VOLKSWAGEN VAS6131/19 Mounting

Definition of Terms

Skilled Worker

A user who, on the basis of training, has specialized knowledge of the handling of sling gear and load handling devices as well as training certificates for specialized tasks.

Qualified Person

A person who, based on technical training and experience, has sufficient knowledge to evaluate the various sling gear and load handling devices, and is sufficiently familiar with the applicable state occupational health and safety regulations, Employer’s Liability Insurance Association regulations, and the generally accepted state of the art (for example, DGUV rules, DIN-EN standards, DIN standards, ISO standards) to evaluate the occupational health and safety state of sling gear and load handling devices.

Load Handling Devices

Components that are not permanently connected to the hoisting equipment, attached between the crane or hoisting equipment hook and the load in order to securely pick up the load. Examples: Spreader bars, lifting clamps, C-hooks, grippers, loading forks, etc.In this operating manual, the assembly fixture is also called a load handling device.

Basis

Machinery Directive 2006/42/ECDIN EN 13155:2009-08Cranes – Safety – Non-fixed load lifting attachments

DIN EN ISO 12100:2011-03Safety of MachineryGeneral principles for design –Risk assessment and risk reduction

DIN 15003:1970-2Lifting appliances; load suspending devices, loads and forces; definitions

DIN EN ISO 20607Safety of machinery – Instruction handbook

DGUV 100-500:2013-06Operation of work equipment

DIN EN 1494:2009-05Mobile or movable jacks and associated lifting equipment

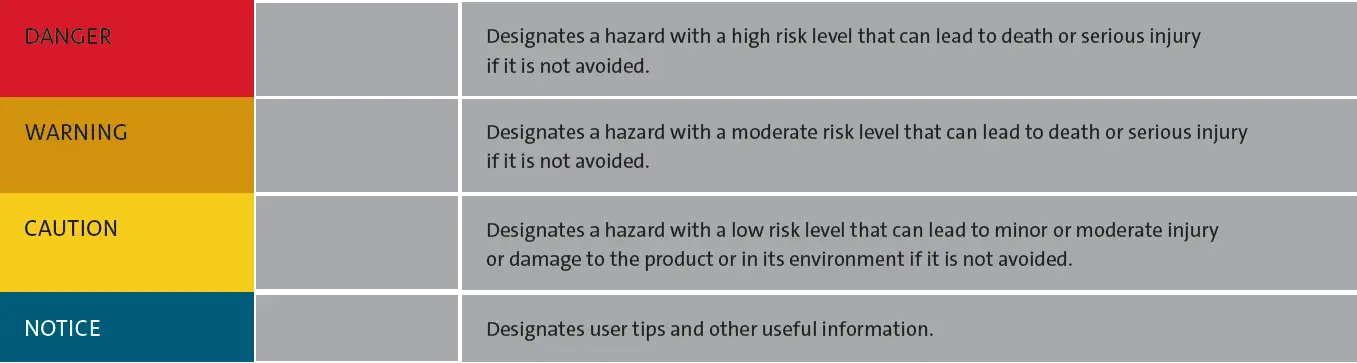

Warnings and Symbols

Hazards and information are classified and represented as follows in this operating manual:

Operating Company Duty of Care

The load handling device was designed and built under consideration of a risk assessment and after careful selectionof the applicable standards as well as additional technical specifications. It therefore corresponds to the state of the art and ensures the highest level of safety. However, this level of safety can only be reached in operational practice if all required measures are implemented. Planning these measures and verifying their execution is part of the duty of care of the operating company for the specialized tool.

The operating company has to supplement this operating manual with instructions, including supervision and reporting obligations, to take into account operational particularities, for example, regarding the organization of work, operational procedures, and the personnel that is deployed.

In particular, the operating company has to ensure that:

- The load handling device is only used as intended.

- The load handling device is only used in proper, functioning condition and, in particular, the functionality of the safety devices is checked regularly.

- The required protective equipment for the operating, maintenance, and repair personnel is on hand and used.

- The operating manual, complete and in legible condition, is always available at the location where the load handling device is used.

- The load handling device is only operated, maintained, and repaired by qualified and authorized personnel.

- This personnel is instructed regularly in all relevant aspects of occupational health and safety and environmental protection, and is familiar with the operating manual and in particular the safety instructions it contains.

- All safety notices and warnings on the load handling device remain in legible condition and are not removed.

DANGERMaking structural changes to the load handling device is prohibited.

Proper Use

- The load handling device is intended for lifting and transporting loads.

- Complying with the manufacturer’s instructions for operation, maintenance, and upkeep as well as repair guides is mandatory for proper use.

- Exceeding the specified limit values is not permitted.

- In case of damage, the load handling device may only be used again after it has been repaired by a qualified person. Only original replacement parts may be used.

- Failing to comply with these provisions voids all warranty claims.

- The manufacturer assumes no liability in case of unauthorized conversion of the components.

- The allowable ambient temperature for storage and operation is -20°C to +60°C.

- Using the device in potentially explosive atmospheres is not permitted.

NOTICESafe operation is not assured if the load handling device is not used as intended. All cases of personal injury and damage to property caused by improper use are the sole responsibility of the operating company.

Foreseeable Misuse

The following applications are not permitted:

- Breaking free of loads.

- Dragging loads along the floor.

- Use in potentially explosive environments, unless the load handling device has been modified for this purpose and identified with corresponding notices.

- Transporting persons and/or animals.

- Use while persons are present underneath the load.

User Qualifications

For safety reasons, only trained or instructed skilled workers are permitted to work with this load handling device. The responsibilities of personnel have to be clearly established. If apprentices are used, then this may only take place with the constant supervision of an experienced, skilled worker. The operating company is liable for all cases of personal injury or damage to property if this provision is not followed. The operating company is obligated to clearly and unmistakably establish the responsibilities of personnel for operation, inspection, and maintenance.

DANGERIn order to avoid severe injuries, the following must be observed when working with the load handling device:

- Use personal protective equipment

- Tie back long hair

- No wearing of loose clothing or jewelry

- Persons are not permitted to be present underneath the load under any circumstances

Fundamental Safety Measures

- Observe the user information (documentation).

- Observe the warnings on the device and in the user information.

- Observe the safety distances.

- Ensure adequate lighting and good visibility.

- Use the load handling device as intended.

- Never exceed the specified load bearing capacity of the load handling device.

- Transporting persons is not permitted under any circumstances. The load handling device is intended solely for moving the loads specified in the repair guide.

- Observe the national accident prevention regulations (UVV).

- Observe DGUV rule 100-500 for the form-fitting and friction-fitting attachment of loads.

- Observe the respective national regulations for use outside of Germany.

- Ensure adequate stability of the building walls, ceilings, floor, or structures on which the load handling device is mounted or engaged. Consult a structural engineer in case of doubt.

- After the load handling device has not been used for a longer period of time, conduct a visual inspection of all components that are essential for proper functioning. Replace damaged components with original replacement parts.

- Do not use a defective load handling device.

- Stop the operation immediately and eliminate the defect.

- Report damage and defects to the responsible person immediately.

- Warn persons in the immediate vicinity about work with the load handling device.

- Ensure that the sling gear is securely engaged in the load hook and lies safely in the bed of the hook.

- Stop lowering the load when the sub-block or load hits the ground or is prevented from lowering further.

- Do not twist the load chain.

- Straighten twisted chains before engaging the load. (The correct alignment of the chain links is identified by the weld seam.)

- Rows of chain links always have to run in one direction.

- Be sure to prevent impacts of the load or hook.

DANGERThe following is not permitted:

- Exceeding the rated load.

- Manipulation of the devices in any form.

- Continuing to use stretched or damaged chains. These must be replaced immediately with new original parts.

Transportation and Storage

CAUTIONTransportation may only be carried out by qualified personnel. No liability is assumed for damage due to improper transportation and/or storage.

- The load handling device is inspected and properly packaged prior to delivery.

- When the load handling device is received, the packaging has to be inspected for damage.

- Only suitable means of transport may be used for the transportation of the load handling device.

- Under no circumstances may the load handling device be dropped or thrown.

- The load handling device must be stored in a clean and dry location.

- The load handling device must be protected against dirt, moisture, and corrosion.

- The load handling device should be inspected for integrity prior to storage.

Operation

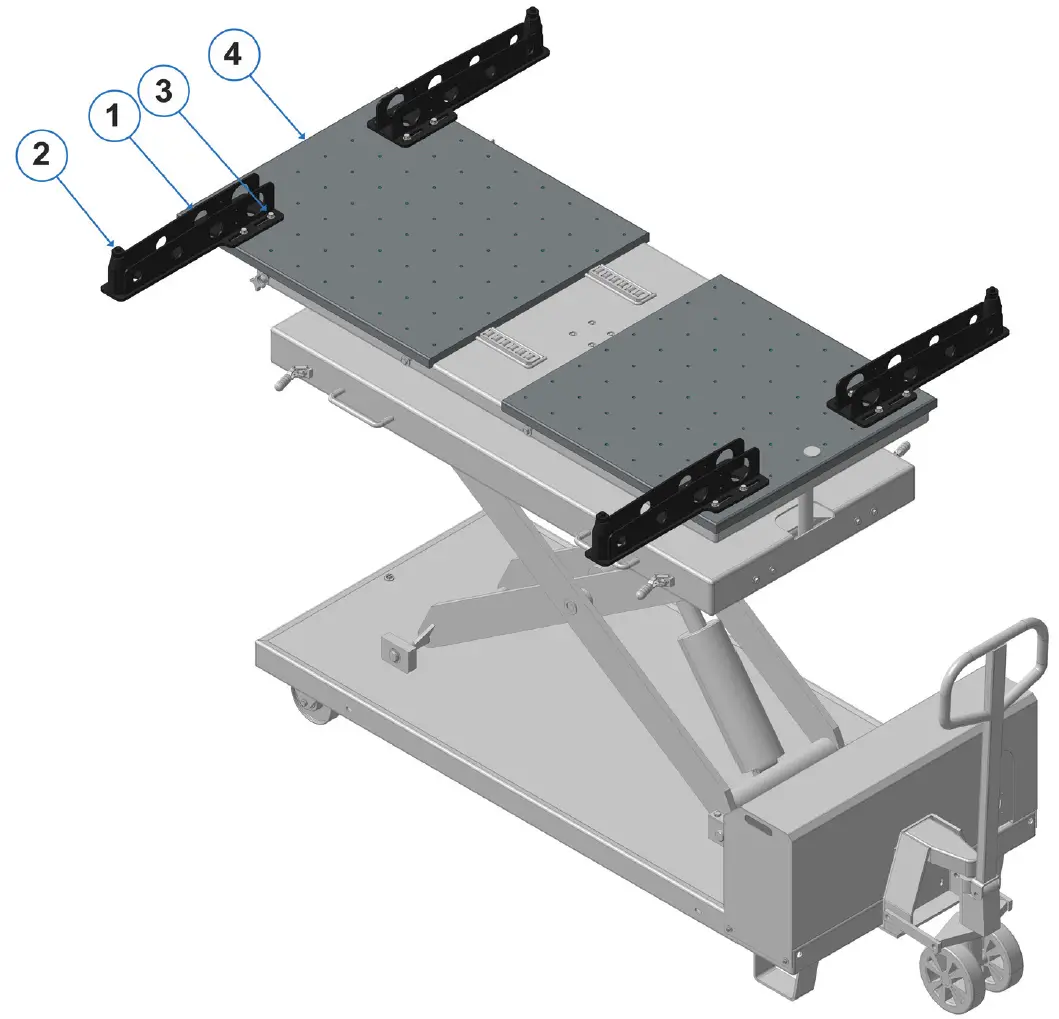

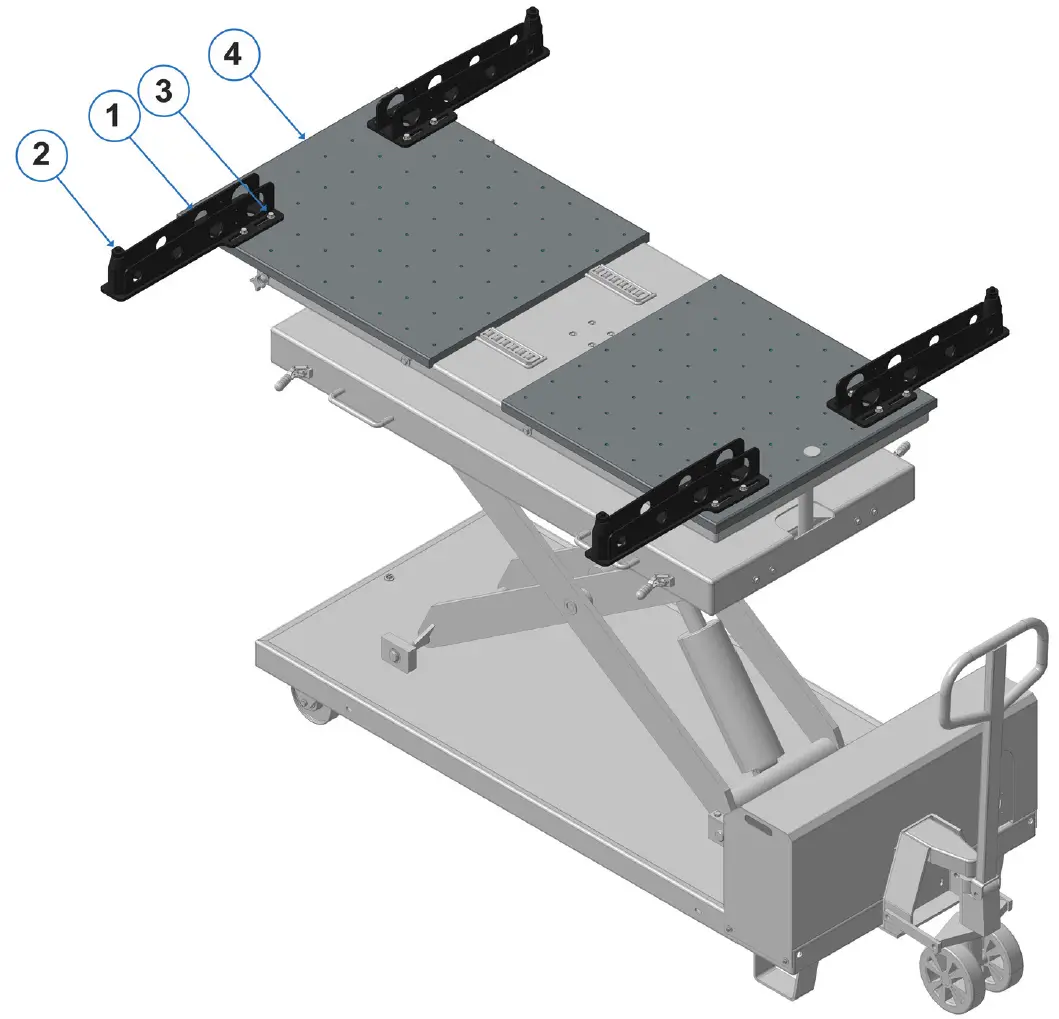

- The VAS6131/19 mounting is a load handling device for the installation and removal of high-voltage motor vehicle batteries.

- Four mountings have to be used for removal.

- The maximum total permissible load bearing capacity of one mounting is 300 kg, and of four mountings 900 kg.

- For use only in the configurations defined in the repair guide for the brands of the VW Group in combination with the VAS6131B lifting table.

- When using the load handling device, ensure that the load being lifted is safely secured by the pins provided (item 2). To do so, extend the pins by hand until they are in full contact with the load.

- All required screw connections on the vehicle have to be unscrewed before lowering the battery.

- Pushing the load while it is raised is not permitted.

- Possible fine-tuning for positioning the battery under the vehicle must be carried out only with the VAS6131B lifting table (item 4).

- The mountings may only be used and moved together with the VAS6131B table.

DANGERThe maximum permissible movement speed is 2 km/h.

- The top of the VAS6131B lifting table has to be lowered before movement.

- The load must be protected against unwanted impacts (e.g. tension belt).

- Tighten the M10x20 hexagon bolts (item 3) to 25 Nm.

- Using parts of this load handling device individually is not permitted.

NOTICEApplications and pulling directions other than those described in the repair guide are not intended and therefore prohibited!

Commissioning

Read this operating manual before putting the load handling device into use for the first time.Observe the applicable national accident insurance provisions, regulations, and the information in this manual.

Verify the following prior to initial use:

- That inspection and test certificates are on hand (acceptance record, declaration of conformity etc.)

- That the identification and information on the load handling device corresponds to the information on the inspection and test certificates.

- That all details of the load handling device were transferred to an inspection log.

Ensure that all packaging materials, tools, implements, etc. have been removed from the load handling device. All safety devices must be installed and functioning.Use the personal protective equipment Check the following points:

- Visual inspection

- No other persons in the danger area

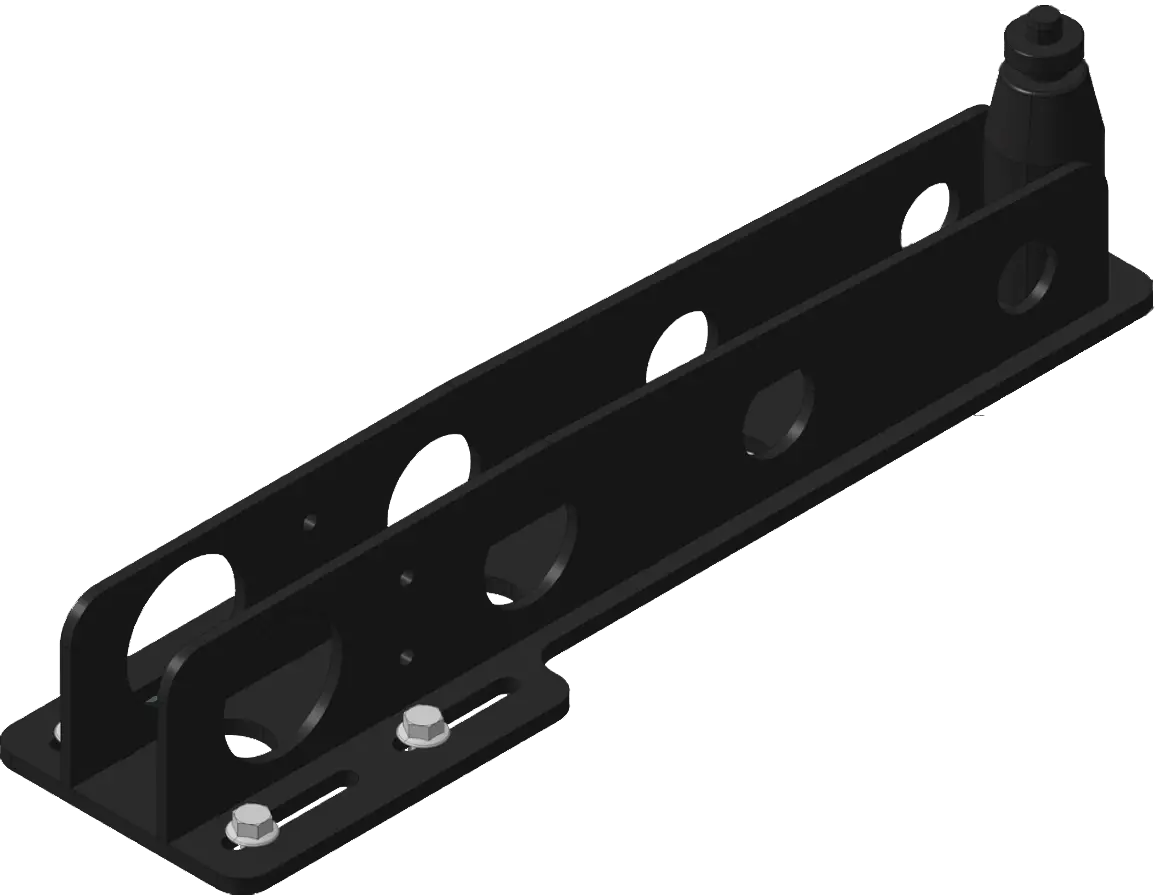

Description

|

Item |

Name |

Standard/Comments |

Qty. |

|

1 |

VAS6131/19 Mounting |

4 |

|

|

2 |

Pin |

42CrMo4+QT |

4 |

|

3 |

Hexagon bolt |

DIN6921 – M10x40 – 8.8 |

16 |

|

4 |

VAS6131B Lifting table |

1 |

Application and Limits

Attaching to the LoadTo ensure safe handling, the attachment to the load must be carried out diligently and in compliance with the maximum limit values.

Operation

Preparation and InspectionThe components must be inspected for apparent damage and correct fit before attaching the load.

Weight of the LoadThe specified load bearing capacity of the load handling device must not be exceeded. Avoid swinging of the load.

Center of GravityThe following conditions have to be met in order to lift the load without twisting or upsetting it:The prescribed and identified settings on the load handling device for the respective load have to be configured before attaching the load.

Safety During Lifting OperationsTo prevent injuries, the hands and other body parts should be kept away from the device. Once the load is ready for lifting, the device should be lifted until it bears the full load. Then check whether the load is securely attached and remains in the intended position. Only then can the operation be completed.

Maintenance and Cleaning

Regular maintenance considerably increases the service life of the load handling device. The load handling device has to be cleaned if it gets dirty. All components must be cleaned so they are free of oil, dirt and corrosion. Any cleaning method that does not attack the base material is permitted.

Methods that can cause hydrogen embrittlement, overheating, material removal or material deformation, or may conceal cracks or other surface defects, have to be avoided.

Inspection

The operating company has to ensure that load handling devices are inspected by a qualified person at least once a year.Depending on the conditions under which the load handling devices are used, inspections may be required more frequently than once per year. This applies, for example, in case of very frequent use, increased wear, corrosion, exposure to heat, or when increased susceptibility to failurecan be expected. Load handling devices should be inspected for the absence of cracks every 3 years by qualified personnel using appropriate inspection equipment. Records of such inspections must be retained. If the user has any doubts that the load handling device is in safe condition, the load handling device should be taken out of use and inspected by qualified personnel.

Maintaining Proof of Inspections

The operating company has to ensure that proof of the inspections of load handling devices is maintained. (See point 5.3. for a template that can be copied) Such proof has to include the following:

- Date and scope of the inspection with information about any partial inspections that are still pending.

- Result of the inspection including any defects that were found.

- Assessment in case of concerns regarding continued use.

- Information about required follow-up inspections.

- Name and if applicable address of the inspector.

The Employer’s Liability Insurance Association may demand that proof of inspections be maintained for other inspections on a case-by-case basis. Proof of inspections must be submitted to the supervisor on request. Therefore, they must be stored so they are readily accessible at all times.

The recurring inspections encompass a visual inspection and functional tests. They essentially extend to the integrity, suitability, and effectiveness of the safety devices as well as the condition of the load handling device in regard to damage, wear, corrosion, or other changes. Disassembly may be required for the assessment of wear parts.

Inspection Criteria

If the following defects or disruptions occur, the device must be taken out of use for maintenance, repair, or entirely:

- Identification of the load bearing capacity or proof of identity are illegible

- Permanent deformation of the components

- Wear

- Incomplete device

- Damaged components: Cracks, notches, grooves

- Surface damage: Corrosion, discoloration due to heat

Template for Proof of Inspection

TYPE:Year of manufacture:Load bearing capacity:

Serial number:Manufacturer: Werner Weitner GmbHOperating company:

|

Inspection prior to initial use |

Inspector: |

Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: |

Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: | Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: | Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: | Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: | Date: |

Signature: |

| Inspection findings: | |||

|

Inspection no.: |

Inspector: | Date: |

Signature: |

| Inspection findings: |

EC Declaration of Conformity

According to the EC Machinery Directive 2006/42/EC, Annex IIA

| We hereby declare that the device specified below, on account of its design and construction and in the version marketed by us, corresponds to the applicable fundamental health and safety requirements of the EC Machinery Directive. If this device is a part that is installed in other machines or similar, we hereby point out that our device may only be put into operation after ensuring that this higher-level machine also meets the requirements of the aforementioned directive. Changes to the machine or device which have not been coordinated with us invalidate this declaration. | ||

| Machine designation: | Mounting | |

| Machine type: | VAS6131/19 | |

| Intended use: | Lifting high-voltage batteries up to 900kg max. | |

| Applicable EC directives: | EC Machinery Directive (2006/42/EC) | |

| Applied harmonized standards: | DIN EN ISO 12100; DIN EN 1494 | |

| Applied national standards: | DGUV 100-500 Section 2.8 | |

| Authorized documentation representative: | Wolfgang Wiesent, Sollnau 14, 85072 Eichstätt, Germany | |

| Date/manufacturer signature: |

25 March 2021 |

|

| Information about the undersigned: | Managing Director | |

| Formal requirements:

– Completion in block letters or by machine – Official language of the country of use – Legally binding signature(s) |

– Original for project folder

– Copy for the customer |

Volkswagen AktiengesellschaftK-GVO-LWKonzern After Sales – Group Service,Literatur und Systeme WerkstattausrüstungBrieffach 011/491538442 Wolfsburg

For internal use onlyTechnical changes reservedLast update: 03/2021

References

[xyz-ips snippet=”download-snippet”]