User’s ManualWS-68N30SSWS-68N36SSWS-68N42SS

ISLAND SERIES

NOTE: PLEASE INSPECT HOOD IMMEDIATELY UPON RECEIVING. CLAIM OF DAMAGE AFTER 7 DAYS OF DELIVERY WILL BE DENIED.This unit is designed for indoor residential use only. DO NOT USE OVER A WOOD GRILL OR MOUNT IN AN OUTDOOR ENVIRONMENT.

Please read this operation manual thoroughly before using your range hood. Store it in a safe location for when you need to reference it in the future.

Please read this operation manual thoroughly before using your range hood. Store it in a safe location for when you need to reference it in the future.

SAFETY INFORMATION

![]() TO REDUCE THE RISK OF A FIRE, ELECTRICAL SHOCK, AND/OR INJURY OBSERVE THE FOLLOWING:

TO REDUCE THE RISK OF A FIRE, ELECTRICAL SHOCK, AND/OR INJURY OBSERVE THE FOLLOWING:

- Unit is intended for indoor residential use only. If you should have questions, contact the manufacturer at the address or telephone number listed in the warranty.

- In case the unit should need to be cleaned or repaired, switch power off at service panel and lock service disconnecting means to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

- Installation work and electrical wiring must be done by a qualified technician in accordance with all applicable codes and standards, including fire-rated construction.

- Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel-burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

- Because the unit is made of stainless steel, it may contain sharp edges. Be careful to avoid cuts and abrasions by wearing protective gloves during installation and cleaning.

- Before you begin to cut or drill into the wall, verify that there is no electrical wiring or any other hidden electrical components.

- Ducted fans must always be vented to the outdoors.

- The unit must be properly grounded and installed at the recommended height before beginning operation.

- To reduce the risk of fire, use only metal ductwork.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Regardless of heat level, never leave any surface materials unattended while operating an open flame.

- Always turn hood ON when cooking at high heat or when flambéing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

- Depending on amount of usage, clean ventilating fans and filters frequently. Grease should not be allowed to accumulate on fan or filter. For instructions on the how to clean, see the maintenance page.

- Never leave surface units unattended at high settings. Boil-overs may cause smoking and greasy spillovers may ignite as result. Heat oils slowly on low or medium settings.

- Use proper pan size. Always use cookware appropriate for the size of the surface element.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL 911.

- NEVER PICK UP A FLAMING PAN —Doing so may result in serious burns and possibly spread the fire.

- DO NOT USE WATER – Grease fire must be extinguished before further action may be taken. Using water will agitate the grease and may cause a violent steam explosion.

- Use a Fire Extinguisher ONLY if:

- You know you have a Class ABC extinguisher, and you already know how to operate it.

- The fire is small and contained in the area where it started.

- The fire department is being called.

- You are able to safely control the fire with your back to an open exit. *Based on ―Kitchen Fire safety Tips‖ published by NFPA.

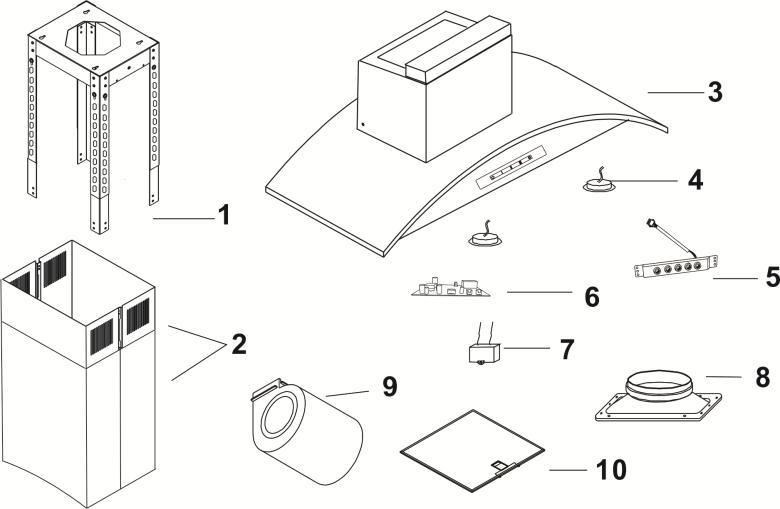

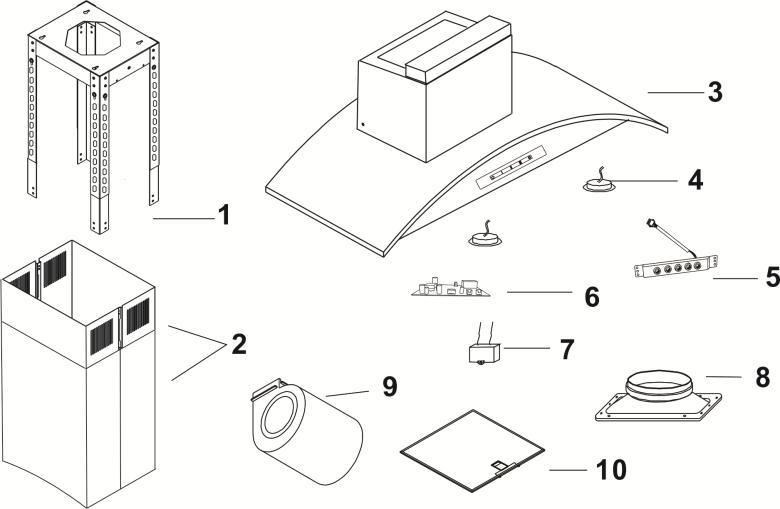

CONTENT CHECKLIST

- CONTENTS INCLUDEDa. (1) WS68-N series (30‖, 36‖ or 42‖) hood assemblyb. (1) Lower duct cover (16-1/2‖)c. (1) upper duct cover (22-3/4‖)d. (1) User’s manuale. (1) 7‖ Damper transition adapter collarf. (1) Aluminum Filter (30‖ model)g. (2) Aluminum Filters (36‖/42‖ model)h. (1) Screw packeti. (1) Duct cover support bracket

- CONTENTS NOT INCLUDEDa. WS68-NLDC (Long duct cover)b. WS68-NSDC (Special duct cover)c. WS68-NBF (Baffle filter)d. WS68-NDK (Ductless kit)e. WS68-NCF (Charcoal filter)f. WS68-NCFMR (CFM reducer)g. 7′ Aluminum or metal piping

- TOOLS REQUIRED (NOT INCLUDED)a. Safety glovesb. Safety glassesc. Electric drill w/ starter bitd. Utility knifee. Spirit levelf. Measuring tapeg. Writing instrument (pen, marker, pencil)h. Aluminum tape

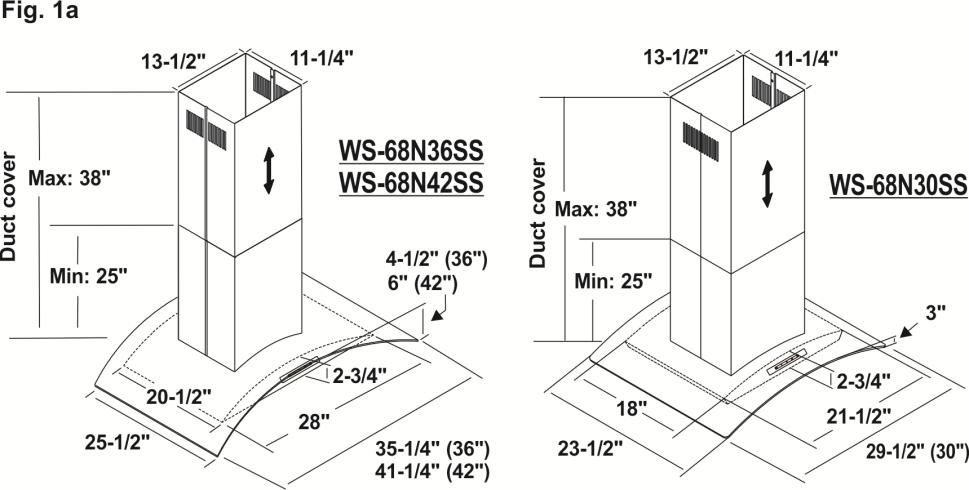

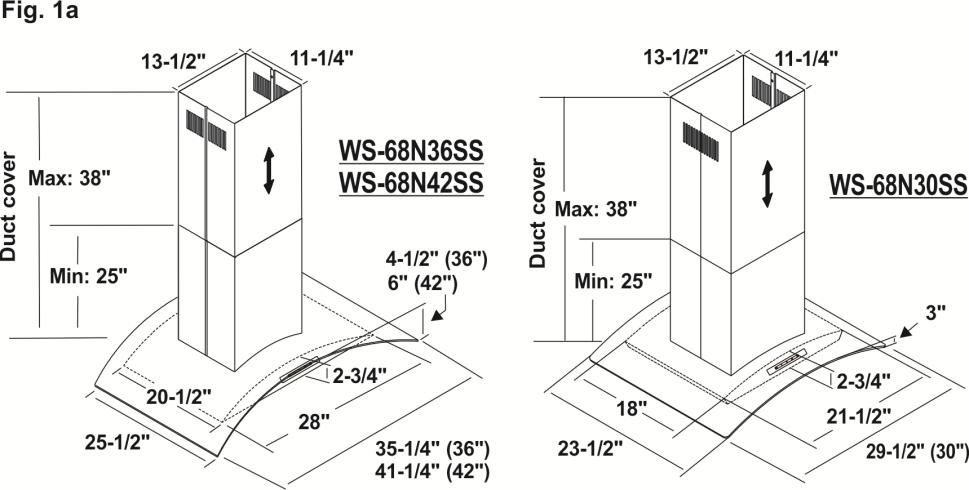

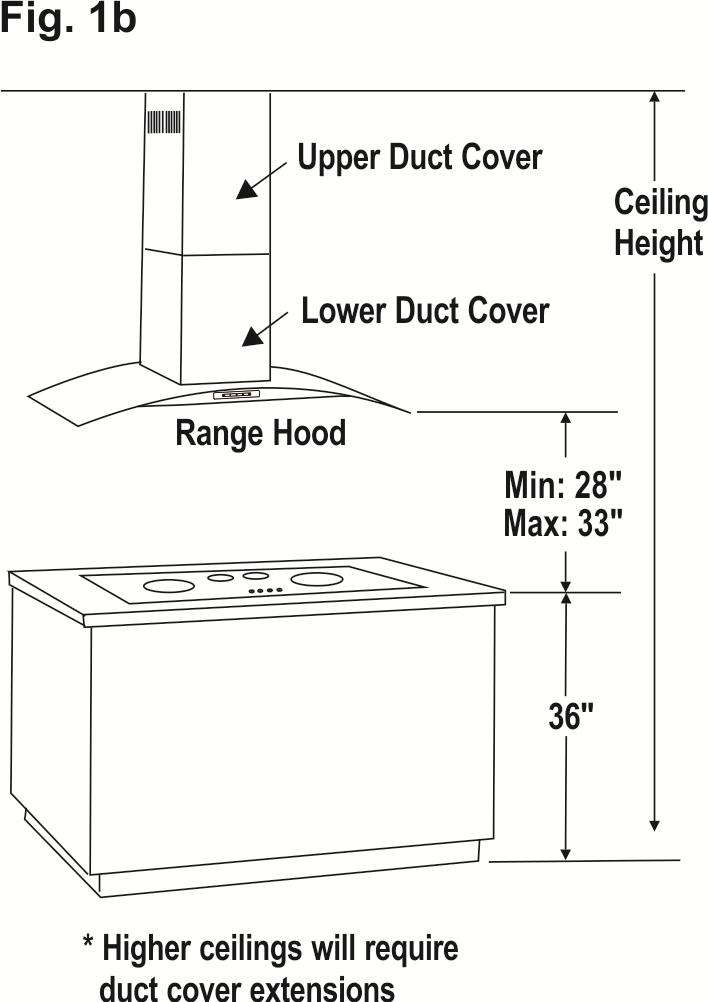

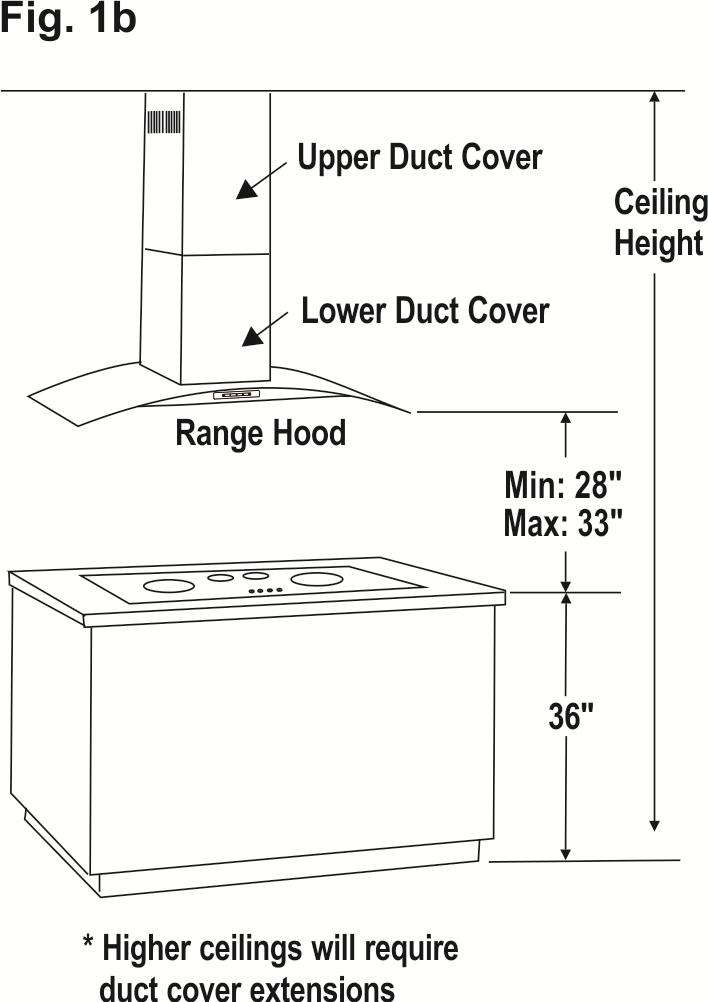

MEASUREMENTS

PREPARATION

- BEFORE YOU START**BE SURE YOUR UNIT WILL FIT YOUR CEILING HEIGHT****DO NOT INSTALL IF DAMAGED****RETURN OR EXCHANGE WILL BE DENIED IF INSTALLED**a. Be sure you have all the content of your purchase and required tools for this installation.b. Installation may take at least 2 to 3 hours from start to finish.c. Plan to use as few elbows or turns as possible for more efficient air flow.d. Collar size may need to be increased if utilizing a long duct run.e. Turns must be made after passing ceiling.f. Do not try to install this unit by yourself, SERIOUS INJURY MAY OCCUR.g. At least two people are needed for installation.h. Hiring a certified installer and electrician is recommended.

- LOCATION**THIS MODEL MAY NOT FIT ALL CEILING HEIGHTS**a. Determine the exact location you where want to install the range hood.b. Recommended distance between cooktop and range hood is 28‖ – 33‖.c. Range hood should be mounted at stated measurements to ensure performance and lifespan of electrical components.d. Correctly measure the dimension needed to install the unit.

- HOODa. Inspect for any sign of defect or damage. (ie. scratches, dents, loose seams, etc.)b. Power up the unit to make sure it is working properly.

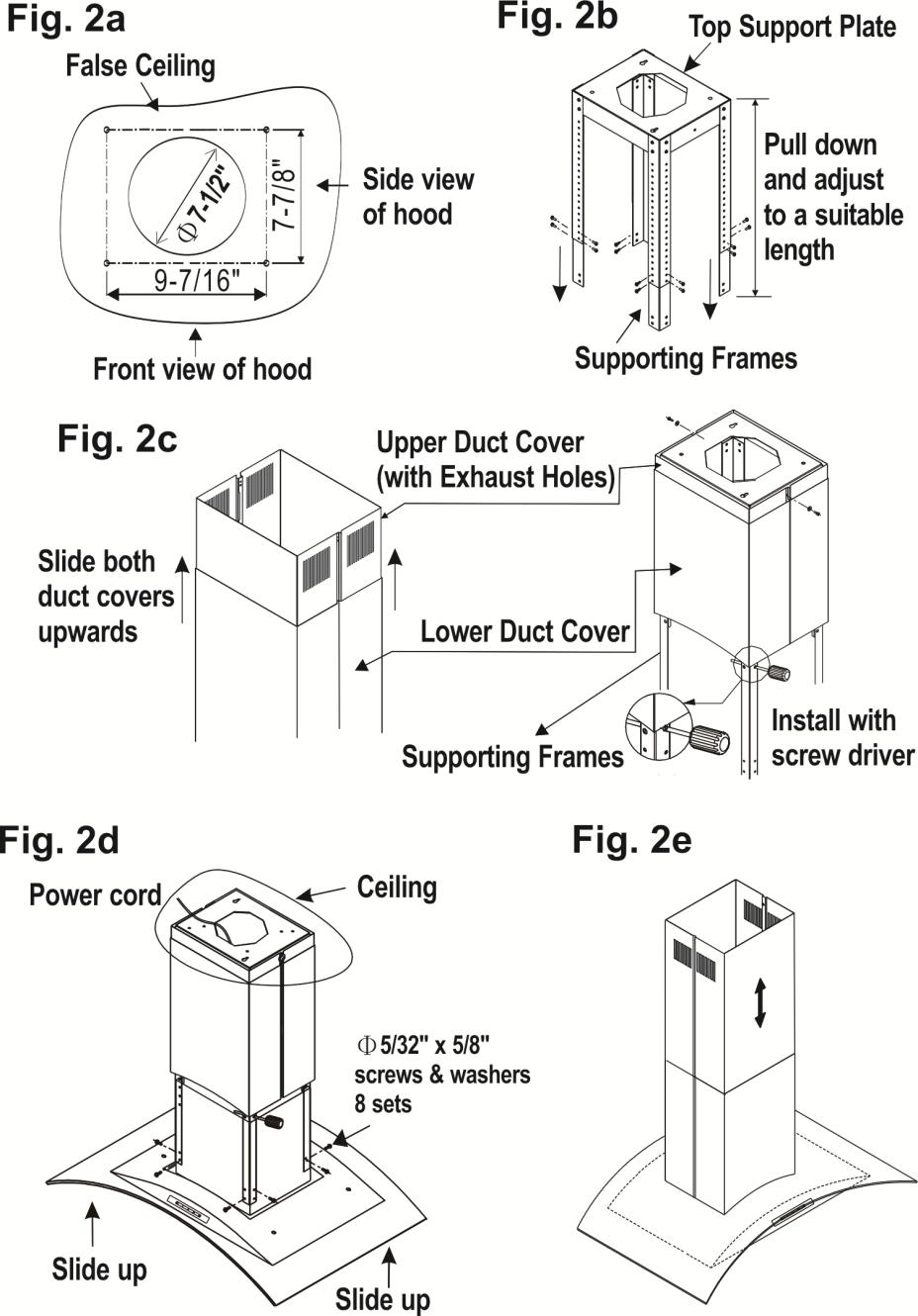

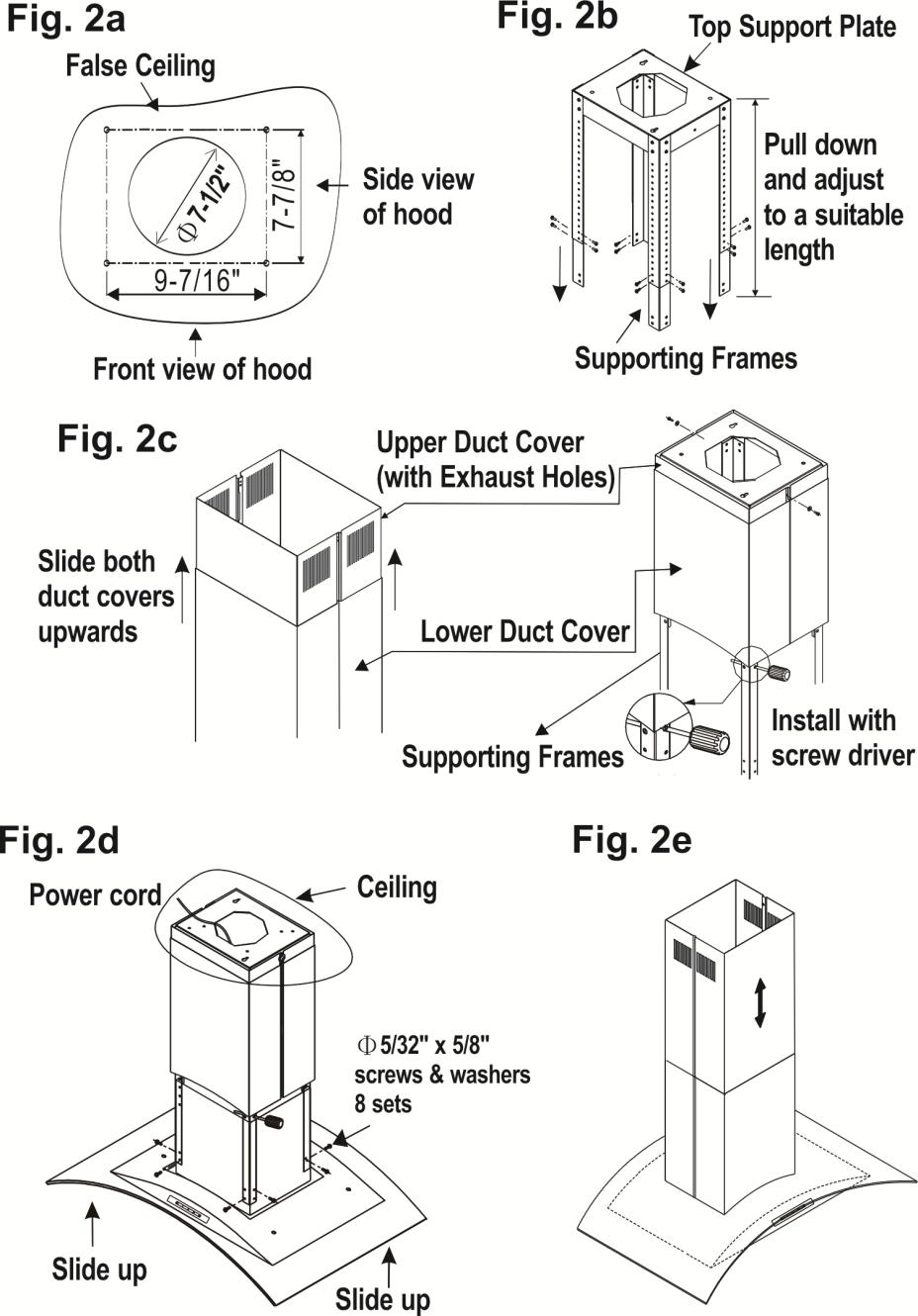

Use Fig. 1a and 1b on page 5 for measurements

INSTALLATION

- STANDARD INSTALLATIONa. Make sure all preparation steps are completed.b. Determine your ceiling height to see if you need an extension.i. Hood unit (with glass) height = 3-1/4″ (30″ model only)ii. Hood unit (with glass) height = 4-1/4″ (36″ model only)iii. Hood unit (with glass) height = 6‖ (42″ model only)iv. Standard DC height = 16-1/2‖ (lower) + 22-7/8″ (upper)v. Minimum height (Standard duct cover only) = 24-3/4″vi. Minimum height (Standard duct cover w/ DK) = 24-3/4″vii. Maximum height (Standard duct cover only) = 38-5/8″viii. (OPTIONAL) WS-68NLDC height = 22-7/8″ (lower) + 36-1/4″ (upper)ix. (OPTIONAL) Long DC minimum height = 40″x. (OPTIONAL) Long DC maximum height = 55-1/8″xi. (OPTIONAL) WS-68NSDC height = 36-3/16″ (lower) + 39-1/4″ (upper)xii. (OPTIONAL) Special DC Minimum height = 42-3/16″xiii. (OPTIONAL) Special DC Maximum height = 75-1/4″xiv. Standard Installation = Hood + standard DCxv. 9’ – 11’ Installation = Hood + Long DCxvi. 11’ – 12’ Installation = Hood + Special DCc. Determine the location you want to install the range hood. (Fig. 2a)d. Prepare ceiling and locate wood support.e. Mount the unit upper support frame to the ceiling.f. Cut a 7‖ round opening at the ceiling for ducting pipe.g. Adjust the (4) arms to desired height. (Fig. 2b)h. Attach upper duct cover to upper support frame.i. Use a spirit level to ensure the balance of the support frame is true.j. Slide lower duct cover toward ceiling and hold. (Fig. 2c)k. Install ducting through the ceiling.l. Secure hood from all sides with the (8) screws. (Fig. 2d)m. Installation is complete when hood is securely in place. (Fig. 2e)

- EXTENSION INSTALLATION (OPTIONAL)a. AFTER COMPLETING STEP A – D OF STANDARD INSTALLATION, replace the standard support frame and duct cover with either the extension set or the short duct cover set.b. REPEAT “STEP F – M” from STANDARD INSTALLATION.

- COLD WEATHER INSTALLATION (OPTIONAL)a. Check with your local building codes to see if a CFM reducer is an acceptable alternative to make-up air.b. Remove the WS68-NCFMR (CFM Reducer) and inspect for any sign of defect or damage. (ie. Cracks, broken flips)c. AFTER COMPLETING Step A – J of STANDARD INSTALLATION, place the CFM reducer onto the outlet of the unit and seal the connection point with aluminum tape. (Be sure it is secure with no opening or gaps)d. Connect piping to the outlet of the hood.e. Installation is complete when hood is securely in place.

- DUCTLESS INSTALLATION (OPTIONAL)a. AFTER COMPLETING Step A – E of STANDARD INSTALLATIONb. Remove the WS68-NDK (ductless kit) and inspect for any sign of defect or damage. (ie. dents, broken inlet)c. Attach the ductless kit to the support frame and secure with screws.d. Install the upper duct cover and secure it to the support frame.e. Slide the lower duct cover up to the upper duct cover and hold in place.f. Connect a 6‖ or 7‖ pipe between the ductless kit and the hood outlet.g. REPEAT “STEP G – M” from STANDARD INSTALLATION.

Installation diagram available on next page

INSTALLATION DIAGRAM

CLEANING & MAINTENANCE

OPERATION & FEATURES

- 2. ALUMINUM FILTERSa. (1) Aluminum filter (30‖ model)b. (2) Aluminum filters (36‖ / 42‖ model)a. Sensor 1 – Dual purpose (Power / Delay Shut-off function 1 minute)b. Sensor 2 – Low Speedc. Sensor 3 – Medium Speedd. Sensor 4 – High Speede. Sensor 5 – Light SwitchRemark:During operation when press ―Sensor 1‖, then hood will automatically shut off after 1 minute. If want to avoid the countdown process, just press ―Sensor 1″ again, the hood will stop immediately.

- ALUMINUM FILTERSa. (1) Aluminum filter (30″ model)b. (2) Aluminum filters (36″ / 42″ model)

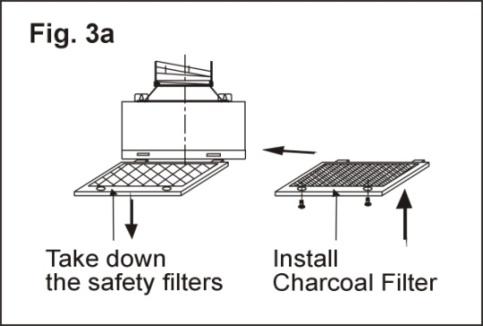

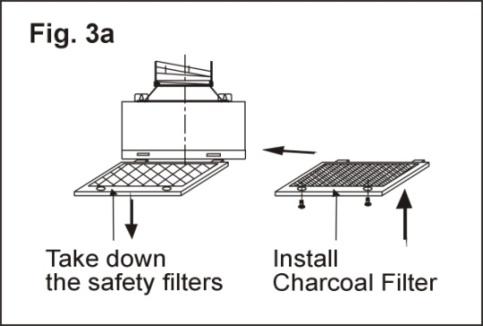

- CHARCOAL FILTERS**DO NOT WASH CHARCOAL FILTERS! IT WILL DISSOLVE!!**a. Replace safety filter with charcoal filter. (Fig. 3a)b. Installation is complete after the charcoal filter is secured in place.c. When to replace a charcoal filter will depend on:i. How often you cook.ii. How long you cook.iii. Types of food you cook

WARNING!!!.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- RANGEHOODa. Use household cleaner to remove grease or dirt from the outer shell of the unit. Spray on wiping cloth or sponge and wipe in the direction of the grain to avoid scratching the unit. (DO NOT SPRAY DIRECTLY ONTO UNIT)b. Clean the inner working of the unit periodically to avoid grease build-up.c. Do not open control switch panel while the hood is connected to power.d. Use stainless steel cleaner to bring back the luster of the unit.

- ALUMINUM FILTERa. Remove aluminum filter from unit and place in warm soapy water.b. Clean the filter regularly to maintain efficient suction power.c. Do not drop filter.d. Let it soak thoroughly and then clean it with a wiping cloth or sponge.e. Filter may also be cleaned using residential dishwasher.

TROUBLESHOOTING

WARNING!!!.![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

| WS-68N Series | |

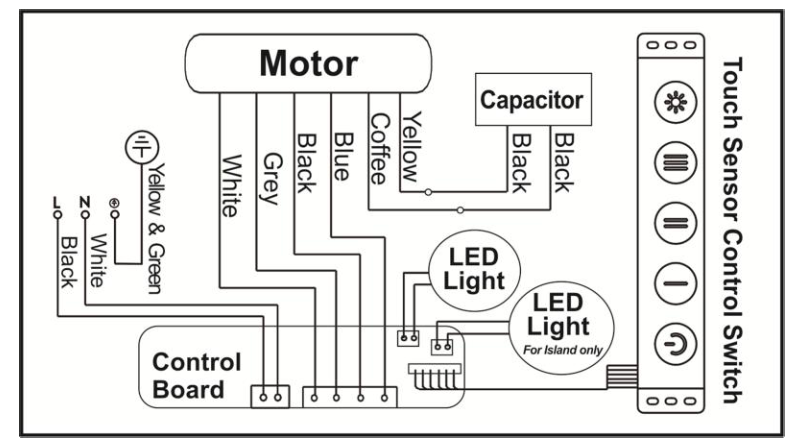

| Light issue LED (All not turning on) | 1.Locate and Replace defective Fixture (All Fixtures run on same circuit).2.New Transformer/ Driver replacement may be required |

| Speed Levels/Controls not working correctly | 1.Complete control switch replacement may be required.2.Check Ventilation / Ducting if installed property. |

| Burnt/melted control switch | 1. Complete control switch replacement is required. |

| Speed levels not working correctly | 1.Ensure all Wiring from Control Switch and Top Junction Box are correctly connected.2.Complete Capacitor replacements may be required. |

| Unit lacking smoke intake | 1.Check ducting for foreign object.2.Ensure the ducting is properly sealed.3.Clean filters to increase airflow. |

| Unit showing no power indication | 1.Ensure power source is working properly.2.Ensure all Wiring from Control Switch and Top Junction Box are correctly connected. |

| Unit making humming noise/motor not starting | 1.Check Ducting / Dampers for proper installation.2.Replace defective capacitor with new one.3. Check/replace defective motor. |

| Loads from coming oad Grinding or Noise like motor | 1.Check if fans are spinning property.2.Ensure Articles have not fallen into Motor Housing3.Complete Motor/Motor Housing may be required. |

| Defective LED Fixture | 1. Replace LED Fixture with New LED Fixture |

PART LIST / REPLACEMENT / WIRING DIAGRAM PART LIST / REPLACEMENT

PART LIST

| # | Description | # | Description |

| 12345 | Chimney Supporting FramesDuct coverHood body assemblyLED lightsTouch sensor control switch | 678910 | Control BoardCapacitorTransition collarSquirrel cage motorAluminum filter |

WIRING DIAGRAM

WARRANTY / CONTACT US

LIMITED WARRANTY

Windster Hoods Inc. warrants its product against defects in material or workmanship as follows:

Labor: For a period of one (1) year from the date of purchase, if the product is determined to be defective, Windster will attempt to repair the product, at its option, at no charge. After the warranty period, customer must pay for all labor charges. During the “labor” warranty period there will be no charge for any work done on the purchased model. (All labor repairs are limited only to the installation of electrical components.)Parts: In addition, Windster will supply, at no charge, new or rebuilt replacements in exchange for defective parts for a period of two (2) years. After the warranty period, you must pay for all parts costs. During the “parts” warranty period, there will be no charge for parts

You must provide the serial number of your unit for any replacement parts during the warranty period. This warranty applies to products purchased and serviced in the United States only.For products purchased in Canada, please contact your local retailer where you purchased the unit for service.

* Windster Hoods, Inc. will attempt to repair malfunctioning units prior to shipping a replacement. In the case that a unit cannot be repaired and must be replaced, Windster Hoods, Inc. will not be held liable for removal/installation fees of the malfunctioning /replacement unit.

WARRANTY / CONTACT USWHAT IS NOT COVERED BY MANUFACTURE WARRANTY

- Damages resulting from any of the following:a. Improper installation or maintenanceb. Any repair, modification, alteration or adjustment not authorized by the manufacturer or an authorized service dealerc. Misuse and/or accidentsd. Incorrect electric current, voltage or power supplye. Improper setting of any control (Pressing multiple selections at the same time)f. Improper chemical cleaning (commercial or industrial cleaning agents)

- Products purchased for use in a commercial or industrial setting (such as in a hotel, office, restaurant, or other business)

- Damage resulting from natural disasters (earthquake, flood, storm, etc.)

- Aluminum Filters, Baffle Filters, Charcoal Filters, and Oil Cup Filters 5. Light Bulbs

CONTACT USWindster Hoods, Inc.E-mail: [email protected]Windster Hoods, Inc.Information subject to change without notice

[xyz-ips snippet=”download-snippet”]