UNIFLOW Chest Freezers User Manual![]()

SERIAL NUMBER INFORMATION

- The serial number of all models is located inside the unit on the rear wall.

- Always have the serial number of your unit available when calling for parts or service.

- This manual covers standard units only. If you have a custom unit, consult customer service department at the number listed on cover page.

READ THIS MANUAL IN ITS ENTIRETY

TO HELP FAMILIARIZE YOURSELF WITH YOUR NEW EQUIPMENT BEFORE PROCEEDING.We have provided many important safety messages in this manual.Always read and obey all safety messages.Understanding of safety messages will assist in alerting you to potential hazards, as well as tell youhow to reduce the chance of injury. Follow the instructions as outlined in this manual.

Due to periodic changes in designs, methods, procedures, policies and regulations, the contents of this manual are subject to change without notice. While we exercise good faith efforts to provide information that is accurate, we are not responsible for errors or omissions in information provided or conclusions reached as a result of using this reference manual. By using the information provided, the user assumes all risks in connection with such use.

APPLIANCE SAFETY

Your safety and the safety of others are very important.Always read and obey all safetymessages in thismanual.This is the Safety Alert Symbol. This symbol alerts you to potential hazards that can kill or injure you and others. All safetymessages will followthe Safety Alert Symbol and either the words”DANGER”, “WARNING” or “CAUTION”.

![]() DANGER means that failure to heed this safety statement may result in Death or Severe Personnel Injury.

DANGER means that failure to heed this safety statement may result in Death or Severe Personnel Injury.![]() WARNING means that failure to heed this safety statement may result in extensive product damage, serious personal injury, or death.

WARNING means that failure to heed this safety statement may result in extensive product damage, serious personal injury, or death.![]() CAUTION means that failure to heed this safety statement may result in minor or moderate personal injury, or property or equipment damage.

CAUTION means that failure to heed this safety statement may result in minor or moderate personal injury, or property or equipment damage.

All safetymessages will alert you towhat the potential hazard is, tell you howto reduce the chance of injury, and let you know what can happen if the instructions are not followed.

NOTE: IMPORTANT SAFETY INSTRUCTIONS

![]() To reduce the risk of fire, electric shock or injury,when using your appliance, followthese basic precautions:

To reduce the risk of fire, electric shock or injury,when using your appliance, followthese basic precautions:

- Plug into grounded 3-prong outlet.

- Do not remove grounding prong.

- Do not use an adapter.

- Do not use an extension cord.

- Disconnectpowerbefore cleaning.

- Disconnectpower before servicing.

- Use 2 or more people to move and install appliance.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFEGUARDS

Before the appliance is used, it must be properly positioned and installed as described in this manual, so read the manual carefully. We strongly recommend that you have a professional install your new machine. The warranty may be affected or voided by an incorrect installation. To reduce the risk of fire, electrical shock or injury when using the appliance, follow basicprecautions, including the following:

DANGER

- It is recommended that a separate circuit, serving only your appliance, be provided. Use receptacles that cannot be turned off by a switch or pull chain.

- Please ensure that the required voltage is being supplied at all times.

- The unit should be plugged into a grounded and properly-sized electrical outlet with appropriate over-current protection.

- Ensure unit is not resting on or against the electrical cord.

- Do not connect or disconnect the electric plug when your hands are wet.

- Never unplug the appliance by pulling on the power cord. Always grip the plug firmly and pull straight out fromthe outlet.

- Never clean appliance parts with flammable fluids. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. The fumes can create a fire hazard or explosion

- Before proceedingwith cleaning andmaintenance operations, make sure the power line of the unit is disconnected.

- Unplug the appliance or disconnect power before cleaning or servicing. Failure to do so can result in electrical shock or death.

- If the unit is not in use for a long period of time, best to unplug the unit from the outlet.

- After unplugging the unit, wait at least 8 minutes before plugging it back in. Failure to do so could cause damage to the compressor.

- If the power cuts off, wait at least 8 minutes before turning the unit on to avoid damage to the compressor.

- Donotattempt torepair orreplaceanypart ofyourappliance unlessit isspecificallyrecommended in thismanual. A qualified technician should do all other servicing or repairs.

- Child entrapment and suffocation are not problems of the past. Junked or abandoned chest freezers are still dangerous.”

- Before you throw away your old chest freezer: Take off the doors.

- Never allowchildren to operate, playwith, or crawl inside the chest freezer.

WARNING

- Use two or more people to move and install appliance. Failure to do so can result in back, knee or other injury.

- This appliance must be properly installed and located in accordance with the Installation Instructions before it is used.

- Do not touch the cold surfaces in the cold compartment when hands are damp or wet. Skin may stick to these extremely cold surfaces.

- To ensure proper ventilation for your appliance, the front of the unit must be completely unobstructed. Choose a well-ventilated area with temperatures above 60°F (16°C) and below 90°F (32°C). This unit must be installed in an area protected from the elements, such as wind, rain, water spray or drips.

- The appliance should not be located next to ovens, grills, broilers or other sources of high heat.

- It is important for the appliance to be level for proper operation. Youmay need to make adjustments to level it.

- Remove the packingmaterials and clean the appliance before using.

- Do not use this apparatus for other than its intended purpose. Electrical Connection

- Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For personal safety, this appliance must be properly grounded.

- The power cord of this appliance is equipped with a 3-prong grounding plug that mates with a standard 3-prong grounding wall outlet tominimize the possibility of electric shock hazard fromthe appliance.

- Have the wall outlet and circuit checked by a qualified electrician tomake sure the outlet is properly grounded.

- The appliance should always be plugged into its own individual electrical outlet which has a voltage rating thatmatches the rating label on the appliance. This provides the best performance and also prevents overloading house wiring circuits which could cause a fire hazard from overheated wires.

- Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use a cord that shows cracks or abrasion damage along its length or at either end.

- When moving the appliance, be careful not to damage the power cord.

Refrigerant Disposal

If you are throwing away your old freezer it may have a cooling system that uses “Ozone Depleting” chemicals. Make sure the refrigerant is removed for proper disposal by a qualified service technician.

DIMENSIONS

TECHNICAL INFORMATION

| Model | UNFL9.6SHC | UNFL12.7SHC | UNFL15.9SHC |

| In: Overall Dimension W*D*H | 40.6 x 29.7 x 33.625 | 50 x 29.7 x 33.625 | 60.2 x 29.7 x 33.625 |

| mm: Overall Dimension W*D*H | 1030 x 755 x 854 | 1270 x 755 x 854 | 1530 x 755 x 854 |

| Nominal Capacity | 9.6 Cu Ft / 272 L | 12.7 Cu Ft / 360 L | 15.9 Cu Ft / 450 L |

| Appliance Weight | 119 lbs / 54 kg | 132 lbs / 60 kg | 165 lbs / 75 kg |

| Hinged Lids | 1 | 1 | 1 |

| Storage Basket | 1 | 1 | 2 |

| Electrical Service | 115V/60Hz/1Ph | 115V/60Hz/1Ph | 115V/60Hz/1Ph |

| Average Amp Draw (WATTS) | 0.6 (105) | 0.8 (125) | 0.85 (145) |

| Temperature Range Fº/Cº | 0º to 11º F

-24º to -18º C |

0º to 11º F

-24º to -18º C |

0º to 11º F

-24º to -18º C |

| Refrigerant | R-134A | R-134A | R-134A |

| Provided 6’ NEMA Cord Set | 5-15 | 5-15 | 5-15 |

| Factory Temperature Setting | 5°F (-15°C) | 5°F (-15°C) | 5°F (-15°C) |

DIMENSIONS

TECHNICAL INFORMATION

| Model | UNFL19.4SHC | UNFL23.6SHC | UNFL30.0SHC |

| In: Overall Dimension W*D*H | 71.3 x 29.7 x 33.625 | 78.75 x 29.7 x 33.625 | 76 x 35.25 x 35.83 |

| mm: Overall Dimension W*D*H | 1810 x 755 x 854 | 2000 x 755 x 854 | 1930 x 895 x 910 |

| Nominal Capacity | 19.4 Cu Ft / 549 L | 23.6 Cu Ft / 669 L | 30 Cu Ft / 850 L |

| Appliance Weight | 181 lbs / 82 kg | 176 lbs / 80 kg | 209 lbs / 95 kg |

| Hinged Lids | 1 | 2 | 2 |

| Storage Basket | 2 | 2 | 2 |

| Electrical Service | 115V/60Hz/1Ph | 115V/60Hz/1Ph | 115V/60Hz/1Ph |

| Average Amp Draw (WATTS) | 1.0 (160) | 2.0 (200) | 2.2 (220) |

| Temperature Range Fº/Cº | 0º to 11º F

-24º to -18º C |

0º to 11º F

-24º to -18º C |

0º to 11º F

-24º to -18º C |

| Refrigerant | R-134A | R-134A | R-134A |

| Provided 6’ NEMA Cord Set | 5-15 | 5-15 | 5-15 |

| Factory Temperature Setting | 5°F (-15°C) | 5°F (-15°C) | 5°F (-15°C) |

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should be taken during unloading so the equipment is not damaged while beingmoved into the building.

- Visually inspect the exterior of the package and skid or container. Any damage should be noted and formally reported to the delivering carrier as soon as possible within 10 days.

- If damaged, open and inspect the contents with the carrier.

- In the event that the exterior is not damaged, yet upon opening, there is concealed damage to the equipment, notify the carrier.Notification should be made verbally as well as in written form.

- Request an inspection by the shipping company of the damaged equipment. This should be done within 10 days from receipt of the equipment.

- Be certain to check the compressor compartment housing and visually inspect the refrigeration package. Be sure lines are secure and base is still intact.

- Freight carriers can supply the necessary damage forms upon request.

- Retain all crating material until an inspection has been made or waived.

INTRODUCTION

This user’s manual is intended for installing, using and servicing your Uniflow Appliance. It is recommended that this manual be kept in an accessible place. Every Uniflow machine is designed and manufactured according to the highest standards of safety and performance. It meets or exceeds the safety standard of UL 471 and sanitation standard NSF 7.Uniflow assumes no liability or responsibility of any kind for products manufactured by Uniflow, that have been altered in any way, including the use of any parts and/or other components not specifically approved by Uniflow. Uniflow reserves the right to make design changes and/or improvements at any time. Specifications and designs are subject to change without notice.

COMPONENT INFORMATION

COMPONENT INFORMATION (cont.)

APPLIANCE INSTALLATION

WARNING

Excessive Weight HazardUse two or more persons to move and install appliance.Failure to do so may result in back or other injury.

Before Using Your Appliance

- Remove the exterior and interior packing.

- \Check to be sure you have all of the following parts:

- 1 or 2 Storage Baskets (quantity of storage baskets depends onmodel)

- 1 Drain Plug

- 1 InstructionManual

- 1 Plastic Scraper

- 2 Keys for Lid Lock

- Locate the unit away from direct sunlight and sources of heat (stove, heater, radiator, etc.). Direct sunlight may affect the acrylic coating and heat sources may increase electrical consumption. Extreme cold ambient temperatures may also cause the appliance not to perform properly.

APPLIANCE INSTALLATION (cont.)

- Avoid locating the unit in damp, very humid or moist areas.

- Before connecting the unit to the power source, let it stand upright for approximately 4 hours. This will reduce the possibility of a malfunction in the cooling system from handling during transportation.

- Clean the interior surface with lukewarm water or mild detergent aqueous solution using a soft cloth that won’t scratch the surface of this appliance.

Remove Packaging Materials IMPORTANT

Do not remove any permanent instruction labels or the data label on your appliance.

- Remove tape and glue from your appliance before using.

- To remove any remaining tape or glue, rub the area briskly with your thumb. Tape or glue residue can also be easily removed by rubbing a small amount of liquid dish soap over the adhesive with your fingers.Wipe with warm water and dry with a soft cloth.

- Do not use sharp instruments, rubbing alcohol, flammable fluids, or abrasive cleaners to remove tape or glue. These products can damage the surface of your appliance.

NOTICE:LOSS OR SPOILAGE OF PRODUCTS IN YOUR APPLIANCE IS NOT COVERED BY WARRANTY. IN ADDITION TO FOLLOWING RECOMMENDED INSTALLATION PROCEDURES. PLEASE RUN THE APPLIANCE 24 HOURS PRIOR TO USAGE.

Location Requirements

- Appliances represented in this manual are intended for indoor use only.

- Be sure the location chosen has a floor strong enough to support the total weight of the appliance and contents as a fully loaded unit can weigh as much as 1500 pounds (680kg).

- Reinforce the floor as necessary to provide for maximum loading.

- For the most efficient refrigeration, be sure to provide good air circulation around appliance.

Installation Clearance

Be sure that the unit has access to ample air. Avoid hot corners and locations near stoves and ovens.Allow 5 inches of space between the back and sides of the unit, which allows the proper air circulation to cool the compressor and condenser.

APPLIANCE INSTALLATION (cont.)

Leveling Ensure the floor where the unit is to be located is level, or shim the unit to level.

Stabilizing

All models are supplied with casters for your convenience. It is very important, however, that the cabinet be installed in a stable condition with the front wheels locked while in use. Should it become necessary to lay the unit on its side or back for any reason, allow at least 24 hours before start-up to allow compressor oil to flow back into place. Failure to meet this requirement can cause compressor failure and unit damage.

NOTICE:

Unit repairs will not be subject to standard unit warranties if due to improper installation procedures. Electrical ConnectionRefer to the amperage data on the Technical Information table, the serial tag, your local code or the National Electrical Code to besure that unit is connected to the proper power source.

The unit must be turned OFF and disconnected from the power source whenever performing service, maintenance functions or cleaning the refrigerated area. Failure to comply may result in Death or Severe Personnel Injury.

OPERATION

Setting the Temperature ControlTo control the internal temperature, adjust the control dials according to the intended use requirements for proper/safeproduct storage.

- The first time you turn the unit on, set the temperature control to “7”. The range of the temperature control is from position “1” [the warmest] to “7” [the coldest] in the freezer section.

- After 24 to 48 hours, adjust the temperature control to the setting that best suits your needs. The setting of “4” should be correct for most home or office use needs or applications.

CAUTION

If the unit is unplugged, has lost power, or is turned off, you must wait at least 8 minutes before restarting the unit. Ifyou attempt to restart before this time delay, the appliance may not start properly.

NOTE:

- Turning the temperature control to “OFF” position stops the cooling cycle but does not shut off the power to the appliance.

- If the unit is unplugged, loses power, or is turned off; you must wait at least 8 minutes before restarting the unit. If you attempt to restart before this time delay, the appliance may not start properly.

- Large amounts of food will lower the cooling efficiency of the appliance and may require a colder thermostat setting.

- If you choose to change the thermostat setting, adjust thermostat control by one numerical increment at a time.

- Allow several hours for temperature to stabilize between adjustments.

OPERATION (cont.)

Defrosting Your Freezer:

- A proper defrost operation may require 3 to 6 hours.

- When? For the most efficient operation and minimum energy consumption, defrost the freezer when the frost on the freezer walls is excessive or becomes ¼ inch thick as that ice or frost build up will negatively impact your appliance’sperformance.

- Choose a time when the stock of frozen food is low or empty the unit if there is another convenient refrigerated storage space for these perishable food items.

- Leaving the lid open will help speed the process. Also, pouring warm water (not boiling) on the ice/frost will help speed melting.

CAUTION

Do not use boiling water because it may damage the plastic parts. In addition, never use a sharp or metallic instrument to remove frost as it may damage the side walls and will void the warranty. We recommend using the plastic scraper providedwith your unit.

- Remove the frozen food from the freezer and place it in a cooler to protect the food.

- Turn the thermostat knob to “OFF”.

- Unplug the freezer. The “POWER ON INDICATOR” light should be OFF.NOTE: During defrosting, the ice melts into the cabinet.

- If the appliance has a drain plug, remove it from the inside floor of the freezer by pulling straight out.

- Place a shallowpan outside drain outlet. The defrost water will drain out.

- Check the pan occasionally so the water does not overflow.

- Clean and dry the interior of the freezer.

- Replace the plug on the inside floor.

- Reconnect electrical connection. The “POWERON INDICATOR” light should be ON.

- Reset the thermostat to desired setting.

- Allow the cabinet to cool for one hour.

- Return food to the freezer.

The Freezer Compartment

- This compartment is designed for the long-term storage of frozen food. Storage time is up to three months.

- The storage lifeof frozenfoods varies and the recommended storage time should notbeexceeded.The instructions regarding the care of frozen foods should be followed when defrosting the freezer.

- Pre-packed commercially frozen food should be stored in accordance with the frozen foods manufacturer’s instructions for a three star frozen food storage compartment or home freezer.

- Place frozen food into the freezer as quickly as possible after purchase. If there are instructions on the packet, carefullyfollow these instructions regarding storage times.

- The freezer lid is susceptible to breaking due to excessive ice buildup. Be sure to properly defrost the appliance if and when the ice reaches ¼ to ½ inch thick. A storage basket is provided for the organization of odd-shaped items. To reach other packages in the freezer, just slide the basket to one side, or lift it out.

Freezing Fresh Foods

- Proper use of the appliance, adequately packed food, correct temperature and taking into account hygienic precautions will substantially influence the quality of freezing the food or storing of the frozen foods.

- This compartment is designed for the long-term storage of frozen food.

- The storage life of frozen foods varies and the recommended storage time should not be exceeded.

- Pre-packed commercially frozen food should be stored in accordance with the frozen foods manufacturer’s instructions for a three star frozen food storage compartment or home freezer.

- Place frozen food into the freezer as quickly as possible after purchase. If there are instructions on the packet, carefullyfollow these instructions regarding storage times.

- Carefully select food you intend to freeze, it should be of adequate quality and suitable for freezing.

- Use correct packaging and wrap it / seal it tight.

- The packaging should be airtight and shouldn’t leak since this could cause substantial vitamin loss and dehydration of foods.

- Foils and bags should be soft enough to tightly wrap around the foods.

- When preparing foods to be frozen, consider sanitary precautions.

- Mark packages with following data: kind and amount of foods and the date of loading.

OPERATION (cont.)

- It is most important that the food is frozen as quickly as possible.

- If the loading amount is too large, the quality of freezing is reduced which affects the quality of frozen foods.

- Do not attempt if there is ¼” of ice or frost build up on the compartment walls until after the appliance has been thoroughly defrosted and returned to its proper holding temperature.

- Do not load food product within 4 inches of the cover.

- Do not load more than 25-percent of the unit’s storage capacity with non-frozen product. It is best if the product is pre-chilled to 50°F (10°C) before product is placed in the storage freezer.

- Ice may be made in the unit if ice trays are placed in the baskets.

CLEANING AND MAINTENANCE

![]() DANGER

DANGER

The unit must be turned OFF and disconnected from the power source whenever performing service, maintenance functions or cleaning the refrigerated area. Failure to comply may result in Death or Severe Personnel Injury.

Exterior and Interior Cleaning of Appliances

Clean using soap and warm water. If this isn’t sufficient, try ammonia and water or a nonabrasive liquid cleaner.Do not use an abrasive cleaner because it will scratch the plastic and can damage the breaker strips and gaskets. Cleaning the Condenser Coil.

CAUTION

Never use a high pressure water wash for this cleaning procedure as water can damage the electrical components located near or at the condenser coil. Regular cleaning is recommended every 90 days. In some instances, you may find that there is a large amount of debris and dust or greasenaccumulated prior to the 90 day time frame. In these cases the condenser coil should be cleaned every 30 days. If the buildup on the coil consists of only light dust and debris, the condenser coil can be cleaned with a simple brush. Heavier dust buildup may require a vacuum or even compressed air to blow through the condenser coil. If heavy grease is present, there are de-greasing agents available for refrigeration use and specifically for the condenser coils. The condenser coil may require cleaning with the de-greasing agent and then blown through with compressed air. Failure to maintain a clean condenser coil can initially cause high temperatures and excessive run times. Continuous operation with dirty or clogged condenser coils can result in compressor failures. Neglecting the condenser coil cleaning procedures will void any warranties associated with the compressor or cost to replace the compressor.

- For efficient operation, keep the condenser surface free of dust, dirt, and lint.

- We recommend cleaning the condenser coil at least once per month.

- Clean the condenser with a commercial condenser coil cleaner and a soft brush, available from any commercial refrigerationequipment retailer, or vacuuming the condenser with a shop vac or use CO2. Gasket Maintenance Gaskets require regular cleaning to prevent mold and mildew build up and also to keep the elasticity of the gasket. Gasket cleaning can be done with the use of warm soapy water. Avoid full strength cleaning products on gaskets. Do not use sharp tools or knives toscrape or clean the gasket. Gaskets can easily be replaced and don’t require the use of tools or authorized service technicians. The gaskets are “Dart” style and can be pulled out of the grove in the lid and replaced by pressing the new one back into place.

TROUBLESHOOTING GUIDE

BEFORE CALLING FOR SERVICEIf the unit appears to be malfunctioning, read through the OPERATION section of this manual first. If the problem persists, seeTroubleshooting below. The problem may be something very simple that can be solvedwithout a service call.

TROUBLESHOOTING

| Fault | Possible Cause | Action |

|

Freezer does not operate. |

Power cord unplugged. | Plug freezer into a grounded 3 prong outlet. |

| Freezer temperature control is set to “OFF”. | Turn the temperature control to a setting between 1 and 7. | |

|

Fuse blown or circuit breaker tripped. |

Replace fuse or reset circuit breaker. If replacement of fuse or reset of circuit breaker doesn’t correct problem contact a

qualified service technician. |

|

|

Compressor runs constantly. |

Room temperature is hotter than normal. |

Bring room temperature to a lower temperature for proper

unit operation. |

| Unit may have a low refrigerant charge. | Contact a qualified service technician. | |

|

Compressor turns on and off frequently. |

Frequent or prolonged lid openings. |

Limit lid openings to maintain the internal temperature of

the freezer. |

| Lid is not closed completely. | Completely close the freezer lid. | |

| Temperature control is not set correctly. | Adjust temperature control to a setting between 1 and 7. | |

| Lid gasket does not seal properly or is

torn/damaged. |

Clean, repair, or replace lid gasket. |

|

|

Freezer does not have the correct clearances. |

Allow 5 inches of space between back and sides of unit,

which allows proper air circulation. See “Installation Instructions”. |

|

| Freezer has recently been disconnected for a

period of time. |

Four hours are required for freezer to cool down completely. |

|

|

Frost or ice has formed on freezer wall. |

Defrost freezer.

See “Defrosting Your Freezer Instructions.” |

|

|

Food temperature is too warm. |

Temperature control is not set to a cold enough temperature. |

Adjust the temperature control to a colder setting and allow several hours for freezer temperature to stabilize. |

|

Frequent or prolonged lid openings. |

Limit lid openings to maintain the internal temperature of

the freezer. |

|

| Lid is not closed completely. | Completely close the freezer lid. | |

| Freezer lid is not sealing properly. | Clean, adjust, repair, or replace lid gasket. | |

| A large load of food was recently added. | Allow time for freezer temperature to stabilize. | |

| Freezer has recently been disconnected for a

period of time. |

Allow four hours for freezer temperature to stabilize. |

|

| There is an ice or frost build up on internal

compartment walls. |

Defrost freezer.

See “Defrosting Your Freezer Instructions.” |

| Fault | Possible Cause | Action |

|

Food temperature is too cold. |

Temperature control is set too cold. |

Turn control to a warmer setting and allow several hours for

freezer temperature to stabilize. |

|

Freezer has an odor. |

Freezer needs cleaning. | Clean the freezer. See “CleaningYour Freezer”. |

| Food is improperly wrapped or sealed and is

giving off odor. |

Wrap and seal food tightly before storing in freezer. |

|

| Temperature of external freezer

surface is warm. |

Exterior freezer walls can be as much as 30°F

(-1°C) warmer than room temperature. |

This is normal while compressor works to transfer heat from

inside freezer cabinet. |

| Popping or cracking sound

when compressor comes on. |

Metal parts undergo expansion and

contraction, as in hot water pipes. |

This is normal. Sound will level off or disappear as freezer

continues to run. |

| Bubbling or gurgling sound, like

water boiling. |

Refrigerant (used to cool freezer) is circulating

throughout the system. |

This is normal. |

|

Excessive vibrations. |

Check to assure that freezer is on a level

surface and sits level. |

Reposition freezer and/or level freezer with wood or metal

shims under part of freezer. |

| Floor is uneven or weak. Freezer rocks on

floor when it is moved slightly. |

Be sure floor can adequately support freezer. Level freezer

with wood or metal shims. |

|

|

Freezer is touching the wall. |

Allow 5 inches of space between back and sides of unit.

See “Installation Instructions”. |

|

|

Moisture forms on inside freezer walls. |

Weather is hot and humid, which increases

internal rate of frost build-up. |

This is normal. |

| Lid is slightly open. | Completely close the freezer lid. | |

| Lid is kept open too long, or is opened too

frequently. |

Don’t leave lid open for long periods, or open lid less often. |

|

| Lid is not sealed properly. | Adjust, clean, repair, or replace lid gasket. | |

|

Moisture forms on outside of freezer. |

Lid is slightly open, causing cold air from

inside freezer to meet outside warm moist air. |

Close lid properly. |

| Room ambient temperature is near or at the dew point resulting in condensation on the

exterior surfaces. |

This is normal. |

|

| Washing the floor around the unit has changed the ambient conditions to be at or below the

dew point. |

This is normal. |

|

|

Lid will not close properly. |

Freezer is not on a level surface or set level. |

Reposition freezer and/or level freezer with wood or metal

shims under part of freezer. |

| Gasket is dirty, or damaged. | Clean, repair, or replace lid gasket as necessary. | |

| Storage basket is out of position. | Reposition storage basket. | |

|

Hinges have been damaged or misaligned. |

Contact a qualified service technician to adjust or replace

as required. |

|

|

Lid latch has failed. |

Contact a qualified service technician to adjust or replace

as required. |

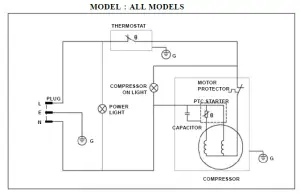

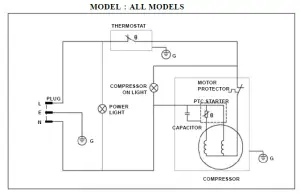

WIRING DIAGRAMS

PARTS

| Item # | Part Number | Descriptions | Qty / Unit |

| 1 | DOOR GASKET-1 | Gasket | 1 |

| 2 | DOOR GASKET-2 | Gasket | 1 |

| 3 | DOOR GASKET-3 | Gasket | 1 |

| 4 | DOOR GASKET-4 | Gasket | 1 |

| 5 | DOOR GASKET-5 | Gasket | 2 |

| 6 | DOOR GASKET-6 | Gasket | 2 |

Read More About This Manual & Download PDF:

[xyz-ips snippet=”download-snippet”]