VMA502BASIC DIY KIT WITH ATMEGA2560 FOR ARDUINO®

USER MANUAL

USER MANUAL

Introduction

To all residents of the European UnionImportant environmental information about this product This symbol on the device or the package indicates that disposal of the device after its lifecycle could harm the environment. Do not dispose of the unit (or batteries) as unsorted municipal waste; it should be taken to a specialized company for recycling. This device should be returned to your distributor or to a local recycling service. Respect the local environmental rules.If in doubt, contact your local waste disposal authorities.Thank you for choosing Velleman®! Please read the manual thoroughly before bringing this device into service. If the device was damaged in transit, do not install or use it and contact your dealer.

This symbol on the device or the package indicates that disposal of the device after its lifecycle could harm the environment. Do not dispose of the unit (or batteries) as unsorted municipal waste; it should be taken to a specialized company for recycling. This device should be returned to your distributor or to a local recycling service. Respect the local environmental rules.If in doubt, contact your local waste disposal authorities.Thank you for choosing Velleman®! Please read the manual thoroughly before bringing this device into service. If the device was damaged in transit, do not install or use it and contact your dealer.

Safety Instructions

![]() This device can be used by children aged from 8 years and above, and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning the use of the device in a safe way and understand the hazards involved. Children shall not play with the device. Cleaning and user maintenance shall not be made by children without supervision.

This device can be used by children aged from 8 years and above, and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning the use of the device in a safe way and understand the hazards involved. Children shall not play with the device. Cleaning and user maintenance shall not be made by children without supervision.

Indoor use only.Keep away from rain, moisture, splashing and dripping liquids.

Indoor use only.Keep away from rain, moisture, splashing and dripping liquids.

General Guidelines

|

|

What is Arduino®

Arduino®is an open-source prototyping platform based in easy-to-use hardware and software. Arduino ® boards are able to read inputs – light-on sensor, a finger on a button or a Twitter message – and turn it into an output – activating of a motor, turning on an LED, publishing something online. You can tell your board what to do by sending a set of instructions to the microcontroller on the board. To do so, you use the Arduino programming language (based on Wiring) and the Arduino ® software IDE (based on Processing).Surf to www.arduino.cc and www.arduino.org for more information.

Contents

- 1 x ATmega2560 Mega development board (VMA101)

- 15 x LED (different colors)

- 8 x 220 Ω resistor (RA220E0)

- 5 x 1K resistor (RA1K0)

- 5 x 10K resistor (RA10K0)

- 1 x 830-hole breadboard

- 4 x 4-pin key switch

- 1 x active buzzer (VMA319)

- 1 x passive buzzer

- 1 x infrared sensor diode

- 1 x LM35 temperature sensor (LM35DZ)

- 2 x ball tilt switch (similar to MERS4 and MERS5)

- 3 x phototransistor

- 1 x single-digit 7-segment LED display

- 30 x breadboard jumper wire

- 1 x USB cable

The ATmega2560 Mega

VMA101

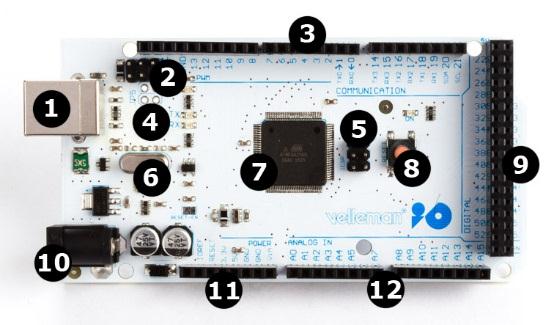

The VMA101 (Arduino®compatible) Mega 2560 is a microcontroller board based on the ATmega2560. It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analogue inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button. It contains everything needed to support the microcontroller. Connect it to a computer with a USB cable or power it with an AC-to-DC adapter or battery to get started. The Mega is compatible with most shields designed for the Arduino ® Duemilanove or Diecimila.

| 1 | USB interface | 7 | Atmel mega2560 |

| 2 | ICSP for 16U2 | 8 | reset button |

| 3 | digital I/O | 9 | digital I/O |

| 4 | Atmel mega16U2 | 10 | 7-12 VDC power input |

| 5 | ICSP for mega2560 | 11 | power and ground pins |

| 6 | 16 MHz clock | 12 | analogue input pins |

| microcontroller ………………………………………………………. ATmega2560operating voltage ……………………………………………………….. 5 VDCinput voltage (recommended) ………………………………………7-12 VDCinput voltage (limits) ……………………………………………………6-20 VDCdigital I/O pins ……………………54 (of which 15 provide PWM output)analogue input pins …………………………………………………… 16DC current per I/O pin ……………………………………………… 40 mADC current for 3.3 V pin …………………………………………….50 mAflash memory …………………………… 256 kB of which 8 KB used by bootloaderSRAM …………………………………………. 8 kBEEPROM……………………………………………………………………… 4 kBclock speed ……………………………………………………………….. 16 MHzdimensions length …………………………………………………………. 112 mmwidth ………………………………………………………………………..55 mmweight ……………………………………………………………………………. 62 g |

Operation

The Breadboard

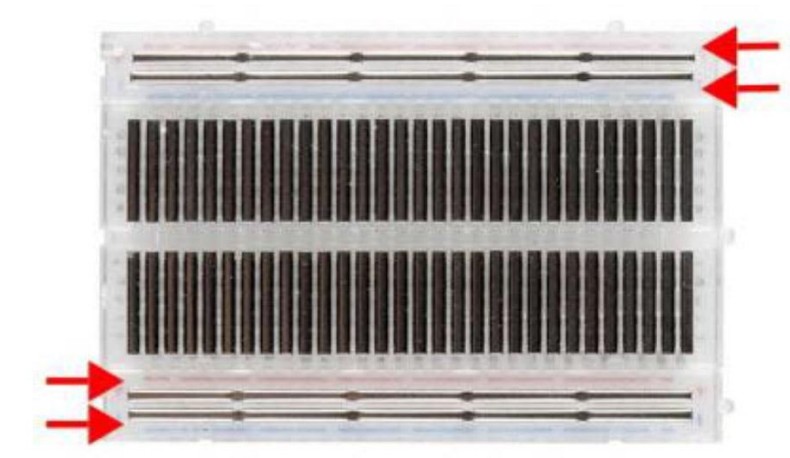

Breadboards are one of the most fundamental pieces when learning how to build circuits. In this tutorial, we will introduce you to what breadboards are and how they work.

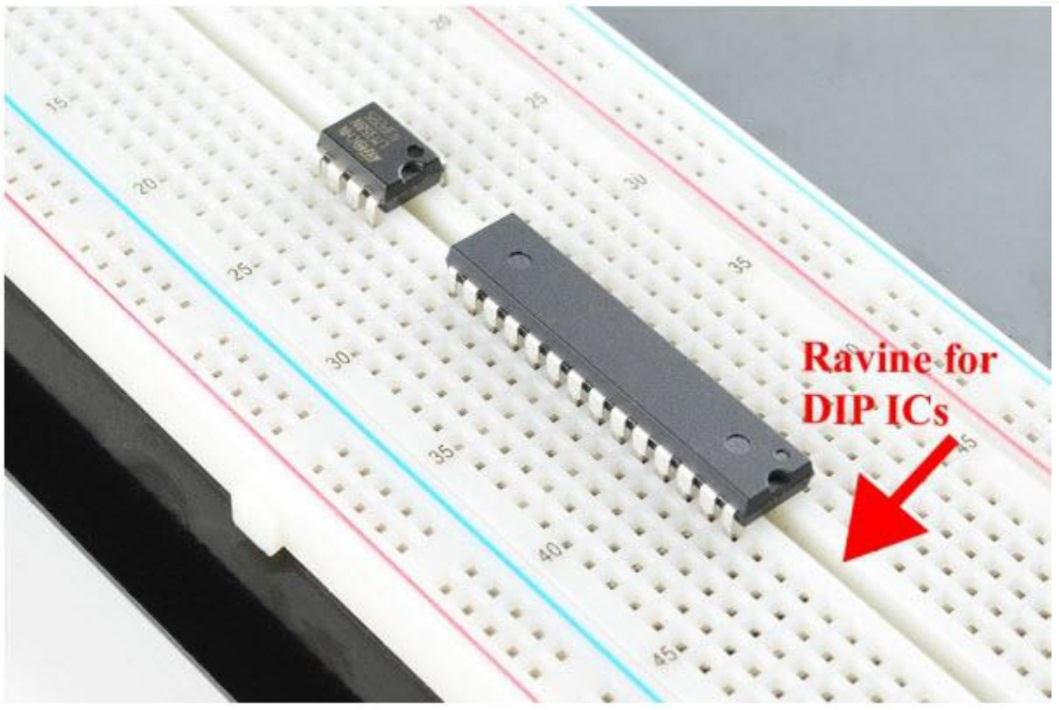

Let us look at a larger, more typical breadboard. Aside from the horizontal rows, breadboards have what are called power rails that run vertically along the sides. Chips have legs that come out of both sides and fit perfectly over the ravine. Since each leg on the IC is unique, we do not want both sides to be connected to each other. That is where the separation in the middle of the board comes in handy. Thus, we can connect components to each side of the IC without interfering with the functionality of the leg on the opposite side.

Chips have legs that come out of both sides and fit perfectly over the ravine. Since each leg on the IC is unique, we do not want both sides to be connected to each other. That is where the separation in the middle of the board comes in handy. Thus, we can connect components to each side of the IC without interfering with the functionality of the leg on the opposite side.

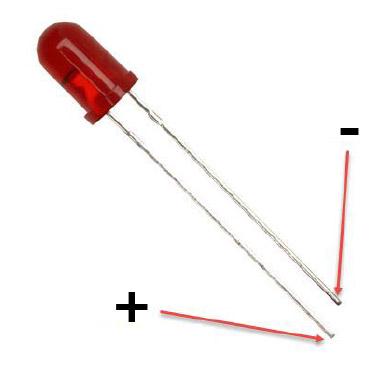

A Blinking LEDLet’s start with a simple experiment. We are going to connect an LED to one of the digital pins rather than using LED13, which is soldered to the board.

Required Hardware

- 1 x red M5 LED

- 1 x 220 Ω resistor

- 1 x breadboard

- jumper wires as needed

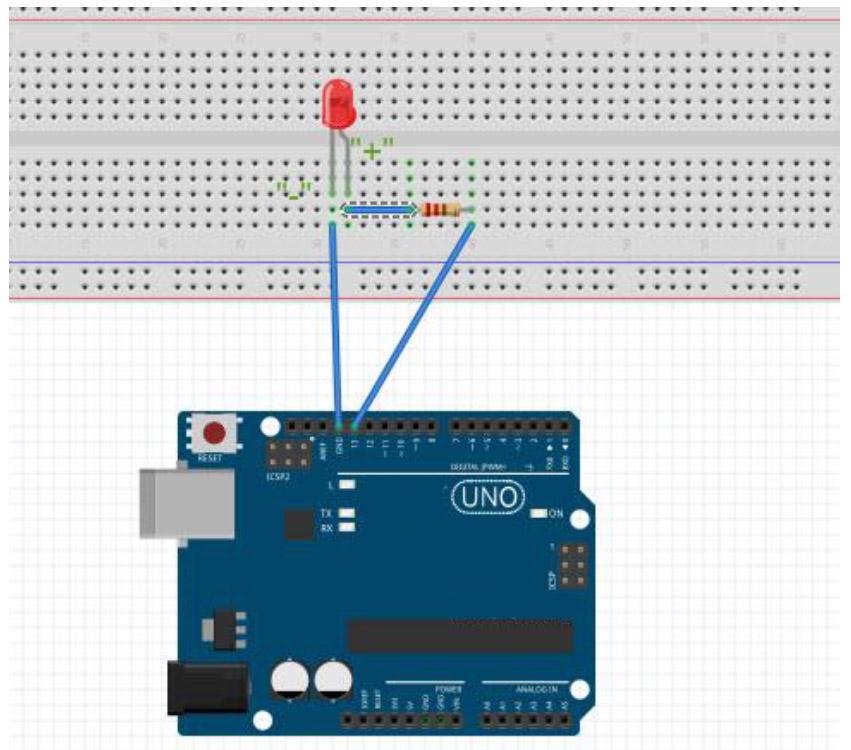

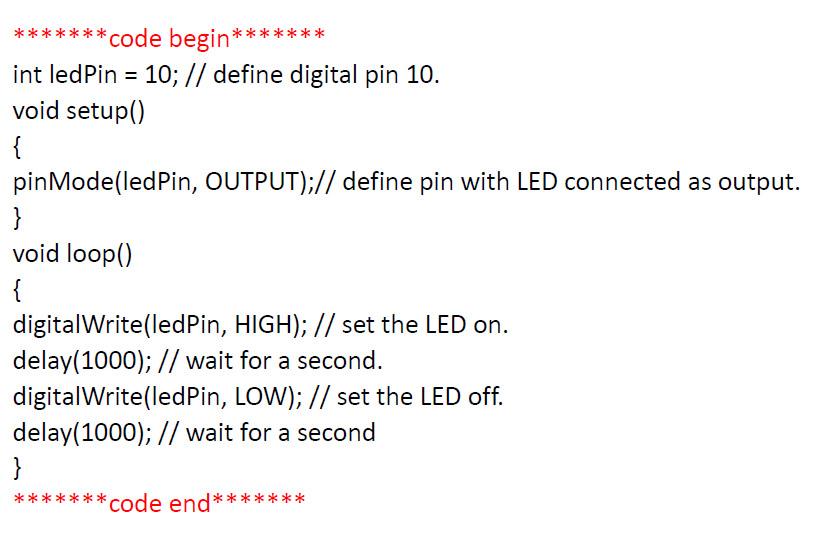

Follow the diagram below. We are using digital pin 10, and connecting the LED to a 220 Ω resistor to avoid high-current damaging the LED.

Connection Programming Code

Programming Code ResultAfter programming, you will see the LED connected to pin 10 blinkings, with an interval of approximately onesecond. Congratulations, the experiment is now successfully completed!

ResultAfter programming, you will see the LED connected to pin 10 blinkings, with an interval of approximately onesecond. Congratulations, the experiment is now successfully completed!

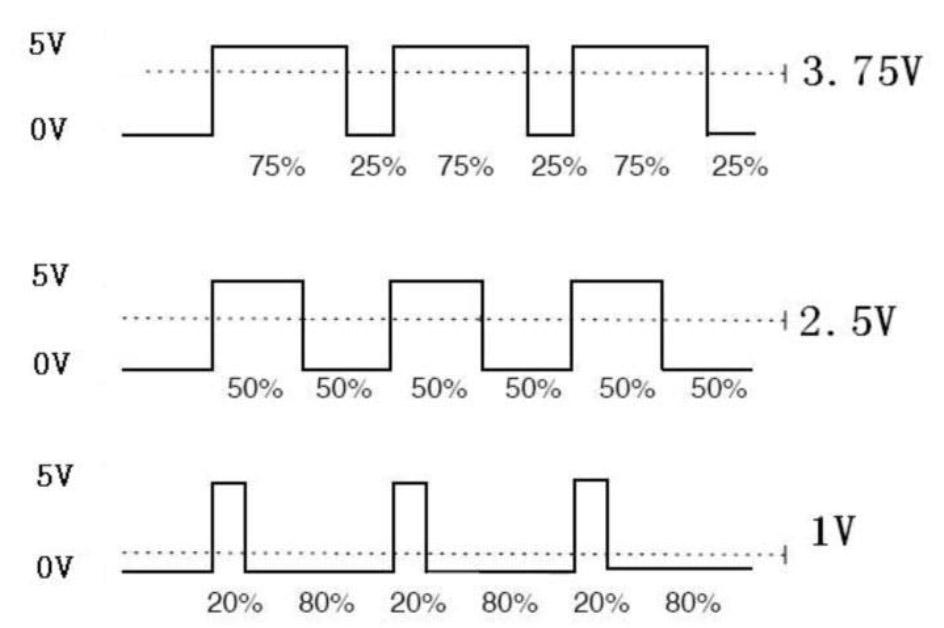

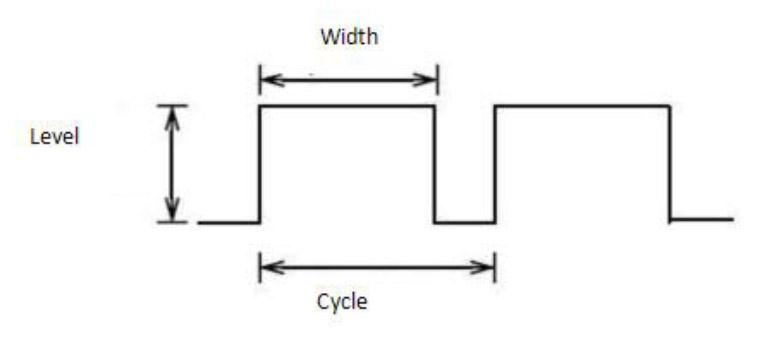

PWM Gradational LEDPWM (Pulse Width Modulation) is a technique used to encode analogue signal levels into digital ones. A computer cannot output analogue voltage but only digital voltage values. So, we will be using a high-resolution counter to encode a specific analogue signal level by modulating the duty cycle of PWM. The PWM signal is also digitalized because in any given moment, fully on DC power is either 5 V (on) of 0 V (off). The voltage or current is fed to the analogue load (the device using the power) by repeated pulse sequence being on or off.Being on, the current is fed to the load; being off, it is not. With adequate bandwidth, any analogue value can be encoded using PWM. The output voltage value is calculated via the on and off time.

output voltage = (turn on time/pulse time) * maximum voltage value

PWM has many applications: lamp brightness regulation, motor speed regulation, sound making, etc. The following are the basic parameters of PWM:

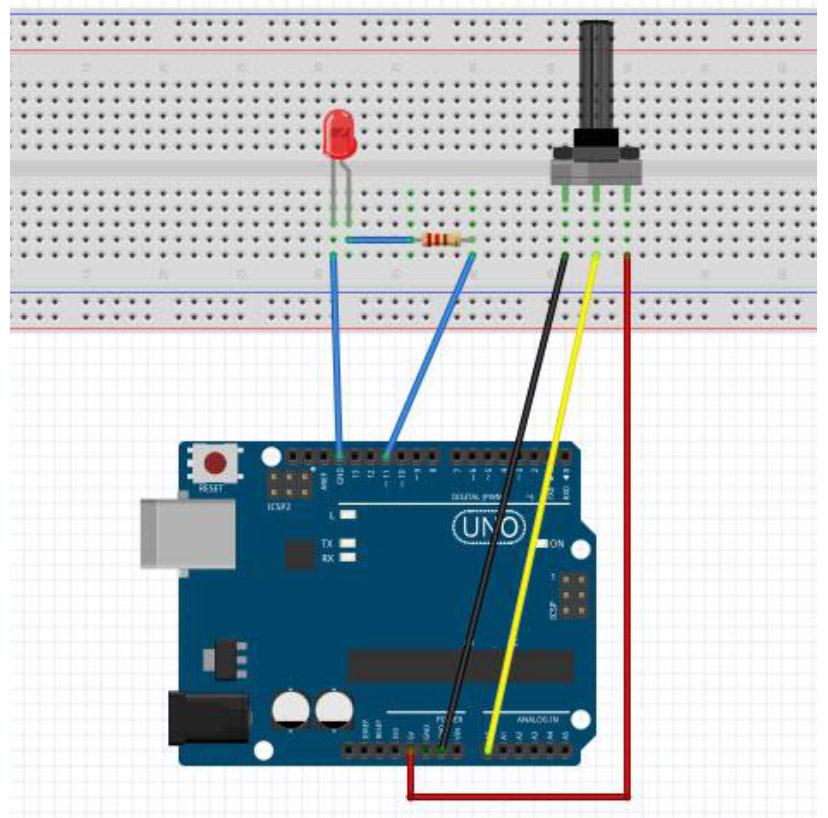

There are six PQM interfaces on Arduino ® , namely digital pin, 3, 5, 6, 9, 10 and 11. In this experiment, we will be using a potentiometer to control the LED brightness.

Required Hardware

- 1 x variable resistor

- 1 x red M5 LED

- 1 x 220 Ω resistor

- 1 x breadboard

- jumper wires as needed

Connection

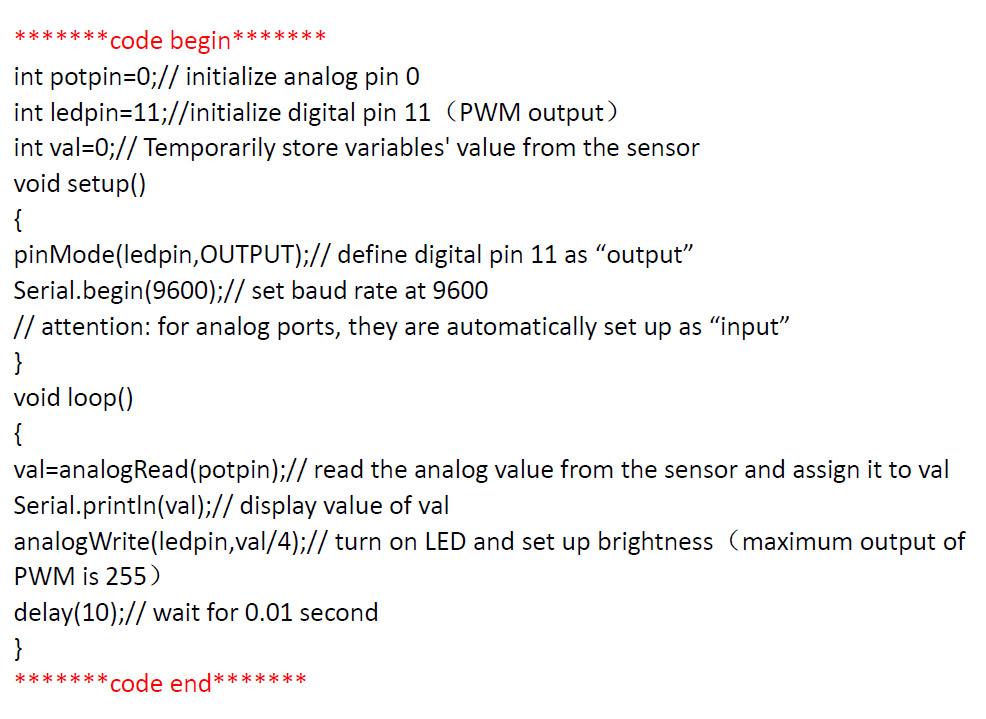

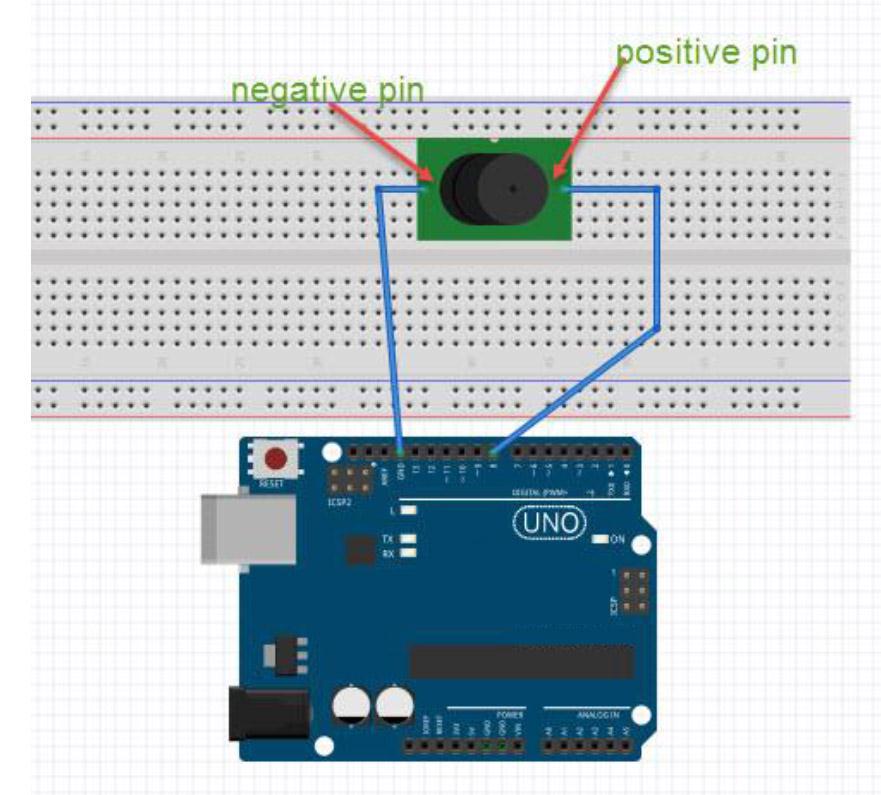

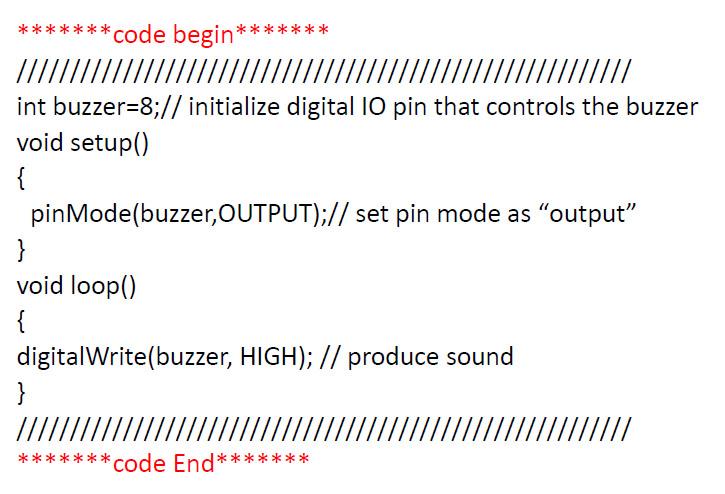

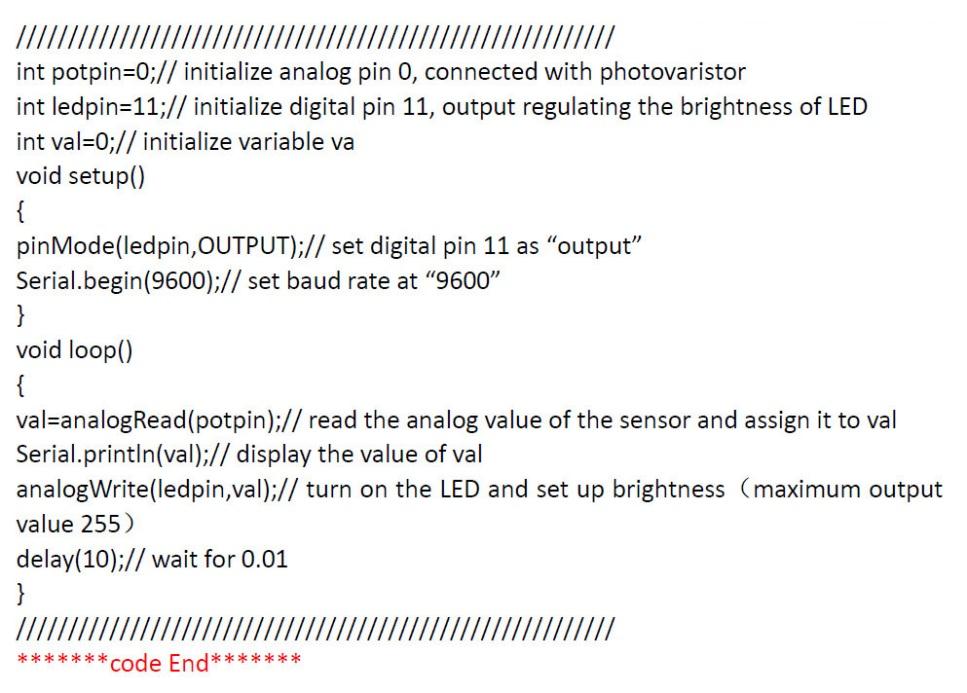

Programming Code In this code, we are using the analogWrite (PWM interface, analogue value) function. We will read the analoguevalue of the potentiometer and assign the value to PWM port, so there will be a corresponding change to thebrightness of the LED. One final part will be displaying the analogue value on the screen. You can consider thisas the analogue value reading project adding the PWM analogue value assigning part.ResultAfter programming, rotate the potentiometer knob to see changes of the displaying value. Also, note the obvious change of brightness on the breadboard.The Active BuzzerAn active buzzer is widely used on computers, printers, alarms, etc. as a sound-making element. It has an inner vibration source. Simply connect it with a 5 V power supply to make it buzz constantly.Required Hardware

In this code, we are using the analogWrite (PWM interface, analogue value) function. We will read the analoguevalue of the potentiometer and assign the value to PWM port, so there will be a corresponding change to thebrightness of the LED. One final part will be displaying the analogue value on the screen. You can consider thisas the analogue value reading project adding the PWM analogue value assigning part.ResultAfter programming, rotate the potentiometer knob to see changes of the displaying value. Also, note the obvious change of brightness on the breadboard.The Active BuzzerAn active buzzer is widely used on computers, printers, alarms, etc. as a sound-making element. It has an inner vibration source. Simply connect it with a 5 V power supply to make it buzz constantly.Required Hardware

- 1 x buzzer

- 1 x key

- 1 x breadboard

- jumper wires as needed

Connection

Programming Code

ResultAfter programming, the buzzer should ring.The PhototransistorA phototransistor is a transistor the resistance of which varies according to different light strengths. It is basedon the photoelectric effect of a semiconductor. If the incident light is intense, the resistance reduces; if theincident light is weak, the resistance increases. A phototransistor is commonly applied in the measurement oflight, light control and photovoltaic conversion.

Let’s start with a relatively simple experiment. The phototransistor is an element that changes its resistance aslight strength changes. Refer to the PWM experiment, replacing the potentiometer with a phototransistor. Whenthere is a change in light strength, there will be a corresponding change on the LED.

Required Hardware

- 1 x phototransistor

- 1 x red M5 LED

- 1 x 10KΩ resistor

- 1 x 220 Ω resistor

- 1 x breadboard

- jumper wires as needed

Connection

Programming Code ResultAfter programming, change the light strength around the phototransistor and observe the LED changing!The Flame Sensor

ResultAfter programming, change the light strength around the phototransistor and observe the LED changing!The Flame Sensor

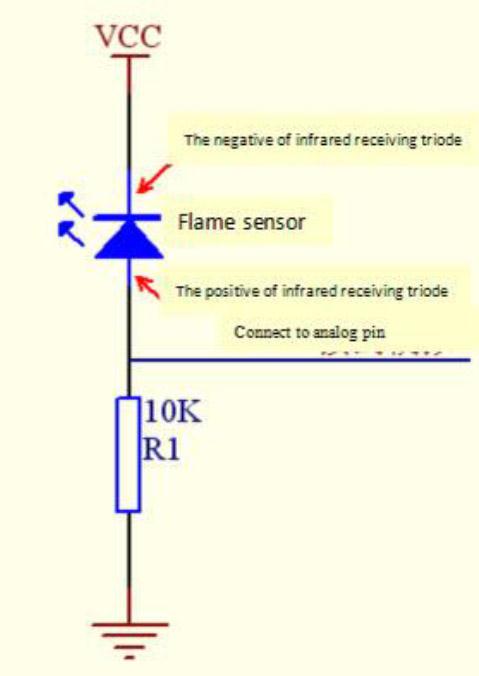

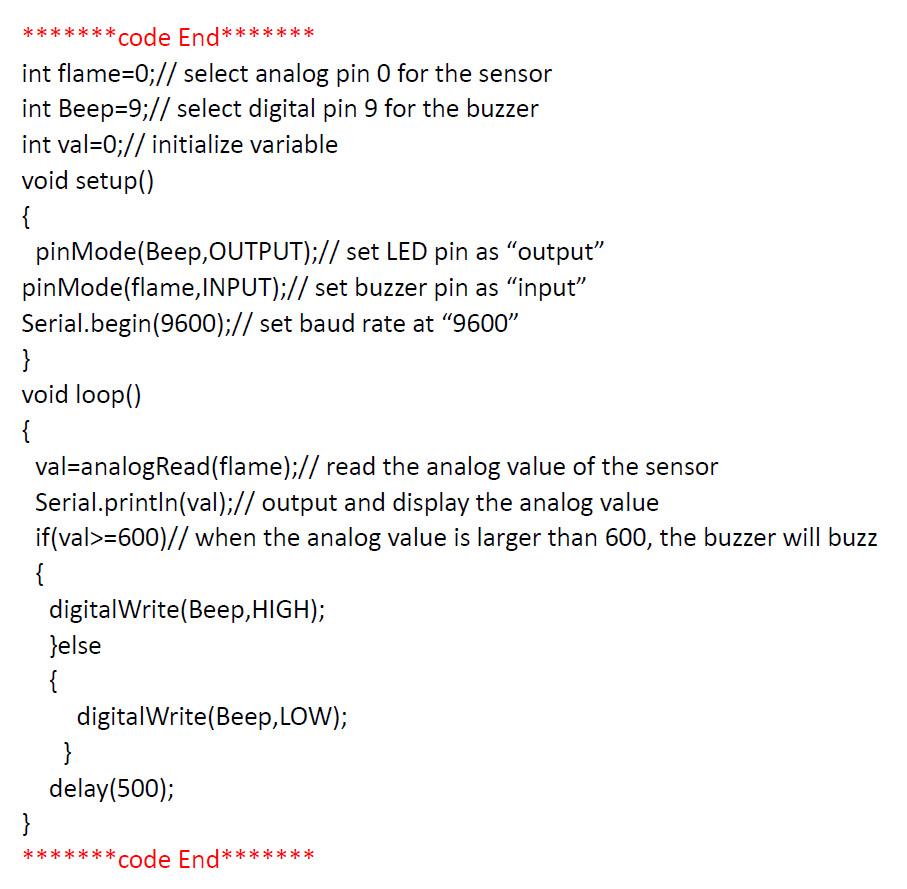

A flame sensor (IR receiving diode) is specifically used on robots to find the fire source. This sensor is highlysensitive to flames.A flame sensor has a specifically designed IR tube to detect fire. The brightness of the flames will then be converted to a fluctuating level signal. The signals are the input into the central processor.

Required Hardware

- 1 x flame sensor

- 1 x buzzer

- 1 x 10KΩ resistor

- 1 x breadboard

- jumper wires as needed

Connection

Connect the negative to the 5 V pin and the positive to the resistor. Connect the other end of the resistor to GND. Connect one end of a jumper wire to a clip, which is electrically connected to sensor positive, the other end to the analogue pin.

Connect the negative to the 5 V pin and the positive to the resistor. Connect the other end of the resistor to GND. Connect one end of a jumper wire to a clip, which is electrically connected to sensor positive, the other end to the analogue pin.

Programming Code

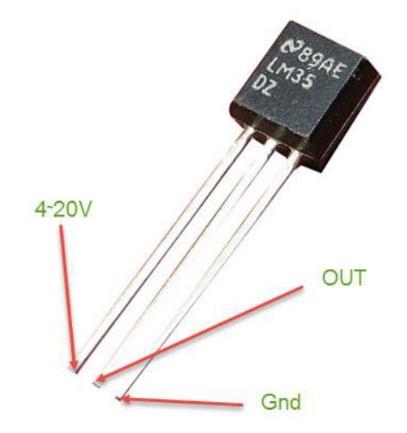

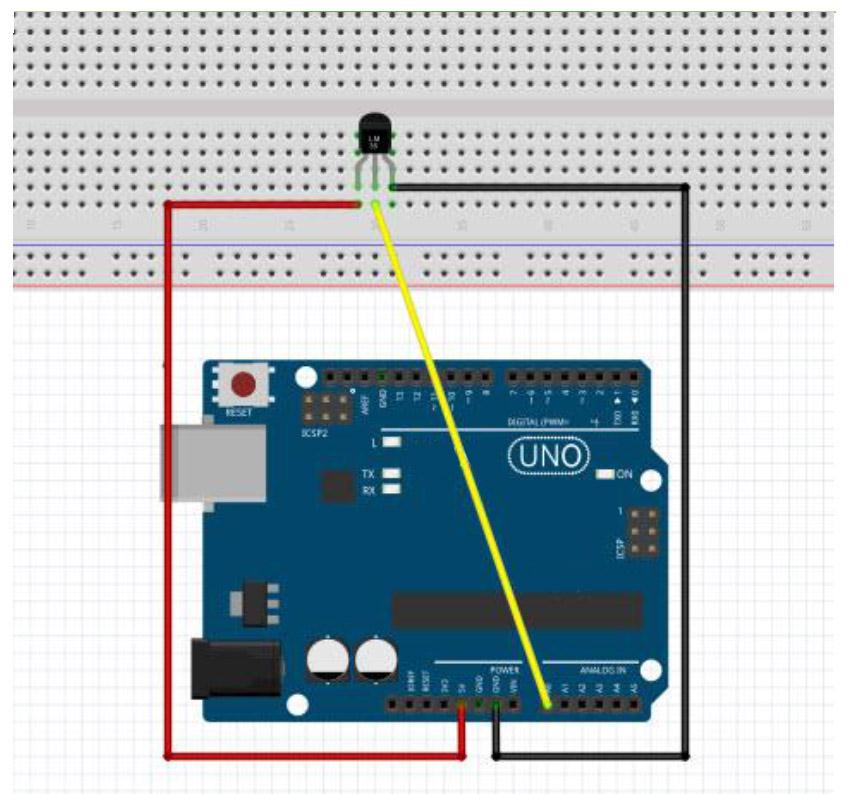

The LM35 Temperature Sensor

The LM35 is a common and easy-to-use temperature sensor. It does not require other hardware, you just need an analogue port to make it work. The difficulty lies in compiling the code to convert the analogue value it reads to Celsius temperature.

The LM35 is a common and easy-to-use temperature sensor. It does not require other hardware, you just need an analogue port to make it work. The difficulty lies in compiling the code to convert the analogue value it reads to Celsius temperature.

Required Hardware

- 1 x LM35 sensor

- 1 x breadboard

- jumper wires as needed

Connection

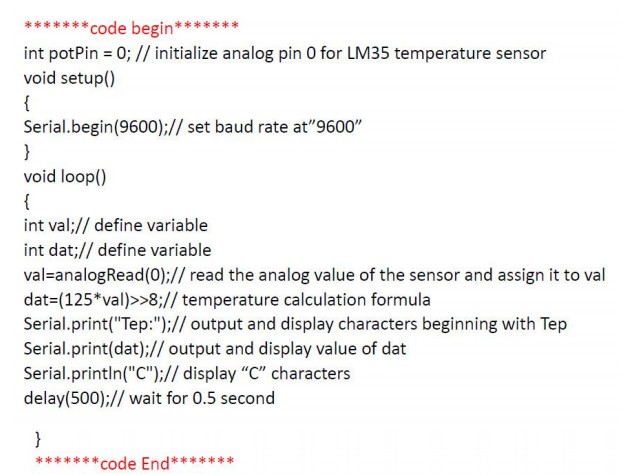

Programming Code ResultAfter programming, open the monitoring window to see the current temperature.

ResultAfter programming, open the monitoring window to see the current temperature.

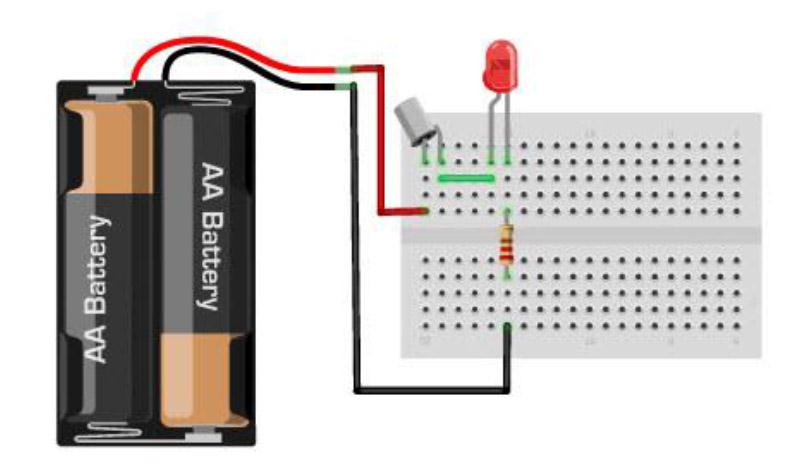

The Tilt Sensor SwitchA tilt sensor will detect orientation and inclination. They are small, low power and easy to use. If used properly, they will not wear out. Their simplicity makes them popular for toys, gadgets and other appliances. They are referred to as mercury, tilt or rolling ball switches.

The Simple Tilt-Activated LEDThis is the most basic connection of a tilt switch but can be handy while one is learning about them. Simply connect in series with an LED, resistor and battery.

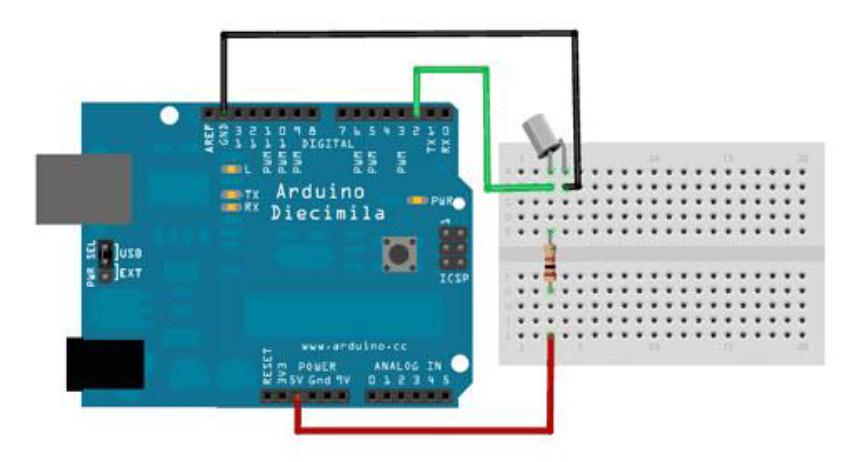

Reading the Switch State with a MicrocontrollerThe layout below shows a 10K pull-up resistor. The code states the built-in pull-up resistor that you can turn on by setting an input pin to the high output. If you use the internal pull-up you can skip the external one.

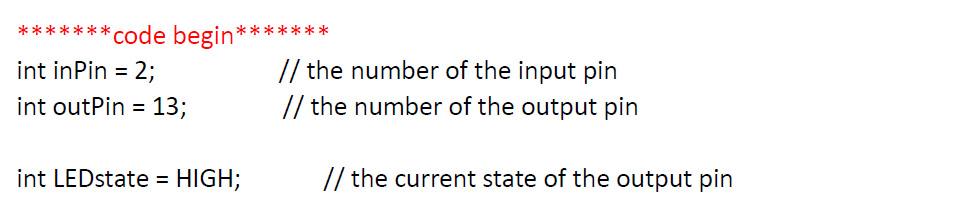

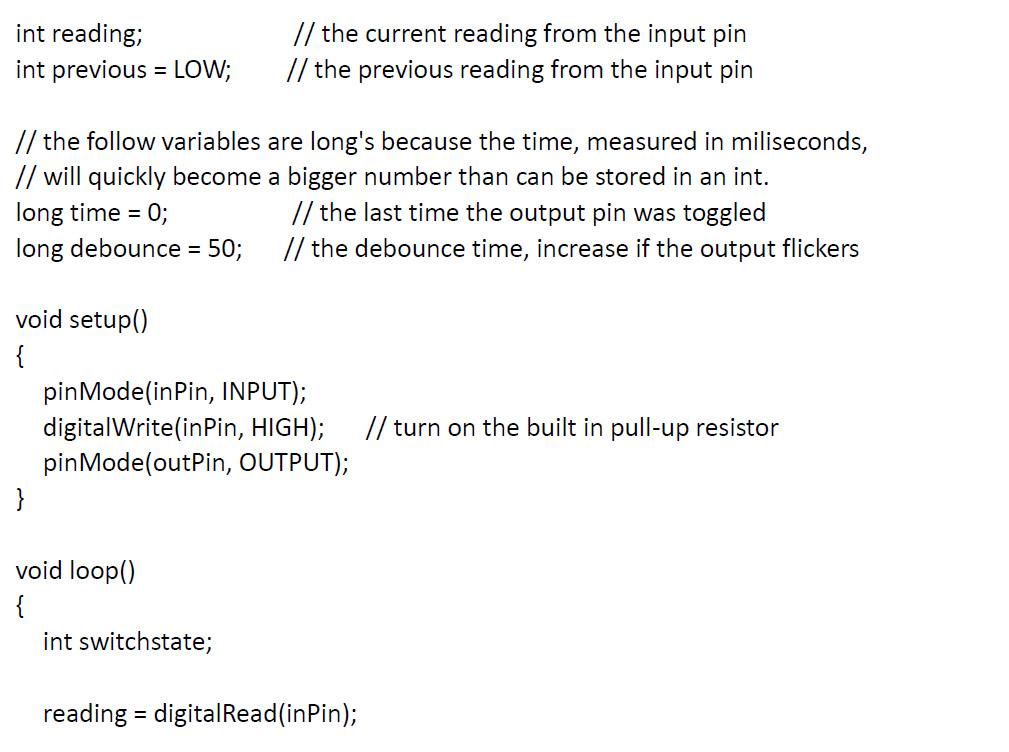

Programming Code

Programming Code

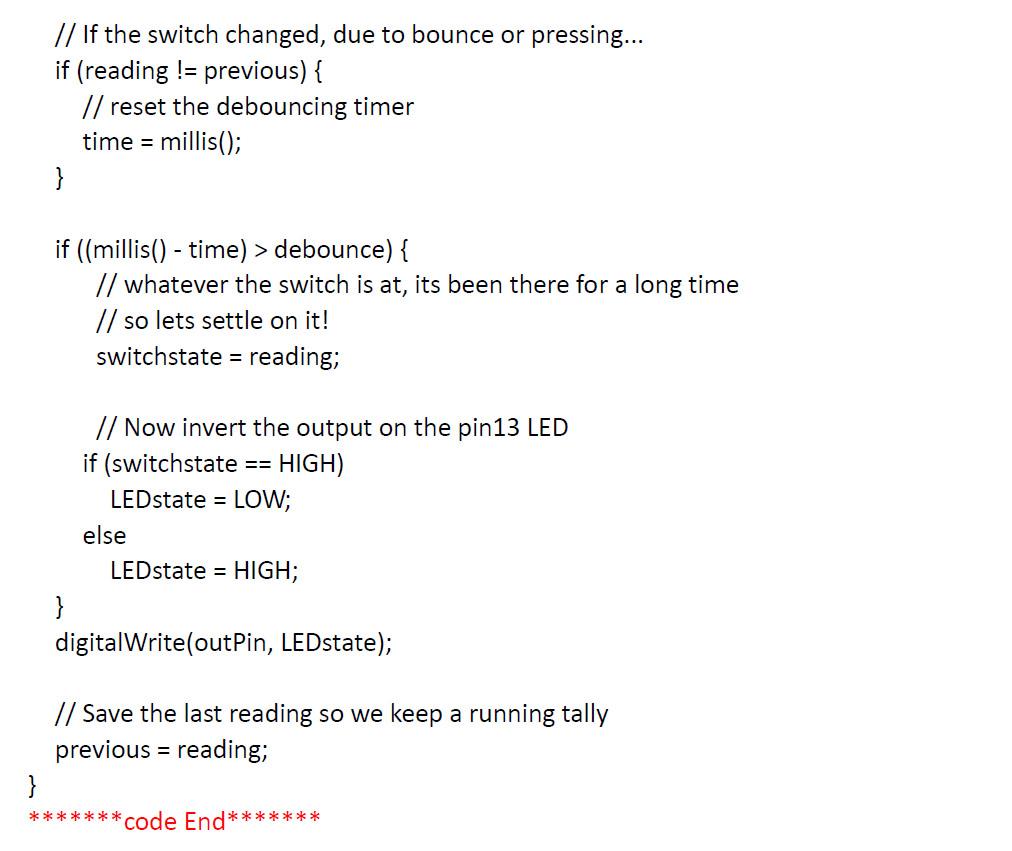

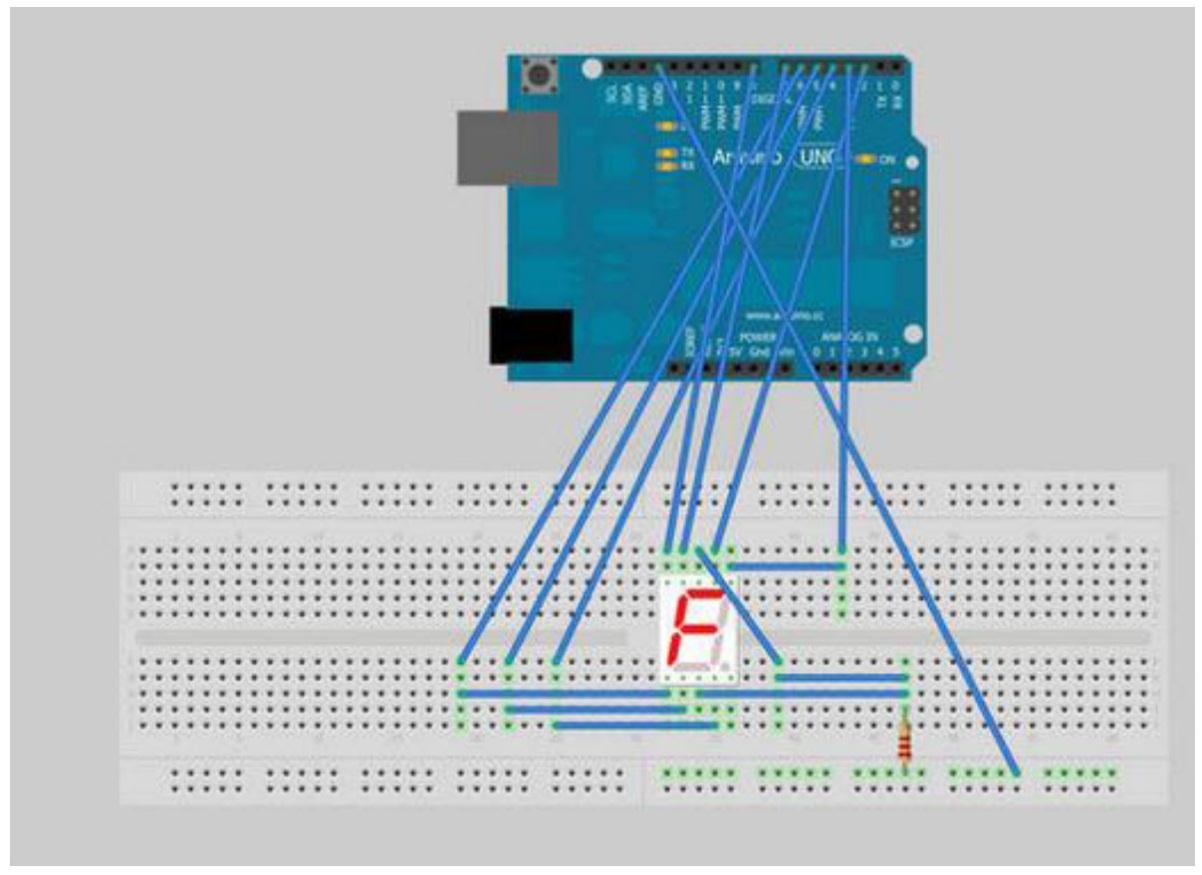

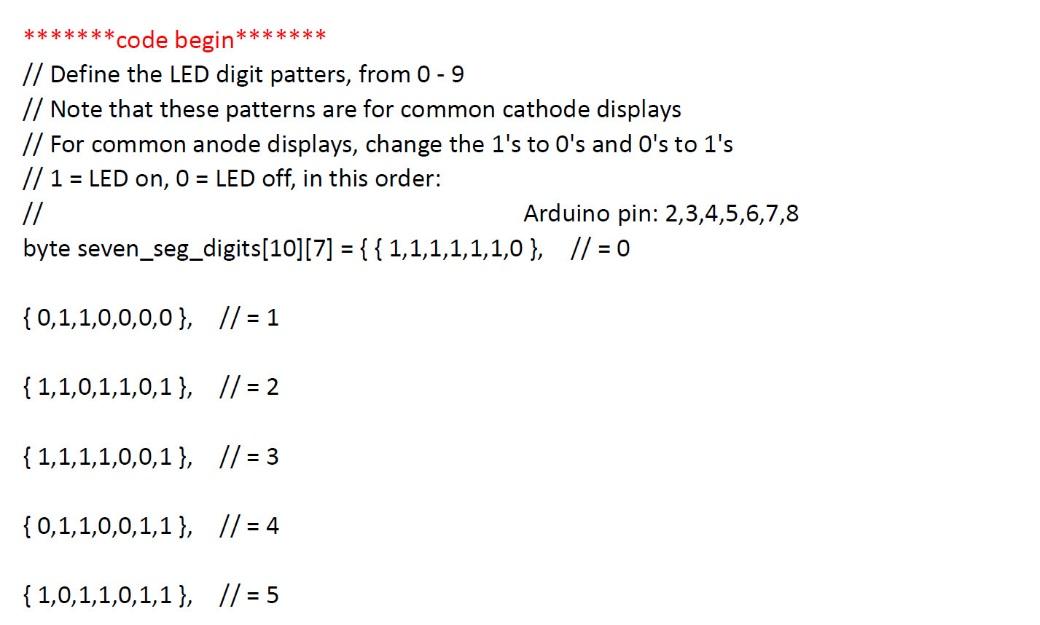

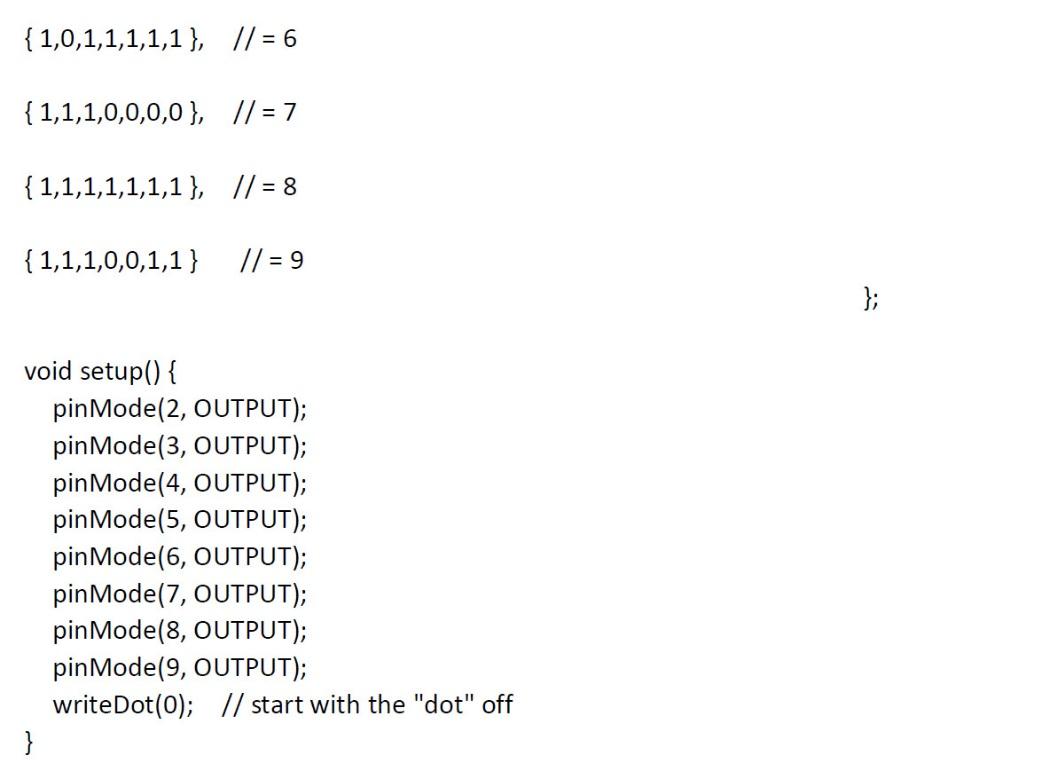

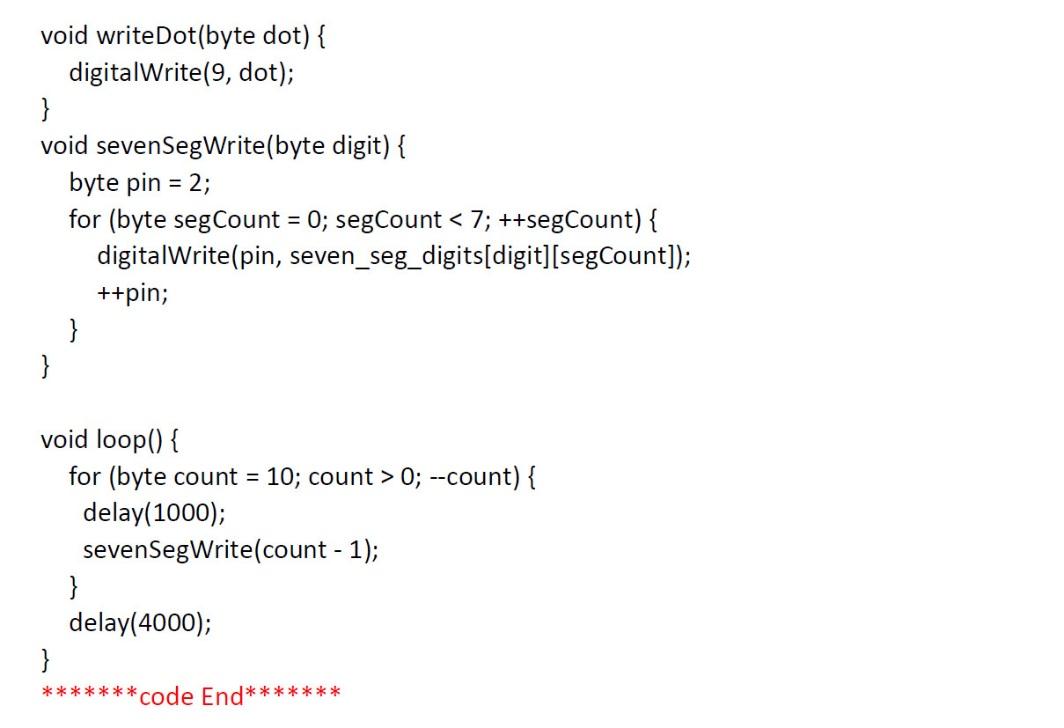

One-Digit Seven-Segment Display

LED segment displays are common for displaying numerical information. They are widely applied on displays of ovens, washing machines, etc. the LED segment display is a semiconductor light-emitting device. Its basic unit is an LED (light-emitting diode). Segment displays can be divided into 7-segment and 8-segment displays.

LED segment displays are common for displaying numerical information. They are widely applied on displays of ovens, washing machines, etc. the LED segment display is a semiconductor light-emitting device. Its basic unit is an LED (light-emitting diode). Segment displays can be divided into 7-segment and 8-segment displays.

According to the wiring method, LED segment displays can be divided into displays with common anode and displays with common cathode. Common anode displays refer to displays that combine all the anodes of the LED units into one common anode (COM).

For the common anode display, connect the common anode (COM) to +5 V. When the cathode level of a certain segment is low, the segment is on; when the cathode level of a certain segment is high, the segment is off. For the common cathode display, connect the common cathode (COM) to GND. When the anode level of a certain segment is high, the segment is on; when the anode level of a certain segment is low, the segment is off.

Connection

Programming Code

Use this device with original accessories only. Velleman nv cannot be held responsible in the event of damage or injury resulting from (incorrect) use of this device. For more info concerning this product and the latest version of this manual, please visit our website www.velleman.eu. The information in this manual is subject to change without prior notice.

Use this device with original accessories only. Velleman nv cannot be held responsible in the event of damage or injury resulting from (incorrect) use of this device. For more info concerning this product and the latest version of this manual, please visit our website www.velleman.eu. The information in this manual is subject to change without prior notice.

| © COPYRIGHT NOTICEThe copyright to this manual is owned by Velleman nv. All worldwide rights reserved. No part of this manual may be copied, reproduced, translated or reduced to any electronic medium or otherwise without the prior written consent of the copyright holder. |

Velleman® Service and Quality WarrantySince its foundation in 1972, Velleman® acquired extensive experience in the electronics world and currently distributes its products in over 85 countries.All our products fulfil strict quality requirements and legal stipulations in the EU. In order to ensure the quality, our products regularly go through an extra quality check, both by an internal quality department and by specialized external organisations. If, all precautionary measures notwithstanding, problems should occur, please make an appeal to our warranty (see guarantee conditions).

General Warranty Conditions Concerning Consumer Products (for EU):

- All consumer products are subject to a 24-month warranty on production flaws and defective material as from the original date of purchase.

- Velleman® can decide to replace an article with an equivalent article or to refund the retail value totally or partially when the complaint is valid and a free repair or replacement of the article is impossible, or if the expenses are out of proportion.You will be delivered a replacing article or a refund at the value of 100% of the purchase price in case of a flaw that occurred in the first year after the date of purchase and delivery, or a replacing article at 50% of the purchase price or a refund at the value of 50% of the retail value in case of a flaw that occurred in the second year after thedate of purchase and delivery.

- Not covered by warranty:– all direct or indirect damage caused after delivery to the article (e.g. by oxidation, shocks, falls, dust, dirt, humidity…), and by the article, as well as its contents (e.g. data loss), compensation for loss of profits;– consumable goods, parts or accessories that are subject to an aging process during normal use, such as batteries (rechargeable, non-rechargeable, built-in or replaceable), lamps, rubber parts, drive belts… (unlimited list);– flaws resulting from fire, water damage, lightning, accident, natural disaster, etc.…;– flaws caused deliberately, negligently or resulting from improper handling, negligent maintenance, abusive use or use contrary to the manufacturer’s instructions;– damage caused by a commercial, professional or collective use of the article (the warranty validity will be reduced to six (6) months when the article is used professionally);– damage resulting from an inappropriate packing and shipping of the article;– all damage caused by modification, repair or alteration performed by a third party without written permission by Velleman®.

- Articles to be repaired must be delivered to your Velleman® dealer, solidly packed (preferably in the original packaging), and be completed with the original receipt of purchase and a clear flaw description.

- Hint: In order to save on cost and time, please re-read the manual and check if the flaw is caused by obvious causes prior to presenting the article for repair. Note that returning a non-defective article can also involve handling costs.

- Repairs occurring after warranty expiration are subject to shipping costs.

- The above conditions are without prejudice to all commercial warranties.

The above enumeration is subject to modification according to the article (see article’s manual).

Made in PRCImported by Velleman nvLegen Heirweg 33, 9890 Gavere, Belgiumwww.velleman.eu

References

[xyz-ips snippet=”download-snippet”]