Supplemental InstructionsModels:W30ABD W36ABD W42ACD W48ACD W60ACD W72ACD

This model provides a unique dehumidification circuit for periods of low outdoor ambient temperature and high indoor humidity conditions.Refer to Specification Sheets S3573 and S3583 for the standard features of the base units and this manual for electrical data.

Dehumidification Circuit

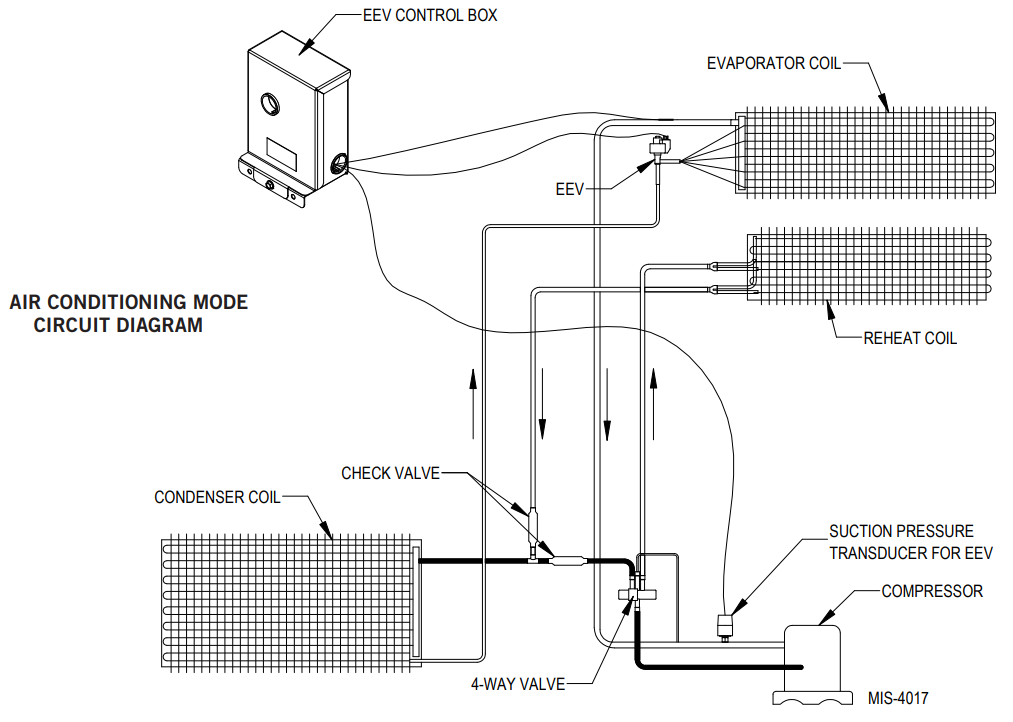

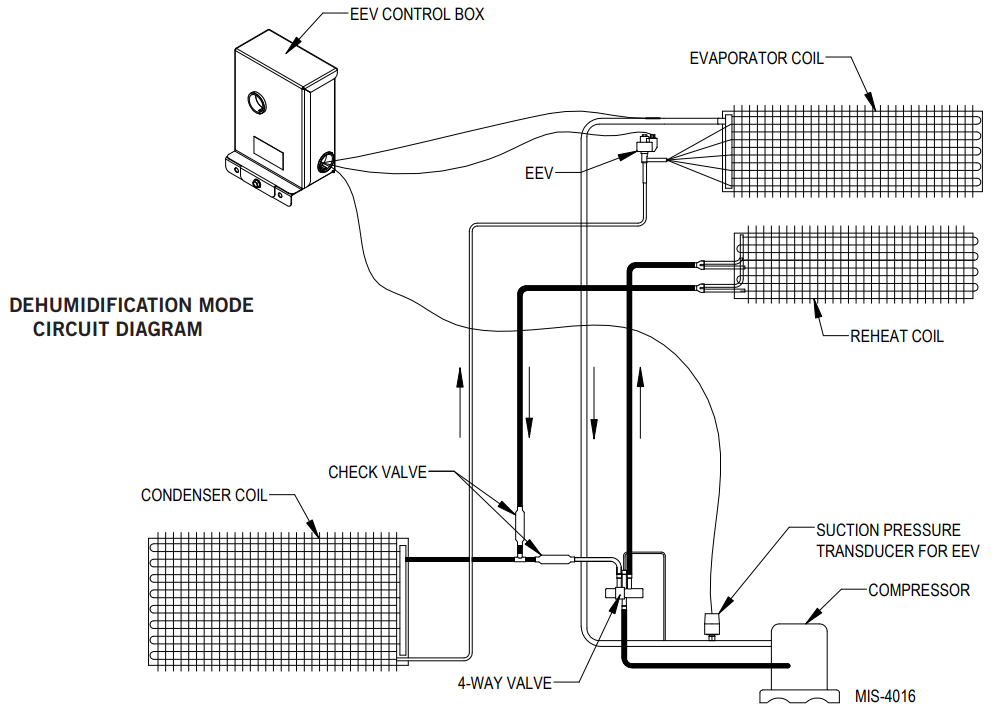

The dehumidification circuit incorporates an independent heat exchanger coil in the supply air stream. This coil reheats the supply air after it passes over the cooling coil without requiring the electric resistance heater to be used for reheat purposes. This results in very high mechanical dehumidification capability from the air conditioner on-demand without using electric resistance reheat.The dehumidification refrigerant reheat circuit is controlled by a dehumidification valve directing the refrigerant gas to the normal condenser during periods when standard air conditioning is required. During periods of high indoor humidity, a humidistat senses the need for mechanical dehumidification. It then energizes both the compressor circuit and the dehumidification valve, thus directing the hot refrigerant discharge gas into a separate desuperheating condenser circuit, which reheats the conditioned air before it is delivered to the room. The refrigerant gas is then routed from the desuperheating condenser to the system condenser for further heat transfer. When the humidistat is satisfied, the system automatically switches off. The result is separate humidity control at minimum operating cost.

This mode will allow the indoor blower to run at a reduced airflow on the first stage of cooling. A 2-stage thermostat connected to Y2 will then allow the airflow to return to normal rated speed if the call for dehumidification or cooling is not satisfied within the allotted time frame specified by the thermostat. See the latest revision of unit installation instructions 2100689 or 2100-692 for more information regarding the Balanced Climateoperation.

Dehumidification Sequence of Operation

Dehumidification is controlled through the thermostat (if capable) or through a separate humidistat. On a call for dehumidification mode of operation, the compressor and dehumidification valve of the unit are energized through circuit R – D to provide dehumidification. Dehumidification will continue until the humidistat is satisfied.A cooling call takes precedence over a dehumidification call as long as the cooling call is present. A heating call takes precedence over a dehumidification call as long as the heating call is present.Refer to the table on page 12 for a full list of outputs that can be expected for different input combinations.

Balanced ClimateTM Mode

It is recommended to enable Balanced Climate mode and utilize a 2-stage thermostat to enhance the dehumidification performance and comfort. To activate this mode, the jumper between Y1 and Y2 on the low voltage terminal strip needs to be removed and the unconnected purple wire laying in the cable duct needs to be pulled out and placed on the terminal block so that it connects to the yellow wire from the outdoor temperature switch. Refer to the unit wiring diagram for clarity.NOTE: In units with dehumidification, never have both the Balanced Climate jumper in place and the outdoor temperature switch connected at the same time!

Operation

This model employs an electronic expansion valve (EEV) which meters the refrigerant to the evaporator. The EEV is made of a stepper motor that is controlledwith a step output from the controller. The valve is capable of 480 steps which drives a needle valve that in turn regulates the flow of refrigerant. The EEV allowsfor tighter control and better capacity management in varying operating conditions than a standard TXV. The EEV system consists of the electronic valve and stator, control board, relay, suction temperature sensor, and suction pressure transducer. The pressure transducer and temperature sensor monitor the suction line to provide real-time data to the control board so that a real-time superheat can be calculated. This then determines the EEV position. The controller is sent to maintain around 13° superheat. The relay is used to activate the EEV system’s controller anytime that the compressor is energized.

WARNING

– Exposure to high-pressure refrigerant hazards.– This unit is equipped with an electronic expansion valve. In order to fully recover refrigerant or evacuate the system during repairs, be sure to use service tool 2151-021 to manually open the electronic expansion valve or be sure to recover and evacuate from all service ports; suction, liquid, and discharge.– Failure to do so could result in eye injuries and/or refrigerant burns.

– Exposure to high-pressure refrigerant hazards.– This unit is equipped with an electronic expansion valve. In order to fully recover refrigerant or evacuate the system during repairs, be sure to use service tool 2151-021 to manually open the electronic expansion valve or be sure to recover and evacuate from all service ports; suction, liquid, and discharge.– Failure to do so could result in eye injuries and/or refrigerant burns.

EEV Instructions for Vacuuming, Reclaiming, and Charging Unit

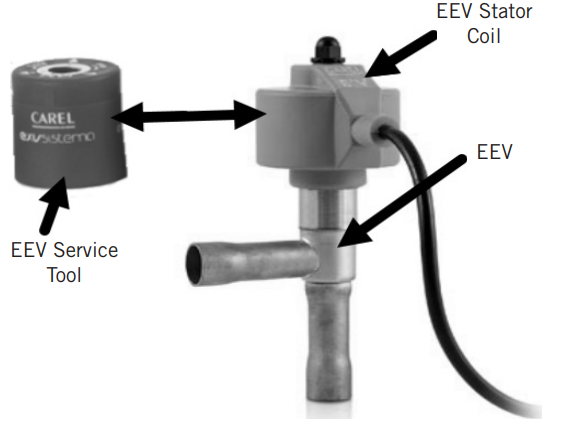

The electronic expansion valve moves to a closed position when there is no call to control. In order to pull a complete vacuum, fully reclaim the system or chargethe unit, connections to all service ports—suction, liquid, and discharge—need to be utilized or the valve needs to be manually opened first. The valve can beopened manually using the magnetic EEV service tool (Bard Part # 2151-021) shown in Figure 1. To do this, remove the EEV stator coil (red color with retainingnut on top), slide the magnetic tool over the shaft where the stator was removed, and turn in a clockwise direction to open the valve to the fully open position(directional arrows are provided on the tool). Reapply the EEV stator coil and retaining nut once complete. Upon powering the unit back up, the control board will automatically drive the EEV back to the fully shut position. Once the compressor starts, the control board will again modulate the EEV position to controlthe system superheat.

FIGURE 1Electronic Expansion Valve (EEV) and Service Tool

Troubleshooting the Electronic Expansion Valve

The control board has two status LEDs.

- The green LED should be lit anytime that the board has power and the control is functioning.

- The red LED is to show that an alarm is present. See Table 1 for a guide to know where to start troubleshooting the EEV. Refer to the appropriate unit replacement parts manual for any parts that are needed.

Control BoardCheck that the controller is getting 24VAC signal (GO 24VAC Hot and G 24VAC common). Reference unit wiring diagram for proper connections. If 24V is present but the green LED is not lit, replace the controller. If the green LED is now lit but the superheat is still not being maintained, troubleshoot the relay to check that the DI is connected to G; refer to Relay in EEV Control Box on page 3.Electronic Expansion ValveCheck to see if valve can be moved by manually moving the stepper motor using the EEV service tool shown in Figure 1 (Bard Part # 2151-021). If valve still does not control, check the transducer and thermistor sensors as described on page 4. If sensors are good, replace the valve.

TABLE 1Electronic Expansion Valve Troubleshooting

|

Problem |

Probable Cause |

Troubleshoot |

| The green LED is not lit. | Controller not receiving 24VAC signal. | Control Board |

| The green LED is lit, but superheat is not being maintained. | The relay is not closing the controller’s DI connection to the ground. | Relay |

| The red LED is flashing and EEV is not controlling superheat properly (13° superheat). One of the following is likely the fault: | ||

| 1. Low superheat is detected and the controller is taking steps to protect the system by closing the valve. | The stator is broken or connected incorrectly. | Stator |

| Valve is stuck open. | EEV Valve | |

| 2. Suction temperature sensor error. | Poor connection of sensor or faulty sensor. | Thermistor |

| 3. Suction pressure transducer error. | Pressure transducer wiring incorrect or faulty transducer. | Transducer |

| The red LED is on steady. | The operating parameters have been damaged. | Replace Control Board |

Relay in EEV Control BoxContacts NO to DI and COM to G must be closed for EEV control to start controlling superheat. Check that the relay is getting 24VAC. Reference unit wiringdiagram for proper connections. If 24V is present, measure the resistance between COM and NO; it should be 0 ohms when the relay is getting 24V. If theresistance is out of range, replace the relay.Stator CoilDisconnect the stator from the valve and the control and measure the resistance of the windings using an electrical tester. The resistance of both windings shouldbe around 40 ohms +/– 10%. The four-wire sets that will have resistance between them are: White and red, green and red, yellow and purple, blue and purple. Ifthe resistance falls outside these values, replace the stator.

Transducer Sensor

- Check that there is a 5VDC Nominal between the red and black wires going to the transducer.

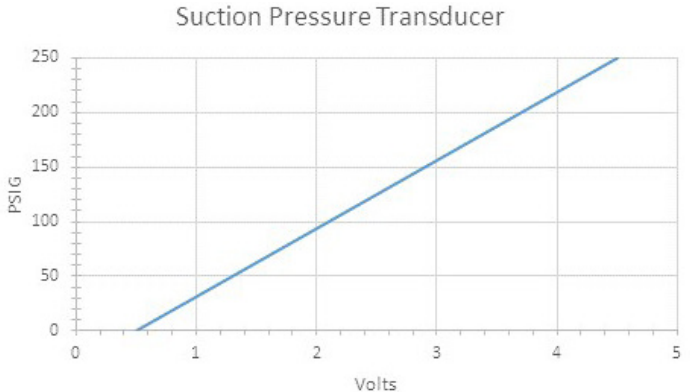

- Check the signal voltage between the blue and black wires (0.5-4.5VDC Actual). The following formula and Figure 2 can be used to determine if the transducer’s voltage to pressure ratio is within range. Replace transducer if out of range.

- Check to ensure wires are correctly connected as follows:Blue wire = pin 1 of controller plug to pin C on transducer plugRed wire = pin 2 of controller plug to pin B on transducer plugBlack wire = pin 3 of controller plug to pin A on transducer plug

- Check continuity of all three wires from the transducer plug to the controller plug. Replace wires if the poor connection in any wire.Formula for Tech:(Measured Pressure x .016) + .5 =Expected Transducer Signal Voltage (see Figure 2)

FIGURE 2Voltage to Pressure: Suction Pressure Transducer

Thermistor Sensor

- Make a visual check for broken wire insulation, broken wires, or cracked epoxy material.

- Disconnect 10k ohm NTC thermistor from the EEV control box.

- Use an ohmmeter to measure the resistance between the two connectors. Also, use the ohmmeter to check for short or open.

- Compare the resistance reading to Table 2. Use sensor ambient temperature. (Tolerance of part is ±10 %.)

- If the sensor is out of tolerance, shorted, open, or reads very low ohms, it should be replaced.

TABLE 210K Ohm NTC Sensor: Temperature/Resistance

| Temperature | Resistance | Temperature | Resistance | Temperature | Resistance | Temperature | Resistance | ||||

| F | C | Ω | F | C | Ω | F | C | LI | F | C | Ω |

| -40 | -40 | 188.500 | 28.4 | -2 | 29.730 | 96.8 | 36 | 6.700 | 165.2 | 74 | 1.980 |

| -38.2 | -39 | 178.500 | 30.2 | -1 | 28.480 | 98.6 | 37 | 6.470 | 167 | 75 | 1.920 |

| -36.4 | -38 | 169.000 | 32 | 0 | 27.280 | 100.4 | 38 | 6.250 | 168.8 | 76 | 1.870 |

| -34.6 | -37 | 160.200 | 33.8 | 1 | 26.130 | 102.2 | 39 | 6.030 | 170.6 | 77 | 1.820 |

| -32.8 | -36 | 151.900 | 35.6 | 2 | 25.030 | 104 | 40 | 5.830 | 172.4 | 78 | 1.770 |

| -31 | -35 | 144.100 | 37.4 | 3 | 23.990 | 105.8 | 41 | 5.630 | 174.2 | 79 | 1.920 |

| -29.2 | -34 | 136.700 | 39.2 | 4 | 23.000 | 107.6 | 42 | 5.440 | 176 | 80 | 1.670 |

| -27.4 | -33 | 129.800 | 41 | 5 | 22.050 | 109.4 | 43 | 5.260 | 177.8 | 81 | 1.620 |

| -25.6 | -32 | 123.300 | 42.8 | 6 | 21.150 | 111.2 | 44 | 5.080 | 179.6 | 82 | 1.580 |

| -23.8 | -31 | 117.100 | 44.6 | 7 | 20.300 | 113 | 45 | 4.910 | 181.4 | 83 | 1.530 |

| -22 | -30 | 111.300 | 46.4 | 8 | 19.480 | 114.8 | 46 | 4.750 | 183.2 | 84 | 1.490 |

| -20.2 | -29 | 105.700 | 48.2 | 9 | 18.700 | 116.6 | 47 | 4.590 | 185 | 85 | 1.450 |

| -18.4 | -28 | 100.500 | 50 | 10 | 17.960 | 118.4 | 48 | 4.440 | 186.8 | 86 | 1.441 |

| -16.6 | -27 | 95.520 | 51.8 | 11 | 17.240 | 120.2 | 49 | 4.300 | 188.6 | 87 | 1.370 |

| -14.8 | -26 | 90.840 | 53.6 | 12 | 16.560 | 122 | 50 | 4.160 | 190.4 | 88 | 1.340 |

| -13 | -25 | 86.430 | 55.4 | 13 | 15.900 | 123.8 | 51 | 4.030 | 192.2 | 89 | 1.300 |

| -11.2 | -24 | 82.260 | 57.2 | 14 | 15.280 | 125.6 | 52 | 3.900 | 194 | 90 | 1.270 |

| -9.4 | -23 | 78.330 | 59 | 15 | 14.690 | 127.4 | 53 | 3.770 | 195.8 | 91 | 1.230 |

| -7.6 | -22 | 74.610 | 60.8 | 16 | 14.120 | 129.2 | 54 | 3.650 | 197.6 | 92 | 1.200 |

| -5.8 | -21 | 71.100 | 62.6 | 17 | 13.580 | 131 | 55 | 3.540 | 199.4 | 93 | 1.170 |

| -4 | -20 | 67.770 | 64.4 | 18 | 13.060 | 132.8 | 56 | 3.430 | 201.2 | 94 | 1.140 |

| -2.2 | -19 | 64.570 | 66.2 | 19 | 12.560 | 134.6 | 57 | 3.320 | 203 | 95 | 1.110 |

| -0.4 | -18 | 61.540 | 68 | 20 | 12.090 | 136.4 | 58 | 3.220 | 204.8 | 96 | 1.080 |

| 1.4 | -17 | 58.680 | 69.8 | 21 | 11.630 | 138.2 | 59 | 3.120 | 206.6 | 97 | 1.050 |

| 3.2 | -16 | 55.970 | 71.6 | 22 | 11.200 | 140 | 60 | 3.020 | 208.4 | 98 | 1.020 |

| 5 | -15 | 53.410 | 73.4 | 23 | 10.780 | 141.8 | 61 | 2.930 | 210.2 | 99 | 1.000 |

| 6.8 | -14 | 50.980 | 75.2 | 24 | 10.380 | 143.6 | 62 | 2.840 | 212 | 100 | 970 |

| 8.6 | -13 | 48.680 | 77 | 25 | 10.000 | 145.4 | 63 | 2.750 | |||

| 10.4 | -12 | 46.500 | 78.8 | 26 | 9.630 | 147.2 | 64 | 2.670 | |||

| 12.2 | -11 | 44.430 | 80.6 | 27 | 9.280 | 149 | 65 | 2.590 | |||

| 14 | -10 | 42.470 | 82.4 | 28 | 8.940 | 150.8 | 66 | 2.510 | |||

| 15.8 | -9 | 40.570 | 84.2 | 29 | 8.620 | 152.6 | 67 | 2.440 | |||

| 17.6 | -8 | 38.770 | 86 | 30 | 8.310 | 154.4 | 68 | 2.360 | |||

| 19.4 | -7 | 37.060 | 87.8 | 31 | 8.010 | 156.2 | 69 | 2.300 | |||

| 21.2 | -6 | 35.440 | 89.6 | 32 | 7.730 | 158 | 70 | 2.230 | |||

| 23 | -5 | 33.900 | 91.4 | 33 | 7.450 | 159.8 | 71 | 2.160 | |||

| 24.8 | -4 | 32.440 | 93.2 | 34 | 7.190 | 161.6 | 72 | 2.100 | |||

| 26.6 | -3 | 31.050 | 95 | 35 | 6.940 | 163.4 | 73 | 2.040 |

W30ABD Cooling and Dehumidification Application Data

| 08AY13 | OD Temp. | 6 ‘F’ | 70″F | 75’f | 807 | 85’i | 90’F | 95’F | 1007 | 105’F | ||||||||

| Mode | NC | Dehum | NC | Dehurn | NC | Dehum | NC | Dehum | NC | Dehum | VC | Dehum | NC | Dehum | NC | Dehum | NC | Dehum |

| 75/62.5(50% RH) | Total Cooling Stub | 32.100 | 14.400 | 31.200 | 12.100 | 30.600 | 10.100 | 29.300 | 7.500 | 28,500 | 5.200 | 27.600 | 2.900 | 26.700 | 500 | 25,900 | 25.000 | |

| Sensible Stuh | 22,500 | 5.400 | 22.000 | 3.700 | 21.500 | 2.300 | 21.100 | 300 | 20.700 | (1.400) | 20,300 | (3.000) | 20.000 | (4.700) | 19.700 | (6.400) | 19.400 | (8,000) |

| SIT | 0.701 | 0.375 | 0.705 | 0.306 | 0.703 | 0.228 | 0.720 | 0.040 | 0.726 | 0 | 0.736 | 0 | 0.749 | 0 | 0.761 | 0 | 0.776 | 0 |

| Latent Shah | 9.600 | 9.000 | 9.200 | 8.400 | 9,100 | 7.1330 | 8.200 | 7.200 | 7.800 | 6.600 | 7.300 | 5.900 | 6.700 | 5200 | 6,200 | 4.500 | 5.600 | 3.800 |

| Lbs. H20/nr. | 9.1 | 8.5 | 8.7 | 7.9 | 8.6 | 7.4 | 7.7 | 6.8 | 7.4 | 6.2 | 6.9 | 5.6 | 6.3 | 4.9 | 5.8 | 4.2 | 5.3 | 3.6 |

| Supply Air 03 | 52.5 | 67.9 | 52.9 | 70.2 | 53.3 | 72.4 | 53.7 | 74.6 | 54.0 | 76.8 | 54.4 | 79.0 | 54.8 | 81.1 | 55.1 | 83.3 | 55.4 | 85.5 |

| Supply Air WB | 50.8 | 55.9 | 51.2 | 57.0 | 51.2 | 57.9 | 51.9 | 592 | 52.2 | 60.3 | 52.6 | 61.3 | 52.9 | 62.4 | 53.2 | 63.4 | 53.5 | 64.5 |

| Suction PSIG‘ | 121 | 115 | 123 | 117 | 125 | 119 | 125 | 121 | 127 | 123 | 128 | 126 | 129 | 128 | 131 | 130 | 132 | 133 |

| Discharge PSIG• | 271 | 228 | 291 | 243 | 311 | 257 | 335 | 272 | 358 | 288 | 382 | 304 | 408 | 320 | 434 | 336 | 462 | 353 |

| 75/64.1(55% RH) | Total Cooling Btuh | 32.900 | 15.400 | 32.000 | 13.100 | 31.100 | 10.900 | 30.200 | 8.500 | 29.300 | 6.200 | 28.400 | 3.900 | 27.600 | 1.500 | 26.700 | 25.900 | |

| Sensible Stub | 22,100 | 4.700 | 21.600 | 3,000 | 21.100 | 1,300 | 20.700 | (400) | 20.300 | (2.100) | 19.900 | (3.800) | 19.600 | (5.400) | 19.300 | (7.100) | 19,000 | (8.700) |

| SIT | 0.672 | 0.31 | 0.675 | 0.23 | 0.678 | 0.12 | 0.685 | 0 | 0.693 | 0 | 0.701 | 0 | 0.710 | 0 | 0.723 | 0 | 0.734 | 0 |

| Latent Btuh | 10,800 | 10,700 | 10.400 | 10,100 | 10,000 | 9,600 | 9.500 | 8,930 | 9.000 | 8,300 | 8.500 | 7.700 | 8.000 | 6,900 | 7,400 | 6,300 | 6,900 | 5,500 |

| Lte. H20/hr. | 10.2 | 10.1 | 9.8 | 9.5 | 9.4 | 9.1 | 9.0 | 8.4 | 8.5 | 7.8 | 8.0 | 7.3 | 7.5 | 6.5 | 7.0 | 5.9 | 6.5 | 5.2 |

| Supply Air 08 | 53.9 | 68.9 | 54.3 | 71.1 | 54.6 | 73.3 | 55.0 | 75.5 | 55.4 | 77.7 | 55.8 | 79.9 | 56.1 | 82.1 | 56.5 | 84.3 | 56.8 | 86.4 |

| Supply Aie WS | 52.3 | 57.0 | 52.6 | 58.1 | 53.0 | 59.2 | 53.3 | 60.3 | 53.7 | 61.4 | 54.0 | 62.4 | 54.4 | 63.5 | 54.7 | 64.5 | 55.0 | 65.6 |

| Suction PSIG’ | 125 | 118 | 126 | 120 | 127 | 122 | 129 | 124 | 130 | 127 | 131 | 129 | 133 | 131 | 134 | 134 | 136 | 136 |

| Discharge P510, | 273 | 231 | 293 | 245 | 314 | 260 | 337 | 275 | 360 | 290 | 384 | 306 | 410 | 322 | 436 | 339 | 463 | 356 |

| 75/65.5160% RID | Toth Cooling Stub | 33800 | 16.400 | 32.900 | 14.200 | 32.300 | 12.200 | 31.100 | 9.600 | 30.200 | 7.200 | 29.300 | 4.900 | 28.400 | 2.500 | 27.600 | 200 | 26.700 |

| Sensible Stub | 21.600 | 3,900 | 21,100 | 2.200 | 20.700 | 800 | 20,200 | (1,100) | 19.900 | (2,800) | 19.500 | (4.500) | 19.200 | (6.200) | 18,900 | (7.800) | 18.600 | (9.500) |

| Sil | 0.639 | 0.238 | 0.641 | 0.155 | 0.641 | 0.066 | 0.650 | 0 | 0.659 | 0 | 0.666 | 0 | 0.676 | 0 | 0.685 | 0 | 0.697 | 0 |

| Latent Btuh | 12200 | 12.500 | 11.800 | 12.000 | 11.600 | 11.403 | 10.900 | 10.700 | 10.300 | 10.000 | 9,800 | 9.400 | 9.200 | 8.700 | 8.700 | 8,000 | 8.103 | 7.300 |

| Lbs. H2O’br. | 11.5 | 11.8 | 11.1 | 11.3 | 10.9 | 10.8 | 10.3 | 10.1 | 9.7 | 9.4 | 9.2 | 8.9 | 8.7 | 8.2 | 8.2 | 7.5 | 7.6 | 6.9 |

| Supply Air 03 | 55.2 | 69.8 | 55.6 | 72.1 | 56.0 | 74.3 | 56.4 | 76.5 | 56.8 | 78.7 | 57.1 | 80.9 | 57.5 | 83.1 | 57.8 | 85.2 | 58.2 | 87.4 |

| Supply Air W8 | 53.7 | 58.1 | 54.1 | 59.2 | 54,0 | 60.0 | 54.8 | 61.4 | 55.1 | 62.5 | 55.5 | 63.5 | 55.8 | 64.6 | 56.1 | 65.6 | 56.4 | 66.7 |

| Suction PSIG4 | 129 | 121 | 130 | 123 | 132 | 125 | 132 | 128 | 134 | 130 | 135 | 132 | 136 | 135 | 138 | 137 | 139 | 140 |

| Discharge PS1G4 | 274 | 233 | 295 | 248 | 314 | 262 | 338 | 277 | 362 | 293 | 386 | 309 | 411 | 325 | 438 | 341 | 465 | 358 |

| 75.’66.7165h RH) | Total Cooling Stub | 34.600 | 17.400 | 33.700 | 15.200 | 33.200 | 13.200 | 31.900 | 10.600 | 31.000 | 8.200 | 30.100 | 5.900 | 29.300 | 3.600 | 28.400 | 1.200 | 27.600 |

| Sensible Btuh | 21.200 | 3,200 | 20.700 | 1,500 | 20.300 | – | 19.800 | (1.900) | 19.400 | (3.600) | 19.100 | (5.200) | 18.700 | (6.900) | 18.400 | (8.600) | 18,200 | (10.200) |

| S/1 | 0.613 | 0.18 | 0.614 | 0.10 | 0.611 | 0.00 | 0.621 | 0 | 0.626 | 0 | 0.635 | 0 | 0.638 | 0 | 0.648 | 0 | 0.659 | 0 |

| Latent Stub | 13,400 | 14,200 | 13.000 | 13,700 | 12,900 | 13,200 | 12,100 | 12,500 | 11.600 | 11,800 | 11.000 | 11,100 | 10.600 | 10.500 | 10.000 | 9.800 | 9,400 | 9,000 |

| Lbs. H201hr. | 12.6 | 13.4 | 12.3 | 12.9 | 122 | 12.5 | 11.4 | 11.8 | 10.9 | 11.1 | 10.4 | 10.5 | 10.0 | 9.9 | 9.4 | 92 | 8.9 | 8.5 |

| Supply Air 08 | 56.6 | 70.8 | 57.0 | 73.0 | 57.4 | 75.2 | 57.8 | 77.4 | 58.1 | 79.6 | 58.5 | 81.8 | 58.8 | 84.0 | 59.2 | 862 | 59.5 | 88.3 |

| Supply Am WB | 55.2 | 59.1 | 55.5 | 60.3 | 55.5 | 61.1 | 56.2 | 62.5 | 56.6 | 63.5 | 56.9 | 64.6 | 57.2 | 65.7 | 57.6 | 66.7 | 57.9 | 67.7 |

| Suction P510′ | 132 | 125 | 133 | 127 | 135 | 129 | 136 | 131 | 137 | 133 | 139 | 136 | 140 | 138 | 142 | 140 | 143 | 143 |

| Discharge P510 | 276 | 236 | 297 | 250 | 316 | 265 | 340 | 280 | 364 | 295 | 388 | 311 | 413 | 327 | 440 | 344 | 467 | 361 |

| 75/68(70% RH) | Total Cooling Stub | 35.500 | 18.400 | 34.600 | 16.200 | 34.000 | 14.200 | 32.800 | 11,600 | 31.900 | 9,300 | 31.000 | 6.900 | 30.100 | 4.600 | 29.300 | 2.200 | 28.400 |

| Sensible Egon | 20,800 | 2,500 | 20.300 | 800 | 19.800 | 1700) | 19.400 | (2,600) | 19.000 | (4,300) | 18,600 | (6.000) | 18,300 | (7.600) | 18,000 | (9.300) | 17.700 | (10.900) |

| SIT | 0.586 | 0.136 | 0.5137 | 0.049 | 0.582 | 0 | 0.591 | 0 | 0.5% | 0 | 0.600 | 0 | 0.608 | 0 | 0.614 | 0 | 0.623 | 0 |

| Latent Btuh | 14,700 | 15,900 | 14,300 | 15,400 | 14,200 | 14,900 | 13.400 | 14,200 | 12,900 | 13,600 | 12,400 | 12.900 | 11.800 | 12.200 | 11.300 | 11,500 | 10.700 | 10.700 |

| Lbs. H20/nr. | 13.9 | 15.0 | 13.5 | 14.5 | 13.4 | 14.1 | 12.6 | 13.4 | 12.2 | 12.8 | 11.7 | 12.2 | 11.1 | 11.5 | 10.7 | 10.8 | 10.1 | 10.1 |

| Supply Air 03 | 58.0 | 71.7 | 58.4 | 74.0 | 58.7 | 76.2 | 59.1 | 78.4 | 59.5 | 80.6 | 59.9 | 82.8 | 60.2 | 85.0 | 60.6 | 87.1 | 60.9 | 89.3 |

| Supply Air W8 | 56.6 | 60.2 | 57.0 | 61.3 | 56.9 | 62.2 | 57.7 | 63.5 | 58.0 | 64.6 | 58.4 | 65.7 | 58.7 | 66.8 | 59.0 | 67.8 | 59.3 | 68.8 |

| Suction P510′ | 136 | 128 | 137 | 130 | 139 | 132 | 139 | 134 | 141 | 137 | 142 | 139 | 144 | 141 | 145 | 144 | 147 | 146 |

| Discharge PSIG” | 278 | 238 | 298 | 252 | 318 | 267 | 342 | 282 | 365 | 298 | 390 | 314 | 415 | 330 | 441 | 346 | 469 | 363 |

| 80/68.3(55% RFD | Total Cooling Stub | 35.200 | 18.400 | 34,300 | 16.100 | 33,800 | 14.100 | 32.500 | 11.500 | 31.600 | 9.200 | 30.700 | 6.800 | 29.900 | 4,500 | 29.000 | 2,100 | 28.200 |

| Sensible Stub | 18,500 | 5,400 | 18.000 | 3.700 | 17.600 | 2.300 | 17.100 | 300 | 16.700 | (1.400) | 16.400 | (3.000) | 16.000 | (4.700) | 15.700 | (6.400) | 15.500 | (8.000) |

| S/T | 0.526 | 0.29 | 0.525 | 0.23 | 0.521 | 0.16 | 0.526 | 0.03 | 0.528 | 0 | 0.534 | 0 | 0.535 | 0 | 0.541 | 0 | 0.550 | 0.00 |

| Latent Btuh | 16,700 | 13,000 | 16,300 | 12,400 | 16,200 | 11 800 | 15.400 | 11,200 | 14.900 | 10,600 | 14.300 | 9.800 | 13.900 | 9200 | 13.300 | 8.500 | 12,700 | 7,700 |

| Lta. H2O hr. | 158 | 12.3 | 15.4 | 11.7 | 15.3 | 11.1 | 14.5 | 10.6 | 14.1 | 10.0 | 13.5 | 9.2 | 13.1 | 8.7 | 12.5 | 8.0 | 12.0 | 7.3 |

| Supply Air DB | 57.3 | 72.4 | 57.7 | 74.6 | 58.0 | 76.9 | 58.5 | 79.1 | 58,8 | 81.3 | 59.2 | 83.5 | 59.5 | 85.6 | 59.9 | 87.8 | 60.2 | 89.9 |

| Supply Am WB | 56.7 | 60.4 | 57.0 | 61.5 | 57.0 | 62.4 | 57.7 | 63.7 | 58.1 | 64.8 | 58.4 | 65.9 | 58.7 | 66.9 | 59.1 | 68.0 | 59.4 | 69.0 |

| Suction P510′ | 135 | 130 | 136 | 132 | 138 | 134 | 138 | 136 | 140 | 138 | 141 | 141 | 143 | 143 | 144 | 145 | 146 | 148 |

| Discharge PSIG | 279 | 239 | 299 | 254 | 319 | 268 | 343 | 284 | 366 | 299 | 390 | 315 | 416 | 331 | 442 | 348 | 469 | 365 |

1. Values listed are with ventilation package disabled2Return air temperature °F @Default airflow (950 CFM) for AC tests and Balanced Climate airflow (705 CFM) for dehumidification tests3Below 50°F, the unit requires a factory or field-installed low ambient control.4Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

W36ABD Cooling and Dehumidification Application Data1

| 08/W8 | OD Temp. | 6 ‘F’ | 70’F | 75’F | 80’i | 85’F | 90’F | 95’F | 100’F | 1115’i | |||||||||

| Mode | A/C | Dehum | A/C | Dehum | NC | Delman | NC | Dehum | NC | Dehum | A/C | Dehum | NC | Datum | NC | Dehum | A/C | Dehum | |

| 75/62.5(50% RH) | Total Cooling Mutt | 39.800 | 18.700 | 38.700 | 16.200 | 37.500 | 13.700 | 36.500 | 11.100 | 35.300 | 8.500 | 34,200 | 5.900 | 33,000 | 3200 | 31.800 | 400 | 30.600 | |

| Sensible Mull | 29200 | 7.100 | 28.700 | 5.300 | 28.200 | 3.500 | 27.700 | 1.60) | 27.200 | (300) | 26.600 | (2.200) | 26.100 | (4.200) | 25.500 | (6.100) | 25.000 | (8.100) | |

| Sit | 0.734 | 0.380 | 0.742 | 0.327 | 0.752 | 0.255 | 0.759 | 0.144 | 0.771 | 0 | 0.778 | 0 | 0.791 | 0 | 0.802 | 0 | 0.817 | 0 | |

| Latent 8tuh | 10.600 | 11.600 | 10.000 | 10.90) | 9.300 | 10.200 | 8,800 | 9.50) | 8.100 | 8.800 | 7.600 | 8.100 | 6,900 | 7.400 | 6,300 | 6.500 | 5.600 | 5,700 | |

| Lbs. H20/hr. | 10.0 | 10.9 | 9.4 | 10.3 | 8.8 | 9.6 | 8.3 | 9.0 | 7.6 | 8.3 | 7.2 | 7.6 | 6.5 | 7.0 | 5.9 | 6.1 | 5.3 | 5.4 | |

| Suppty An 08 | 52.0 | 67.0 | 52.4 | 69.0 | 52.8 | 71.1 | 53.3 | 73.2 | 53.7 | 75.4 | 54.1 | 77.5 | 54.4 | 79.7 | 54.8 | 81.9 | 55.1 | 84.1 | |

| Supply Air WB | 50.5 | 55.1 | 51.0 | 56.1 | 51.3 | 57.0 | 51.7 | 5111 | 52.1 | 59.2 | 52.4 | 60.2 | 52.8 | 61.3 | 53.1 | 62.5 | 53.4 | 63.6 | |

| Suction F510. | 125 | 119 | 127 | 120 | 128 | 120 | 130 | 122 | 131 | 123 | 133 | 124 | 134 | 126 | 135 | 128 | 137 | 130 | |

| Discharge PSIG | 287 | 239 | 307 | 254 | 329 | 269 | 351 | 284 | 376 | 300 | 401 | 317 | 427 | 334 | 455 | 352 | 484 | 371 | |

| 75/64.1(55′ RH) | Total Cooling Club | 40.900 | 19.800 | 39.800 | 17.400 | 38.600 | 14,900 | 37.500 | 12,300 | 36.300 | 9,700 | 35.200 | 7.100 | 34.000 | 4.400 | 32.800 | 1.600 | 31,700 | |

| Sensible E4uh | 27,500 | 6,200 | 27,000 | 4400 | 26,500 | 2,500 | 26.000 | 700 | 25.500 | (1203) | 25,000 | (3,200) | 24,500 | (5.100) | 23.900 | (7,000) | 23,300 | (9.000) | |

| S/T | 0.672 | 0.31 | 0.678 | 0.25 | 0.687 | 0.17 | 0.693 | 0.06 | 0.702 | 0 | 0.710 | 0 | 0.721 | 0 | 0.729 | 0 | 0.735 | 0 | |

| Latent Btuh | 13.400 | 13.600 | 12.800 | 13.000 | 12.100 | 12.400 | 11.500 | 11.600 | 10,800 | 10,930 | 10.200 | 10.300 | 9.500 | 9.500 | 8.900 | 8.600 | 8.400 | 7.800 | |

| LW. H213/Tir. | 12.6 | 12.8 | 12.1 | 12.3 | 11A | 11.7 | 10.8 | 10.9 | 10.2 | 10.3 | 9.6 | 9.7 | 9.0 | 9.0 | 8.4 | 8.1 | 7.9 | 7.4 | |

| Supply Air 06 | 53.2 | 68.0 | 53.6 | 70.1 | 54.1 | 72.2 | 54.5 | 74.3 | 54.9 | 76.4 | 55.3 | 78.6 | 55.6 | 80.7 | 56.0 | 83.0 | 56.4 | 85.2 | |

| Supply Ai WB | 51.9 | 56.2 | 52.3 | 57.2 | 52.7 | 58.2 | 53.1 | 592 | 53.5 | 60.3 | 53.8 | 61.3 | 54.2 | 62.4 | 54.5 | 63.5 | 54.8 | 64.7 | |

| Suction P510′ | 128 | 122 | 130 | 123 | 131 | 124 | 133 | 125 | 134 | 126 | 136 | 127 | 137 | 129 | 138 | 131 | 140 | 133 | |

| Drt.charge P510` | 288 | 242 | 309 | 256 | 330 | 271 | 353 | 287 | 377 | 303 | 402 | 320 | 429 | 337 | 457 | 355 | 485 | 373 | |

| 75/65.5(60% RH) | Total Cooling Stub | 41.900 | 21.000 | 40,800 | 18.600 | 39.500 | 16.100 | 38.500 | 13.500 | 37.400 | 10.900 | 36.200 | 8.300 | 35.000 | 5.600 | 33.900 | 2.800 | 32.700 | |

| Sensible Elluh | 25.900 | 5,300 | 25.400 | 3.500 | 24.900 | 1.700 | 24.400 | (300) | 23,900 | (2.100) | 23.400 | (4.100) | 22,800 | (6.000) | 22.300 | (7.900) | 21.700 | (9,900) | |

| 5/1 | 0.618 | 0.252 | 0.623 | 0.188 | 0.630 | 0.106 | 0.634 | 0 | 0.639 | 0 | 0.646 | 0 | 0.651 | 0 | 0.658 | 0 | 0.664 | 0 | |

| Latent 8tuh | 16.000 | 15.700 | 15.400 | 15.100 | 14,600 | 14,400 | 14,100 | 13,800 | 13,500 | 13.000 | 12,800 | 12.400 | 12,200 | 11.600 | 11.600 | 10.700 | 11.000 | 9,900 | |

| Lbs. H201nr. | 15.1 | 14.8 | 14.5 | 14.2 | 13.8 | 13.6 | 13.3 | 13.0 | 12.7 | 12.3 | 12.1 | 11.7 | 11.5 | 10.9 | 10.9 | 10.1 | 10.4 | 9.3 | |

| Supply Am 06 | 54.4 | 69.1 | 54.9 | 71.1 | 552 | 73.2 | 55.7 | 75.3 | 56.1 | 77.4 | 56.5 | 79.6 | 56.9 | 81.8 | 57.2 | 84.0 | 57.6 | 86.2 | |

| Supply An W8 | 53.3 | 57.3 | 53.7 | 58.3 | 54.0 | 59.2 | 54.5 | 60.3 | 54.8 | 61.3 | 55.2 | 62.4 | 55.5 | 63.5 | 55.9 | 64.6 | 56.2 | 65.8 | |

| Suction P510′ | 131 | 125 | 133 | 126 | 134 | 126 | 136 | 128 | 137 | 129 | 138 | 130 | 140 | 132 | 141 | 134 | 143 | 136 | |

| Discharge P5104 | 290 | 245 | 310 | 259 | 332 | 274 | 355 | 290 | 379 | 306 | 404 | 322 | 431 | 340 | 458 | 3513 | 487 | 376 | |

| 75/66.7165′ RH) | Taal Cooling Blob | 42.900 | 22.200 | 41.800 | 19.800 | 40.600 | 17.300 | 39.500 | 14.700 | 38.400 | 12.103 | 37.200 | 9.500 | 36.100 | 6.800 | 34,900 | 4.003 | 33.700 | 1.200 |

| Sensible Mull | 24200 | 4.400 | 23.800 | 2,603 | 23.300 | 70) | 22.800 | (1.200) | 22.200 | (3.100) | 21.700 | (5.000) | 21.200 | (6.900) | 20.600 | (8.800) | 20.10) | (10.800) | |

| S/T | 0.564 | 0.20 | 0.569 | 0.13 | 0.574 | 0.04 | 0.577 | 0 | 0.578 | 0 | 0.583 | 0 | 0.587 | 0 | 0.590 | 0 | 0.596 | 0 | |

| Latent Binh | 18.700 | 17.800 | 18.000 | 17,200 | 17.300 | 16,600 | 16.700 | 15,903 | 16.200 | 15,200 | 15.500 | 14.500 | 14.900 | 13.700 | 14.300 | 12.800 | 13.600 | 12.000 | |

| Lte.11204N. | 17.6 | 16.8 | 17.0 | 16.2 | 16.3 | 15.7 | 15.8 | 15.0 | 15.3 | 14.3 | 14.6 | 13.7 | 14.1 | 12.9 | 13.5 | 12.1 | 12.8 | 11.3 | |

| Supply Air 06 | 55.7 | 70.1 | 56.1 | 72.2 | 56.5 | 74.2 | 56.9 | 76.3 | 57.3 | 78.5 | 57.7 | 80.6 | 58.1 | 82.8 | 58.4 | 85.0 | 58.8 | 87.3 | |

| Supply Al WB | 54.7 | 58.4 | 55.1 | 59.4 | 55.4 | 60.3 | 55.8 | 6IA | 56.2 | 62.4 | 56.6 | 63.5 | 56.9 | 64.6 | 57.2 | 65.7 | 57.5 | 66.9 | |

| Suction P510′ | 134 | 128 | 136 | 129 | 137 | 129 | 139 | 131 | 140 | 132 | 141 | 133 | 143 | 135 | 144 | 137 | 146 | 139 | |

| Discharge F510′ | 292 | 247 | 312 | 262 | 334 | 277 | 356 | 292 | 380 | 308 | 406 | 325 | 432 | 342 | 460 | 360 | 489 | 379 | |

| 7968170% RH) | Total Cooling Stub | 43.900 | 23.400 | 42.800 | 21.000 | 41.600 | 18.500 | 40,600 | 15.900 | 39.400 | 13.300 | 38,300 | 10.600 | 37.100 | 7.900 | 35,900 | 5.200 | 34.700 | 2.400 |

| Sensible Elluh | 22.600 | 3.500 | 22.100 | 1.700 | 21.700 | (200) | 21.100 | (2.100) | 20,600 | (4.000) | 20.100 | (5.900) | 19.500 | (7.800) | 19.000 | (9.700) | 18.400 | (11.700) | |

| S/T | 0.515 | 0.150 | 0.516 | 0.081 | 0.522 | 0 | 0.520 | 0 | 0.523 | 0 | 0.525 | 0 | 0.526 | 0 | 0.529 | 0 | 0.530 | 0 | |

| Latent Shah | 21.300 | 19.900 | 20700 | 19.300 | 19.900 | 18.700 | 19,500 | 18.000 | 18.800 | 17.300 | 18,200 | 16.500 | 17.600 | 15.700 | 16,900 | 14.900 | 16.300 | 14.100 | |

| Lbs. H20/hr. | 20.1 | 18.8 | 19.5 | 18.2 | 18.8 | 17.6 | 18.4 | 17.0 | 17.7 | 16.3 | 17.2 | 15.6 | 16.6 | 14.8 | 15.9 | 14.1 | 15.4 | 13.3 | |

| Supply Am 03 | 56.9 | 71.1 | 57.3 | 73.2 | 57.7 | 75.2 | 58.1 | 77.4 | 58.5 | 79.5 | 58.9 | 81.7 | 59.3 | 83.9 | 59.7 | 86.1 | 60.0 | 88.3 | |

| Supply An W8 | 56.0 | 59.5 | 56.4 | 60.4 | 56.7 | 61.4 | 57.2 | 62.5 | 57.6 | 63.5 | 57.9 | 64.6 | 58.3 | 65.7 | 58.6 | 66.8 | 58.9 | 68.0 | |

| Suction P510′ | 137 | 131 | 139 | 132 | 140 | 132 | 142 | 134 | 143 | 135 | 144 | 136 | 146 | 138 | 147 | 140 | 149 | 142 | |

| Discharge P510′ | 293 | 250 | 314 | 264 | 335 | 279 | 358 | 295 | 382 | 311 | 407 | 328 | 434 | 345 | 462 | 363 | 490 | 382 | |

| 80/683(55% RIO | Tolal Cooling Stub | 44.300 | 24.700 | 43.200 | 22.200 | 42.000 | 19.700 | 41,000 | 17.200 | 39.800 | 14.600 | 38.700 | 11.900 | 37.500 | 9200 | 36.300 | 6.500 | 35.100 | 3.700 |

| Sensible Bluh | 28.800 | 7.600 | 28.300 | 5.800 | 27.800 | 3.900 | 27.300 | 2.000 | 26.800 | 100 | 26.200 | (1.800) | 25.700 | (3.700) | 25.200 | (5.700) | 24.600 | (7.600) | |

| S/T | 0.650 | 0.31 | 0.655 | 0.26 | 0.662 | 0.20 | 0.666 | 0.12 | 0.673 | 0.01 | 0.677 | 0 | 0.685 | 0 | 0.694 | 0 | 0.701 | 0 | |

| Latent Ettuh | 15,500 | 17,100 | 14.900 | 16,400 | 14,200 | 15,803 | 13.700 | 15,200 | 13.000 | 14,500 | 12.500 | 13,700 | 11.800 | 12,900 | 11.100 | 12,200 | 10.500 | 11,300 | |

| Lbs. H2111r. | 14.6 | 16.1 | 14.1 | 15.5 | 13A | 14.9 | 12.9 | 14.3 | 12.3 | 13.7 | 11.8 | 12.9 | 11.1 | 12.2 | 10.5 | 11.5 | 9.9 | 10.7 | |

| Supply Air 06 | 57.6 | 72.1 | 58.0 | 74.2 | 58.4 | 76.2 | 58.9 | 78A | 59.3 | 80.5 | 59.6 | 82.6 | 60.0 | 84.8 | 60.4 | 87.0 | 60.7 | 89.3 | |

| Supply An WB | 56.4 | 59.5 | 56.8 | 60.5 | 57.1 | 61.4 | 57.5 | 62.5 | 57.9 | 63.5 | 58.3 | 64.6 | 58.6 | 65.7 | 58.9 | 66.8 | 59.2 | 68.0 | |

| Socha, P510′ | 138 | 133 | 140 | 134 | 141 | 134 | 143 | 136 | 144 | 137 | 145 | 139 | 147 | 140 | 148 | 142 | 150 | 144 | |

| Discharge P510 | 293 | 250 | 313 | 265 | 335 | 280 | 357 | 295 | 381 | 311 | 407 | 328 | 433 | 345 | 461 | 363 | 490 | 382 |

Values listed are with ventilation package disabledReturn air temperature °F @ Default airflow (1150 CFM) for AC tests and Balanced Climate airflow (790 CFM) for dehumidification testsBelow 50°F , unit requires a factory or field installed low ambient control.Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

W42ACD Cooling and Dehumidification Application Data1

| D8fW8 | 00 Temp. | 65T1 | 70T | 75T | 80’F | 85T | 90’F | 95T | 100T | 105T | |||||||||

| Mode | A/C | Odium | NC | Odium | NC | Delman | NC | Odium | A/C | Odium | NC | Odium | NC | Deleon | NC | ()Mum) | MC | ()thorn | |

| 75/62.5(50% RH) | Total Cooling 130M | 45.1300 | 22500 | 44.50) | 19.700 | 43.200 | 16,800 | 41.800 | 14.000 | 40.600 | 11.000 | 39.300 | 8.00) | 38.100 | 4.900 | 36.900 | 1.700 | 35.700 | |

| Sensible Blub | 33.30) | 9,200 | 32.600 | 7,000 | 32.100 | 4,900 | 31.500 | 2,500 | 30.900 | 300 | 30,300 | (2.000) | 29.800 | (4.300) | 29.300 | (6,600) | 28,800 | (9.000) | |

| ST | 0.725 | 0.409 | 0.733 | 0.355 | 0.743 | 0.292 | 0.754 | 0.179 | 0.761 | 0.027 | 0.771 | 0 | 0.782 | 0 | 0.794 | 0 | 0.807 | 0 | |

| Latent Blurt | 12.600 | 13.300 | 11.90) | 12.700 | 11.100 | 11.900 | 10.300 | 11.500 | 9.700 | 10.700 | 9.000 | 10.00) | 8.300 | 9.20) | 7.600 | 8.30) | 6,900 | 7.500 | |

| Lbs. H20/M. | 11.9 | 12.5 | 11.2 | 12.0 | 10.5 | 11.2 | 9.7 | 10.8 | 9.2 | 10.1 | 8.5 | 9.4 | 7.8 | 8.7 | 7.2 | 7.8 | 6.5 | 7.1 | |

| Supply Alf DB | 52.6 | 66.1 | 53.0 | 68.3 | 53.3 | 70.4 | 53.8 | 72.6 | 54.2 | 74.8 | 54.5 | 76.9 | 54.9 | 79.1 | 55.3 | 81.4 | 55.6 | 83.6 | |

| Supply Air WO | 50.8 | 54.9 | 51.2 | 55.9 | 51.6 | 56.8 | 51.9 | 58.0 | 52.3 | 59.0 | 52.6 | 60.1 | 52.9 | 61.1 | 53.3 | 62.1 | 53.6 | 63.2 | |

| Suction PSIG• | 119 | 108 | 120 | 109 | 121 | 110 | 122 | 112 | 123 | 114 | 125 | 116 | 126 | 118 | 127 | 121 | 129 | 124 | |

| Dacharge PSIG• | 274 | 243 | 295 | 260 | 315 | 273 | 339 | 292 | 362 | 307 | 384 | 322 | 407 | 335 | 431 | 348 | 455 | 360 | |

| 75/64.1(55% RH) | Total Cooling BUM | 47.200 | 24.000 | 45.800 | 21.200 | 44.500 | 18.300 | 43.200 | 15.400 | 41.900 | 12.400 | 40.600 | 9.40) | 39.400 | 6.30) | 38.200 | 3.20) | 37.000 | |

| Sensible Stub | 31,500 | 8.200 | 30,900 | 6,000 | 30,300 | 3,800 | 29,700 | 1.500 | 29,100 | (70)) | 28,600 | (3,000) | 28.000 | (5.300) | 27,500 | (7,600) | 27.000 | (10,000) | |

| SR | 0.667 | 0.34 | 0.675 | 0.28 | 0.681 | 0.21 | 0.688 | 0.10 | 0.695 | 0 | 0.704 | 0 | 0.711 | 0 | 0.720 | 0 | 0.730 | 0 | |

| Latent Stub | 15.700 | 15.800 | 14.903 | 15200 | 14.200 | 14.500 | 13.500 | 13.900 | 12.800 | 13,100 | 12.000 | 12.403 | 11.400 | 11.603 | 10.700 | 10,803 | 10.000 | 10.000 | |

| Lbs. H20/fir. | 14.8 | 14.9 | 14.1 | 14.3 | 13.4 | 13.7 | 12.7 | 13.1 | 12.1 | 12.4 | 11.3 | 11.7 | 10.8 | 10.9 | 10.1 | 102 | 9.4 | 9.4 | |

| Supply Air DB | 53.8 | 67.1 | 542 | 69.2 | 54.6 | 71.4 | 54.9 | 73.5 | 55.3 | 75.7 | 55.7 | 77.9 | 56.1 | 80.1 | 56.4 | 82.3 | 56.8 | 84.5 | |

| Sup* Air WB | 522 | 56.0 | 52.6 | 57.0 | 53.0 | 58.0 | 53.3 | 59.0 | 53.7 | 60.1 | 54.0 | 61.1 | 54.3 | 622 | 54.6 | 632 | 54.9 | 64.3 | |

| Suction PSIS. | In | 111 | 123 | 112 | 124 | 113 | 125 | 115 | 126 | 117 | 128 | 119 | 129 | 122 | 130 | 124 | 132 | 128 | |

| De.411.9ge PSIG | 275 | 246 | 297 | 263 | 319 | 280 | 341 | 295 | 363 | 310 | 386 | 325 | 409 | 338 | 433 | 351 | 456 | 363 | |

| 75/65.5(60% RH) | Total Cooling alai | 48.500 | 25.400 | 47.100 | 22.600 | 45.800 | 19.700 | 44.500 | 16.900 | 43.200 | 13,900 | 41.900 | 10.900 | 40.700 | 7.800 | 39.500 | 4.603 | 38.400 | 1.400 |

| Sensible Mull | 29.700 | 7.200 | 29.100 | 5.000 | 28.500 | 2,900 | 27.900 | 500 | 27.400 | (1.700) | 26.800 | (4.000) | 26.300 | (6.300) | 25.700 | (8.600) | 25,200 | (11.000) | |

| ST | 0.612 | 0.283 | 0.618 | 0.221 | 0.622 | 0.147 | 0.627 | 0.030 | 0.634 | 0 | 0.640 | 0 | 0.646 | 0 | 0.651 | 0 | 0.656 | 0 | |

| Latent Club | 18.80) | 18.200 | 18.000 | 17.600 | 17.300 | 16,800 | 16.600 | 16.400 | 15.800 | 15.600 | 15.100 | 14.90) | 14.400 | 14.10) | 13.800 | 13.20) | 13,200 | 12.400 | |

| Lbs. H20lre. | 17.7 | 17.2 | 17.0 | 16.6 | 16.3 | 15.8 | 15.7 | 15.5 | 14.9 | 14.7 | 142 | 14.1 | 13.6 | 13.3 | 13.0 | 12.5 | 12.5 | 11.7 | |

| Supply Air DB | 54.9 | 68.0 | 55.3 | 70.2 | 55.6 | 72.3 | 56.1 | 74.5 | 56.5 | 76.7 | 56.9 | 78.8 | 57.2 | 81.0 | 57.6 | 83.3 | 58.0 | 85.5 | |

| Soppy Au WO | 53.6 | 57.0 | 54.0 | 58.1 | 54.3 | 59.0 | 54.7 | 60.1 | 55.0 | 61.1 | 55.4 | 62.2 | 55.7 | 63.2 | 56.0 | 64.3 | 56.3 | 65.3 | |

| Suction PSIG• | 125 | 114 | 126 | 115 | 127 | 117 | 128 | 118 | 129 | 120 | 131 | 122 | 132 | 125 | 134 | 128 | 135 | 131 | |

| Ditchers* PSIG• | 277 | 249 | 298 | 266 | 318 | 279 | 342 | 298 | 365 | 313 | 387 | 328 | 411 | 341 | 434 | 354 | 458 | 366 | |

| 75/66.7(65% RH) | Total Cooling Blob | 49,800 | 26.800 | 48,400 | 24.000 | 47,100 | 21.100 | 45.800 | 18.300 | 44.500 | 15,300 | 43.300 | 12,300 | 42.000 | 9.200 | 40.800 | 6.100 | 39.700 | 2.800 |

| Sensible Dull | 28,000 | 6.200 | 27,300 | 4.000 | 26,800 | 1.900 | 26.200 | (500) | 25.600 | (2,700) | 25.000 | (5,000) | 24.500 | (7.300) | 24.000 | (9.600) | 23.500 | (12.000) | |

| ST | 0.562 | 0.23 | 0.564 | 0.17 | 0.569 | 0.09 | 0.572 | 0 | 0.575 | 0 | 0.577 | 0 | 0.583 | 0 | 0.588 | 0 | 0.592 | 0 | |

| Latent 131uh | 21,800 | 20.600 | 21.100 | 20.000 | 20,300 | 19.200 | 19.600 | 18.800 | 18.900 | 18,000 | 18.300 | 17,300 | 17.500 | 16.500 | 16.800 | 15.700 | 16.200 | 14.800 | |

| Lbs. H20/M. | 20.6 | 19.4 | 19.9 | 18.9 | 19.2 | 18.1 | 18.5 | 17.7 | 17.8 | 17.0 | 17.3 | 16.3 | 16.5 | 15.6 | 15.8 | 148 | 15.3 | 14.0 | |

| Supply Air DB | 56.1 | 69.0 | 56.5 | 71.1 | 56.8 | 73.3 | 57.3 | 75.4 | 57.7 | 77.6 | 58.0 | 79.8 | 58.4 | 82.0 | 58.8 | 842 | 59.1 | 86.4 | |

| Sup* Air WO | 55.0 | 58.1 | 55.3 | 59.1 | 55.7 | 60.0 | 56.1 | 61.2 | 56.4 | 62.2 | 56.8 | 63.2 | 57.1 | 64.3 | 57.4 | 65.3 | 57.7 | 66.4 | |

| Suction PSIS’ | 128 | 118 | 129 | 119 | 130 | 120 | 131 | 121 | 133 | 123 | 134 | 126 | 135 | 128 | 137 | 131 | 138 | 134 | |

| Discharge PSIG• | 279 | 252 | 30D | 269 | 320 | 282 | 344 | 301 | 366 | 316 | 389 | 331 | 412 | 344 | 436 | 357 | 459 | 369 | |

| 75/68(70% RIO | TOW Cooling Ruh | 51.100 | 28.300 | 49,800 | 25.500 | 48,500 | 22.500 | 47.100 | 19.700 | 45.800 | 16,800 | 44.600 | 13,700 | 43.400 | 10,600 | 42.200 | 7,500 | 41.000 | 4,300 |

| Sensible Club | 26.20) | 5.200 | 25.60) | 3,000 | 25.0)0 | 900 | 24,400 | 11.50)) | 23.800 | (3.70)) | 23.300 | (6.000) | 22.700 | (8.300) | 22.200 | (10.600) | 21.700 | (13.000) | |

| ST | 0.513 | 0.184 | 0.514 | 0.118 | 0.515 | 0.040 | 0.518 | 0 | 0.520 | 0 | 0.522 | 0 | 0.523 | 0 | 0.526 | 0 | 0.529 | 0 | |

| Latent Club | 24.90) | 23.100 | 24.200 | 22,500 | 23,500 | 21.600 | 22,700 | 21.200 | 22.000 | 20.500 | 21.300 | 19.700 | 20,700 | 18.900 | 20,000 | 18.100 | 19,300 | 17.300 | |

| Lbs. H20.Mr. | 23.5 | 21.8 | 22.8 | 21.2 | 22.2 | 20.4 | 21.4 | 20.0 | 20.8 | 19.3 | 20.1 | 18.6 | 19.5 | 17.8 | 18.9 | 17.1 | 18.2 | 16.3 | |

| Supply Air DB | 57.3 | 69.9 | 57.7 | 72.1 | 58.0 | 74.2 | 58.5 | 76.4 | 58.8 | 78.6 | 59.2 | 80.8 | 59.6 | 83.0 | 59.9 | 85.2 | 60.3 | 87.4 | |

| Supply All WO | 56.4 | 59.2 | 56.7 | 60.2 | 57.1 | 61.1 | 57.5 | 62.2 | 57.8 | 63.3 | 58.1 | 64.3 | 58.5 | 65.4 | 58.8 | 66.4 | 59.1 | 67.5 | |

| Suction PSIG• | 131 | 121 | 132 | 122 | 133 | 123 | 134 | 125 | 136 | 127 | 137 | 129 | 138 | 131 | 140 | 134 | 141 | 137 | |

| Deglusge PSIS’ | 280 | 255 | 302 | 272 | 322 | 285 | 345 | 304 | 368 | 319 | 391 | 334 | 414 | 347 | 437 | 360 | 461 | 372 | |

| 80168.3(55% RH) | Total Coslirre BUM | 51.700 | 29.200 | 50.303 | 26.400 | 49.000 | 23.400 | 47.603 | 20,600 | 46.400 | 17.700 | 45.100 | 14.603 | 43.900 | 11.503 | 42.700 | 8.403 | 41.500 | 5.200 |

| Sensible Stub | 32,900 | 9.900 | 32,200 | 7.700 | 31,700 | 5.600 | 31.100 | 3.200 | 30.500 | 1,000 | 29.900 | (1,300) | 29.400 | (3.600) | 28.900 | (5.900) | 28.400 | (8.300) | |

| SR | 0.636 | 0.34 | 0.640 | 0.29 | 0.647 | 0.24 | 0.653 | 0.16 | 0.657 | 0.06 | 0.663 | 0 | 0.670 | 0 | 0.677 | 0 | 0.684 | 0 | |

| Latent Stub | 18,800 | 19.300 | 18,103 | 18,700 | 17,303 | 17.800 | 16,500 | 17.400 | 15.900 | 16,700 | 15.200 | 15,900 | 14.500 | 15,103 | 13,800 | 14,303 | 13.100 | 13,500 | |

| Lbs. 1120/M. | 17.7 | 18.2 | 17.1 | 17.6 | 16.3 | 16.8 | 15.6 | 16.4 | 15.0 | 15.8 | 14.3 | 15.0 | 13.7 | 142 | 13.0 | 13.5 | 12.4 | 12.7 | |

| Supply Air DB | 58.0 | 70.4 | 58.4 | 72.5 | 58.7 | 74.6 | 59.2 | 76.8 | 59.6 | 79.0 | 60.0 | 81.2 | 60.4 | 83.4 | 60.7 | 85.6 | 61.1 | 87.8 | |

| Supply Air WI3 | 56.3 | 59.2 | 56.7 | 60.2 | 57.0 | 61.2 | 57.4 | 62.3 | 57.7 | 63.3 | 58.1 | 64.4 | 58.4 | 65.4 | 58.7 | 66.4 | 59.0 | 67.5 | |

| Suction PSIS’ | 131 | 121 | 132 | 122 | 133 | 123 | 135 | 125 | 136 | 127 | 137 | 129 | 139 | 132 | 140 | 135 | 141 | 138 | |

| Dtscliten PSIS’ | 280 | 255 | 302 | 273 | 322 | 285 | 346 | 305 | 368 | 320 | 391 | 334 | 414 | 348 | 437 | 360 | 461 | 373 |

1.Values listed are with ventilation package disabled2.Return air temperature °F @ Default airflow (1350 CFM) for AC tests and Balanced Climate airflow (950 CFM) for dehumidification tests3.Below 50°F , unit requires a factory or field installed low ambient control.4.Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

W48ACD Cooling and Dehumidification Application Data1

| D8AV8 | OD te.

rm |

65D | 70–F | 75–F | 80–F | 85–F | 90’i | 95 T | 1013–F | 105–F | |||||||||

| Node | At | ()sham | NC | Dehum | At | Odium | NC | Osborn | A/C | Odium | NC | (*hum | NC | Dehum | NC | Oakum | A/C | Oakum | |

| 75/62.5(50% RH) | Total Coaling [Ruh | 53.100 | 26.400 | 52.100 | 23.400 | 50.800 | 20.000 | 49.600 | 17.000 | 48.000 | 13.600 | 46.200 | 10.103 | 44.200 | 6.503 | 42.100 | 2.800 | 39,700 | |

| Sensible Club | 39.800 | 11.100 | 39.303 | 8,700 | 39.200 | 6,300 | 38200 | 3,900 | 37.500 | 1.400 | 36.700 | (1.100) | 35.900 | (3.600) | 35,000 | (6.100) | 34,000 | (8.700) | |

| SR | 0.750 | 0.420 | 0.754 | 0.372 | 0.772 | 0.315 | 0.770 | 0.229 | 0.781 | 0.103 | 0.794 | 0 | 0.812 | 0 | 0831 | 0 | 0.856 | 0 | |

| Latent Club | 13.300 | 15.300 | 12.800 | 14.700 | 11.600 | 13.700 | 11.400 | 13.100 | 10.500 | 12.200 | 9.500 | 11.2120 | 8.300 | 10.100 | 7.100 | 8.900 | 5.700 | 7,700 | |

| Lbs. 1120/nr. | 12.5 | 14.4 | 12.1 | 13.9 | 10.9 | 12.9 | 10.8 | 12.4 | 9.9 | 11.5 | 9.0 | 10.6 | 7.8 | 9.5 | 6.7 | 8.4 | 5.4 | 7.3 | |

| Supply /or DB | 51.5 | 65.9 | 51.7 | 67.9 | 52.0 | 69.8 | 52.3 | 71.9 | 52.7 | 73.9 | 53.2 | 76.0 | 53.8 | 78.0 | 54.4 | 80.1 | 55.1 | 82.2 | |

| Supply Air WI3 | 50.4 | 54.8 | 50.7 | 55.7 | 50.9 | 56.7 | 51.3 | 57.7 | 51.7 | 58.7 | 522 | 59.8 | 52.6 | 60.8 | 53.1 | 61.9 | 53.7 | 63.0 | |

| Suction PSIG• | 127 | 117 | 129 | 118 | 130 | 119 | 132 | 121 | 134 | 123 | 135 | 125 | 136 | 127 | 136 | 130 | 137 | 133 | |

| Discharge PSIG• | 287 | 237 | 307 | 254 | 328 | 269 | 349 | 288 | 373 | 304 | 397 | 320 | 424 | 336 | 451 | 351 | 480 | ||

| 75/64.1(55% RH) | Total Cooling WO | 54.400 | 28.000 | 53.40) | 25.000 | 52.200 | 21.800 | 50.800 | 18.600 | 49.300 | 15.200 | 47.500 | 11.700 | 45.500 | 8.100 | 43.300 | 4.40) | 41.000 | 600 |

| Sensible Stull | 37,500 | 9.700 | 37,000 | 7.400 | 36,500 | 5.000 | 35,900 | 2,600 | 35.200 | 100 | 34,400 | (2,400) | 33.600 | (4,900) | 32.600 | (7.400) | 31.600 | (10.000) | |

| SR | 0.689 | 0.35 | 0.693 | 0.30 | 0.699 | 0.23 | 0.707 | 0.14 | 0.714 | 0.01 | 0.724 | 0 | 0.738 | 0 | 0.753 | 0 | 0.771 | 0 | |

| Latent Slut, | 16.903 | 18.300 | 16.400 | 17.600 | 15.700 | 16.800 | 14.900 | 16.000 | 14.100 | 15.100 | 13.100 | 14.100 | 11.900 | 13.000 | 10.700 | 11.800 | 9.400 | 10.600 | |

| Lbs. 1120/1”. | 15.9 | 17.3 | 15.5 | 16.6 | 14.8 | 15.8 | 14.1 | 15.1 | 13.3 | 14.2 | 12A | 13.3 | 11.2 | 12.3 | 10.1 | 11.1 | 8.9 | 10.0 | |

| Supply Air DB | 52.9 | 67.0 | 53.1 | 68.9 | 53.4 | 70.9 | 53.7 | 73.0 | 542 | 75.0 | 54.6 | 77.0 | 55.2 | 79.1 | 55.8 | 812 | 56.5 | 83.3 | |

| Supply Air we | 51.9 | 55.9 | 522 | 56.8 | 52.5 | 57.8 | 52.9 | 58.8 | 532 | 59.8 | 53.7 | 60.9 | 54.1 | 61.9 | 54.7 | 63.0 | 55.2 | 64.1 | |

| Suction PSIG• | 130 | 120 | 132 | 121 | 134 | 122 | 135 | 124 | 137 | 126 | 138 | 128 | 139 | 130 | 139 | 133 | 140 | 136 | |

| Diachspe PSIGI | 289 | 239 | 308 | 257 | 329 | 274 | 351 | 291 | 374 | 307 | 399 | 323 | 425 | 338 | 452 | 354 | 481 | 368 | |

| 75/65.5(60% RH) | Total Cooling Stub | 55.600 | 29.600 | 54.700 | 26.500 | 53.300 | 23.200 | 52.100 | 20.100 | 50.500 | 16.800 | 48.800 | 13.300 | 46.800 | 9.700 | 44.600 | 6,000 | 42.300 | 2200 |

| Sensible (Huh | 35.200 | 8.400 | 34.700 | 6.100 | 34.500 | 3.700 | 33.600 | 1.300 | 32.900 | (1.200) | 32.100 | (3.700) | 31.200 | (6200) | 30.300 | (8.700) | 29.300 | (11.300) | |

| SR | 0.633 | 0.284 | 0.634 | 0.230 | 0.647 | 0.159 | 0.645 | 0.065 | 0.651 | 0 | 0.658 | 0 | 0.667 | 0 | 0.679 | 0 | 0.693 | 0 | |

| Latent Stub | 20.400 | 21.200 | 20.000 | 20.400 | 18.800 | 19.500 | 18.500 | 18,800 | 17.600 | 18.000 | 16.700 | 17.00) | 15.600 | 15.900 | 14.300 | 14.700 | 13,000 | 13.500 | |

| Lbs. 1120/hr. | 19.2 | 20.0 | 18.9 | 19.2 | 17.7 | 18.4 | 17.5 | 17.7 | 16.6 | 17.0 | 158 | 16.0 | 14.7 | 15.0 | 13.5 | 13.9 | 12.3 | 12.7 | |

| Supply Alf DB | 54.3 | 68.0 | 54.5 | 70.0 | 54.8 | 72.0 | 55.2 | 74.0 | 55.6 | 76.1 | 56.1 | 78.1 | 56.6 | 80.2 | 57.2 | 82.2 | 57.9 | 84.3 | |

| Supply Air W8 | 53.4 | 57.0 | 53.7 | 57.9 | 53.9 | 58.9 | 54.4 | 59.9 | 54.8 | 60.9 | 55.2 | 62.0 | 55.7 | 63.0 | 56.2 | 64.1 | 56.7 | 65.2 | |

| 133 | 123 | 135 | 124 | 137 | 125 | 138 | 127 | 140 | 129 | 141 | 131 | 142 | 134 | 142 | 136 | 143 | 139 | ||

| Sucbon PSIG | |||||||||||||||||||

| Nichols PSIG | 290 | 242 | 309 | 259 | 331 | 274 | 352 | 293 | 375 | 309 | 400 | 325 | 426 | 341 | 454 | 356 | 483 | 371 | |

| 75/66.7(65% RH) | Total Gaoling Btu% | 56,900 | 31.200 | 56.003 | 28.100 | 54.603 | 24.800 | 53.403 | 21.700 | 51.833 | 18.400 | 50.100 | 14.903 | 48.100 | 11.300 | 45.900 | 7.603 | 43.500 | 3.800 |

| Sensible Stub | 32,800 | 7.100 | 32.400 | 4,800 | 32.200 | 2.400 | 31200 | (100) | 30,500 | (2.500) | 29.800 | (5.000) | 28.900 | (7.500) | 28,000 | (10.000) | 27,000 | (12.600) | |

| SR | 0.576 | 0.23 | 0.579 | 0.17 | 0.590 | 0.10 | 0.584 | 0 | 0.589 | 0 | 0.595 | 0 | 0.601 | 0 | 0.610 | 0 | 0.621 | 0 | |

| Latent Stub | 24,100 | 24.100 | 23.600 | 23.300 | 22,400 | 22.400 | 22200 | 21.800 | 21.300 | 20.900 | 20.300 | 19.900 | 19.200 | 18.800 | 17.900 | 17.600 | 16.500 | 16.400 | |

| Lbs. 1120/1”. | 22.7 | 22.7 | 22.3 | 22.0 | 21.1 | 21.1 | 20.9 | 20.6 | 20.1 | 19.7 | 192 | 18.8 | 18.1 | 17.7 | 16.9 | 16.6 | 15.6 | 15.5 | |

| Supply Air DB | 55.8 | 69.1 | 56.0 | 71.1 | 56.2 | 73.0 | 56.6 | 75.1 | 57.0 | 77.1 | 57.5 | 79.2 | 58.0 | 812 | 58.6 | 83.3 | 59.3 | 85.4 | |

| Sup* Air WI3 | 54.9 | 58.0 | 552 | 59.0 | 55.4 | 60.0 | 55.9 | 61.0 | 56.3 | 62.0 | 56.7 | 63.0 | 57.2 | 64.1 | 57.7 | 65.2 | 58.2 | 66.3 | |

| Suction PSIG• | 136 | 126 | 138 | 127 | 140 | 129 | 141 | 130 | 143 | 132 | 144 | 134 | 145 | 137 | 145 | 139 | 146 | 142 | |

| Discharge PSIG | 291 | 244 | 311 | 262 | 332 | 276 | 353 | 296 | 377 | 312 | 402 | 328 | 428 | 343 | 455 | 359 | 484 | 373 | |

| 75/68(70% RH) | TOM coding BILti | 58.200 | 32.800 | 57.200 | 29.700 | 55,900 | 26.400 | 54.700 | 23.300 | 53.100 | 20.000 | 51.300 | 16.500 | 49.400 | 12.900 | 47.200 | 9.200 | 44.800 | 5.300 |

| Sensible (Huh | 30.500 | 5.800 | 30.100 | 3.400 | 29.900 | 1.100 | 28.900 | 11.4001 | 28.200 | (3.800) | 27.400 | (6.300) | 26.600 | (8.800) | 25.700 | (11,300) | 24.700 | (13.900) | |

| SR | 0.524 | 0.177 | 0.526 | 0.114 | 0.535 | 0.042 | 0.528 | 0 | 0.531 | 0 | 0.534 | 0 | 0.538 | 0 | 0.544 | 0 | 0.551 | 0 | |

| Latent Stub | 27.700 | 27.000 | 27.100 | 26.300 | 26.000 | 25,300 | 25.800 | 24.700 | 24.900 | 23.800 | 23.900 | 22.800 | 22.800 | 21.700 | 21.500 | 20.500 | 20.100 | 19.200 | |

| Lbs. H20/hr. | 26.1 | 25.5 | 25.6 | 24.8 | 24.5 | 23.9 | 24.3 | 23.3 | 23.5 | 22.5 | 22.5 | 21.5 | 21.5 | 20.5 | 20.3 | 19.3 | 19.0 | 18.1 | |

| Supply Air DO | 57.2 | 70.2 | 57.4 | 72.1 | 57.6 | 74.1 | 58.0 | 76.2 | 58.4 | 78.2 | 58.9 | 80.2 | 59.4 | 82.3 | 60.1 | 84.4 | 60.7 | 86.5 | |

| Supply Air WI3 | 56.5 | 59.1 | 56.7 | 60.1 | 57.0 | 61.1 | 57.4 | 62.1 | 57.8 | 63.1 | 58.2 | 64.1 | 58.7 | 65.2 | 59.2 | 66.3 | 59.7 | 67.4 | |

| Suction PSIG | 139 | 130 | 141 | 131 | 143 | 132 | 144 | 134 | 146 | 136 | 147 | 138 | 148 | 140 | 148 | 143 | 149 | 146 | |

| Discharge PSIG• | 293 | 247 | 312 | 264 | 333 | 279 | 355 | 298 | 378 | 314 | 403 | 330 | 429 | 346 | 457 | 361 | 485 | 376 | |

| 80/68.3(55% RH) | Total Coaling 13tLD | 58.200 | 33.300 | 57.300 | 30.200 | 55.900 | 26.900 | 54.700 | 23.800 | 53.100 | 20.500 | 51.400 | 17.000 | 49.400 | 13.400 | 47.200 | 9.700 | 44.800 | 5.800 |

| Sensible Stull | 37,900 | 11,200 | 37,500 | 8800 | 37,300 | 6.500 | 36.300 | 4.000 | 35.600 | 1,600 | 34.900 | (900) | 34.000 | (3.400) | 33,100 | (5,900) | 32.100 | (8.500) | |

| SR | 0.651 | 0.34 | 0.654 | 0.29 | 0.667 | 0.24 | 0.664 | 0.17 | 0.670 | 0.08 | 0.679 | 0 | 0.688 | 0 | 0.701 | 0 | 0.717 | 0 | |

| Latent Stub | 20,300 | 22.100 | 19,800 | 21.400 | 18,600 | 20.400 | 18.400 | 19.800 | 17.500 | 18,900 | 16.500 | 17,900 | 15.400 | 16,800 | 14.100 | 15,600 | 12.700 | 14,300 | |

| Lbs. 1120/hr. | 192 | 20.8 | 18.7 | 20.2 | 17.5 | 19.2 | 17.4 | 18.7 | 16.5 | 17.8 | 15.6 | 16.9 | 14.5 | 15.8 | 13.3 | 14.7 | 12.0 | 13.5 | |

| Supply Air DB | 57.5 | 70.5 | 57.7 | 72.5 | 58.0 | 74.4 | 58.3 | 76.5 | 58.8 | 78.5 | 592 | 80.6 | 59.8 | 82.7 | 60.4 | 84.7 | 61.1 | 86.8 | |

| Sup* Air WI3 | 56.5 | 59.1 | 56.8 | 60.1 | 57.0 | 61.1 | 57.4 | 62.1 | 57.8 | 63.1 | 58.3 | 64.1 | 58.7 | 652 | 59.2 | 66.3 | 59.8 | 67.4 | |

| Suction PSIG | 139 | 130 | 142 | 131 | 143 | 133 | 145 | 134 | 146 | 136 | 147 | 138 | 148 | 141 | 149 | 143 | 149 | 146 | |

| Discharge PSIG4 | 288 | 241 | 307 | 258 | 329 | 272 | 350 | 292 | 373 | 308 | 398 | 324 | 424 | 340 | 452 | 355 | 481 | 370 |

1.Values listed are with ventilation package disabled2.Return air temperature °F @ Default airflow (1550 CFM) for AC tests and Balanced Climate airflow (1090 CFM) for dehumidification tests3.Below 50°F , unit requires a factory or field installed low ambient control.4.Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

W60ACD Cooling and Dehumidification Application Data1

| DBMS | OD Temp. | 65’F’ | 70″F | 75″F | 80’F | 85•F | 90″F | 957 | 100″F | 105•F | |||||||||

| Mode | AC | Delman | NC | Dehum | NC | Dehum | WC | Debum | NC | Debum | NC | Dehum | NC | Dehum | NC | Dehum | AIC | Dehum | |

| 75/62.5(50% RH) | Total Cooling Mull | 65.400 | 31.900 | 63.800 | 28.500 | 62,100 | 24.700 | 60.500 | 21.600 | 58.800 | 18.000 | 57.000 | 14.300 | 55.200 | 10.50) | 53.300 | 6.600 | 51.400 | 2.600 |

| Sensible Stub | 47.600 | 13.600 | 46.900 | 11.200 | 46.200 | 8.700 | 45.400 | 6.400 | 44.700 | 3.800 | 43.900 | 1.300 | 43.100 | (1.300) | 42.300 | (4.000) | 41.500 | (6.700) | |

| SR | 0.728 | 0.426 | 0.735 | 0.393 | 0.744 | 0.352 | 0.750 | 0.296 | 0.760 | 0.211 | 0.770 | 0.091 | 0.781 | 0 | 0.794 | 0 | 0.807 | 0 | |

| Latent Stun | 17.800 | 18.300 | 16.900 | 17.300 | 15.900 | 16.000 | 15.100 | 15,200 | 14.100 | 14,200 | 13.100 | 13.000 | 12.100 | 11.800 | 11,000 | 10.60) | 9,900 | 9.300 | |

| Lbs. H20/hr. | 16.8 | 17.3 | 15.9 | 16.3 | 15.0 | 15.1 | 14.2 | 14.3 | 13.3 | 13.4 | 12.4 | 12.3 | 11.4 | 11.1 | 10.4 | 10.0 | 9.3 | 8.8 | |

| Supply Air DB | 50.3 | 65.2 | 50.7 | 66.9 | 51.0 | 68.7 | 51.4 | 70.4 | 51.8 | 72.3 | 52.2 | 74.1 | 52.6 | 76.1 | 53.0 | 78.0 | 53.4 | 80.0 | |

| Supply Air WI3 | 49.4 | 54.2 | 49.7 | 55.1 | 50.0 | 56.0 | 50.4 | 57.0 | 50.8 | 58.0 | 512 | 58.9 | 51.5 | 59.9 | 51.9 | 60.9 | 52.3 | 61.9 | |

| Suction PSIG• | 126 | 118 | 127 | 119 | 127 | 120 | 128 | 122 | 130 | 123 | 131 | 124 | 132 | 125 | 133 | 127 | 135 | 128 | |

| Discharge PSIS’ | 296 | 278 | 316 | 291 | 339 | 305 | 359 | 318 | 382 | 333 | 405 | 348 | 430 | 364 | 455 | 381 | 481 | 398 | |

| 75164.1(55% RH) | Total Ccolirel3kti | 66.870 | 33.600 | 65,200 | 30.300 | 63,600 | 26.800 | 61.900 | 23.300 | 60.200 | 19,700 | 58.400 | 16.000 | 56.600 | 12,200 | 54.700 | 8,300 | 52.800 | 4.400 |

| Sensible Stub | 45,000 | 12.000 | 44,350 | 9.600 | 43,500 | 7.200 | 42.800 | 4.700 | 42,000 | 2,200 | 41,200 | (300) | 40,400 | (3.000) | 39.600 | (5.600) | 38.800 | (8400) | |

| SIT | 0.674 | 0.36 | 0.679 | 0.32 | 0.684 | 0.27 | 0.691 | 0.20 | 0.698 | 0.11 | 0.705 | 0 | 0.714 | 0 | 0.724 | 0 | 0.735 | 0 | |

| Latent Stub | 21.800 | 21.600 | 20.900 | 20.700 | 20.103 | 19.600 | 19.100 | 18.600 | 18.200 | 17,500 | 17.200 | 16.300 | 16.200 | 15,200 | 15.100 | 13,903 | 14.000 | 12.800 | |

| Lbs. H20/ht. | 20.6 | 20.4 | 19.7 | 19.5 | 19.0 | 18.5 | 18.0 | 17.5 | 17.2 | 16.5 | 162 | 15.4 | 15.3 | 14.3 | 14.2 | 13.1 | 13.2 | 12.1 | |

| Supply Air DB | 51.7 | 66.3 | 52.0 | 68.1 | 52.4 | 69.8 | 529 | 71.6 | 53.1 | 73.4 | 53.5 | 75.3 | 53.9 | 772 | 54.3 | 792 | 54.7 | 81.2 | |

| Supply Alf WI3 | 50.9 | 55.3 | 512 | 56.3 | 51.5 | 57.2 | 51.9 | 58.1 | 52.3 | 59.1 | 52.6 | 60.1 | 53.0 | 61.0 | 53.4 | 62.0 | 53.8 | 63.1 | |

| Suction PSIG• | 129 | 121 | 130 | 122 | 131 | 124 | 132 | 125 | 133 | 126 | 134 | 127 | 135 | 129 | 137 | 130 | 138 | 132 | |

| Dochsge PSIG | 298 | 282 | 318 | 295 | 340 | 308 | 362 | 322 | 384 | 337 | 408 | 352 | 432 | 368 | 458 | 385 | 484 | 402 | |

| 75/65.5(60% RH) | Total Cooling Stub | 68,200 | 35.300 | 66.600 | 32,000 | 65.000 | 28.100 | 63.300 | 25.000 | 61.600 | 21.400 | 59.800 | 17.700 | 58.000 | 13.900 | 56,100 | 10.100 | 54.200 | 6.100 |

| Sensible Stun | 42.300 | 10.300 | 41.600 | 8,000 | 40.900 | 5.400 | 40.100 | 3.100 | 39.400 | 600 | 38.600 | (2.000) | 37.800 | (4.600) | 37.000 | (7,300) | 36.100 | (10.000) | |

| SR | 0.620 | 0.292 | 0.625 | 0.250 | 0.629 | 0.192 | 0.633 | 0.124 | 0.640 | 0.028 | 0.645 | 0 | 0.652 | 0 | 0.660 | 0 | 0.666 | 0 | |

| Latent Btuh | 25.900 | 25,000 | 25.000 | 24,000 | 24.100 | 22,700 | 23.200 | 21,900 | 22.200 | 20.800 | 21.200 | 19.700 | 20.200 | 18.500 | 19,100 | 17.400 | 18.100 | 16,100 | |

| Lbs. 1120/M. | 24.4 | 23.6 | 23.6 | 22.6 | 22.7 | 21.4 | 21.9 | 20.7 | 20.9 | 19.6 | 20.0 | 18.6 | 19.1 | 17.5 | 18.0 | 16.4 | 17.1 | 15.2 | |

| Supply All DB | 53.0 | 67.5 | 53.4 | 69.2 | 53.7 | 71.0 | 54.1 | 72.8 | 54.5 | 74.6 | 54.9 | 76.5 | 55.3 | 78.4 | 55.7 | 80.3 | 56.1 | 82.3 | |

| Supply Alf WI3 | 52.3 | 56.5 | 52.7 | 57.4 | 52.9 | 58.3 | 53.4 | 59.3 | 53.7 | 60.2 | 54.1 | 61.2 | 54.5 | 622 | 54.9 | 63.2 | 55.3 | 64.2 | |

| Suction PSIG• | 132 | 125 | 133 | 126 | 134 | 127 | 135 | 128 | 136 | 129 | 137 | 131 | 139 | 132 | 140 | 133 | 141 | 135 | |

| Disclutv PSIG4 | 301 | 286 | 321 | 299 | 344 | 313 | 364 | 326 | 387 | 341 | 410 | 356 | 435 | 372 | 460 | 389 | 486 | 406 | |

| 75/66.7(65% RH) | Total Cooling [Huh | 69.603 | 37,100 | 68.000 | 33.700 | 66.400 | 29.900 | 64.700 | 26.800 | 63.000 | 23.100 | 61.200 | 19.400 | 59.400 | 15.700 | 57.600 | 11.803 | 55.600 | 7.800 |

| Sensible Slut, | 39.700 | 8.700 | 38,900 | 6.400 | 38.200 | 3,800 | 37.500 | 1.500 | 36700 | (1.000) | 35.900 | (3.600) | 35.100 | (6200) | 34.300 | (8.900) | 33.500 | (11.600) | |

| S/T | 0.570 | 0.23 | 0.572 | 0.19 | 0.575 | 0.13 | 0.580 | 0.06 | 0.583 | 0 | 0.587 | 0 | 0.591 | 0 | 0.595 | 0 | 0.603 | 0 | |

| Latent Stub | 29.900 | 28,400 | 29,100 | 27300 | 28,200 | 26.100 | 27200 | 25,300 | 26.300 | 24,100 | 25.300 | 23.000 | 24.300 | 21,900 | 23300 | 20,700 | 22,100 | 19,400 | |

| Lbs. 1420/ht. | 282 | 26.8 | 27.5 | 25.8 | 26.6 | 24.6 | 25.7 | 23.9 | 24.8 | 22.7 | 23.9 | 21.7 | 22.9 | 20.7 | 22.0 | 19.5 | 20.8 | 18.3 | |

| Supply Air DB | 544 | 68.7 | 54.7 | 70.4 | 55.1 | 72.2 | 55.5 | 73.9 | 55.9 | 75.7 | 56.2 | 77.6 | 56.6 | 79.5 | 57.1 | 81.5 | 57.5 | 83.5 | |

| Supply Alf WO | 53.8 | 57.6 | 54.1 | 58.5 | 54.4 | 59.4 | 54.8 | 60.4 | 552 | 61.4 | 55.5 | 62.3 | 55.9 | 63.3 | 56.3 | 64.3 | 56.7 | 65.3 | |

| Suction PSIS’ | 136 | 128 | 137 | 129 | 138 | 130 | 139 | 131 | 140 | 133 | 141 | 134 | 142 | 135 | 143 | 137 | 145 | 138 | |

| Drschsge PSIG | 303 | 290 | 324 | 303 | 347 | 317 | 367 | 330 | 389 | 345 | 413 | 360 | 437 | 376 | 463 | 393 | 489 | 410 | |

| I

75/613(70% RH) I |

Total Cooling Stir | 71.000 | 38.800 | 69.400 | 35,500 | 67.800 | 31.600 | 66.100 | 28.500 | 64.400 | 24.900 | 62.700 | 21.200 | 60.800 | 17.400 | 59.000 | 13.500 | 57.100 | 9.600 |

| Sensible [Huh | 37.000 | 7.100 | 36.300 | 4,700 | 35.600 | 2,200 | 34.800 | ( ICO) | 34.000 | (2.600) | 33.300 | (5.200) | 32.500 | (7900) | 31.600 | (10.500) | 30,800 | (13.200) | |

| SR | 0.521 | 0.183 | 0.523 | 0.132 | 0.525 | 0.070 | 0.526 | 0 | 0.528 | 0 | 0.531 | 0 | 0.535 | 0 | 0.536 | 0 | 0.539 | 0 | |

| Latent Slut, | 34.000 | 31700 | 33,100 | 30.800 | 32.200 | 29.400 | 31.300 | 28.600 | 30.400 | 27,500 | 29.400 | 26.400 | 28,300 | 25.200 | 27.400 | 24.000 | 26,300 | 22.800 | |

| Lbs. 1120/nr. | 32.1 | 29.9 | 31.2 | 29.1 | 30.4 | 27.7 | 29.5 | 27.0 | 28.7 | 25.9 | 27.7 | 24.9 | 26.7 | 23.8 | 25.8 | 22.6 | 24.8 | 21.5 | |

| Supply All D13 | 55.8 | 69.8 | 56.1 | 71.5 | 56.5 | 73.3 | 56.8 | 75.1 | 57.2 | 76.9 | 57.6 | 78.8 | 58.0 | 80.7 | 58.4 | 82.7 | 58.8 | 84.6 | |

| Supply Aw WB | 55.2 | 58.7 | 55.6 | 59.6 | 55.8 | 60.6 | 56.3 | 61.5 | 56.6 | 62.5 | 57.0 | 63.5 | 57.4 | 64.4 | 57.8 | 65.4 | 58.2 | 66.5 | |

| Suction PSIG | 139 | 131 | 140 | 132 | 141 | 134 | 142 | 135 | 143 | 136 | 144 | 137 | 146 | 139 | 147 | 140 | 148 | 142 | |

| Drscharge FSIG• | 306 | 294 | 326 | 307 | 349 | 321 | 369 | 334 | 392 | 349 | 416 | 364 | 440 | 380 | 465 | 397 | 491 | 414 | |

| 80A58.3(55% RH) | Total Costing Bluh | 71.400 | 39.200 | 69.900 | 35.900 | 68.200 | 32.000 | 66.600 | 28.900 | 64.800 | 25.300 | 63.100 | 21.600 | 61.300 | 17.800 | 59.400 | 14.000 | 57.500 | 10.000 |

| Sensible Stub | 45,800 | 13,600 | 45,100 | 11,200 | 44,400 | 8.700 | 43,600 | 6,400 | 42.800 | 3,800 | 42,000 | 1,300 | 41,200 | (1,300) | 40,400 | (4.000) | 39,600 | (6,700) | |

| SOT | 0.641 | 0.35 | 0.645 | 0.31 | 0.651 | 0.27 | 0.655 | 0.22 | 0.660 | 0.15 | 0.666 | 0.06 | 0.672 | 0 | 0.680 | 0 | 0.689 | 0 | |

| Latent Stub | 25,600 | 25,600 | 24,803 | 24,700 | 23,800 | 23.300 | 23,000 | 22,500 | 22.000 | 21,500 | 21,100 | 20,300 | 20.100 | 19,100 | 19,000 | 18,000 | 17,900 | 16,700 | |

| Lbs. 1120atir. | 242 | 24.2 | 23.4 | 23.3 | 22.5 | 22.0 | 21.7 | 21.2 | 20.8 | 20.3 | 19.9 | 19.2 | 19.0 | 18.0 | 17.9 | 17.0 | 16.9 | 15.8 | |

| Supply Air DB | 56.1 | 70.2 | 56.5 | 71.9 | 56.8 | 73.7 | 57.2 | 75.5 | 57.6 | 77.3 | 58.0 | 79.2 | 58.4 | 81.1 | 58.8 | 83.1 | 59.2 | 85.1 | |

| Supply Air WS | 55.4 | 58.9 | 55.7 | 59.9 | 56.0 | 60.8 | 56.4 | 61.7 | 56.8 | 62.7 | 572 | 63.7 | 57.5 | 64.7 | 57.9 | 65.7 | 58.3 | 66.7 | |

| Suction PSIS’ | 140 | 132 | 141 | 133 | 142 | 134 | 143 | 135 | 144 | 137 | 145 | 138 | 146 | 139 | 148 | 141 | 149 | 142 | |

| Discharge PSIS’ | 305 | 295 | 325 | 308 | 348 | 322 | 368 | 336 | 391 | 350 | 415 | 366 | 439 | 381 | 464 | 398 | 490 | 415 |

1.Values listed are with ventilation package disabled2.Return air temperature °F @ Default airflow (1750 CFM) for AC tests and Balanced Climate airflow (1180 CFM) for dehumidification tests3.Below 50°F , unit requires a factory or field installed low ambient control.4.Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

W72ACD Cooling and Dehumidification Application Data1

| 08.5/13 | 00 Temp. | 65’F’ | 70’F | 75F | 807 | 85F | 907 | 957 | 1007 | 1057 | |||||||||

| Mode | NC | Delman | AC | Dehum | A/C | Dehum | AC | Denum | NC | Dehum | NC | Dehum | NC | Dehum | NC | Clehurn | MC | Dehum | |

| 75/62.5(50% RH) | Total Cooling MLA | 79.000 | 38,500 | 77.000 | 35,000 | 75.200 | 31.700 | 73.100 | 27.700 | 71.000 | 23.800 | 69.000 | 19.800 | 67.000 | 15.703 | 64.900 | 11.400 | 62.800 | 6.900 |

| Sensible Mutt | 55.100 | 15.100 | 54.100 | 12.400 | 53.200 | 9.800 | 52200 | 6.900 | 51.200 | 4.100 | 50,300 | 1.200 | 49.400 | (1.700) | 48,500 | (4.700) | 47.700 | (7.700) | |

| SR | 0.697 | 0.392 | 0.703 | 0.354 | 0.707 | 0.309 | 0.714 | 0.249 | 0.721 | 0.172 | 0.729 | 0.061 | 0.737 | 0 | 0.747 | 0 | 0.760 | 0 | |

| Latent Bluti | 23.900 | 23.400 | 22.900 | 22,600 | 22.000 | 21.900 | 20.900 | 20,800 | 19.800 | 19.700 | 18,700 | 18.600 | 17.600 | 17.400 | 16.400 | 16.100 | 15.100 | 14.600 | |

| Lbs. H20/hr. | 22.5 | 22.1 | 21.6 | 21.3 | 20.8 | 20.7 | 19.7 | 19.6 | 18.7 | 18.6 | 17.6 | 17.5 | 16.6 | 16.4 | 15.5 | 15.2 | 14.2 | 13.8 | |

| Supply Air DB | 48.5 | 64.9 | 48.9 | 66.7 | 49.4 | 68.3 | 49.8 | 70.3 | 50.3 | 72.2 | 50.7 | 74.2 | 51.1 | 76.1 | 51.6 | 78.1 | 52.0 | 80.2 | |

| Supply Ao WB | 47.6 | 53.1 | 48.1 | 54.0 | 48.5 | 54.9 | 48.9 | 56.0 | 49.4 | 57.0 | 49.8 | 58.0 | 50.2 | 59.0 | 50.6 | 60.0 | 50.9 | 61.1 | |

| Suctnn PSIG• | 117 | 109 | 119 | 111 | 120 | 112 | 121 | 113 | 122 | 115 | 124 | 116 | 125 | 117 | 126 | 119 | 127 | 120 | |

| Drscharge PSIS’ | 301 | 300 | 321 | 313 | 342 | 326 | 365 | 341 | 389 | 356 | 413 | 372 | 439 | 389 | 466 | 406 | 494 | 425 | |

| 75/651(55% RH) | Total Cooling BILO | 80.800 | 40.600 | 78.900 | 37.200 | 76.900 | 33.600 | 74.900 | 29.800 | 72.900 | 26.000 | 70.900 | 21.900 | 68.800 | 17.800 | 66.700 | 13.500 | 64.600 | 9.000 |

| Sensible Stub | 52,200 | 13.200 | 51,200 | 10.600 | 50,200 | 7.800 | 49,200 | 5,100 | 48.300 | 2300 | 47.400 | (600) | 46,500 | (3,500) | 45.600 | (6,500) | 44.700 | (9,500) | |

| WI | 0.646 | 0.33 | 0.649 | 0.28 | 0.653 | 0.23 | 0.657 | 0.17 | 0.663 | 0.09 | 0.669 | 0 | 0.676 | 0 | 0.684 | 0 | 0.692 | 0 | |

| Latent Stub | 28.600 | 27.400 | 27.700 | 26.600 | 26.700 | 25.800 | 25.700 | 24.700 | 24.600 | 23.700 | 23.500 | 22.500 | 22.300 | 21.300 | 21.100 | 20,000 | 19.900 | 18.500 | |

| Lbt, H20/ht. | 27.0 | 25.8 | 26.1 | 25.1 | 25.2 | 24.3 | 24.2 | 23.3 | 232 | 22.4 | 222 | 21.2 | 21.0 | 20.1 | 19.9 | 18.9 | 18.8 | 17.5 | |

| Supply Air DB | 49.9 | 66.2 | 50.4 | 67.9 | 50.8 | 69.7 | 51.3 | 71.6 | 51.7 | 73.5 | 52.1 | 75.4 | 52.6 | 77.3 | 53.0 | 79.4 | 53.4 | 81.4 | |

| Sup* Air W13 | 49.1 | 54.2 | 49.6 | 55.1 | 50.0 | 56.1 | 50.4 | 57.0 | 50.9 | 58.0 | 51.3 | 59.0 | 51.7 | 60.1 | 52.1 | 61.1 | 52.4 | 62.2 | |

| Suction PSIS, | 120 | 112 | In | 114 | 123 | 115 | 124 | 116 | 125 | 118 | 127 | 119 | 128 | 120 | 129 | 122 | 130 | 123 | |

| DeschargenSEG’ | 301 | 305 | 324 | 317 | 346 | 331 | 368 | 345 | 392 | 361 | 416 | 377 | 442 | 394 | 469 | 411 | 497 | 430 | |

| 75/65.5(60% RH) | Total [colic* WO | 82.700 | 42.700 | 80.700 | 39.300 | 78.900 | 36,000 | 76,700 | 32,000 | 74.700 | 28.100 | 72.700 | 24.100 | 70.600 | 19.900 | 68.600 | 15.600 | 66.500 | 11200 |

| Sensible °tun | 49.300 | 11.400 | 48.200 | 8,700 | 47.300 | 6,200 | 46.300 | 3,300 | 45.400 | 400 | 44.400 | (2.400) | 43.500 | (5.400) | 42.700 | (8,300) | 41,800 | (11.300) | |

| SR | 0.596 | 0.267 | 0.597 | 0221 | 0.599 | 0.172 | 0.604 | 0.103 | 0.608 | 0.014 | 0.611 | 0 | 0.616 | 0 | 0.622 | 0 | 0.629 | 0 | |

| Latent ChM | 33.400 | 31.300 | 32.500 | 30,600 | 31.600 | 29,800 | 30.400 | 28.700 | 29.300 | 27.700 | 28,300 | 26.500 | 27.100 | 25.300 | 25.900 | 23.900 | 24.700 | 22.500 | |

| Lbs. 1120/hr. | 31.5 | 29.5 | 30.7 | 28.9 | 29.8 | 28.1 | 28.7 | 27.1 | 27.6 | 26.1 | 26.7 | 25.0 | 25.6 | 235 | 24.4 | 22.5 | 23.3 | 21.2 | |

| Supply Alf DB | 51.3 | 67.4 | 51.8 | 69.2 | 52.2 | 70.8 | 52.7 | 72.8 | 53.1 | 74.7 | 53.6 | 76.6 | 54.0 | 78.6 | 54.4 | 80.6 | 54.8 | 82.6 | |

| Supply Air WB | 50.6 | 55.2 | 51.1 | 56.2 | 51.5 | 57.1 | 51.9 | 58.1 | 52.3 | 59.1 | 529 | 60.1 | 53.2 | 612 | 53.5 | 62.2 | 53.9 | 63.3 | |

| Suctmen PSIG• | 124 | 115 | 125 | 117 | 126 | 118 | 127 | 119 | 129 | 121 | 130 | 122 | 131 | 123 | 132 | 125 | 133 | 126 | |

| Disclusge PSIS’ | 307 | 309 | 327 | 322 | 349 | 335 | 371 | 350 | 395 | 365 | 420 | 381 | 445 | 398 | 472 | 416 | 500 | 434 | |

| 75/66.7(65% RH) | Total Cooling 131uh | 84.500 | 44.800 | 82.600 | 41.400 | 80.700 | 38.100 | 78.600 | 34.100 | 76.600 | 30200 | 74.500 | 26.200 | 72.500 | 22.000 | 70.400 | 17.700 | 68,300 | 13.300 |

| Sensible Club | 46.300 | 9.600 | 45.300 | 6.900 | 44.400 | 4.400 | 43.400 | 1.400 | 42.400 | (1.400) | 41.500 | (4.300) | 40.600 | (7200) | 39.700 | (10,100) | 38.900 | (13.200) | |

| SR | 0.548 | 0.21 | 0.548 | 0.17 | 0.550 | 0.12 | 0.552 | 0.04 | 0.554 | 0 | 0.557 | 0 | 0.560 | 0 | 0.564 | 0 | 0.570 | 0 | |

| Latent (Ruh | 38,200 | 35.200 | 37,300 | 34.500 | 36,300 | 33.700 | 35.200 | 32.700 | 34.200 | 31.600 | 33.000 | 30.500 | 31.900 | 29.200 | 30.700 | 27.800 | 29.400 | 26.500 | |

| Lbs. 1120/fr. | 36.0 | 33.2 | 352 | 32.5 | 34.2 | 31.8 | 33.2 | 30.8 | 32.3 | 29.8 | 31.1 | 28.8 | 30.1 | 27.5 | 29.0 | 262 | 27.7 | 25.0 | |

| Supply Air 08 | 52.7 | 68.6 | 532 | 70.4 | 53.6 | 72.0 | 54.1 | 74.0 | 54.5 | 75.9 | 55.0 | 77.8 | 55.4 | 79.8 | 55.8 | 81.8 | 56.2 | 83.9 | |

| Supply Air W8 | 52.1 | 56.3 | 52.5 | 57.3 | 53.0 | 58.2 | 53.4 | 59.2 | 558 | 60.2 | 542 | 61.2 | 54.6 | 622 | 55.0 | 63.3 | 55.4 | 64.3 | |

| Suction PSIS’ | 127 | 118 | 128 | 120 | 129 | 121 | 131 | 122 | 132 | 123 | 133 | 125 | 134 | 126 | 135 | 128 | 136 | 129 | |

| Coschrge PSIG | 310 | 314 | 331 | 327 | 352 | 340 | 375 | 355 | 398 | 370 | 423 | 386 | 448 | 403 | 475 | 421 | 503 | 439 | |

| 75/68(70% RH) | Total Cooling (Ruh | 86.400 | 47.000 | 84.400 | 43.500 | 82.600 | 40.200 | 80.400 | 36.200 | 78.400 | 32.300 | 76.400 | 28.300 | 74.300 | 24.200 | 72.200 | 19.900 | 70.100 | 15.400 |

| Sensible Club | 43.400 | 7.800 | 42.400 | 5,100 | 41.500 | 2.500 | 40.400 | (4001 | 39.500 | (3.20)) | 38.600 | (6.100) | 37.700 | (9.000) | 36.800 | (12.000) | 36,000 | (15.000) | |

| SR | 0.502 | 0.166 | 0.502 | 0.117 | 0.502 | 0.062 | 0.502 | 0 | 0.504 | 0 | 0.505 | 0 | 0.507 | 0 | 0.510 | 0 | 0.514 | 0 | |

| Latent Club | 43.000 | 39.200 | 42.000 | 38.400 | 41.100 | 37.700 | 40.000 | 36.600 | 38.900 | 35.500 | 37.800 | 34.40) | 36.600 | 33.20) | 35.400 | 31.900 | 34.100 | 30.400 | |

| Lbs. 1120rter. | 40.6 | 37.0 | 39.6 | 36.2 | 38.8 | 35.6 | 37.7 | 34.5 | 36.7 | 33.5 | 35.7 | 32.5 | 34.5 | 31.3 | 33.4 | 30.1 | 32.2 | 28.7 | |

| Supply /or DB | 54.2 | 69.8 | 54.6 | 71.6 | 55.1 | 73.3 | 55.5 | 75.3 | 56.0 | 77.2 | 56.4 | 79.1 | 56.8 | 81.0 | 57.2 | 83.0 | 57.6 | 85.1 | |

| Supply Air WB | 53.6 | 57.4 | 54.0 | 58.4 | 54.5 | 59.2 | 54.9 | 60.3 | 55.3 | 61.3 | 55.7 | 62.3 | 56.1 | 63.3 | 56.5 | 64.4 | 56.9 | 65.4 | |

| Suctron PSIS’ | 130 | 121 | 131 | 123 | 132 | 124 | 134 | 125 | 135 | 126 | 136 | 128 | 137 | 129 | 138 | 131 | 140 | 132 | |

| Carthage PSIG• | 313 | 319 | 334 | 332 | 355 | 344 | 378 | 360 | 401 | 375 | 426 | 391 | 452 | 408 | 478 | 425 | 506 | 444 | |

| 80/68.3(55% RH) | Total Cooling elute | 86.500 | 46.800 | 84.600 | 43.300 | 82.700 | 40.000 | 80.600 | 36,000 | 78.600 | 32.100 | 76,500 | 28.100 | 74,500 | 23.900 | 72.400 | 19.600 | 70.300 | 15.200 |

| Sensible Stub | 53,200 | 14.300 | 52.200 | 11.700 | 51,300 | 9.100 | 50.300 | 6.200 | 49.300 | 3,300 | 48.400 | 500 | 47,500 | (2,400) | 46.700 | (5,400) | 45.800 | (8.400) | |

| SOT | 0.615 | 0.31 | 0.617 | 0.27 | 0.620 | 0.23 | 0.624 | 0.17 | 0.627 | 0.10 | 0.633 | 0.02 | 0.638 | 0 | 0.645 | 0 | 0.651 | 0 | |

| Latent Stull | 33,300 | 32.500 | 32,400 | 31.600 | 31,400 | 30.900 | 30.300 | 29.800 | 29.300 | 28,800 | 28.100 | 27,600 | 27.000 | 26,300 | 25.700 | 25,000 | 24.500 | 23.600 | |

| Lbs. 1120/hr. | 31A | 30.7 | 30.6 | 29.8 | 29.6 | 29.2 | 28.6 | 28.1 | 27.6 | 27.2 | 26.5 | 26.0 | 25.5 | 24.8 | 24.2 | 23.6 | 23.1 | 22.3 | |

| Supply Air DB | 54.3 | 70.4 | 54.8 | 72.2 | 55.3 | 73.8 | 55.7 | 75.8 | 562 | 77.7 | 56.6 | 79.6 | 57.0 | 81.6 | 57.4 | 83.6 | 57.8 | 85.6 | |

| Supply Air we | 53.5 | 57.6 | 54.0 | 58.6 | 54.4 | 59.5 | 54.8 | 60.5 | 55.3 | 61.5 | 55.7 | 62.5 | 56.1 | 63.6 | 56.5 | 64.6 | 56.8 | 65.6 | |

| Suction PSIS’ | 131 | 122 | 132 | 123 | 133 | 124 | 135 | 126 | 136 | 127 | 137 | 128 | 138 | 130 | 139 | 131 | 140 | 133 | |

| oscine PSIS’ | 314 | 321 | 334 | 334 | 356 | 346 | 378 | 362 | 402 | 377 | 426 | 393 | 452 | 410 | 479 | 427 | 507 | 446 |

1. Values listed are with ventilation package disabled2. Return air temperature °F @ Default airflow (1900 CFM) for AC tests and Balanced Climate airflow (1330 CFM) for dehumidification tests3. Below 50°F , unit requires a factory or field installed low ambient control.4. Suction pressure +/- 4 psi, Discharge pressure +/- 10 psi

|

|

TABLE 3Dehumidification Relay Logic Board

| Energize on UnitTerminal Strip | Mode | Occupied/Unoccupied | Inputs to the Board | Outputs from theBoard | ||

| Y | W2 | A 1 | D | TWV | YO | |

| Yl. G | Cooling | Unoccupied | X | X | ||

| Yl. G. A | Cooling | Occupied | X | X | X | |

| Yl. G, A. D | Cooling w/Dehum 0 | Occupied | X | X | X | X |

| Yl, G, D | Cooling w/Dehum 0 | Unoccupied | X | X | X | |

| G, 6/W1 | 1st Stage Electric Heat | Unoccupied | X | |||

| G. 6/W1, A | 1st Stage Electric Heat | Occupied | X | X | ||

| G. BN111, A, D | 1st Stage Electric Heat w/Dehum | Occupied | X | X | ||

| G. 6/W1, D | 1st Stage Electric Heat w/Dehum | Unoccupied | X | |||

| G, 6/W1, W2 | 2nd Stage Electric Heat | Unoccupied | X | |||

| G, 6/W1, W2, A | 2nd Stage Electric Heat | Occupied | X | X | ||

| G, B/W1, W2, A, D | 2nd Stage Electric Heat and Dehum Q) | Occupied | X | X | ||

| G, 6/W1, W2, D | 2nd Stage Electric Heat and Dehum 0) | Unoccupied | X | |||

| D | Dehum | Unoccupied | X | X 0 | X 0 | |

| D, A | Deum | Occupied | X | X | X | X |

- Cooling takes precedence over dehumidification. A cooling call cancels dehumidification.

- The dehumidification input “D” is not received by the board because of an isolation relay that is energized by the call for heating (B/ W1). Thus, the heating call (B/W1) always takes precedence over dehumidification.

- The relay logic board has a jumper (J1) on it to choose between “any-time dehumidification” and “occupied dehumidification”. The factory default is P1-P2. With the jumper in the P1-P2 position, dehumidification is available any time there is a “D” input to the relay logic board. With the jumper in the P2-P3 position, dehumidification is available when there is an occupancy signal to the “A1” terminal, “D” would also need to be energized to dehumidify.Refer to the sequence of operation. In most cases, cooling and heating modes take priority over dehumidification.

TABLE 4Electrical Specifications

| Model | Rate Voltsd

& Phase |

No. Field Power Circuits | Single Circuit | Dual Circuit | ||||||||||

| CUMinimumCircuitAmpacitv• | 1.Max mumExternalFuse orCkt. Brkr. | 0 Field Power Wire Size | 13)GroundWire | 1.MinimumCircuitAmpacity | 2.Ma)d mumExternal Fuseor Ckt. Breaker | 3.Field PowerWire Size | Gro3undWire Size | |||||||

| Ckt A | Ckt. B | Ckt. A | Ckt. B | Ckt A | Ckt. B | Ckt. A | ad. B | |||||||

| W30ABDA00,A0Z | 23 | 35 | 10 | |||||||||||

| A05A08 | 230/208.1 | .■11 41■1 | 31

47 |

3550 | 03 03 | 1010 | ||||||||

| A10 | 57 | 60 | 10 | |||||||||||

| W304B DBOO, BOZ | 1 | 17 | 20 | 12 | 12 | |||||||||

| 806 | 230/208-3 | 1 | 23 | 25 | 10 | 10 | ||||||||

| 809 | 1 | 32 | 35 | 8 | 10 | |||||||||

| W30ABDCOO,COZ | 1 | 9 | 15 | 14 | 14 | |||||||||

| 406 | 460-3 | 1 | 13 | 15 | 14 | 14 | ||||||||

| C09 | 1 | 17 | 20 | 12 | 12 | |||||||||

| W36ABDA00,A0Z | 28 | 35 | 10 | |||||||||||

| A05A08 | 230/208-1 | · ■I 1■11 | 32

48 |

3550 | 0303 | 1010 | ||||||||

| A10 | 58 | 60 | 10 | |||||||||||

| W36AB DBOO, BOZ | 1 | 20 | 25 | 10 | 10 | |||||||||

| B06 | 230/208-3 | 1 | 24 | 25 | 10 | 10 | ||||||||

| B09 | 1 | 33 | 35 | 8 | 10 | |||||||||

| W36ABDCOO,COZ | 1 | 13 | 15 | 14 | 14 | |||||||||

| C06 | 460-3 | 1 | 14 | 15 | 14 | 14 | ||||||||

| CO9 | 1 | 18 | 20 | 12 | 12 | |||||||||

| W42ACDA00, AOZ | 1 | 31 | 50 | 10 | ||||||||||

| A05A10 | 230/208.1 | 11 | 3157 | 5060 | OD 0 | 1010 | ||||||||

| A15 | 1 or 2 | 83 | 90 | 8 | 57 | 26 | 60 | 30 | 6 | 10 | 10 | 10 | ||

| W42ACDBOO,BOZ | 23 | 35 | 10 | |||||||||||

| B05809 | 230/208.3 | ■•■IP 41■1 | 23

33 |

3535 | 03 03 | 1010 | ||||||||

| B18 | 60 | 60 | 10 | |||||||||||

| W42ACDCOO, COZ | 1 | 13 | 15 | 14 | 14 | |||||||||

| CO5 | 460.3 | 1 | 13 | 15 | 14 | 14 | ||||||||

| C09 | 1 | 18 | 20 | 12 | 12 | |||||||||

| W48ACDA00, AOZ | 34 | 50 | 10 | |||||||||||

| A05A10 | 230/208-1 | · ■I •■I | 34

59 |

50

60 |

0303 | 1010 | ||||||||

| A15 | 85 | 90 | 8 | 59 | 26 | 60 | 30 | 6 | 10 | 10 | 10 | |||

| W48ACD800,80Z | 25 | 35 | 10 | |||||||||||

| 805809 | 230/208-3 | 1■1 1■11 | 25

34 |

3535 | 03 03 | 1010 | ||||||||

| 818 | 60 | 60 | 10 | |||||||||||

| W48ACDCOO, COZ | 1 | 12 | 15 | 14 | 14 | |||||||||

| CO5 | 460-3 | 1 | 12 | 15 | 14 | 14 | ||||||||

| CO9 | 1 | 17 | 20 | 12 | 12 | |||||||||

| W6OACDA00, MOZ | 1 | 41 | 50 | 8 | 10 | |||||||||

| A05 | 2301208-1 | 1 | 41 | 50 | 8 | 10 | ||||||||

| A10 | 1 | 59 | 60 | 6 | 10 | |||||||||

| W604CDBOO,BOZ | 1 | 28 | 40 | 8 | 10 | |||||||||

| B09 | 230/208-3 | 1 | 35 | 40 | 8 | 10 | ||||||||

| B15 | 1 | 53 | 60 | 6 | 10 | |||||||||

| W60ACDC00,C0Z | 1 | 15 | 20 | 12 | 12 | |||||||||

| C09 | 460-3 | 1 | 18 | 20 | 12 | 12 | ||||||||

| C15 | 1 | 27 | 30 | 10 | 10 | |||||||||

| W72ACDA00, AOZ | 1 | 56 | 60 | 10 | ||||||||||

| A05A 10 | 230/208-1 | 11 or 2 | 56

60 |

6070 | 0303 | 10

8 |

59 | 26 | 60 | 30 | ‘o | 10 | 10 | 0 |

| A15 | 1 or 2 | 86 | 90 | 8 | 60 | 26 | 60 | 30 | 10 | 10 | ||||

| W72ACD1300,80Z | 38 | 50 | COCO CO k0 | 10 | ||||||||||

| 606809 | 230/208-3 | 1■11 1■1 | 3838 | 5050 | 1010 | |||||||||

| 815 | 54 | 60 | 10 | |||||||||||

| W72ACDCOO,COZ | 1 | 19 | 25 | 10 | 10 | |||||||||

| C09 | 460-3 | 1 | 19 | 25 | 10 | 10 | ||||||||

| C15 | 1 | 27 | 30 | 10 | 10 |

- These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical Code (latest version), Article 310 for power conductor sizing. CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of Table 310 regarding Ampacity Adjustment Factors when more than three (3) current-carrying conductors are in a raceway.

- Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.

- Based on 75°copper wire. All wiring must conform to the National Electrical Code and all local codes.NOTE: The Maximum Overcurrent Protection (MOCP) value listed is the maximum value as per UL 1995 calculations for MOCP (branch-circuit conductor sizes in this chart are based on this MOCP). The actual factory-installed overcurrent protective device (circuit breaker) in this model may be lower than the maximum UL 1995 allowable MOCP value, but still above the UL 1995 minimum calculated value or Minimum Circuit Ampacity (MCA) listed.

Bard Manufacturing Company, Inc.Bryan, Ohio 43506www.bardhvac.com

[xyz-ips snippet=”download-snippet”]