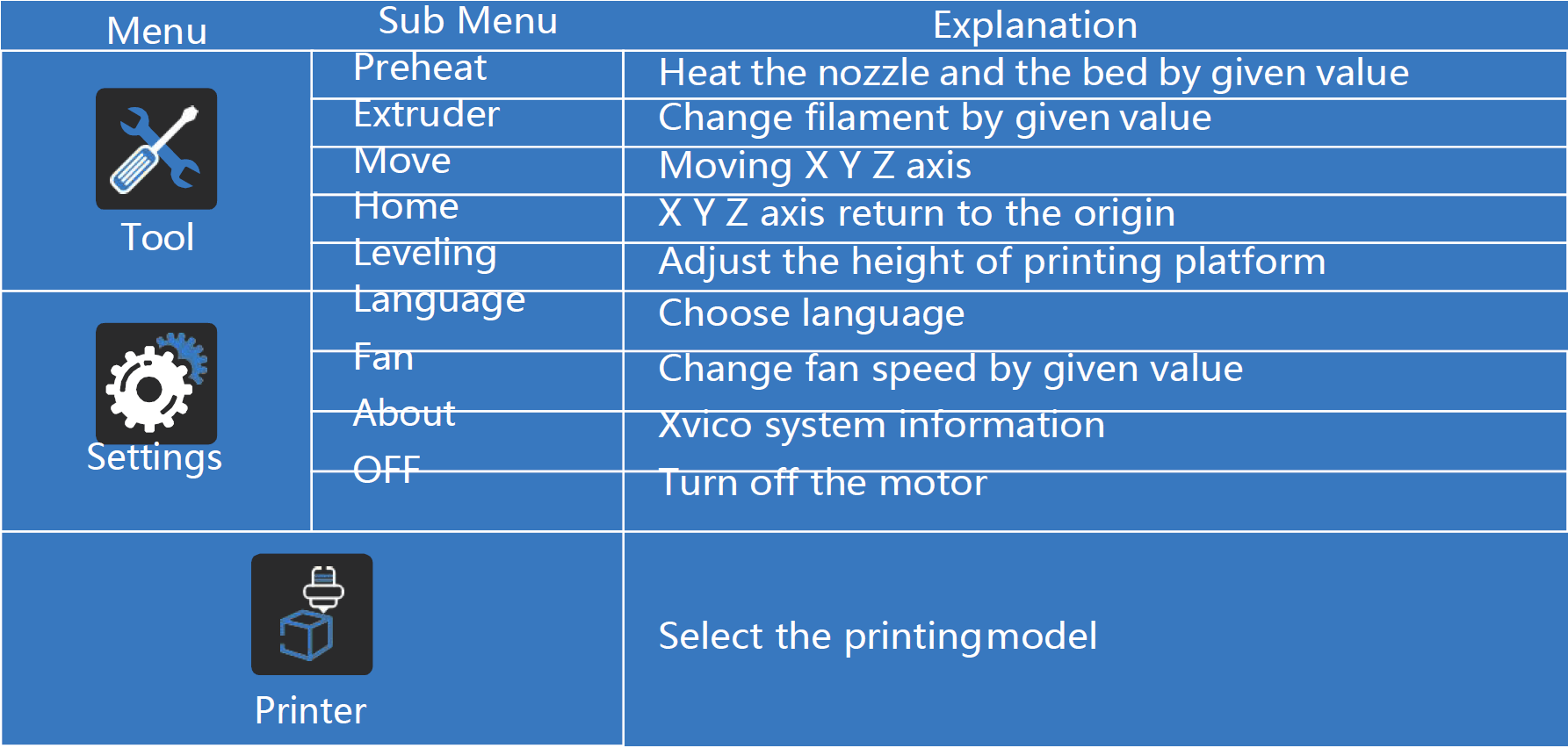

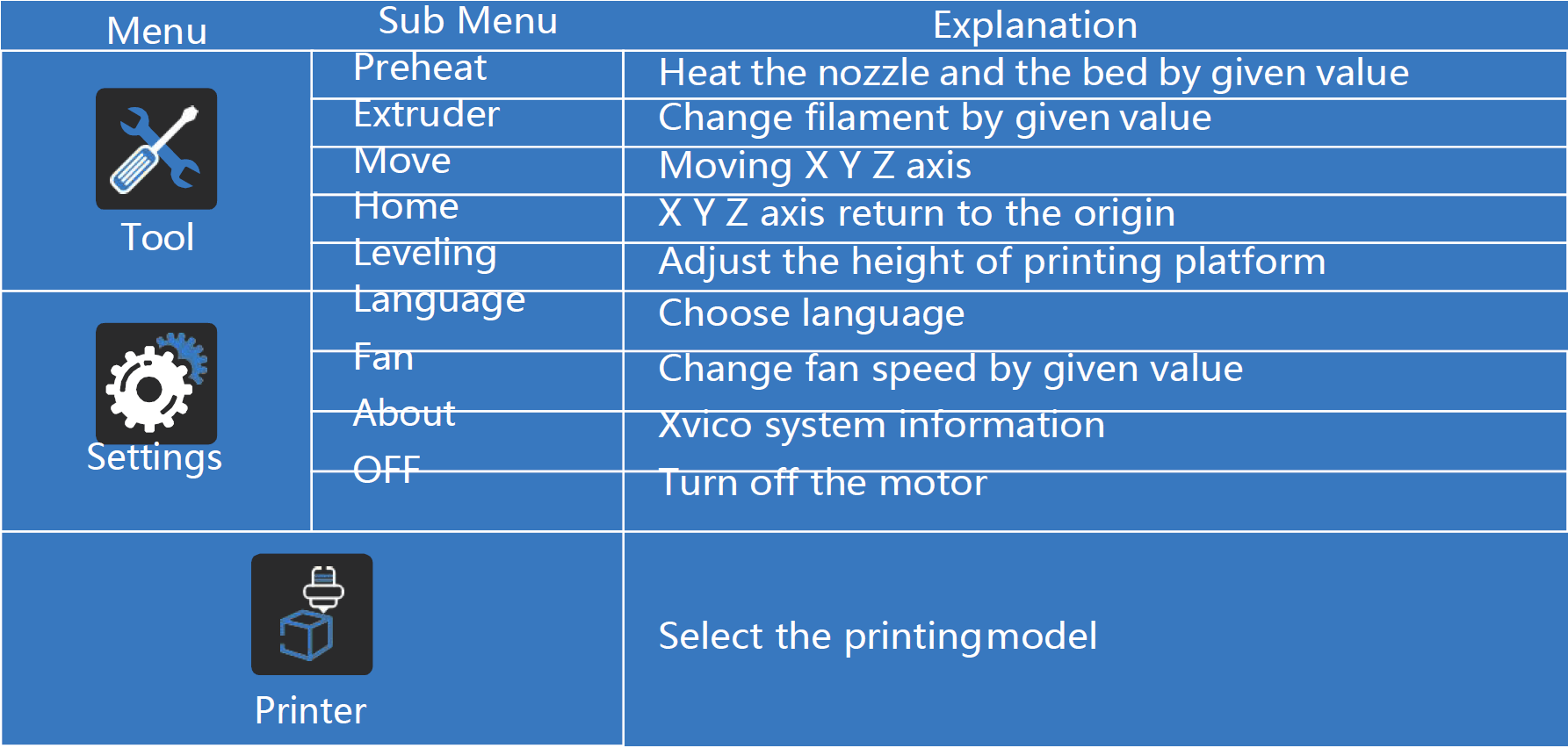

XVICO X3S 3D Printer

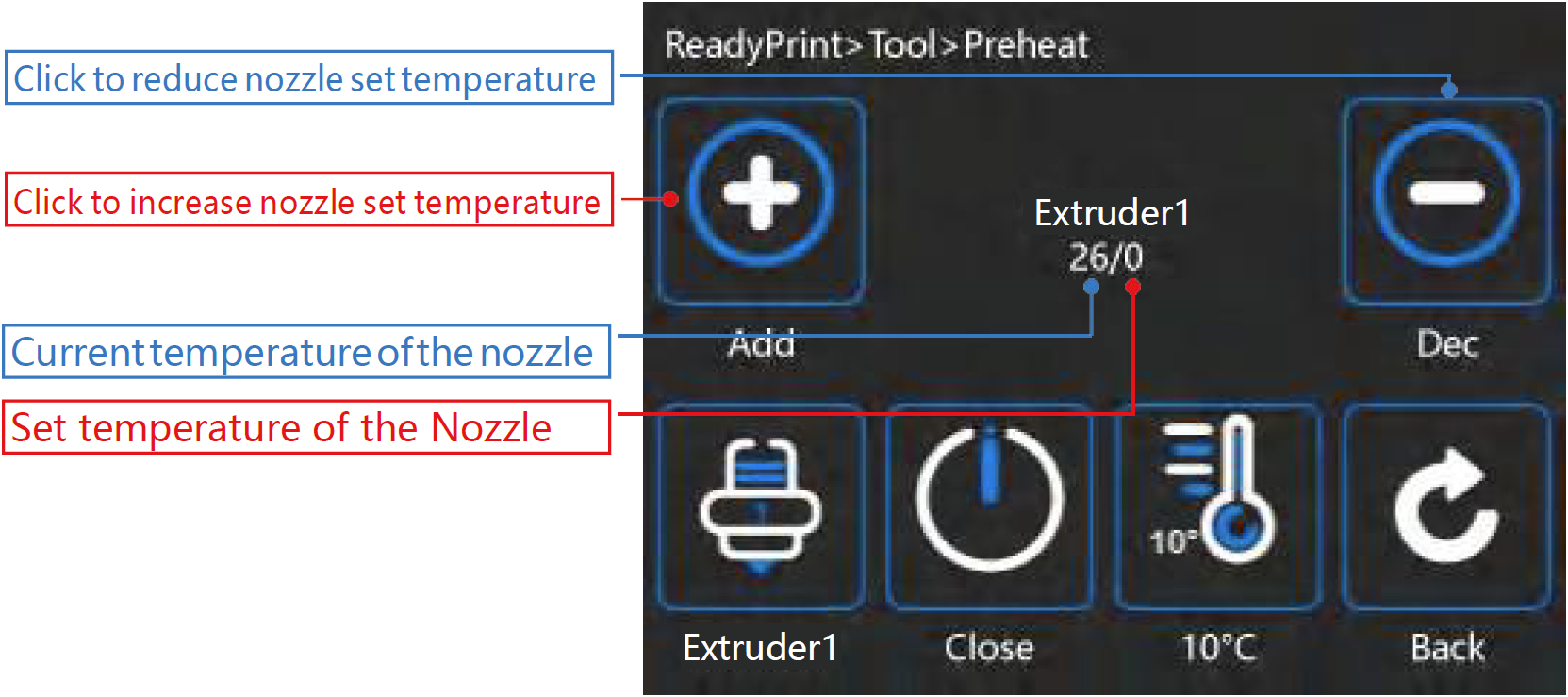

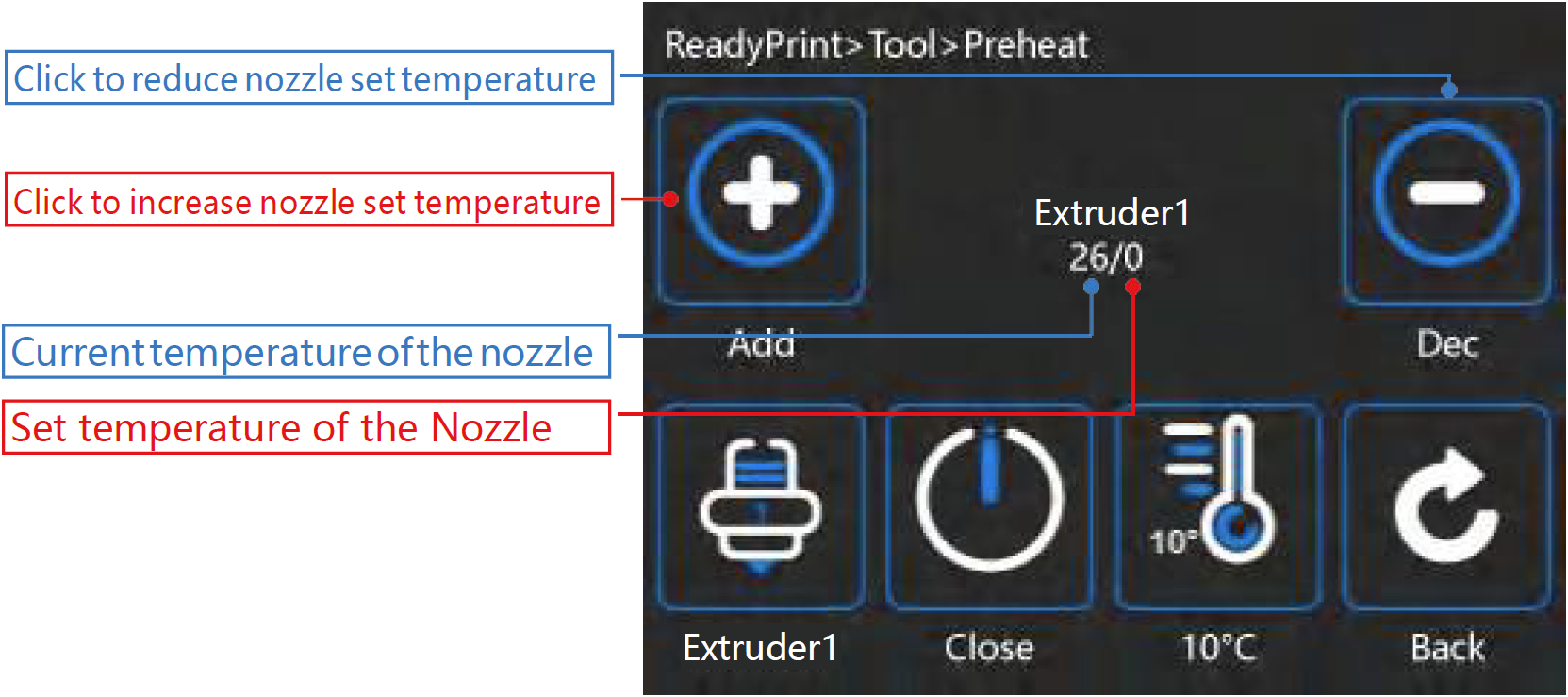

Preheat

You can set the nozzle and hot bed temperature in the preheating interface. Click the nozzle icon to switch to hot bed heating mode.

Extruder

Press and hold the extruder lever then insert 1.75mm filament through the small hole of the extruder. Continue feeding until you see filament come out of the nozzle.

Tip: Replace Consumables

- The extruder needs to be heated to the corresponding temperature of consumables

- Preheat the nozzle, after reaching the extrusion temperature, draw back the consumables until the consumables come out of the extruder(Note: the consumables can be extracted manually by pressing the black gas pipe connector)

- Put 1.75mm consumables into the feeding port of extruder

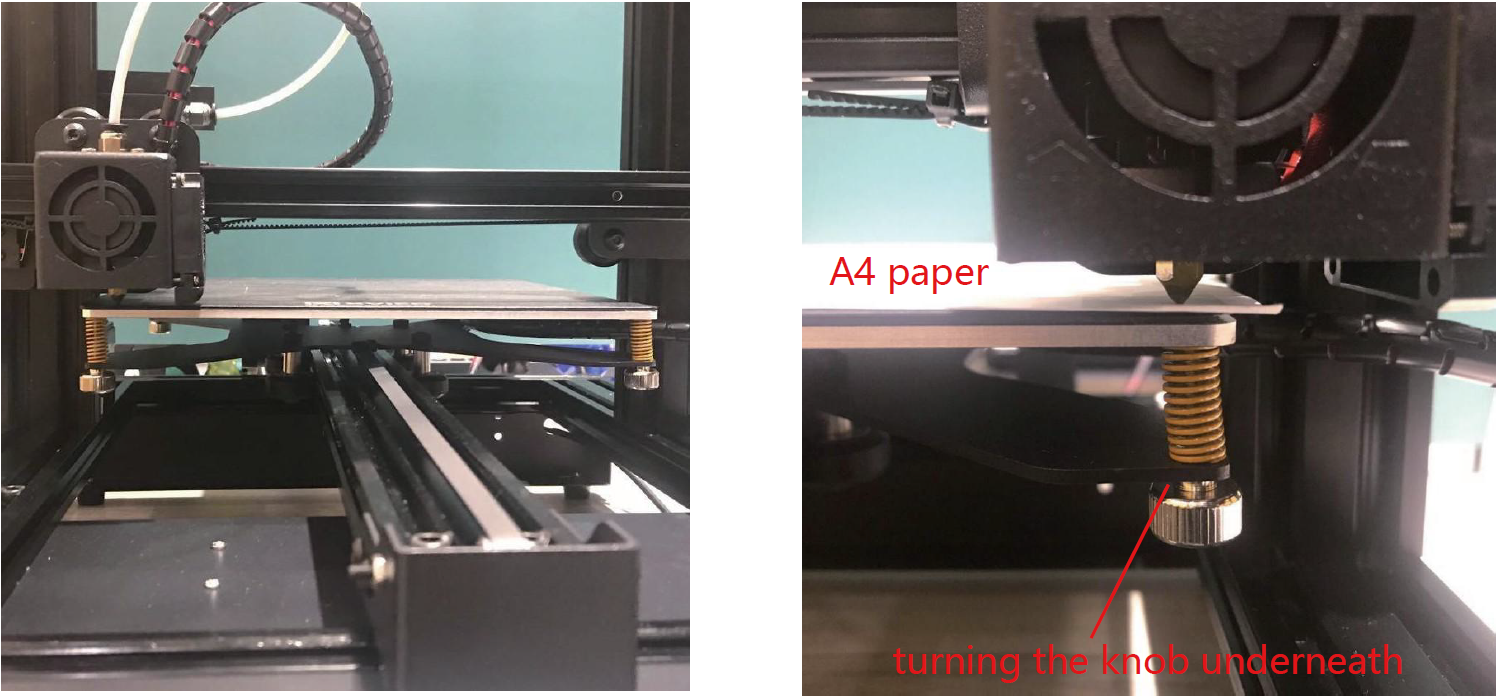

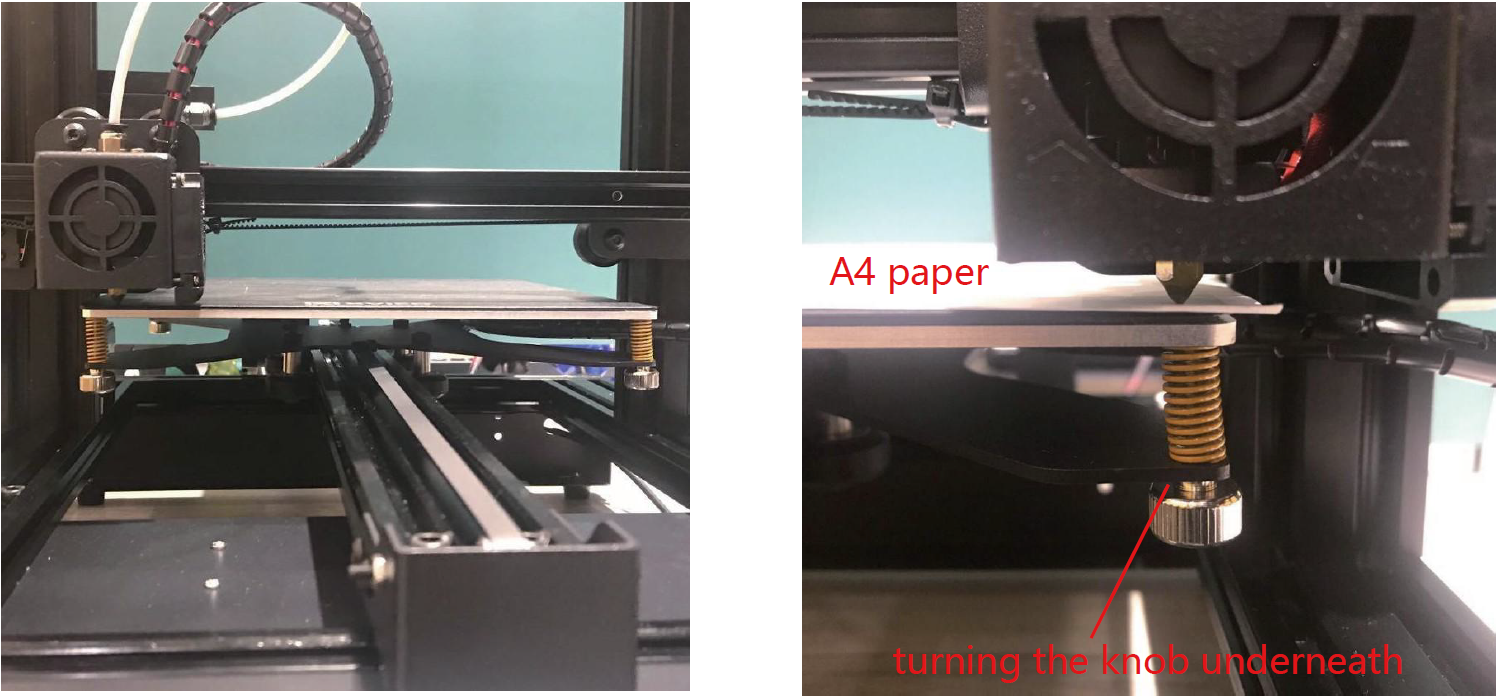

Leveling

- Tool →Leveling. Click point1 Wait for the nozzle to move to the left/front of the platform.

- Move the nozzle the front/left leveling screw and adjust the platform height by turning theknob underneath. Use a piece of A4 paper (standard printer paper) to assist with the adjustment, making sure that the nozzle lightly scratches the paper.

- Complete the adjustment on all 4 corners

- Repeat above steps 1-2 times if necessary.

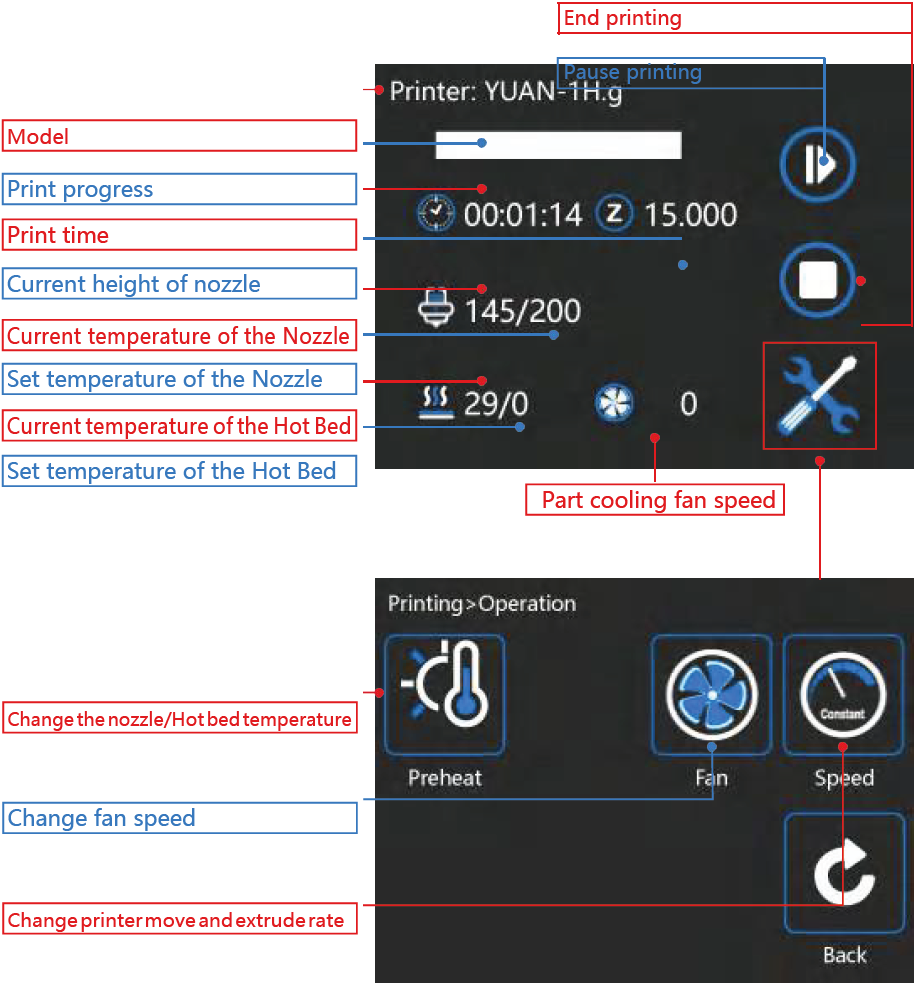

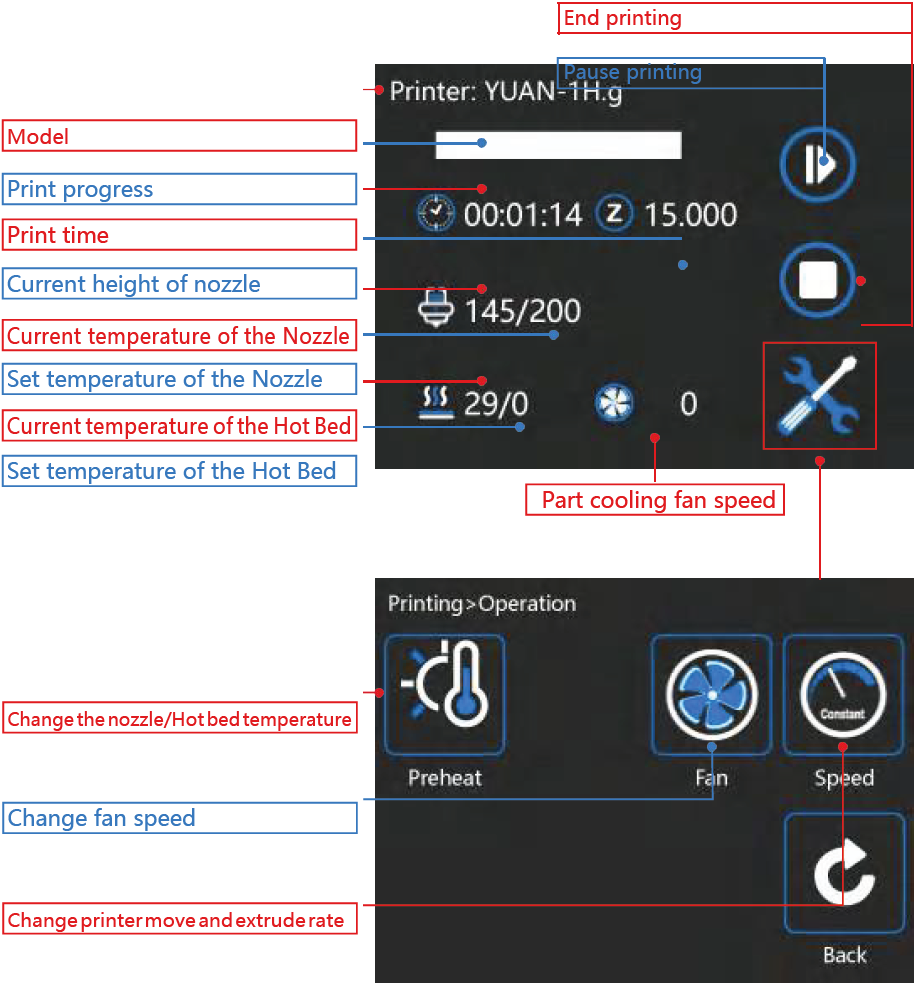

You can change the nozzle / hot bed temperature, fan speed, printspeed and other related values in the operation interface

Maintenance

The 3D printer can continue to operate for a long time. For some long-time working parts, especially some moving parts, it needs to be maintained. Here are some instructions on how to care for your machine:

- Maintenance of X,Y,Z axis : Add some lubricants on the rods to reduce friction when the machine works noisy and a little bit shake. Take a clean cloth, add some oil, and slide it back and forth on the slide bar.

- Filament are not easily pulled out from the extruder after being melted at high temperature and cooled, and use iron wire to dredge outlet. Of course, we still recommend that you empty the extruder as much as possible after the print job is finished. This is also the basic maintenance of the 3D printer.

- Belt tightness: The tightness of the belt should be suitable, otherwise it will affect the service life of the belt. The belt is too tight and the radial force of the motor axis and the pulley is too large, which affects its service life. After the belt is installed, you can judge whether the belt is too tight by turning the pulley. When the belt is pulled, if the belt makes a loud sound, it means that the belt is too tight. If the belt is too loose, it will cause transmission error and affect the printing effect. Test whether the belt is loose, you can rotate the motor synchronous wheel in the opposite direction and positive direction. If the moving distance of extruder before and after is not equal, indicating too loose; you can also press the middle of the belt, if you gently press the belt arc is verylarge, indicating that the belt is too loose; there is a test method is to download cylindrical data, if one side is flat, it means that the shaft on this side is too loose.

Maintenance

- This product executes regulations of “Product Warranty Card”.

- Please contact supplier or customer service if the product have any problems . Do not repair it by yourself, otherwise you need to bear all the consequences.

Amazon support: [email protected]Ebay Support: [email protected]Skype: XVICOXVICO Facebook Group( XVICO 3D Printer Owners): https://www.facebook.com/groups/583066442160349 Website: www.xvico3d.comShenzhen Zhongxin Microscience Software Co., Ltd

References

[xyz-ips snippet=”download-snippet”]