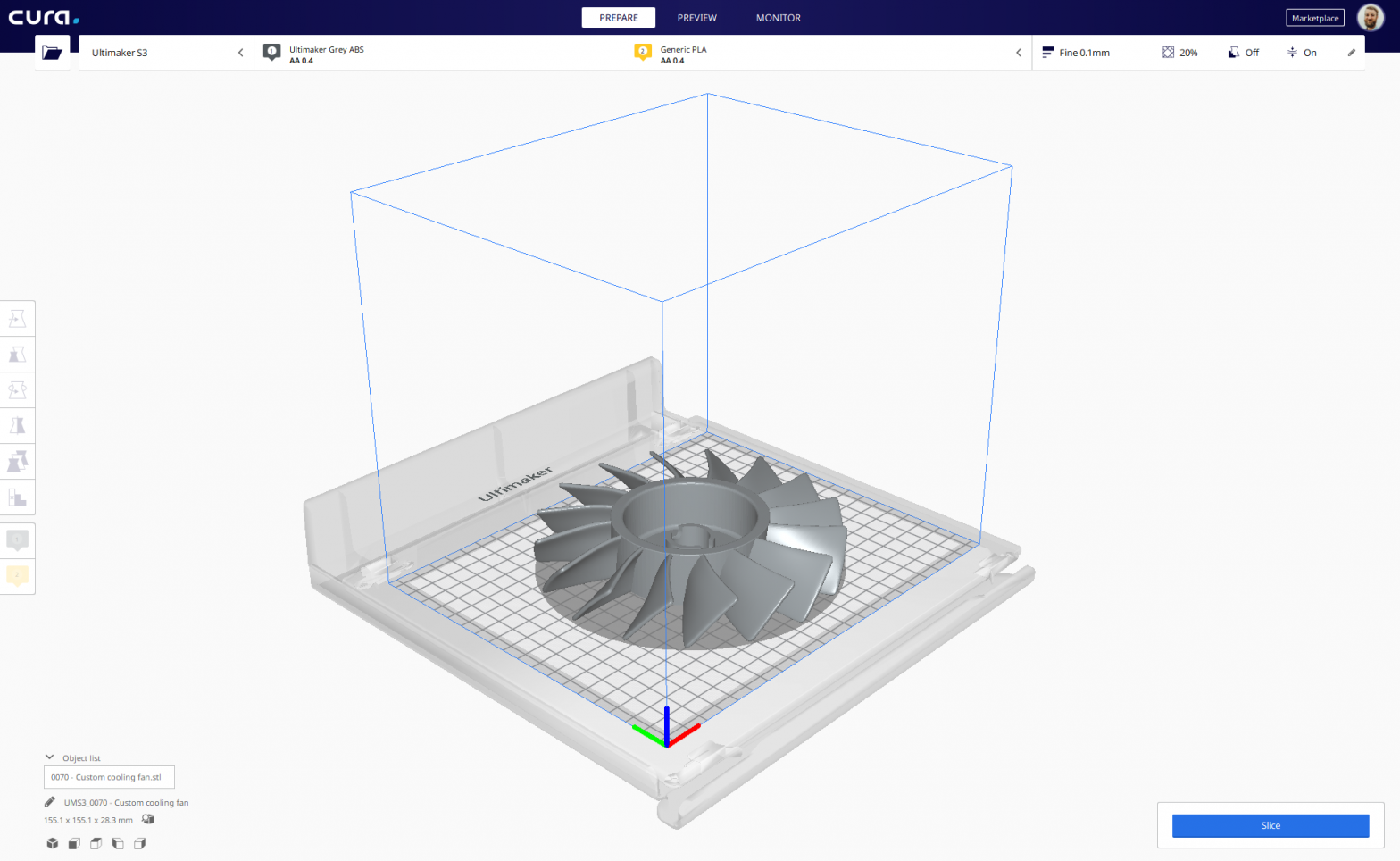

Once you have a 3D model, you will need to prepare it for 3D printing. For this, you will need print preparation, or slicing, software.This converts your 3D model into layers and sends a readable file format to the printer.Some software packages are proprietary, while others – such as Ultimaker Cura – can be used with multiple 3D printer brands.Your slicing software should be intuitive and simple to use. It will be even easier to start printing if your software includes default and customizable profiles for specific materials and your 3D printer. This means that you won’t have to calibrate the printer or manually enter data such as nozzle and build plate temperature. With experience, you may also find it important for the software to let you fine-tune your print settings.

Ultimaker Cura software interface

Managing the printing processYour chosen software should provide insight into the printing process at all times. Some printers only provide information on the built-in display, so you have to be in front of the printer to know its status. But for the production process to run smoothly, it’s important that errors are quickly detected. Information about a print’s progress should therefore be remotely accessible via software such as Ultimaker Connect and Ultimaker Cloud.

Additional hardware requirements

In this guide, we’ve looked at the specifications your 3D printer may require. There are, however, other factors that affect the quality of your printed parts and how you operate the printer.Open or semi-closed printerIn an FFF printer, plastic filament is melted and extruded in thin layers. This technique is temperature-sensitive and, if the temperature inside the printer cools too rapidly, warping can occur. Choose a closed or semi-closed printer to reduce heat loss and temperature changes, and limit warping.Type of build plateMost 3D printers include a glass build plate, but not all materials adhere easily to a glass surface. In some cases, sheets can be applied to aid adhesion. You can also choose a printer with a replaceable build plate.Removable build plates are easier to keep clean, which is important for good adhesion.

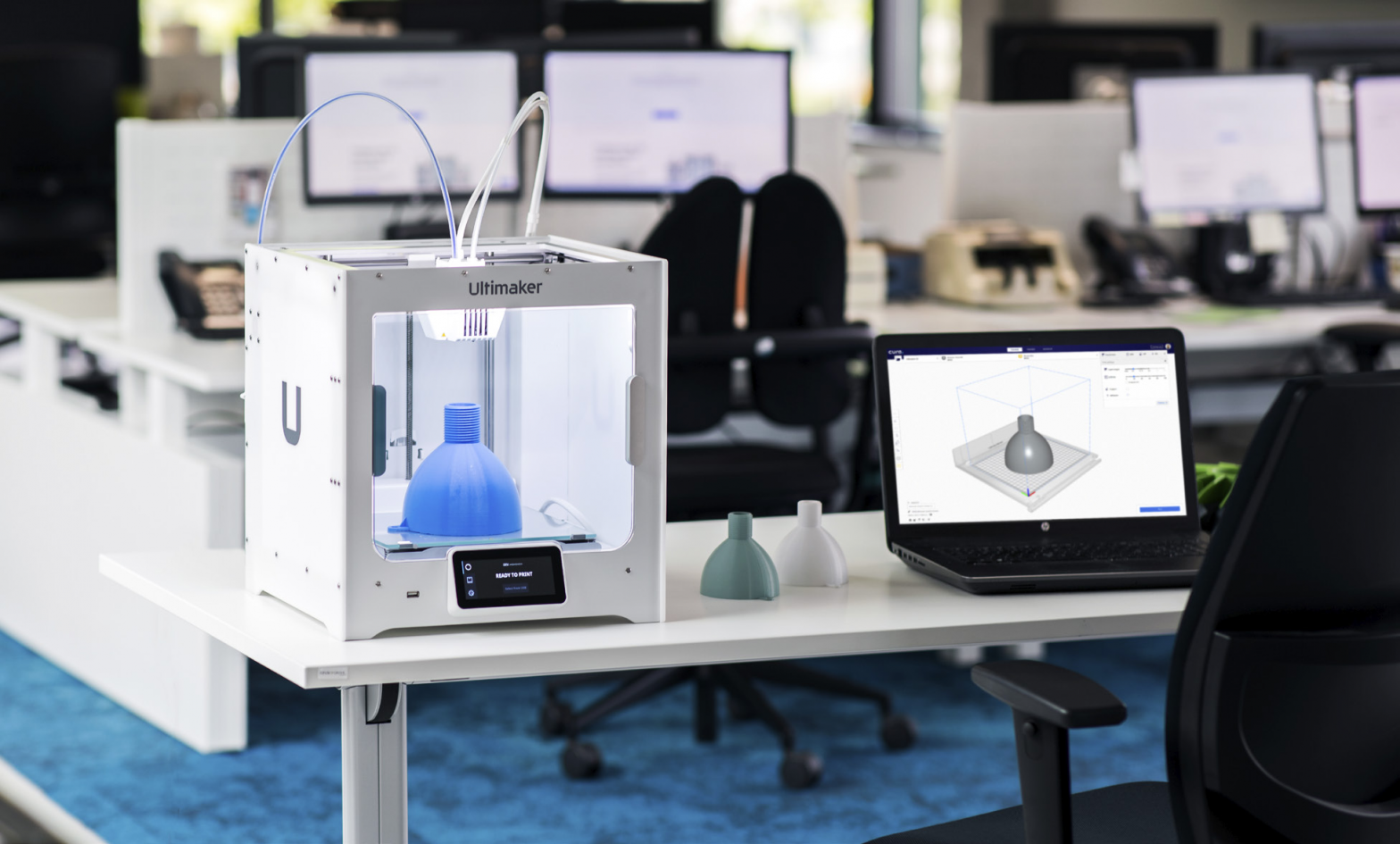

An Ultimaker S5 in an office environment

Printer locationWhere do you plan to install the printer? FFF is clean and safe, and requires no protective clothing or precautions, beyond levels of ventilation achievable in an office or workshop. Ventilation requirements will depend on the material being printed, so you should check the safety data sheets of materials that you plan to use, for precise instructions on ventilation. If you are concerned about safety, consider an accessory that removes a high percentage of ultrafine particles (UFPs), as the Ultimaker S5 Air Manager.In some cases, the operating sound and design of the printer may make the machine less suitable for an office environment. An operating sound level above 60 decibels is not recommended in an office environment.

3D printers can safely be installed on a user’s desk for maximum convenience

Unattended useTo produce larger prints or maximize the availability of your 3D printer, you may need to leave it running outside of working hours.For this reason, it is important to ensure that your printer comes with a safety declaration.This document outlines the safety standards and testing is done on the printer. Ultimaker provides a ‘Declaration of safe unattended professional use’ for its FFF printers.

ConnectivityMost 3D printers support a variety of connection methods. Software such as Ultimaker Connect makes it easy to centralize the management of multiple printers. Print jobs are added to a queue and allocated to the next available printer with matching material and print core configuration.Ultimaker Cloud lets you print remotely from anywhere in the world and enables you to back up your settings to the cloud. This lets you access your 3D printer and preferred profiles from anywhere, at any time.

Uptime and support

When your business relies on a 3D printer, maximum availability and uptime are critical. Malfunctions and maintenance mean downtime and have a negative effect on business productivity.That’s why local, high-quality, and quick-response support is important. A local dealer can provide you with training, periodic maintenance, and a quick solution in case of malfunctions.Choose a respected manufacturer with extensive experience and a support network that covers your location. This ensures continuity in the form of ongoing software and firmware development and the availability of spare parts over a long period.

Request for information

On the next page, we list the questions that will help you research your options and talk to various suppliers. With their help, you can compare 3D printers and create a shortlist. You should also ask your seller to provide sample prints as part of the selection process.Once you have narrowed your search, you can ask your supplier to provide the following information for your shortlisted printers. With this information, you can compare their key features and make your final decision. We have used the Ultimaker S5 as an example.Define your requirementsBefore you ask suppliers for information, decide on the printer features and characteristics most important to you.

- What is the required minimum build volume of your 3D printer?(e.g. 150 x 150 x 150 mm)

- What is the required printing quality? (e.g. 50 microns)

- Is dual extrusion required?

- Is a heated build plate required?

- Which materials should it support?

Questions to be answered by the seller

| Printer | Ultimaker printers |

| Printer brand and type | Ultimaker, FFF 3D printer |

| Price | Ultimaker 55: 55,995 (E5.500) Excluding taxes |

| Software | Ultimaker software |

| What software is included? (Supported OS) | Ultimaker Cura (MacOS, Windows, and Linux) |

| Are additional software licenses required? | No. Ultimaker Cura is free to use |

| What 3D model file formats are supported? | STL. OBJ, X3D, 3MF |

| Can printing profiles be created? | Yes, and custom settings can be saved for future use |

| Which printer settings can be customized? | Over 300 customizable settings, including material, Infill, support, cooling, and more |

| Hardware | Ultimaker hardware |

| Is the printer an open or a semi-closed model? | Semi-closed, with the build chamber enclosed on four sides. |

| What type of build plates are available? | Glass build plate |

| What is the expected maintenance? | Monthly, quarterly, and annual maintenance tasks (see ultimaker.com) |

| Can I perform simple maintenance tasks myself, such as cleaning the print head or calibration? | Yes |

| What safety documentation does the manufacturer provide? | Safety information in the product manual, plus EC declaration of conformity, VPAT certificate, CB certificate, Declaration of safe unattended use, and material safety data sheets (see ultimaker.com) |

| Working space | Ultimaker working space |

| I the printer suitable for an office environment? | Yes, all Ultimaker printers are suitable for office use |

| at is the noise level of the printer? | Up to 50 dBA |

| ich protocols for data transfer (e.g. Wi-Fi, Ethernet, USB) are supported? | Wi-Fi, LAN, USB’With Ultimaker Stine and Ultimaker 3 printers |

| ow can the printing process be monitored? Can it is done remotely? | Network-enabled Ultimaker printers offer remote monitoring via Ultimaker Connect and the Ultimaker app (including live camera feed). Ultimaker Cloud enables remote printing and monitoring from anywhere in the world. |

| Manufacturer | Ultimaker |

| How long has the manufacturer been in business? | Since 2011 |

| Does the manufacturer have a worldwide network with a service partner in this region? | Ultimaker has a global network of resellers and service partners (see ultimaker.com) |

| Does the dealer offer onboarding training? What are the additional costs? | Yes, ask your Ultimaker reseller for details |

| Does the brand have an active online community? | Yes, over 40,000 members are ready to share knowledge and best practice |

| . • es the dealer offer a maintenance contract? at are the additional costs? | Maintenance contracts are not required with an Ultimaker printer. Ask your reseller for options |

| I the printer only compatible with the manufacturer’s own materials, or also with materials from third parties? | Ultimaker offers a material range optimized for Its printers, but other brands’ materials can also be used |

*Product details for Ultimaker S5. Information on other Ultimaker 3D printers is available on our website.ultimaker.com

References

[xyz-ips snippet=”download-snippet”]