Stainless Steel SinksInstallation Guide and Users Manual

Each ZLINE sink is handcrafted and intuitively designed to offer the most efficient washing experience. Inspired by professional kitchens, every sink is versatile and spacious. The extra-deep, high-capacity basins easily accommodate large pots, pans, and plates. With over 10 inches of depth, there is maximum room for any size wash job.

The geometric design silences sound and creates a quieter workspace. With its stain, scratch, and rust-resistant properties in addition to superior drainage, your new ZLINE sink will provide more usable space and eliminate free-standing water up to three times faster than competitors.

ZLINE is fueled by a passion for innovation; A relentless pursuit of bringing the highest-end luxury designs and professional features into everyone’s homes. Because we continually strive to improve our products, we may change specifications and designs without prior notice.

SAFETY INSTRUCTIONS

- The installer and/or user must read, understand, and follow these instructions before installing the product. This product must be properly installed before it is used. If instructions are not followed, the manufacturer will not be held responsible for any problems or product malfunction. Failure to follow installation and/or operating instructions voids the warranty.

- We recommend that this product be installed by a certified plumber. In some states or provinces, it is a legal requirement for this type of product to be installed by a certified plumber, according to the plumbing and building codes effective in the region where the sink is used.

- Shut off the water valves before installing the sink or doing any maintenance.

- Open the sink packaging and verify that the sink is in perfect condition. Put the sink back in its packaging to protect it until the time of installation.

- To replace a sink, ensure that the hole in the counter is adequate.

- The outermost measurement on the sink diagrams is the lip. The innermost measurement on the sink diagrams is the basin.

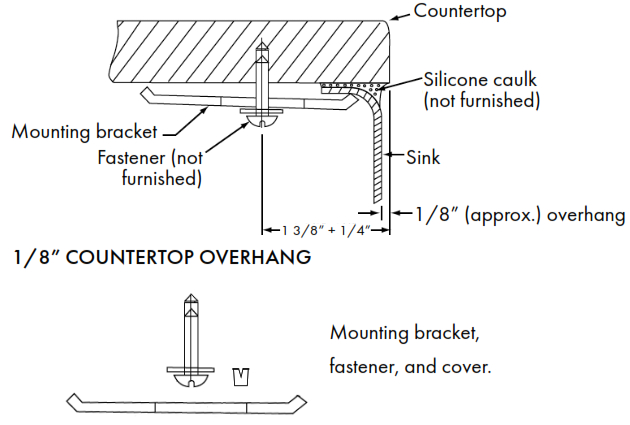

- If you have a sink with 1/8” overhang, the enclosed cutout template will create an overhang of approximately 1/8”. It is recommended that you discuss this with your customer and agree that this finished appearance is the desired effect. ZLINE is not responsible for improper sink or countertop installations. Due to the aesthetic qualities of the converging bowl radii, the template furnished with each sink provides the only opening recommended for the installation of undermount sinks. See illustration below.

INSTALLATION

BEFORE INSTALLATIONInspect the sink for any visible defects. Do not install the sink if defects are found. Call customer service at 1-614-777-5004 for assistance.Remove the drain by unscrewing the screw from the drain until it is completely separated from the sink.

TOP MOUNT INSTALLATION

1. Trace the Opening

- Locate the top mount template in the box.

- Carefully cut along the dotted lines. Keep the inside portion of the template. It contains important information concerning the care and maintenance of your sink.

- Place the template on the counter where you would like your sink to be installed. When installing the template, make sure that the tank will not interfere with cabinet doors or panels. Ensure that there is enough space for the water supply installation. Fix the template on the counter using masking tape. Trace the inside of the template meticulously with a pencil. Remove the template.

OR

- Turn the sink upside down and place it on top of the counter. Note the location of cabinet doors and panels to ensure that they will be compatible with the sink installation.

- Ensure that there is enough space for the water supply installation.

- Trace the outer edge of the sink with a pencil, then remove the sink.

- Measure 7 mm from the initial sink measurement and trace another line on the inside of the drawing. This second line will be the cutting line.

2. Cut the Opening

- Using the drill, make a small starting hole of about 1.2 cm (0.5 in) on the inside of the cutting line. Drill a second time in this same hole with a larger bit so the jigsaw can be inserted properly.

- Put masking tape on the outer side of the cutting line. This will protect the counter from scratches and shattered fragments caused by the jigsaw.

- Using the jigsaw, trim the inside of the cutting line.

- Insert the sink and adjust the opening if required.

3. Drain Installation

- Insert the metal strainer into the rubber seal, and then into the draining hole.

- Install the rubber gasket and the main drain body underneath the sink.

- Using the screw, tighten the main drain body and the metal strainer into place.

- Install the basket on top of the metal strainer.

- Repeat the same procedure for the installation of the second draining hole (double and triple bowls only).

- Note: plumber putty is not required for the installation of these drains.

4. Insert SinkVerify that the sink fits perfectly. The lip of the sink should be resting on the countertop.5. Insert ClipsInsert clips into the rails.6. Fix the ClipsFix the clips into place.7. Seal with Silicone-based Sealant.Seal with silicone-based sealant all around the sink.8. Pipe InstallationInstall the faucet following the manufacturer’s instructions.NOTE: Excess sealant must be removed promptly with a suitable clean-up solvent recommended for use on both the counter and sink to ensure damage does not occur.

UNDERMOUNT INSTALLATION

1. Trace the Opening

- Locate the undermount installation template in the box.

- Cut carefully along the dotted lines. Keep the inside portion of the template. It contains important information concerning the care and maintenance for your sink.

- Place the template on the counter where you would like your sink to be. When installing the template, make sure that the tank will not interfere with cabinet doors or panels. Ensure that there is enough space for the water supply installation.

- Fix the template on the counter using masking tape.

- Trace the inside of the template meticulously with a pencil.

- Remove the template.

2. Cut the Opening

- Using a drill, make a small starting hole of about 1.2 cm (0.5 in) inside of the cutting line.

- Drill a second time in this same hole with a larger bit so the jigsaw can be inserted properly.

- Put masking tape on the outer side of the cutting line. This will protect the counter from scratches and shattered fragments caused by the jigsaw.

- Using the jigsaw, trim the inside of the cutting line.

3. Pre-Drill for the Mounting Brackets

- Drill into the bottom of the countertop to create holes for the mounting brackets.

- Use the appropriate drill bit for the material of the countertop.

- Use epoxy to adhere the plastic cover to the hole. This will help hold the weight of the sink.

4. Build a Support Frame

- Build a support frame to hold the sink.

- Make sure there is enough space for the rails on the support frame.

5. Drain Installation

- Insert the metal strainer into the rubber seal, and then into the draining hole.

- Install the rubber gasket and the main drain body underneath the sink.

- Using the screw, tighten the main drain body and the metal strainer into place.

- Install the basket on top of the metal strainer.

- Repeat the same procedure for the installation of the second draining hold (double and triple bowls only).

- Note: Plumber putty is not required for the installation of these drains.

6. Insert the SinkInsert the sink on the support frame. Apply silicone-based sealant to each corner between the frame and the sink.7. Seal with Silicone-based Sealant

- Apply silicone-based sealant on the border of the sink and install the countertop.Remove excess sealant.

- Install the brackets

- The bracket should rest against the countertop and the lip of the sink.

8. Pipe InstallationInstall the faucet following the manufacturer’s instructions. Make proper water and waste pipe connections.NOTE: Excess sealant must be removed promptly with a suitable clean-up solvent recommended for use on both the counter and sink to ensure damage does not occur.

MAINTENANCE AND CLEANING

EASY CLEANING INSTRUCTIONS

Rinsing is the most important part of sink care. A stainless steel sink finish will retain its original bright appearance if the sink is rinsed thoroughly after each use. Running the water from the spray hose for a few minutes will be thorough. Typically, a rinse and towel drying after each use will take care of most everyday clean-ups. Ideally, once a week, the sink should be scoured with a mildly abrasive cleaner, such as Comet. Rubbing back and forth in the direction of the polish or grain lines will not only remove stubborn stains and greasy film buildups but will blend usage scratches into the satin finish of the sink. After scouring, rinse thoroughly and wipe dry.

SCRATCHESLike most metals, your new stainless steel sink will scratch. These are merely usage scratches and over time will blend into the overall finish of your sink with proper cleaning.

KNIVESYour sink is designed to serve as many things but not as a cutting board or chopping block. This type of use will lead to deep scratches in the sink finish and will dull your knives.

WATER QUALITYThe quality of your water can affect your sink’s appearance. If your water has a high 1 iron content, a brown surface stain can form on the sink giving the appearance of rust. Additionally, in areas with a high concentration of minerals, or with oversoftened water, a white film may develop on the sink. To combat these problems, we suggest that the sink be towel dried after use, and again, on a weekly basis, the sink should be cleaned using a recommended cleanser.

FOODSHeavy salt concentration or foods containing high levels of salt should not be allowed to dry on the sink surface. Rinse your sink thoroughly after use.

DO rinse thoroughly after each use.

DO towel dry after each use to prevent mineral deposits from building upon the surface of the sink.

DO clean the sink once a week, being sure to rub in the direction of the satin finish grain lines.

DO use a bottom grid or rinsing basket to “protect” the finish. Bottom grids and rinsing baskets can remain in the sink and will not cause rusting or pitting.

DO NOT rub the sink across the satin finish lines. Scouring across the satin finish lines can damage the original sink finish.

DO NOT allow soap or other household cleansers to dry on the surface of the sink. Most brands contain chemical additives which will affect the original finish.

DO NOT use solutions of chlorine bleach and water in the sink. Chlorides, which are found in most soaps, detergents, bleaches, and cleansers, are very aggressive to stainless steel. If left on the sink too long they can cause surface pitting.

DO NOT use a steel wool pad to clean your sink. If a more abrasive product is needed, use a green Scotch Brite pad being sure to rub in the direction of the satin finish grain lines. Steel wool pads have a tendency to break apart and small particles of steel can become embedded in the surface of the sink. The steel particles will rust and will give the appearance that the sink itself is rusting.

DO NOT use rubber mats or dishpans in the sink. Leaving rubber mats or dishpans in the sink can lead to surface rust or possible pitting. However, if you insist on using mats or dishpans, please remove them after each use and rinse thoroughly.

DO NOT leave wet sponges, cloths, or cleaning pads on the sink. This can lead to surface rust.

NOTE: Following these recommendations for the care and cleaning of your stainless steel sink will ensure that it will provide you with many years of service.

Need additional information? Visit www.zlinekitchen.com/manuals-1 to view the most up-to-date version of our user manual and installation guide.

Need additional information? Visit www.zlinekitchen.com/manuals-1 to view the most up-to-date version of our user manual and installation guide.

Registering Your ProductPlease register your ZLINE appliance to activate your warranty.Begin the simple registration process by scanning the QR code.

Registering Your ProductPlease register your ZLINE appliance to activate your warranty.Begin the simple registration process by scanning the QR code.

https://l.ead.me/bbvHArBy registering your appliance, you will have access to:

- Technical Support

- Warranty Service

- Tracking your support inquiries

WARNING: This product can expose you to chemicals including nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

WARNING: This product can expose you to chemicals including nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

Three Locations:350 Parr CircleReno, NV 89512 916 Delaware AvenueMarysville, OH 43040 427 Rowland Mill RoadBruceton, TN 38317www.zlinekitchen.com1-614-777-5004

References

[xyz-ips snippet=”download-snippet”]