User Manual

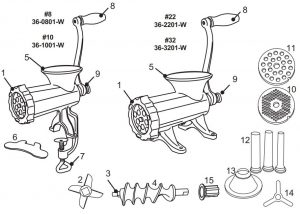

WESTON 36-0801-W, 36-1001-W, 36-2201-W, 36-3201-W Meat Grinder and Sausage Stuffer

DUE TO CONSTANT FACTORY IMPROVEMENTS, THE PRODUCT PICTURED MIGHT DIFFER SLIGHTLY FROM THE PRODUCT IN THIS BOX. 010716

GENERAL SAFETY RULES

GENERAL SAFETY RULES

READ AND FULLY UNDERSTAND ALL INSTRUCTIONS AND WARNINGS PRIOR TO USING THIS UNIT. YOUR SAFETY IS MOST IMPORTANT! FAILURE TO COMPLY WITH PROCEDURES AND SAFE GUARDS MAY RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE. REMEMBER: YOUR PERSONAL SAFETY IS YOUR RESPONSIBILITY!

- KEEP FINGERS CLEAR of the Auger and Plate at all times. NEVER reach into any Grinder inlet.

- Close adult supervision is necessary when any appliance is used near children. This grinder is NOT to be used by children.

- CHECK FOR DAMAGED PARTS. Before using the Grinder, check that all parts are operating properly, and perform the intended functions. Check for alignment of moving parts, binding of moving parts, mounting and any other conditions that may affect the operation.

- If the Grinder becomes jammed, briefly turn in reverse to clear blockage.

- NEVER insert fingers or foreign objects into Grinder opening.

- TIE BACK loose hair and clothing and roll up long sleeves before operating the Grinder. REMOVE ties, rings, watches, bracelets, or other jewelry before operating the Grinder.

- WEAR EYE PROTECTION. Wear safety glasses. Everyday eye glasses are not safety glasses. Safety glasses conform to ANSI Z87.1 requirements. Note: approved safety glasses have Z87 printed or stamped on them.

- Trim meat of all clots, cords, tendons, bones, etc. before grinding.

- DO NOT grind bones or other hard objects.

- DO NOT use the Grinder while under the influence of drugs or alcohol.

SAVE THESE INSTRUCTIONS

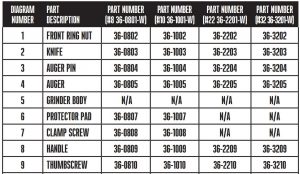

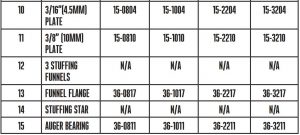

COMPONENT LIST

If any components of this unit are broken, the unit does not operate properly or youneed a replacement instruction manual, visit us on the web atWestonProducts.comOr call Weston Brands LLC Toll Free at 1-800-814-4895Monday thru Friday 8:00am-5:00pm ET. Outside the U.S. call 001-216-801-6801

IMPORTANT NOTE PRIOR TO USE

- A protective coating is applied to this unit prior to shipment. This coating protects the unit in shipment and during its shelf life.

- It is very important to thoroughly clean the unit before using it, especially around the edges or areas that have been soldered or welded. Completely disassemble and thoroughly clean all parts with hot water, dish detergent and a soft cloth. Rinse with clean water and dry thoroughly. DO NOT use any harsh or abrasive brushes, chemicals or detergents. Avoid using detergents or cleansers containing high percentages of free alkali or acid.

- DO NOT clean any parts of this unit in a dishwasher.

- Coat all metal parts with a food grade silicone spray after cleaning and before storing.

- Be certain to store the unit in the original box in a cool, dry location.

- Run a small “Test Batch” through the unit before initial use.

CLEANING INSTRUCTIONS

- PROPERLY CLEAN THE GRINDER PRIOR TO INITIAL USE!

- Disassemble the Grinder and hand wash each part thoroughly in warm, soapy water, taking particular care to remove all grease and oil from the surfaces.

- Dry all parts thoroughly before re-assembling. DO NOT ALLOW parts to air dry.

- Coat all metal parts, including the Plates and Knife, with a food grade silicone spray to prevent corrosion.

- The Grinder is NOT dishwasher safe.

SPECIAL NOTE FOR #32 GRINDERS ONLY: If the Front Ring Nut is difficult to remove, the Handle is designed with a small hole drilled into the back, which allows it to be used as a wrench to remove the Front Ring Nut only. DO NOT use this feature to tighten the Front Ring Nut.

CAUTION! It is important to follow the “Food Safety” guidelines outlined in this manual. For the most up to date instruction visit the USDA website.

GRINDER ASSEMBLY

- A. If you are using a clamp down #8 or #10 Grinder, slide the Protector Pad onto the foot of the Grinder and tighten the Clamp Screw to secure the Grinder to the work surface. Allow ample room for the Handle to rotate.B. If you are using a bolt down #22 or #32 Grinder, the body of the Grinder can be attached to a solid work surface using appropriately sized screws (not provided). Allow ample room for the Handle to rotate.

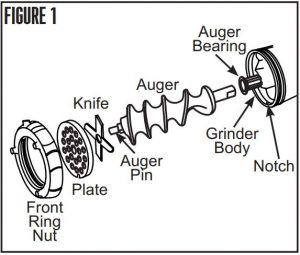

- Slip the plastic Auger Bearing flange-end, face-first, over the Auger driver end. FIGURE 1

- Together, carefully insert the Auger Bearing & Auger inside the Grinder Body

- Slide the Knife over the square portion of the Auger Pin on the front of the Auger, making sure the cutting edges of the Knife are facing outward.

- Slide the Plate of choice over the round portion of the Auger Pin. Align the notch on the Plate with the notch in the Grinder Body so that the Plate fully sits in the opening of the Grinder Body.

- Snugly screw on the Front Ring Nut. DO NOT OVER TIGHTEN! If the Front Ring Nut is screwed onto the Grinder Body too tightly, the Auger will be hard to turn/will not turn.

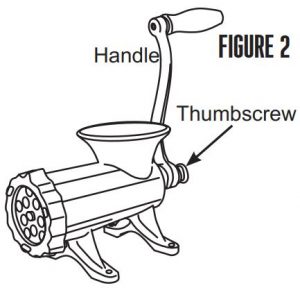

- Slide the Handle over the exposed end of the Auger and lock it in place with the Thumbscrew. FIGURE 2

STUFFER ASSEMBLY

- A. If you are using a clamp down #8 or #10 Grinder, slide the Protector Pad onto the foot of the Grinder and tighten the Clamp Screw to secure the Grinder to the work surface. Allow ample room for the Handle to rotate.B. If you are using a bolt down #22 or #32 Grinder, the body of the Grinder can be attached to a solid work surface using appropriately sized screws. Allow ample room for the Handle to rotate.

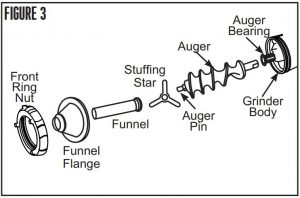

- Insert the Auger Bearing into the Grinder Body through the hole in the back of the Grinder. FIGURE 3

- Insert the Auger into the Grinder Body. Rotate the Auger while inserting to fully seat the Auger into the Grinder Body.

- Slide the Stuffing Star over the round portion of the Auger Pin.

- Attach the Stuffing Flange to the Funnel that will be used. Slide the Stuffing Funnel through the Front Ring Nut.

- Snugly screw on the Front Ring Nut. DO NOT OVER TIGHTEN! If the Front Ring Nut is screwed onto the Grinder Body too tightly, the Auger will be hard to turn/will not turn.

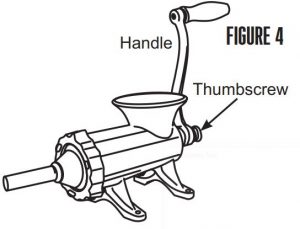

- Slide the Handle over the exposed end of the Auger and lock it in place with the Thumbscrew. FIGURE 4

GRINDING INSTRUCTIONS

- Trim meat of all blood clots, cords, tendons, bones, etc. NEVER grind bones or other hard objects.

- For best results, be sure that all meat has been chilled to between 32-34°F (0-1°C) before grinding. DO NOT allow meat to sit out at room temperature longer than is absolutely necessary. Follow the Food Safety Guidelines as outlined.

- Cut meat into sizes small enough to fit into the Grinder. Approximately 1” (2.5 cm) cubes.

- As you feed chunks of meat into the Grinder, turn the Handle clockwise (when facing the Handle side of the Grinder). Be sure to have something to catch the meat as it comes out of the Grinder.

- If the Grinder should get stuck or become hard to turn, turn the Handle counter-clockwise to loosen the obstruction, then resume grinding. If this doesn’t free the back-up, remove the Front Ring Nut, Plate, Knife and Auger to remove the obstruction.

STUFFING INSTRUCTIONS

- For the best stuffing results, two people are recommended for this operation.

- Fill the Grinder hopper with pre-ground, seasoned meat.

- Slide a sausage casing over the end of the Stuffing Funnel, leaving 4-6” (10.2-15.2 cm) of casing off the end of the Stuffing Funnel. Tie a knot in the end of the casing.

- While holding the casing on the Stuffing Funnel with one hand, rotate the Handle clockwise (when facing the Handle side of the Grinder) to move the meat through the Grinder and into the casing. Gently lay the filled casing on a plate as the casing fills.

- Do not fill the last 3-4” (7.6-10.2 cm) of the casing. When finished stuffing, twist and tie the end closed.

FOOD SAFETY

There are basic rules to follow when handling food.They are COOK, SEPARATE, CLEAN, and CHILL.

COOKIt’s crucial to cook food to a safe internal temperature to destroy bacteria that is present. The safety of hamburgers and other foods made with ground meat has been receiving a lot of attention lately, and with good reason. When meat is ground, the bacteria present on the surface is mixed throughout the ground mixture. If this ground meat is not cooked to at least 160oF to 165oF (71oC to 74oC), bacteria will not be destroyed and there’s a good chance you will get sick.

Solid pieces of meat like steaks and chops don’t have dangerous bacteria like E. coli on the inside, so they can be served more rare. Still, any beef cut should be cooked to an internal temperature of at least 145oF (63oC) (medium rare). The safe temperature for poultry is 165oF (75oC) and solid cuts of pork should be cooked to 145oF (63oC).

SEPARATEFoods that will be eaten uncooked and foods that will be cooked before eating MUST ALWAYS be separated. Cross-contamination occurs when raw meats or eggs come in contact with foods that will be eaten uncooked. This is a major source of food poisoning. Always double-wrap raw meats and place them on the lowest shelf in the refrigerator so there is no way juices can drip onto fresh produce. Then use the raw meats within 1-2 days of purchase, or freeze for longer storage. Defrost frozen meats in the refrigerator, not on the counter.

When grilling or cooking raw meats or fish, make sure to place the cooked meat on a clean platter. Don’t use the same platter you used to carry the food out to the grill. Wash the utensils used in grilling after the food is turned for the last time on the grill, as well as spatulas and spoons used for stir-frying or turning meat as it cooks.

Make sure to wash your hands after handling raw meats or raw eggs. Washing hands with soap and water, or using a pre-moistened antibacterial towelette is absolutely necessary after you have touched raw meat or raw eggs. Not washing hands and surfaces while cooking is a major cause of cross-contamination.

CLEANWash your hands and work surfaces frequently when you are cooking. Washing with soap and warm water for at least 15 seconds, then dry with a paper towel.

CHILLChilling food is very important. The danger zone where bacteria multiply is between 40oF and 140oF (4oC and 6oC). Your refrigerator should be set to 40oF (4oC) or below; your freezer should be 0oF (-17oC) or below. Simple rule: serve hot foods hot, cold foods cold. Use chafing dishes or hot plates to keep food hot while serving. Use ice water baths to keep cold foods cold. Never let any food sit at room temperature for more than 2 hours – 1 hour if the ambient temperature is 90oF (32oC) or above. When packing for a picnic, make sure the foods are already chilled when they go into the insulated hamper. The hamper won’t chill food – it just keeps food cold when properly packed with ice. Hot cooked foods should be placed in shallow containers and immediately refrigerated so they cool rapidly. Make sure to cover foods after they are cool.

NOTE: Special considerations must be made when using venison or other wild game, since it can become heavily contaminated during field dressing. Venison is often held at temperatures that could potentially allow bacteria to grow, such as when it is being transported. Refer to the USDA Meat and Poultry Department for further questions or information on meat and food safety.

SAUSAGE INFORMATION

MEAT SELECTION FOR SAUSAGE MAKINGSausage making has evolved over many years and generations, and as a result there are countless types of sausage you can make using the basic ingredients of meat, fat and a few carefully blended spices. Following are a few simple guidelines that will help you make the best tasting sausage possible.

Any type of meat can be used for making sausage: pork, beef, bison, moose and caribou, even antelope make great sausage. It is important when preparing venison or other red game meats to trim all the fat from the meat, as red game tallow will turn rancid in as few as five days. Replace the fat with either pork or beef fat, depending on the type of product you are making, at a ratio of 1 pound (0.5 kg) of fat for every 4 pounds (1.8 kg) of game meat.

The fat content of your sausage will affect the taste, texture, cooking characteristics and shelf life of your product. Most commercially made sausage has a fat content of about 20%. Using less than 12% fat will result in a very dry tasting sausage, while using more than 20% may result in a sticky flavorless sausage that will be difficult to cook.

CURINGIt is important to properly cure meats to preserve meat and poultry, and to destroy undesirable microorganisms on the meat surfaces that cause spoilage and foodbourne illnesses. There are many steps that help in this process, including smoking, cooking, drying, chilling and the addition of cure ingredients. The oldest means of accomplishing this is by introducing salt into the meat. The resistance of bacteria to salt varies widely among different types of bacteria. The growth of some bacteria is inhibited by salt concentrations as low as 3%, e.g., Salmonella, whereas other types are able to survive in much higher salt concentrations, e.g., Staphylococcus. Fortunately, the growth of many undesirable organisms normally found in cured meat and poultry products is inhibited at low concentrations of salt.

Modern curing is based on Nitrates and is very scientific. Purchase Weston Pink Curing Salt(02-0000-W) and follow the included instructions to ensure that you are properly curing your homemade sausage.

CASINGWeston offers a complete variety of casings. The right choice depends on personal preference as well as the type of sausage you wish to make. For most sausages, your choices are natural or collagen. Don’t let the names fool you; collagen casings are not a synthetic. They are made from beef skin and other tissues. Collagen casings are uniform in size and texture and require almost no preparation. “Natural” casings are the intestines of lamb, sheep, hogs or beef. They are less uniform in size and require preparation. There are also fibrous non-edible casings that are most commonly used for summer sausage and ring bologna

TYPES OF SAUSAGEMost sausages fall into one of four categories: Fresh, Smoked, Cooked or Dried. All sausages, except dried, require refrigerated storage. There is also a sub-category of uncooked smoked sausages.

Among the fresh and uncooked smoked sausages, you will find such flavors as kielbasa or Polish sausage, Italian sausage, breakfast sausage and many others. Both fresh and uncooked smoked sausages require cooking before eating and also require refrigerated storage.

Smoked and cooked sausages include salami, bologna, the ever-popular hot dogs and many others. Proper smoking requires a smokehouse or smoker. Weston offers Outdoor Propane Smokers in a variety of sizes (41-0701-W, 41-0301-W, or 41-0401-W). Most smoked sausages are warmed before serving. Many people think that a smoked sausage will last much longer without spoilage, but this is not true. Smoked sausages should be treated the same as fresh sausage in terms of storage.

Dried sausages require the longest processing time, as they are air dried over a long period of time. Dry cured sausages include salami, chorizo, pepperoni, among others. The conditions under which the meat is dried are very exacting; temperature, time and humidity must all be carefully monitored for a safe and delicious product.

STORAGEFor the best flavors, we recommend vacuum sealing your fresh sausages, then storing them in the refrigerator (short term) or freezer (long term). Weston manufactures a variety of vacuum sealers. Ask the retailer from which you purchased this unit for their selection. Store dry cured products in paper or other breathable wrapping, unrefrigerated.

ONE-YEAR LIMITED WESTON WARRANTY

This warranty applies to products purchased and used in the U.S. and Canada, which have been properly registered within 30 days of the date of original purchase. This is the only express warranty for this product and is in lieu of any other warranty or condition. This product is warranted to be free from defects in material and workmanship for a period of one (1) year from the date of original purchase. During this period, your exclusive remedy is repair or replacement of this product or any component found to be defective, at our option.

To register your product: complete the online form atwww.WestonProducts.com/Warranty.

This warranty does not cover unregistered products, unauthorized repairs or service to products, products sold “as-is” by retailers, glass, filters, wear from normal use, use not in conformity with the printed directions, or damage to the product resulting from accident, alteration, abuse, or misuse. This warranty extends only to the original consumer purchaser or gift recipient and is not transferrable. Keep the original sales receipt, as proof of purchase is required to make a warranty claim. This warranty is void if the product is subjected to any voltage and waveform other than as specified on the rating label (e.g., 120V ~ 60 Hz).

We exclude all claims for special, incidental and consequential damages caused by breach of express or implied warranty. All liability is limited to the amount of the purchase price. Every implied warranty, including any statutory warranty or condition of merchantability or fitness for a particular purpose, is disclaimed except to the extent prohibited by law, in which case such warranty or condition is limited to the duration of this written warranty. This warranty gives you specific legal rights. You may have other legal rights that vary depending on where you live. Some states or provinces do not allow limitations on implied warranties or special, incidental, or consequential damages, so the foregoing limitations may not apply to you.

Before returning the product for any repair or service: it must be clean and free from any food particles or other debris; otherwise, we will return it or impose a $50 cleaning surcharge, at our option.

To make a warranty claim: go to www.WestonProducts.com/Contact; or call 1.800.814.4895 in the U.S. and 001.440.638.3131 outside the U.S., Monday – Friday, 8 am – 5 pm Eastern. You are responsible for all costs associated with shipping us the product freight prepaid. If the product qualifies for a warranty repair or replacement, we will bear the cost of returning it to you. We are not responsible for shipping damage.

For non-warranty work: call 1.800.814.4895 in the U.S. and 001.216.801.6801 outside the U.S., Monday – Friday, 8 am – 5 pm Eastern, to obtain a Return Merchandise Authorization Number (RMA Number). We will refuse all returns without an RMA Number. We charge US$35/hour for all diagnostic, service, repair and processing work. We will not start any service or repair work without prior authorization. You are responsible for all costs associated with shipping us the product freight prepaid and our returning it to you.

ATTENTION!PLEASE INSPECT THIS PACKAGE THOROUGHLY FOR MISSING PARTS OR ANY PRODUCT DAMAGE. IF YOUR PRODUCT CONTAINS SHIPPING DAMAGE, PLEASE CONTACT RETAILER FOR ASSISTANCE.

For all other questions regarding product usage, missing parts, product damage, difficulty or warranty activation, please contact the Weston Brands Customer Service Team:8:00 am to 5:00 pm ET, Monday thru Friday

U.S. Residents Customer Service Line: 1-800-814-4895 (Outside U.S. Call: 001-216-801-6801)Weston Brands LLC, Cleveland, Ohio 44149WestonProducts.com

Please DO NOT return this item to the retailer before contactingWeston Brands Customer Service.

SAVE THESE INSTRUCTIONS!Refer to them often and use them to instruct others.

WESTON 36-0801-W, 36-1001-W, 36-2201-W, 36-3201-W Meat Grinder and Sausage Stuffer Manual – WESTON 36-0801-W, 36-1001-W, 36-2201-W, 36-3201-W Meat Grinder and Sausage Stuffer Manual –

Questions about your Manual? Post in the comments!

[xyz-ips snippet=”download-snippet”]